Santec Novo II 7831UL-TM User manual

Other Santec Plumbing Product manuals

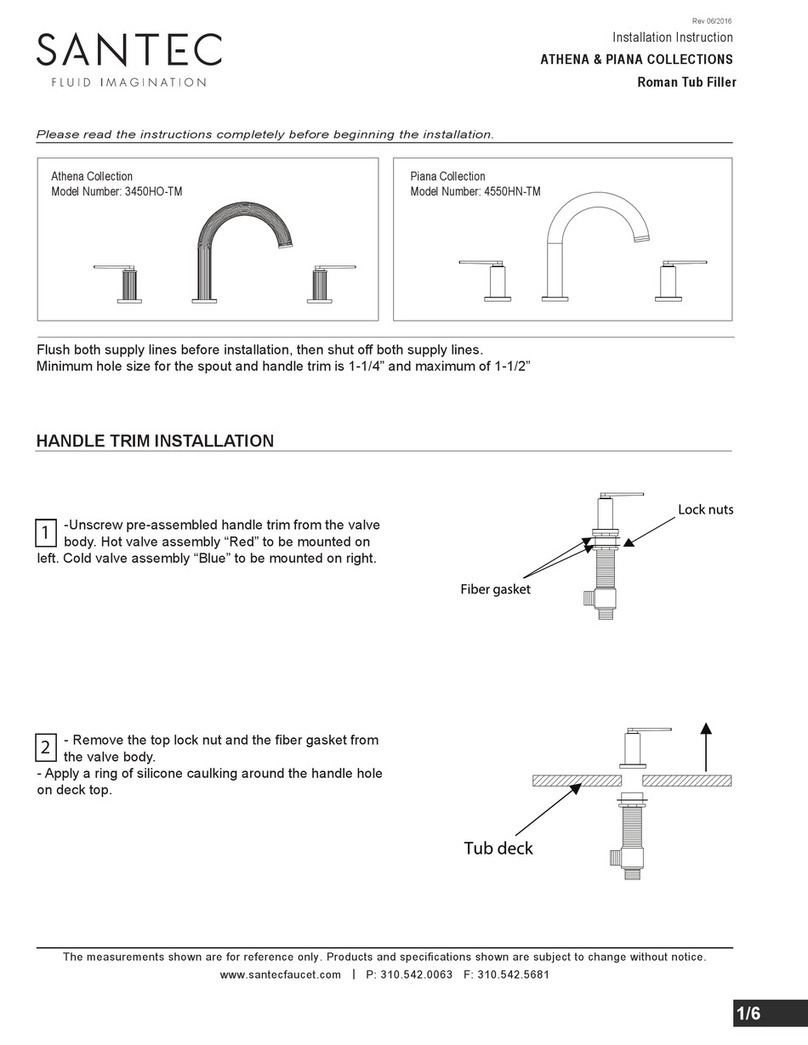

Santec

Santec TH-8010 User manual

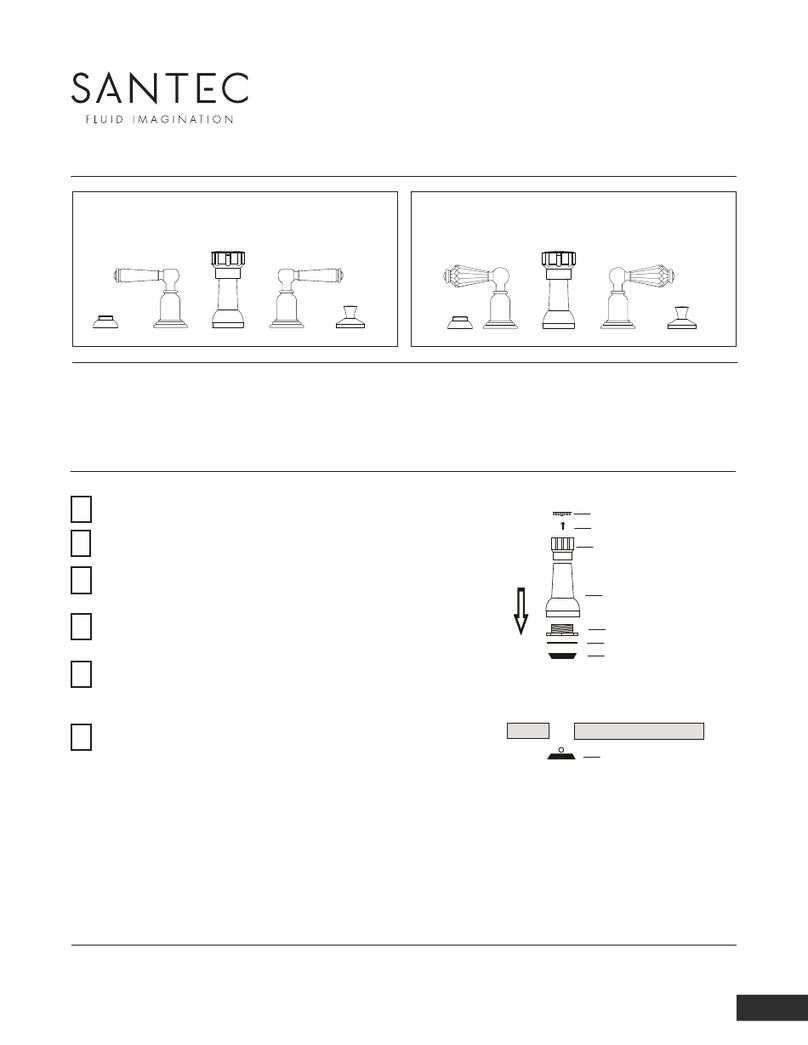

Santec

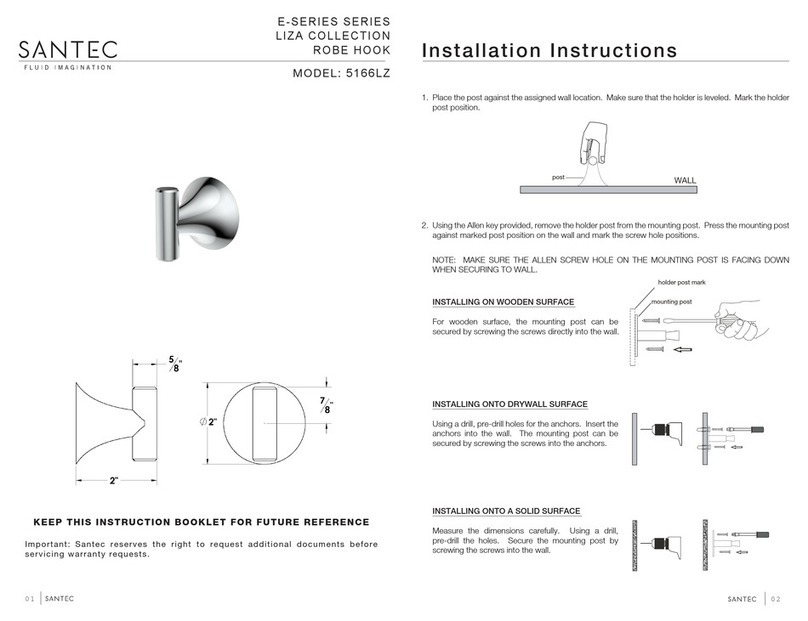

Santec LIZA 5166LZ User manual

Santec

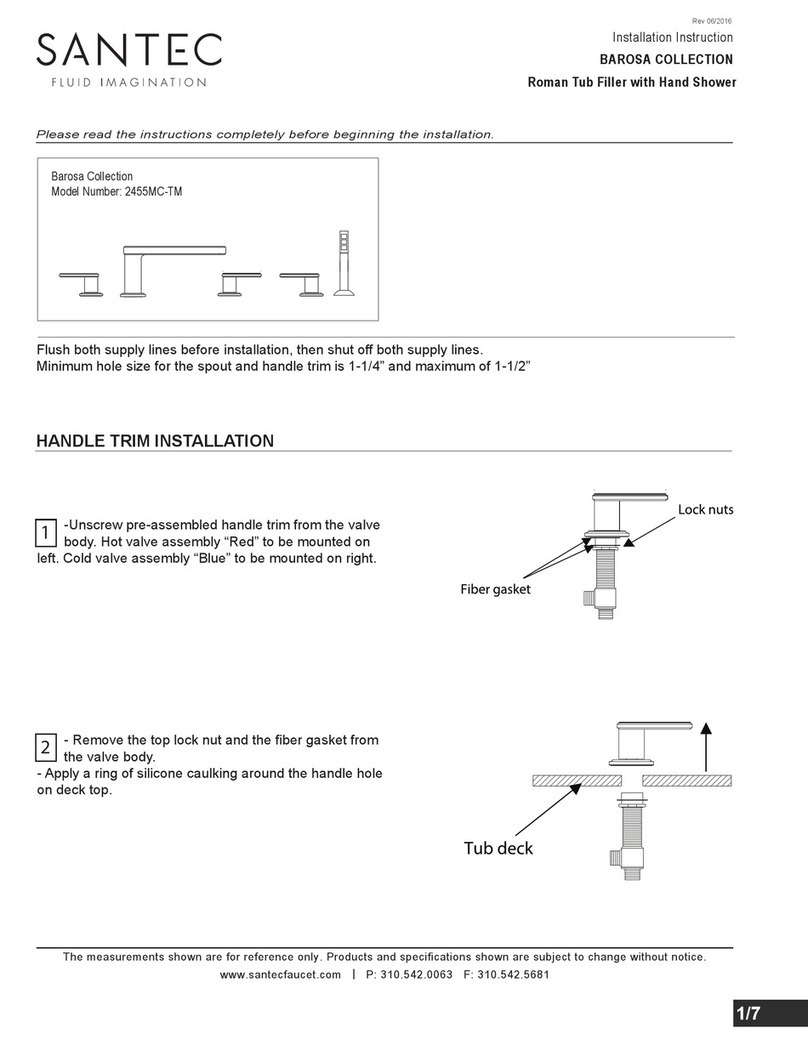

Santec BAROSA 2455MC-TM User manual

Santec

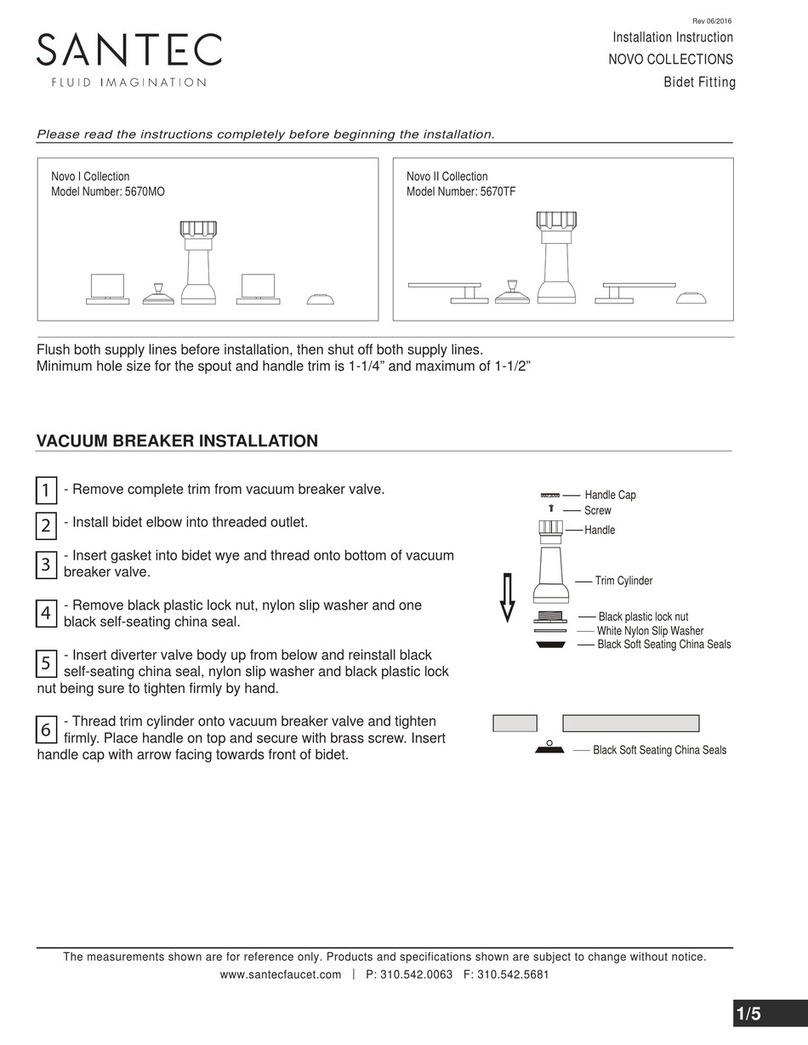

Santec Novo I 5670MO User manual

Santec

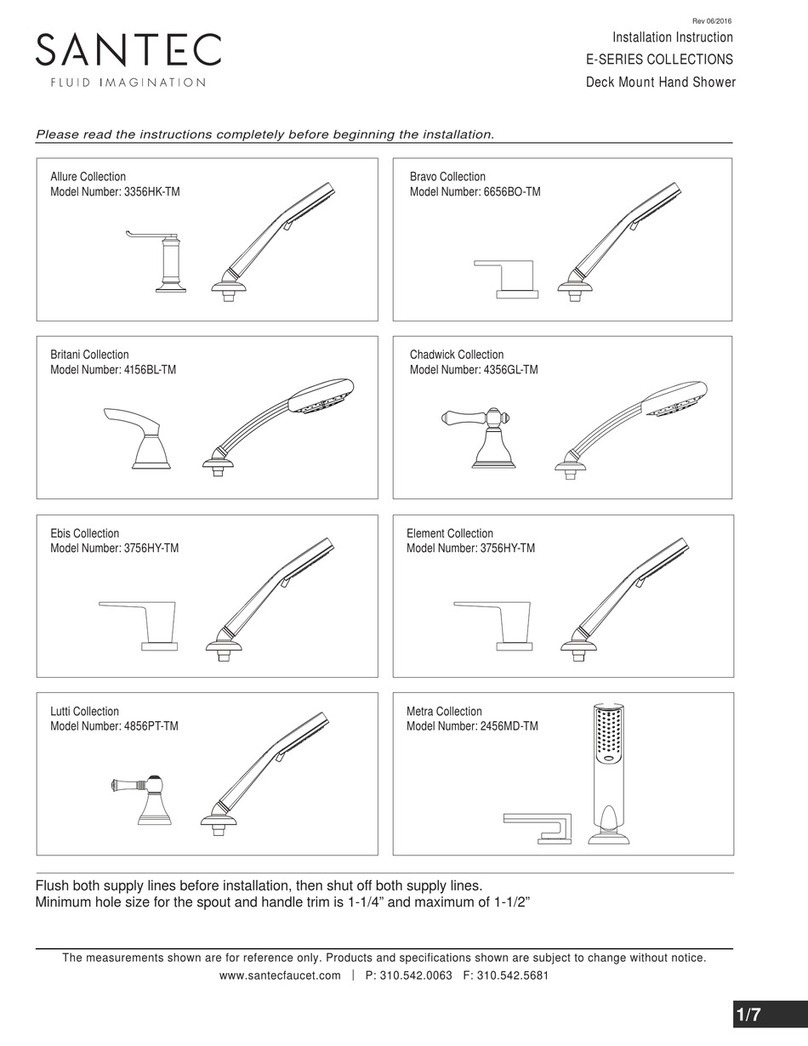

Santec E-Series User manual

Santec

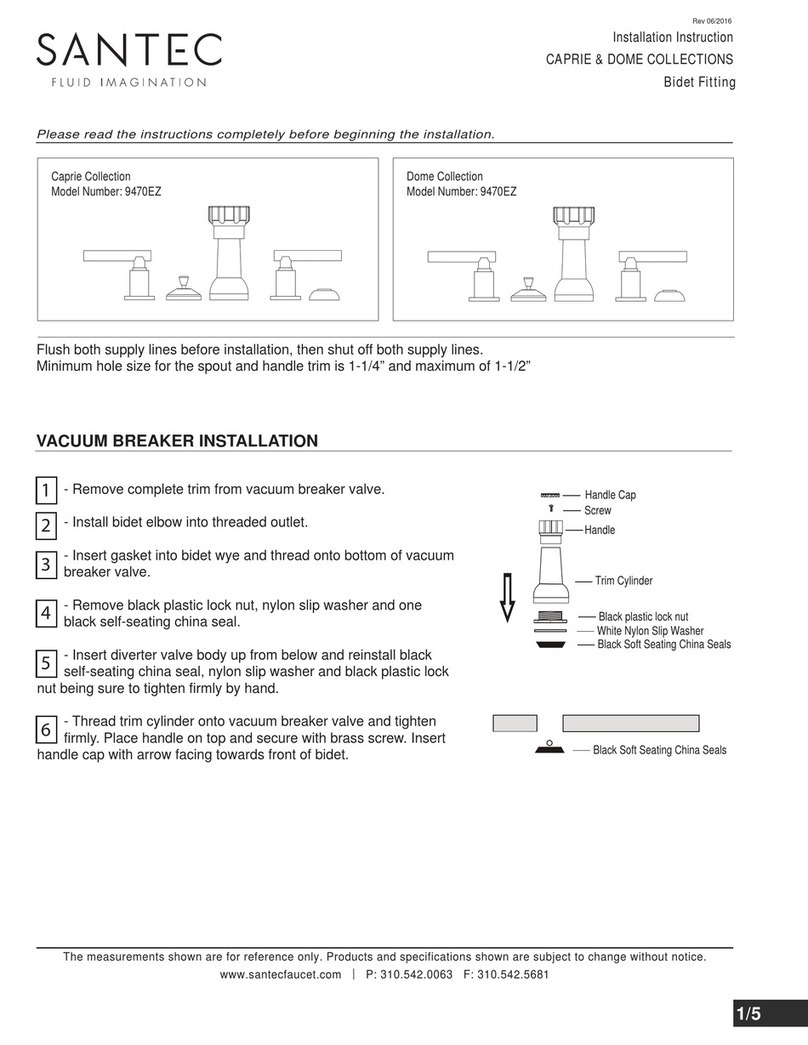

Santec Caprie 9470EZ User manual

Santec

Santec 7089SE User manual

Santec

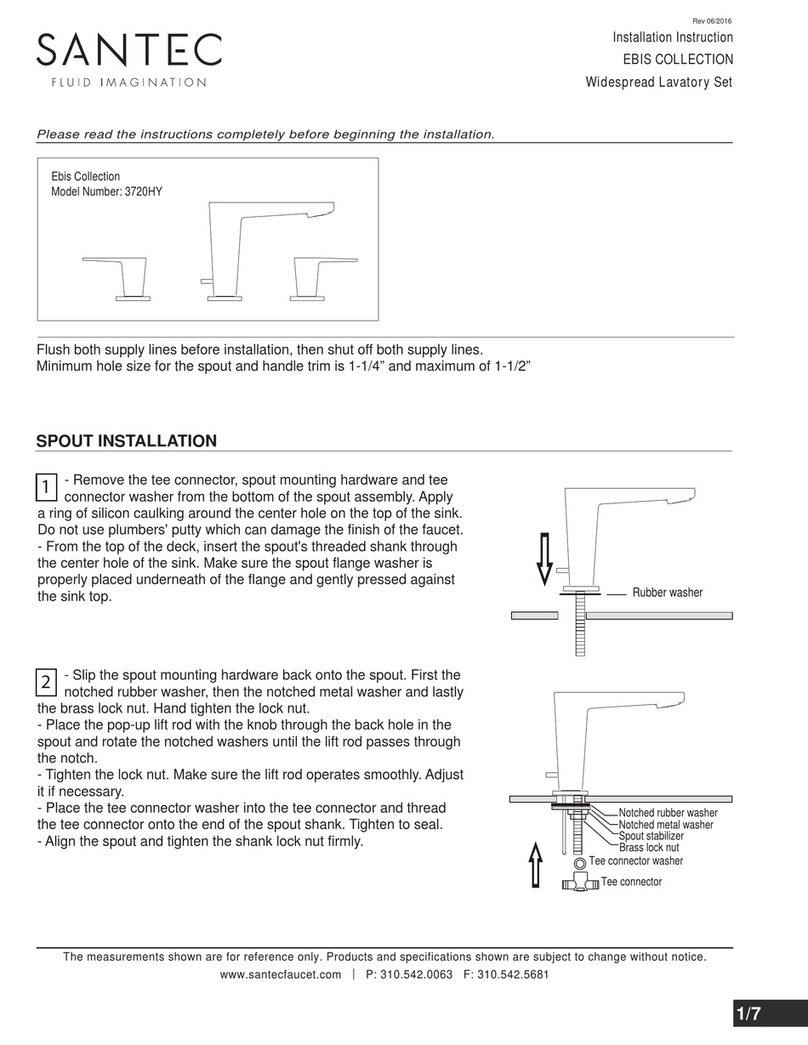

Santec Ebis 3720HY User manual

Santec

Santec CIRC CZ User manual

Santec

Santec E-Series User manual

Santec

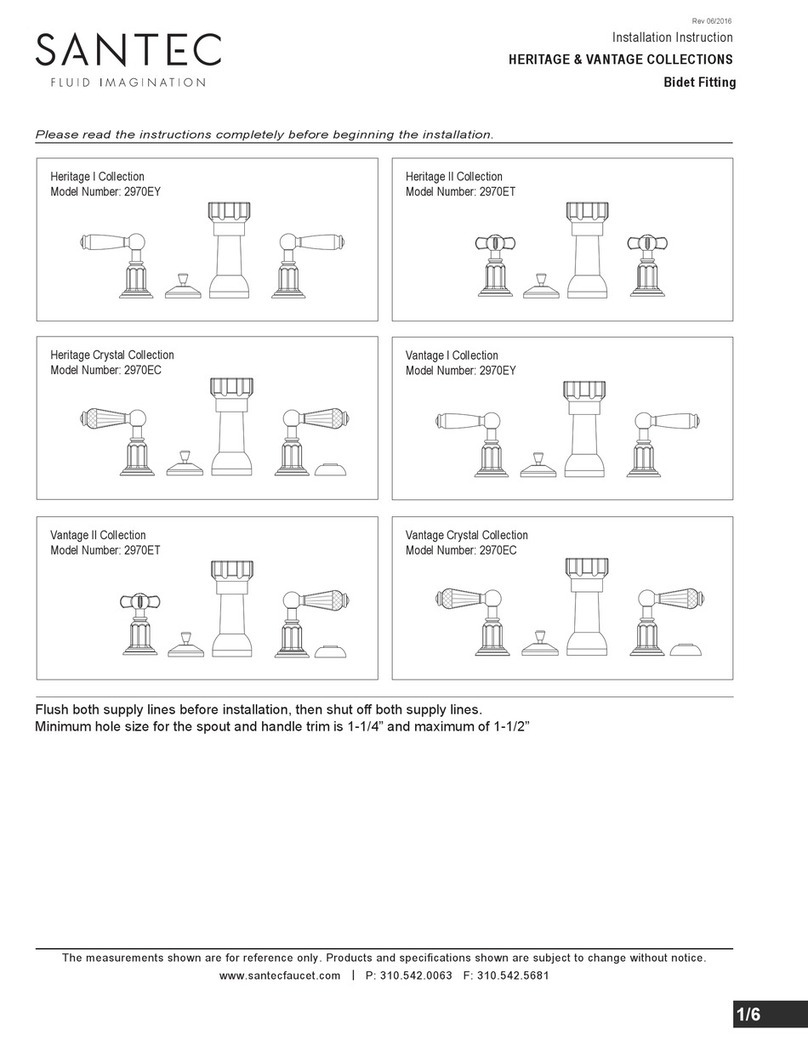

Santec Heritage I 2970EY User manual

Santec

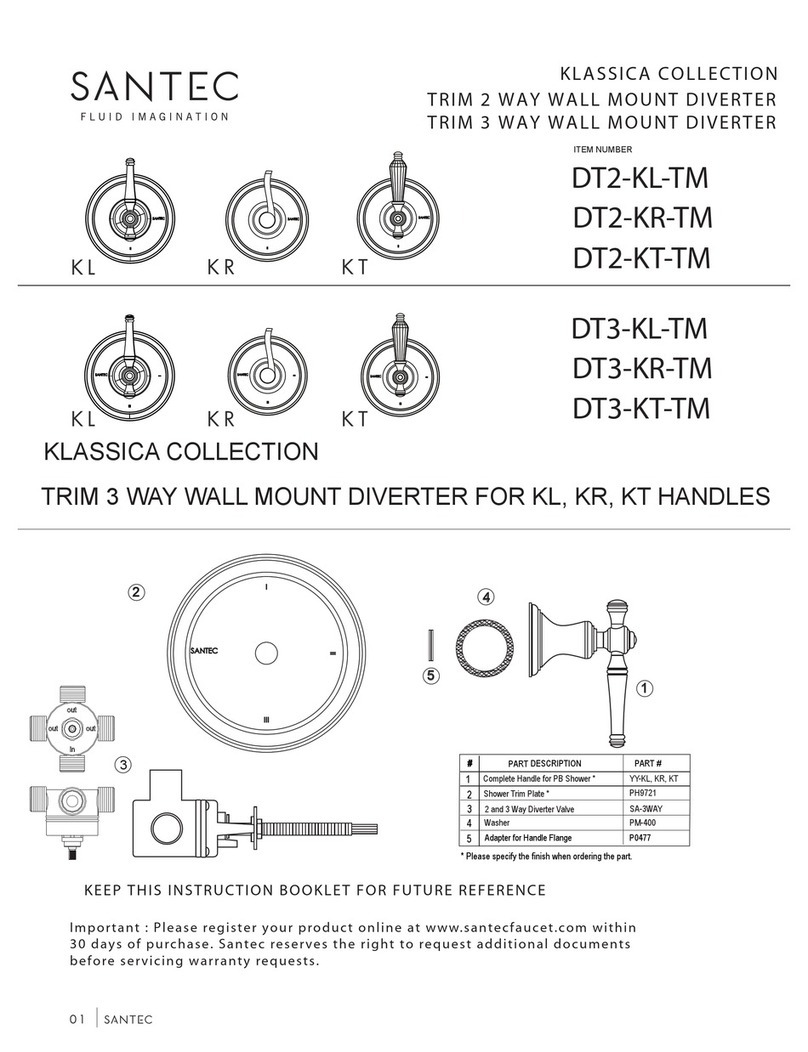

Santec DT2-KL-TM User manual

Santec

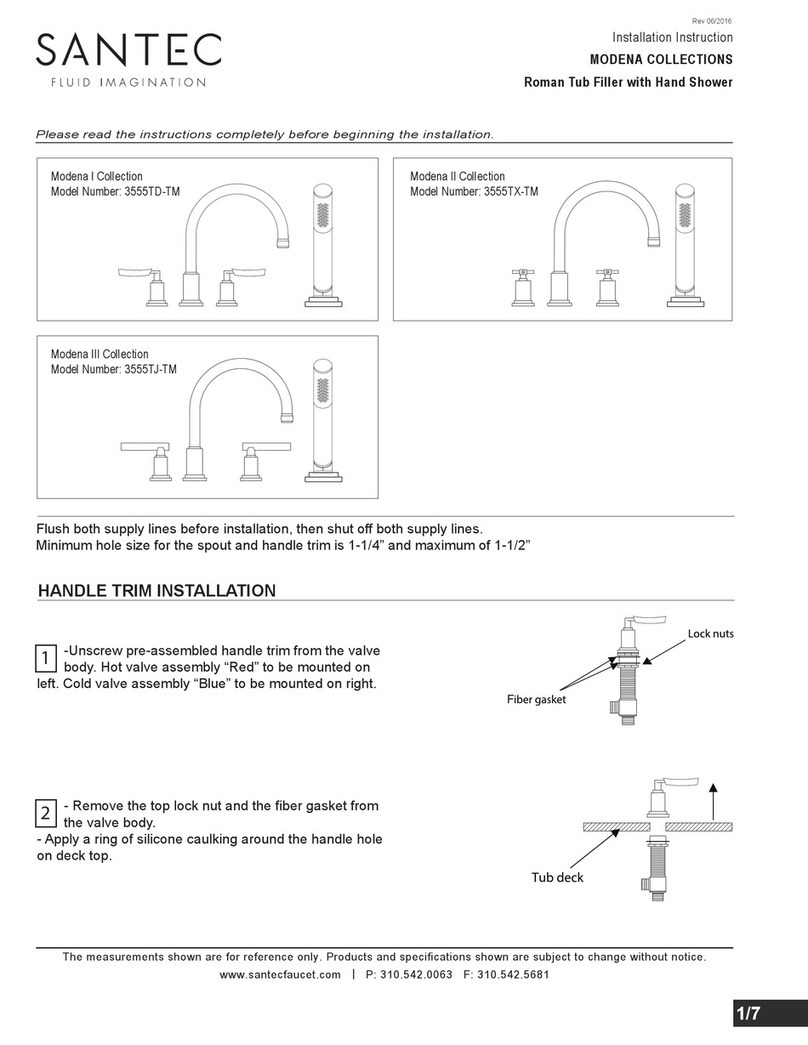

Santec Modena I 3555TD-TM User manual

Santec

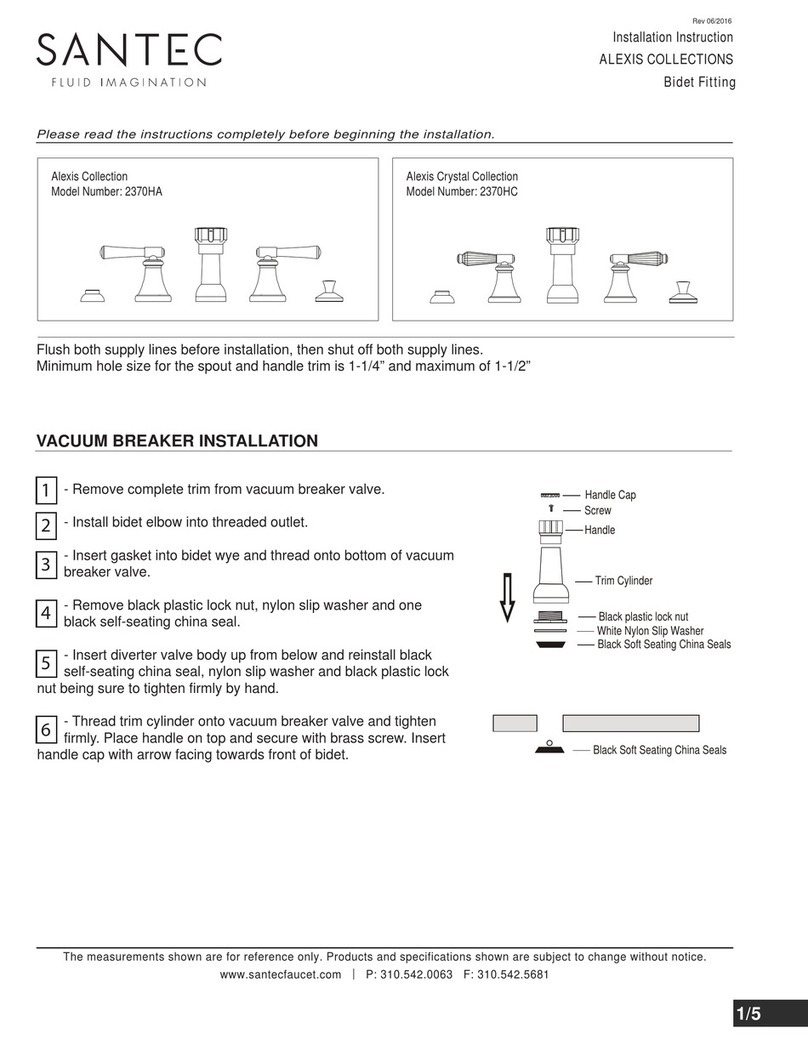

Santec Alexis 2370HA User manual

Santec

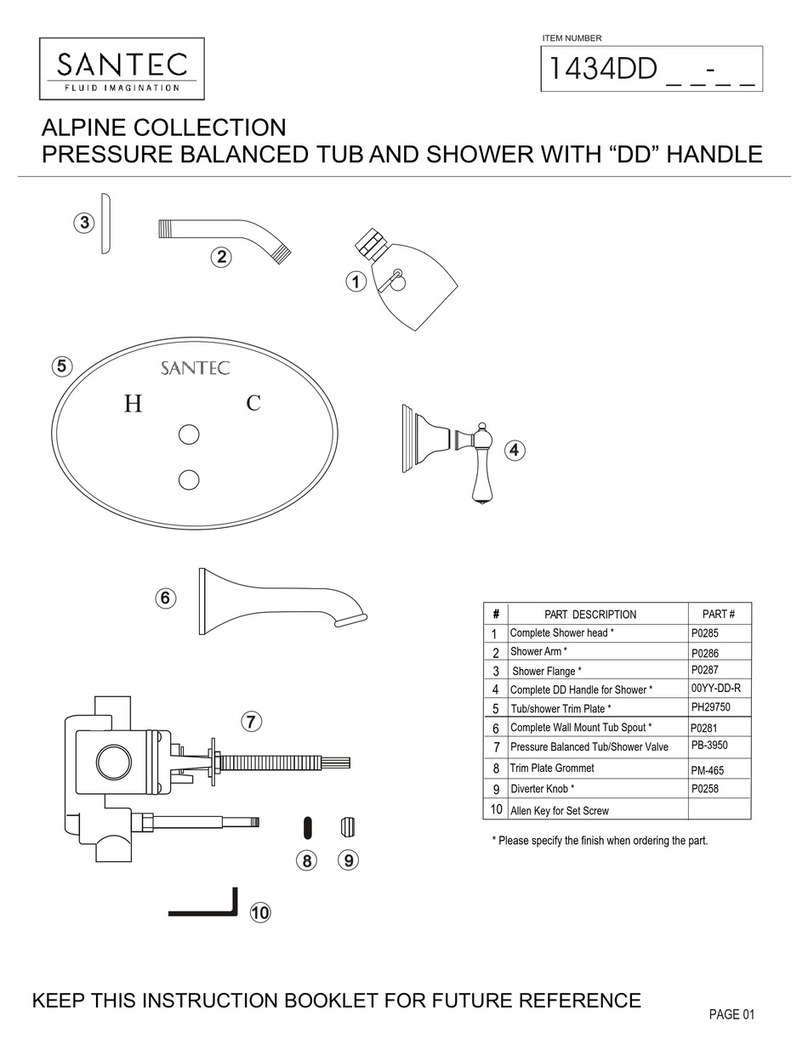

Santec 1434DD Series User manual

Santec

Santec CIRC 3920CI User manual

Santec

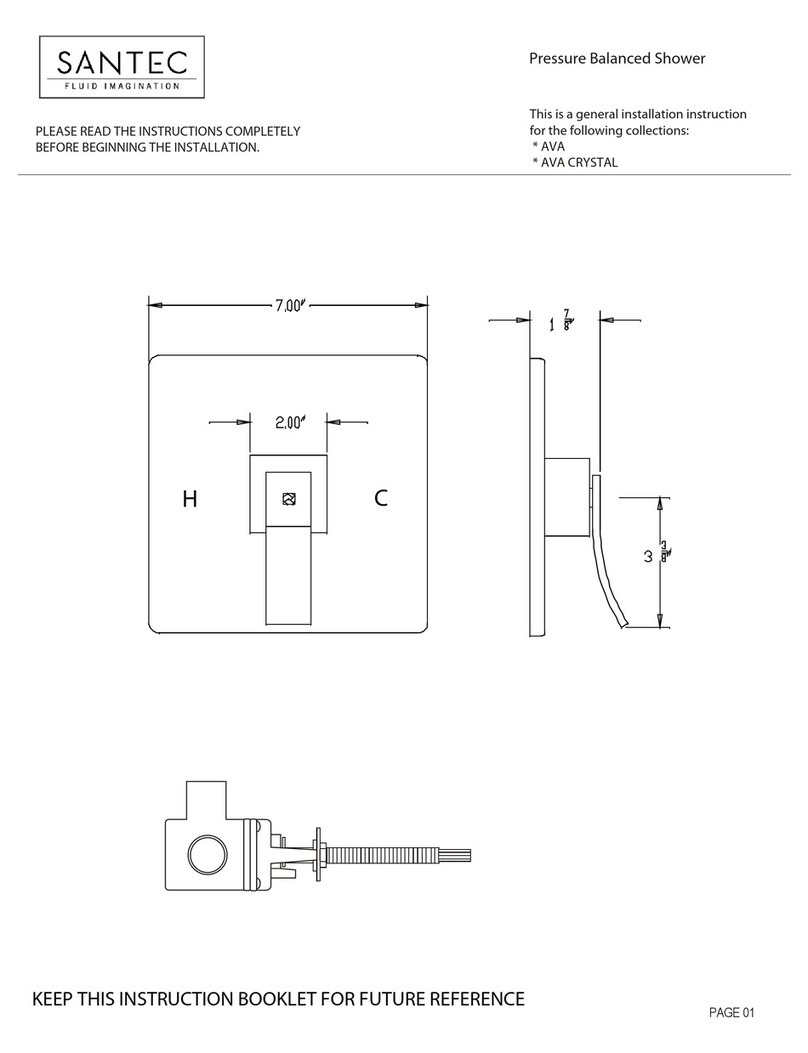

Santec AVA User manual

Santec

Santec TH-8010 User manual

Santec

Santec Designer Series User manual

Santec

Santec EBIS E Series User manual

Popular Plumbing Product manuals by other brands

Moen

Moen SANI-STREAM 8797 manual

Grohe

Grohe Allure Brilliant 19 784 manual

Cistermiser

Cistermiser Easyflush EVO 1.5 manual

Kohler

Kohler Triton Rite-Temp K-T6910-2A installation guide

BEMIS

BEMIS FNOTAB100 Installation instruction

Hans Grohe

Hans Grohe ShowerTablet Select 700 13184000 Instructions for use/assembly instructions

Akw

Akw Stone Wash Basin Installation instructions manual

Enlighten Sauna

Enlighten Sauna Rustic-4 user manual

Moen

Moen ShowHouse S244 Series quick start guide

Sanela

Sanela SLWN 08 Mounting instructions

Franke

Franke 7612982239618 operating instructions

Heritage Bathrooms

Heritage Bathrooms Granley Deco PGDW02 Fitting Instructions & Contents List

Tres

Tres TOUCH-TRES 1.61.445 instructions

STIEBEL ELTRON

STIEBEL ELTRON WS-1 Operation and installation

Miomare

Miomare HG00383A manual

BELLOSTA

BELLOSTA revivre 6521/CR1 quick start guide

American Standard

American Standard Heritage Amarilis 7298.229 parts list

BorMann

BorMann Elite BTW5024 quick start guide