Page 6

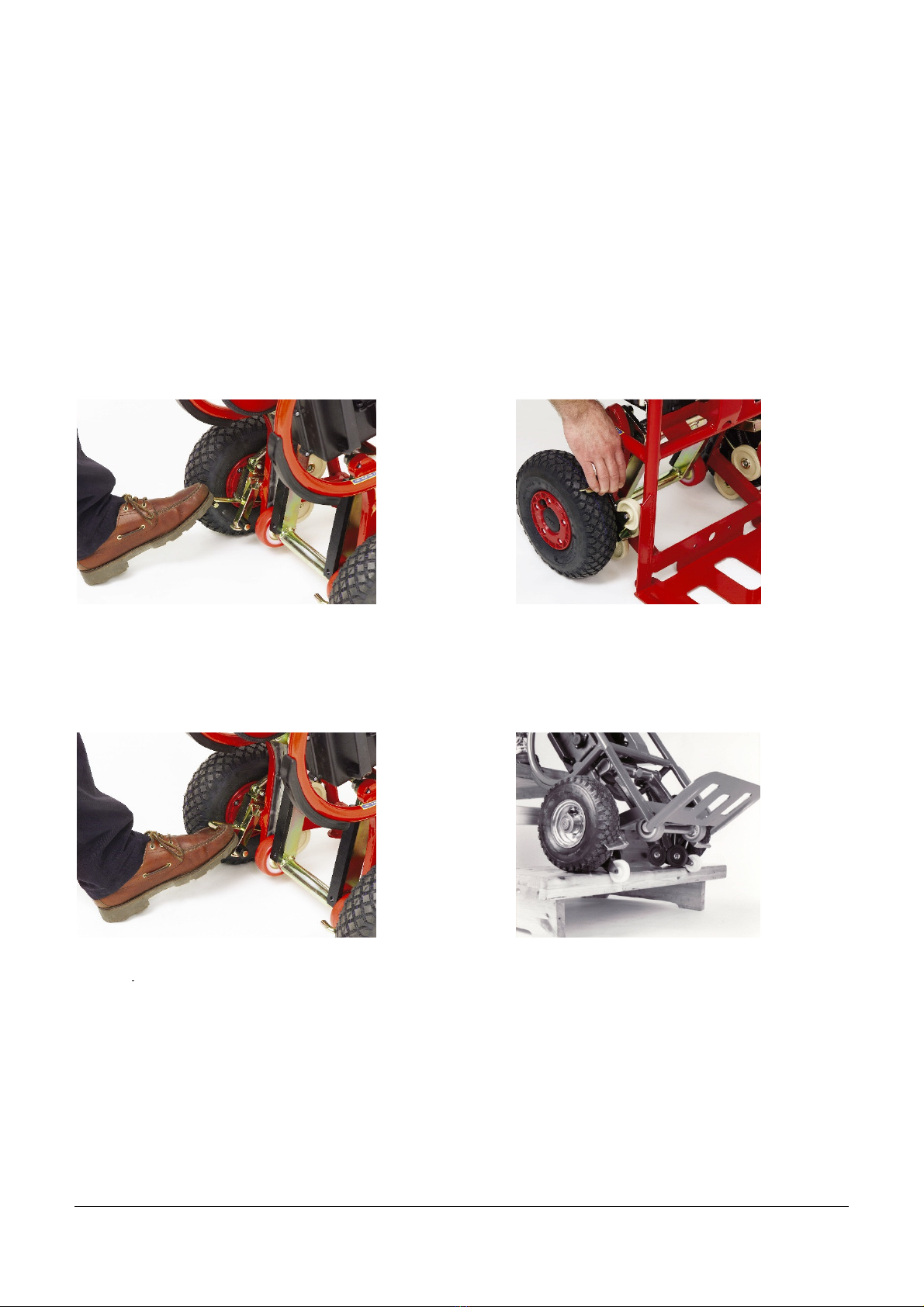

4.1. System of GO NG DOWNSTA RS

(pictures from top to bottom)

Moving to a safe distance from the step margin -

(4-10 cm distance wheel shaft to step margin) then

STOP!

Actuate the switch (arrow forward).

The crank drive s stem with the small support wheels

moves forward and reaches over to the next step below.

As soon as LIFTKAR is lifting, the permanentl braked

support wheels pull the hand truck forward over the step

margin and LIFTKAR is descending under controlled

balance.

mportant:

1. Moving to 4 - 10 cm to the step margin and STOP!

2. As soon as LIFTKAR is lifting, let it go.

Do not pull back too strongl !

3. On winding stairs: LIFTCAR has to be turned a bit

on each step so that both wheels are stopped at

the same distance from the step margin.

General remark:

Alwa s tr to find the balance.

As soon as ou have this under control ou will see, how

eas it is to work with LIFTKAR.

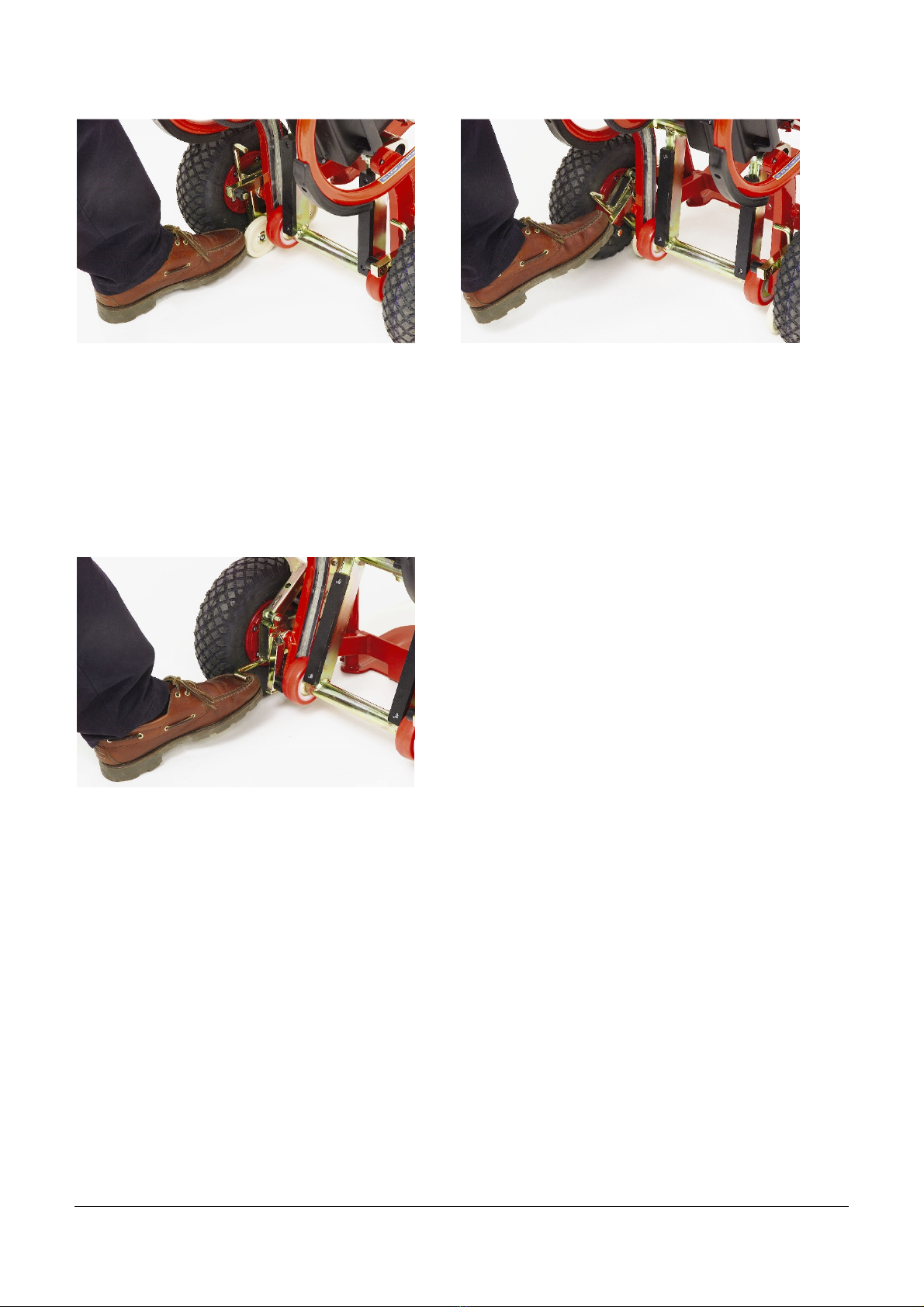

4.2. System of GO NG UPSTA RS

(pictures from bottom to top)

Pull back to the step margin of the next step above. B

actuating the switch (arrow backward) the crank drive

with the support wheels is extending backward and is

lifting LIFTKAR to the next step above.

mportant:

1. Alwa s pull back to the step margin. On winding

stairs both wheels have to be pulled back to the

stap margin on each step. After short exercising

the switch could be pressed permanentl making it

possible to work permanentl and quickl .

2. Minimum t re pressure 2.5 bar.