Sanyo M7700L User manual

Other Sanyo Cassette Player manuals

Sanyo

Sanyo RD 5055 User manual

Sanyo

Sanyo MCD-S860F User manual

Sanyo

Sanyo MCD-Z8F (AU) User manual

Sanyo

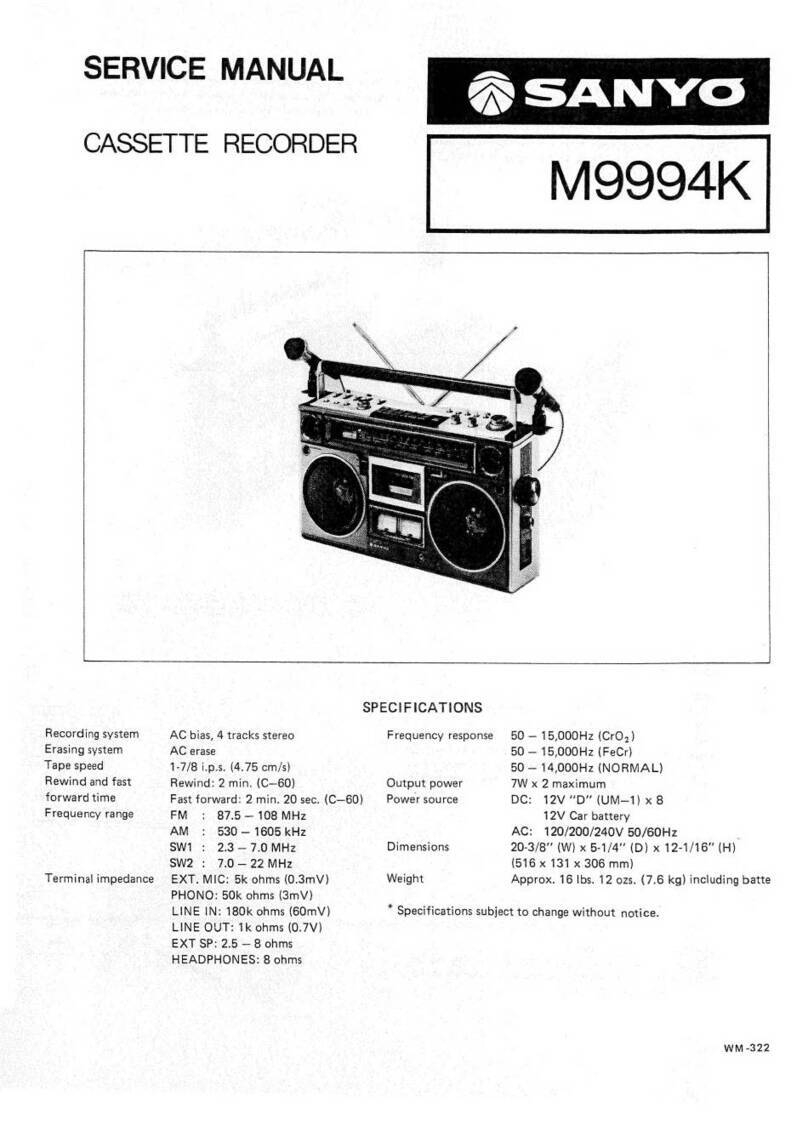

Sanyo M9998K User manual

Sanyo

Sanyo MCD-Z150F User manual

Sanyo

Sanyo MCD-ZX530F User manual

Sanyo

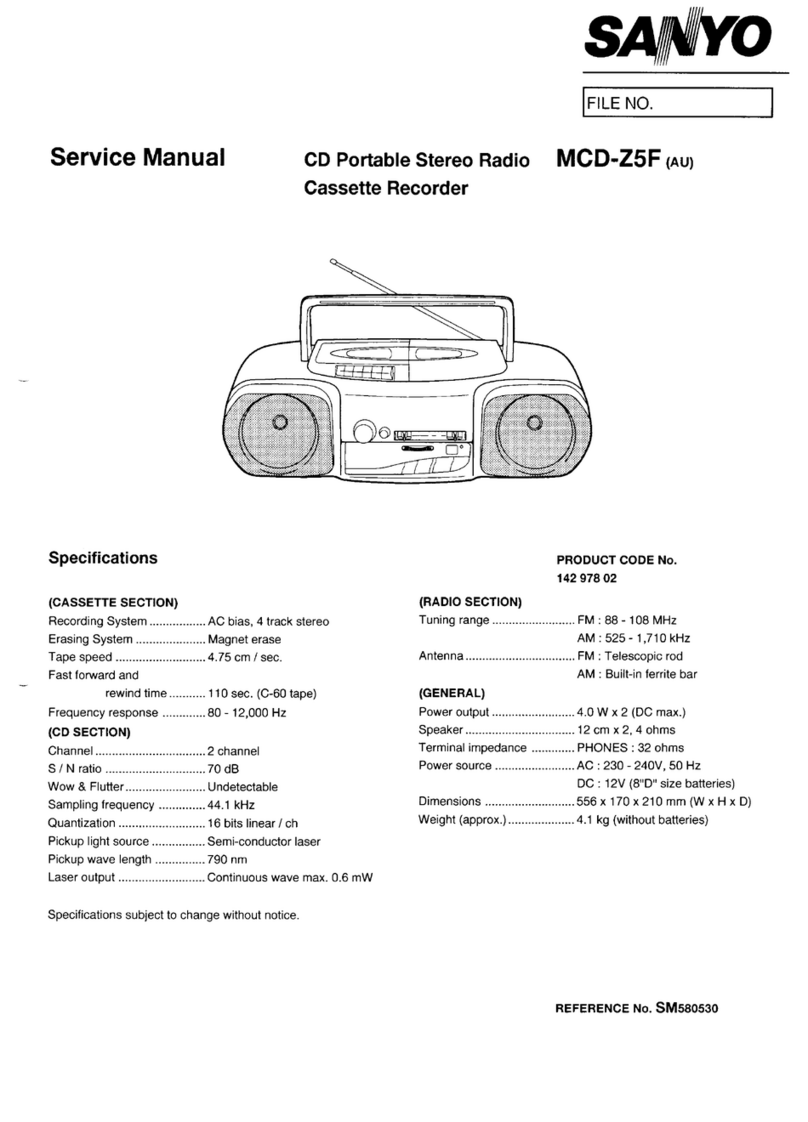

Sanyo MCD-Z5F User manual

Sanyo

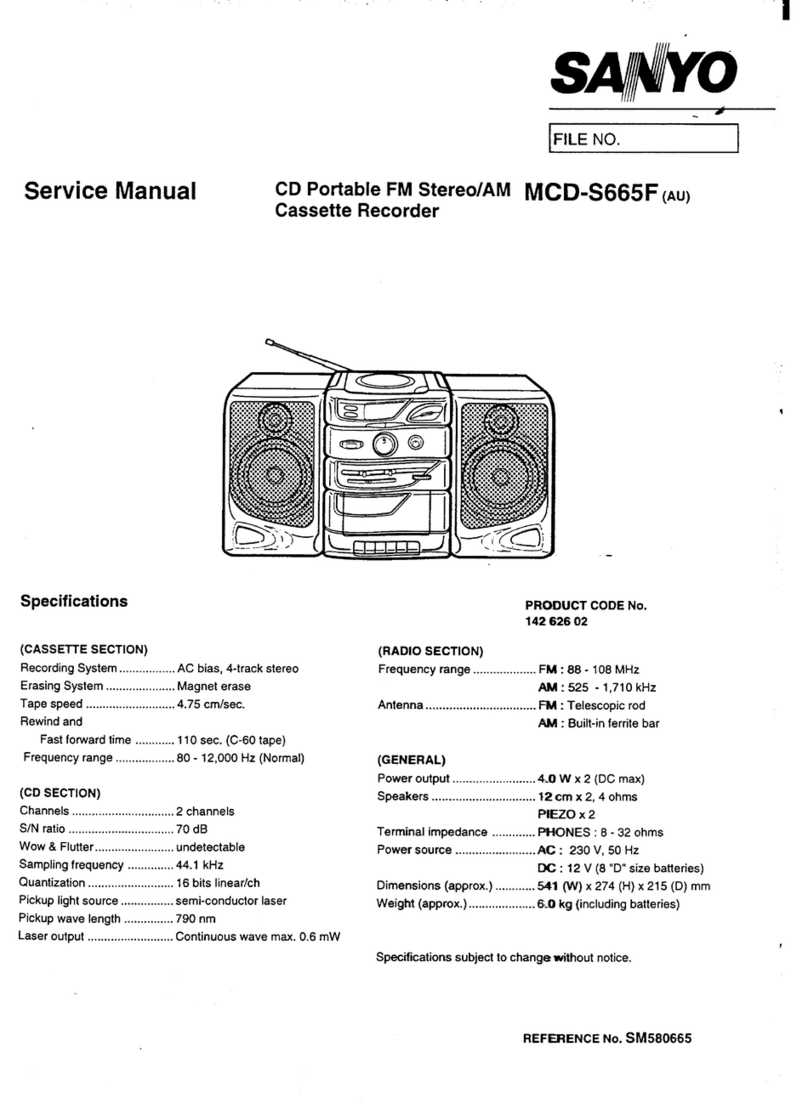

Sanyo MCD-S665F User manual

Sanyo

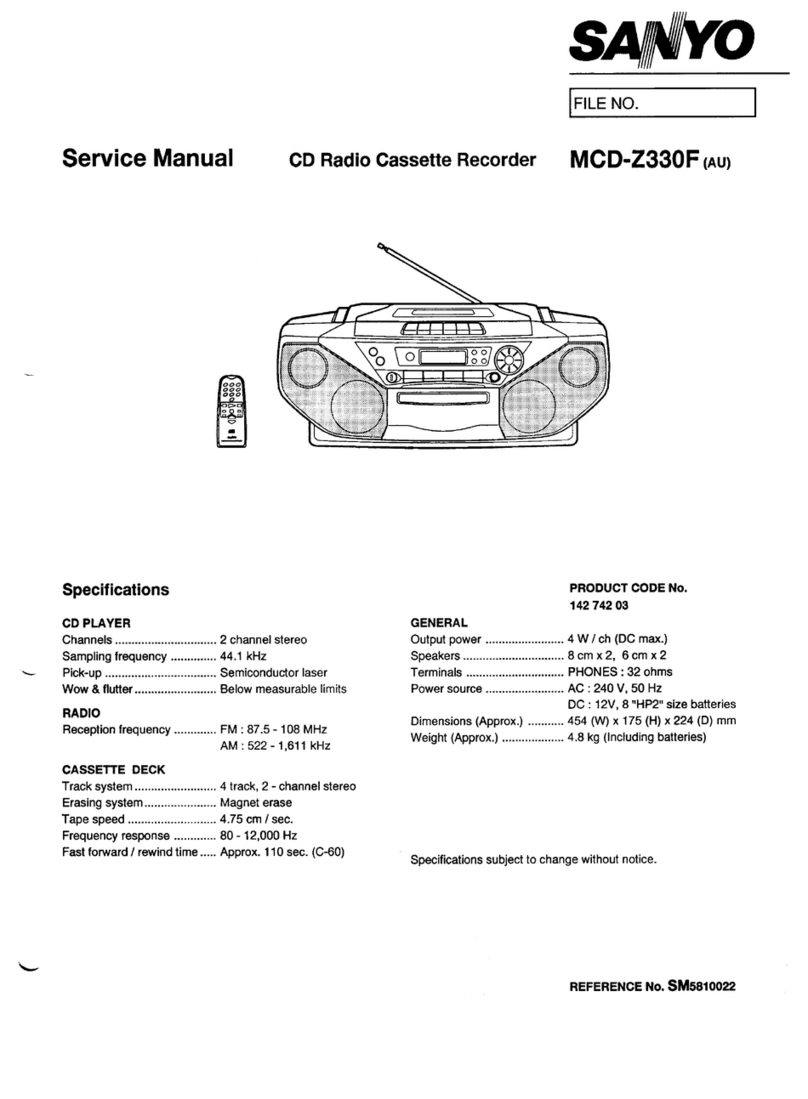

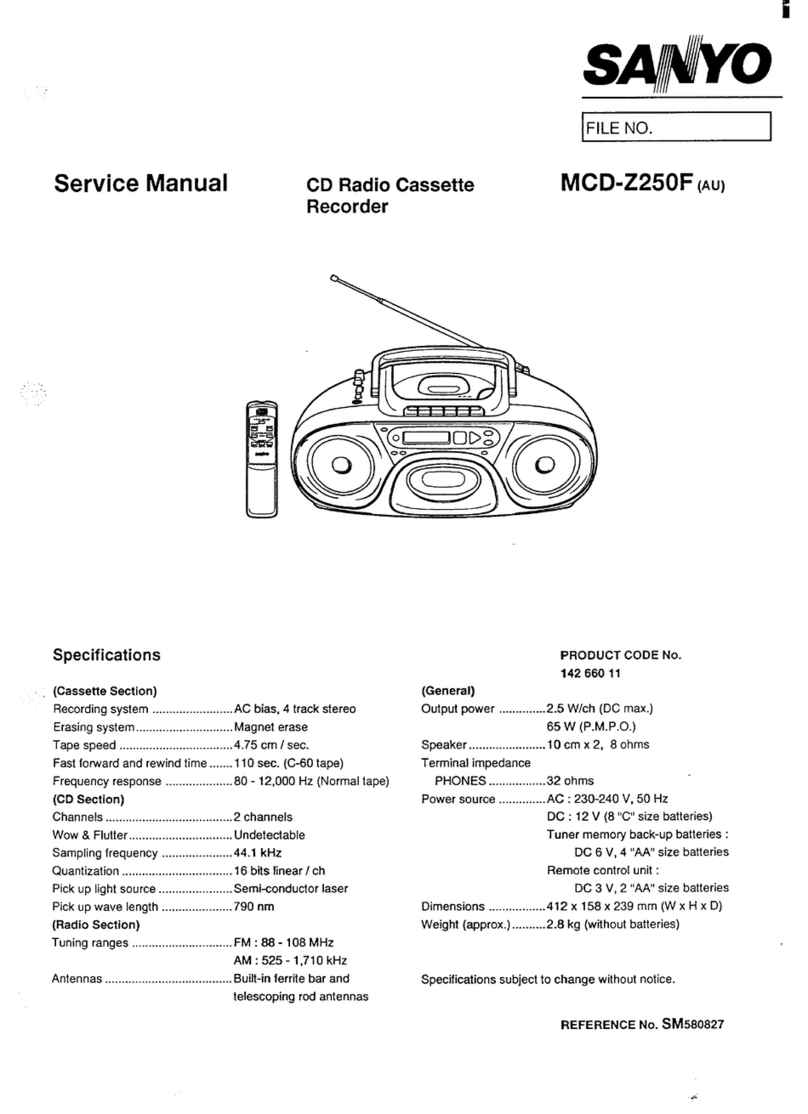

Sanyo MCD-Z250F User manual

Sanyo

Sanyo MCD-S660F User manual

Sanyo

Sanyo TRC-960C User manual

Sanyo

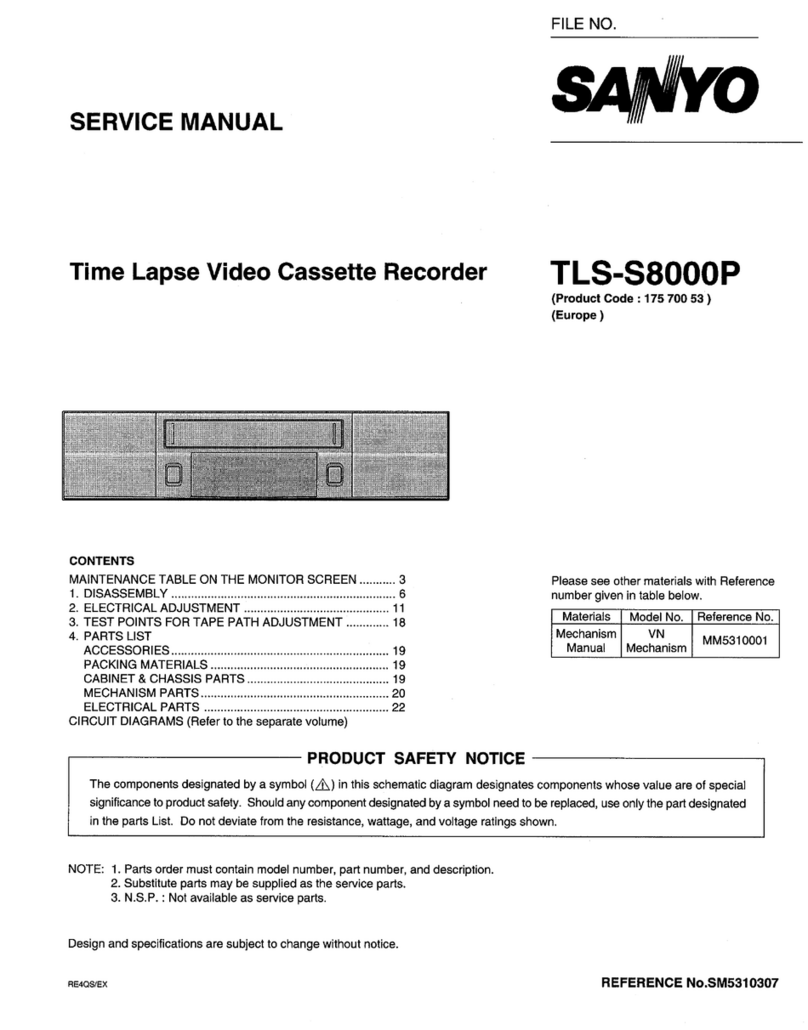

Sanyo TLS-S8000P User manual

Sanyo

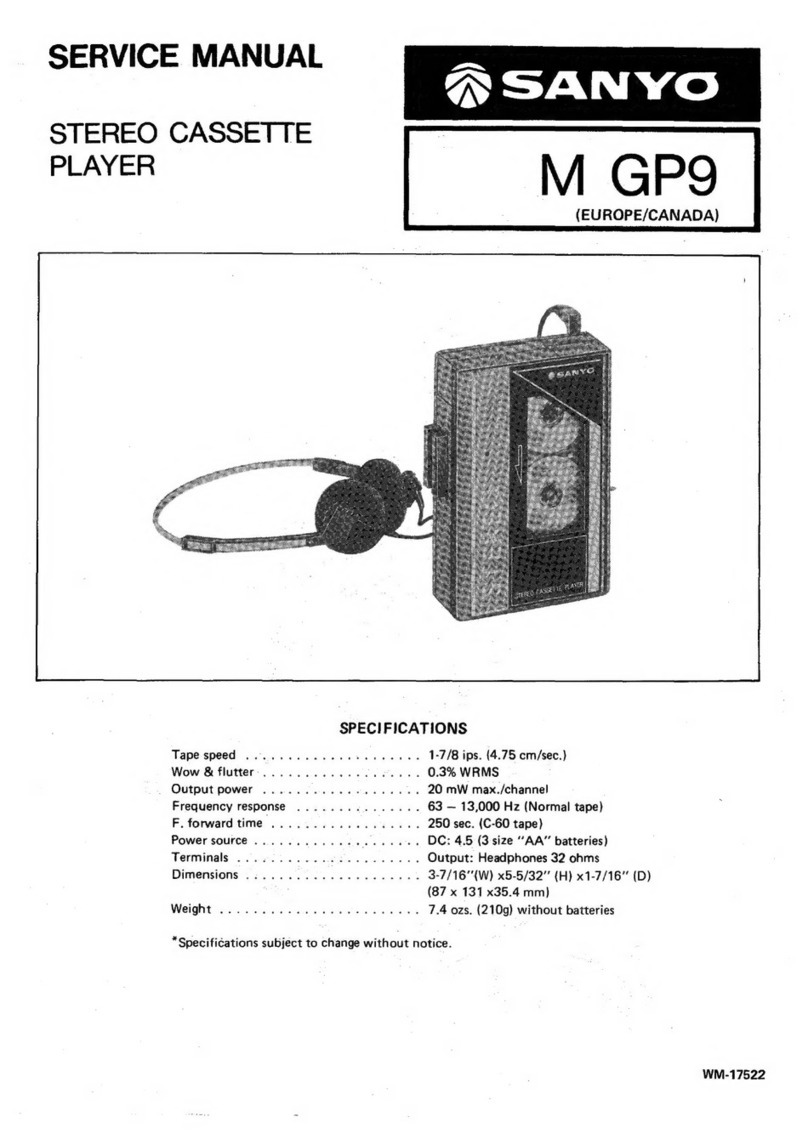

Sanyo M GP9 User manual

Sanyo

Sanyo M1990FE User manual

Sanyo

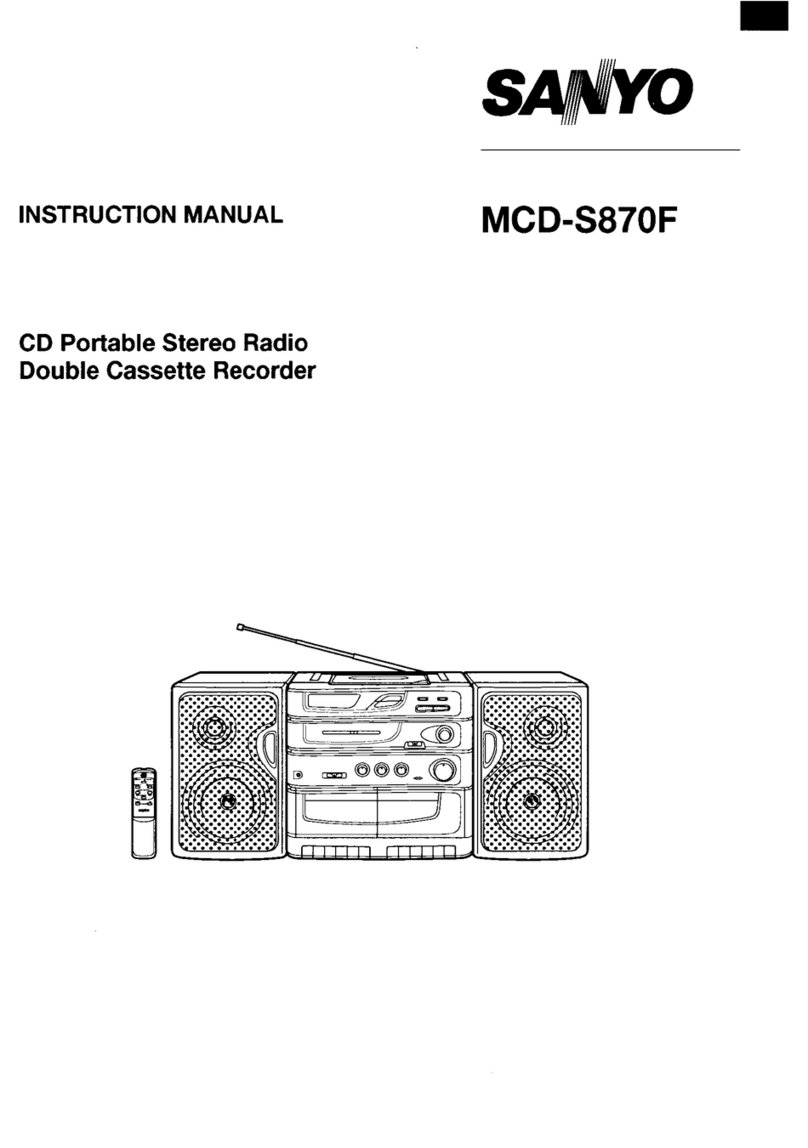

Sanyo MCD-S870F User manual

Sanyo

Sanyo MCD-S920F User manual

Sanyo

Sanyo TRC-2050C User manual

Sanyo

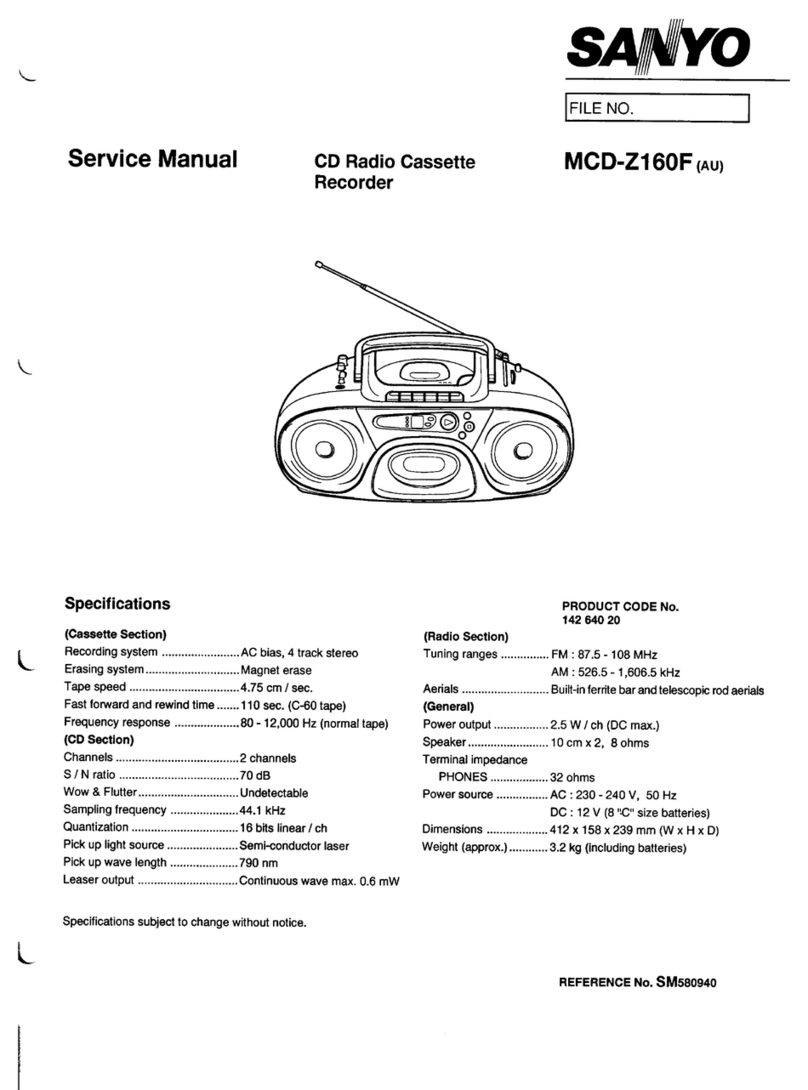

Sanyo MCD-Z160F User manual

Sanyo

Sanyo MCD-UB575M User manual

Sanyo

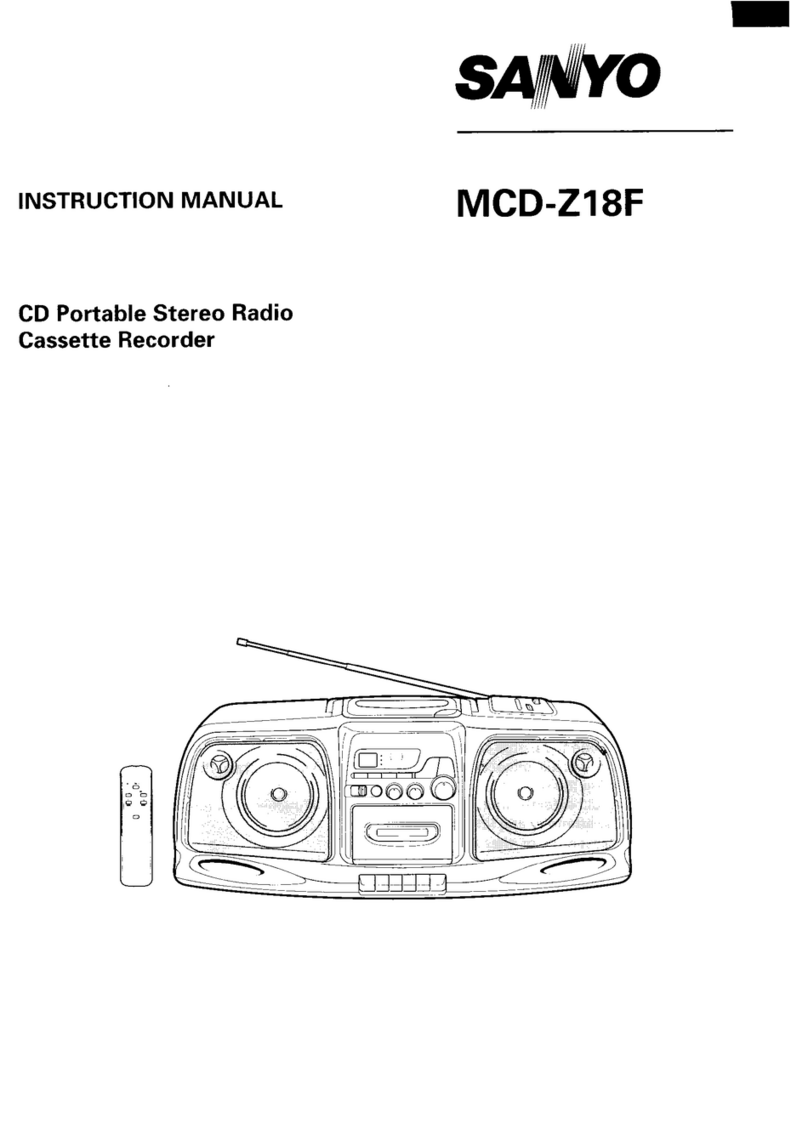

Sanyo MCD-Z18F User manual

Popular Cassette Player manuals by other brands

Sony

Sony CFS-B15 - Am/fm Stereo Cassette Recorder operating instructions

Sony

Sony WMFS220 - Portable Sports AM/FM Cassette... operating instructions

Aiwa

Aiwa HS-TA21 operating instructions

Aiwa

Aiwa CS-P77 Service manual

Sony

Sony Pressman TCM-465V operating instructions

Sony

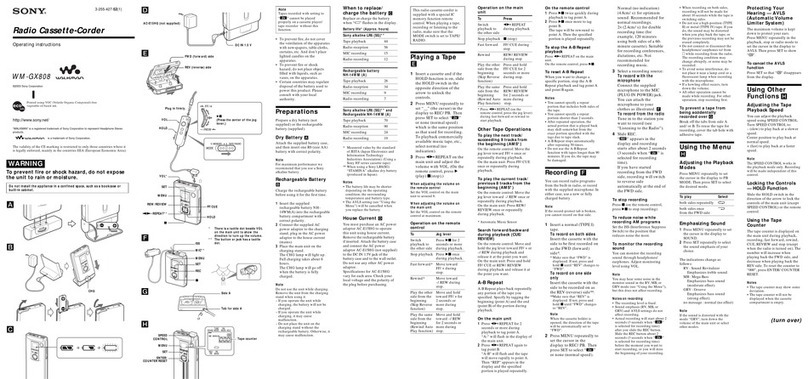

Sony WALKMAN WM-GX808 operating instructions