Sanyo M9994K User manual

Other Sanyo Cassette Player manuals

Sanyo

Sanyo MCD-S920F User manual

Sanyo

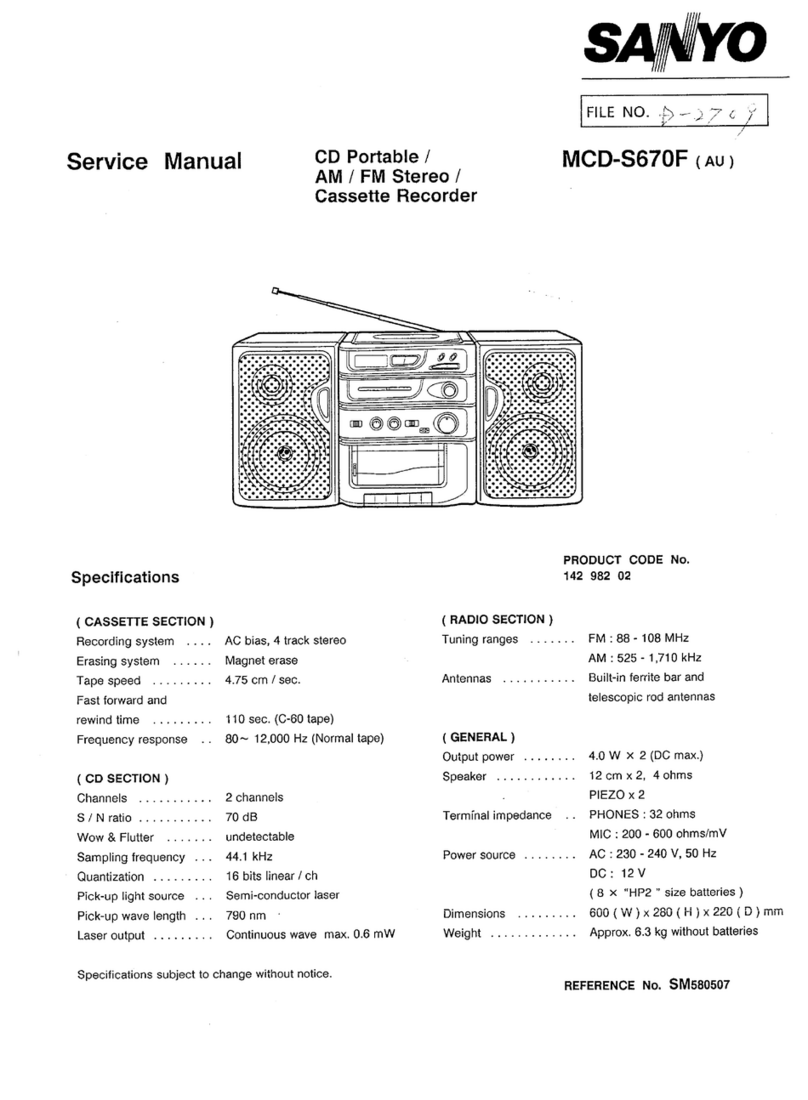

Sanyo MCD-S670F User manual

Sanyo

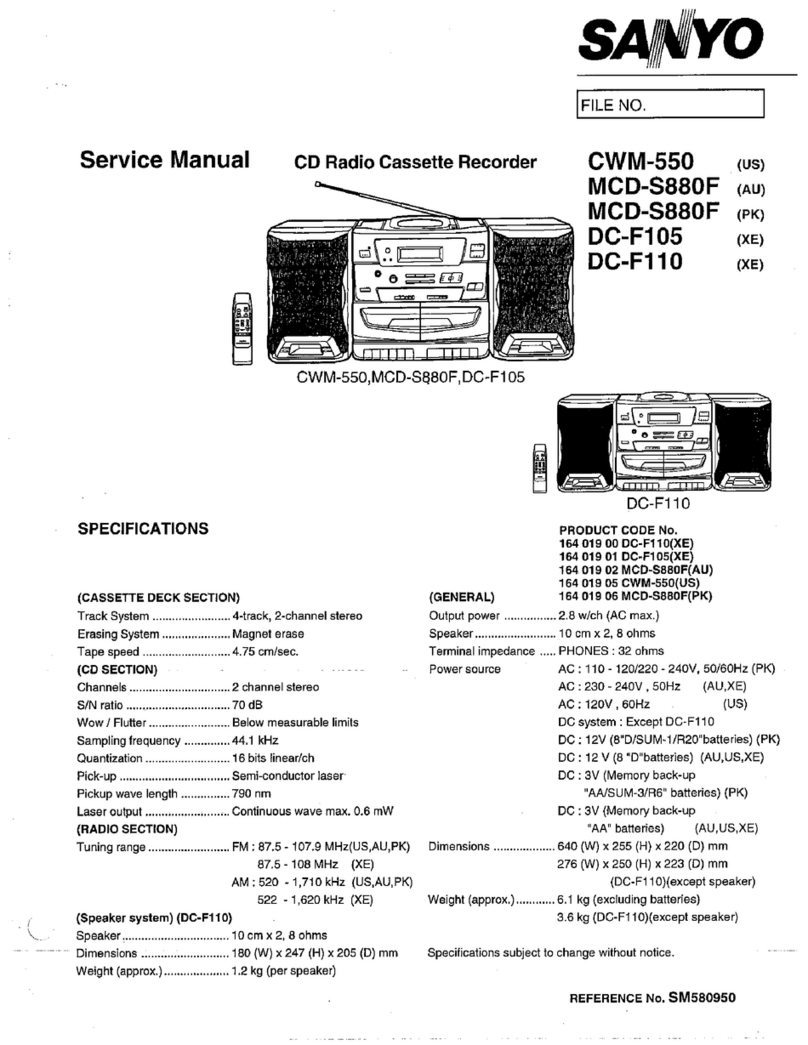

Sanyo CWM-550 User manual

Sanyo

Sanyo FXR-303GB User manual

Sanyo

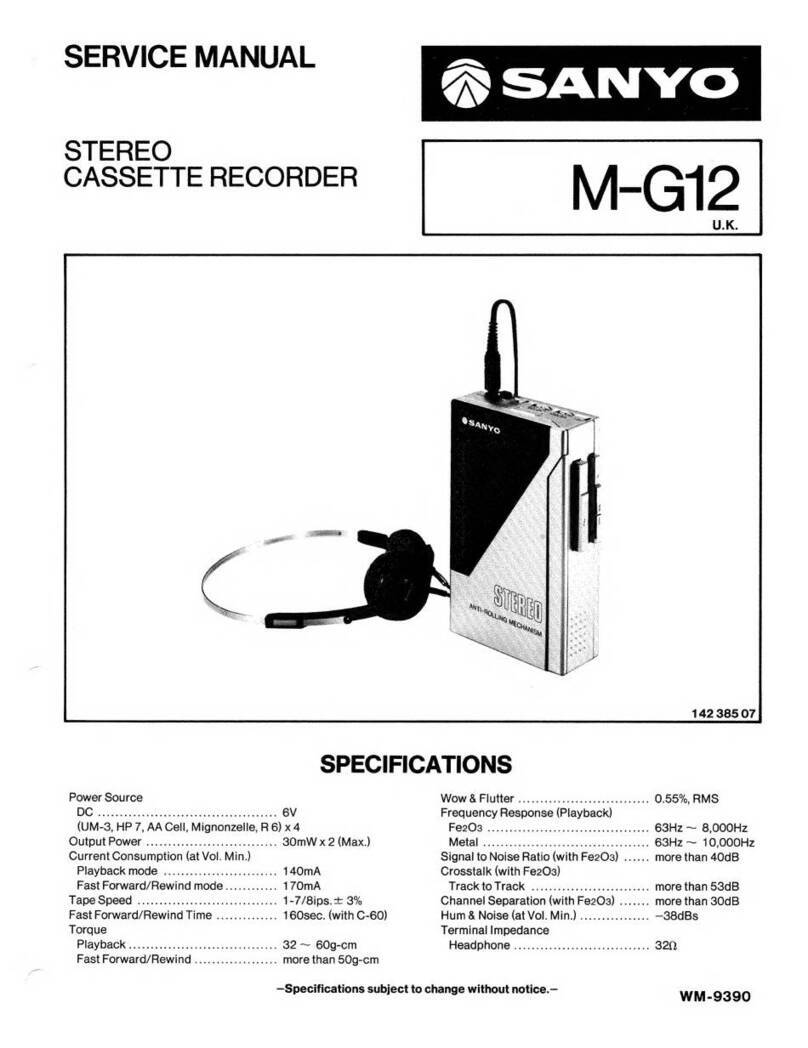

Sanyo M-G12 User manual

Sanyo

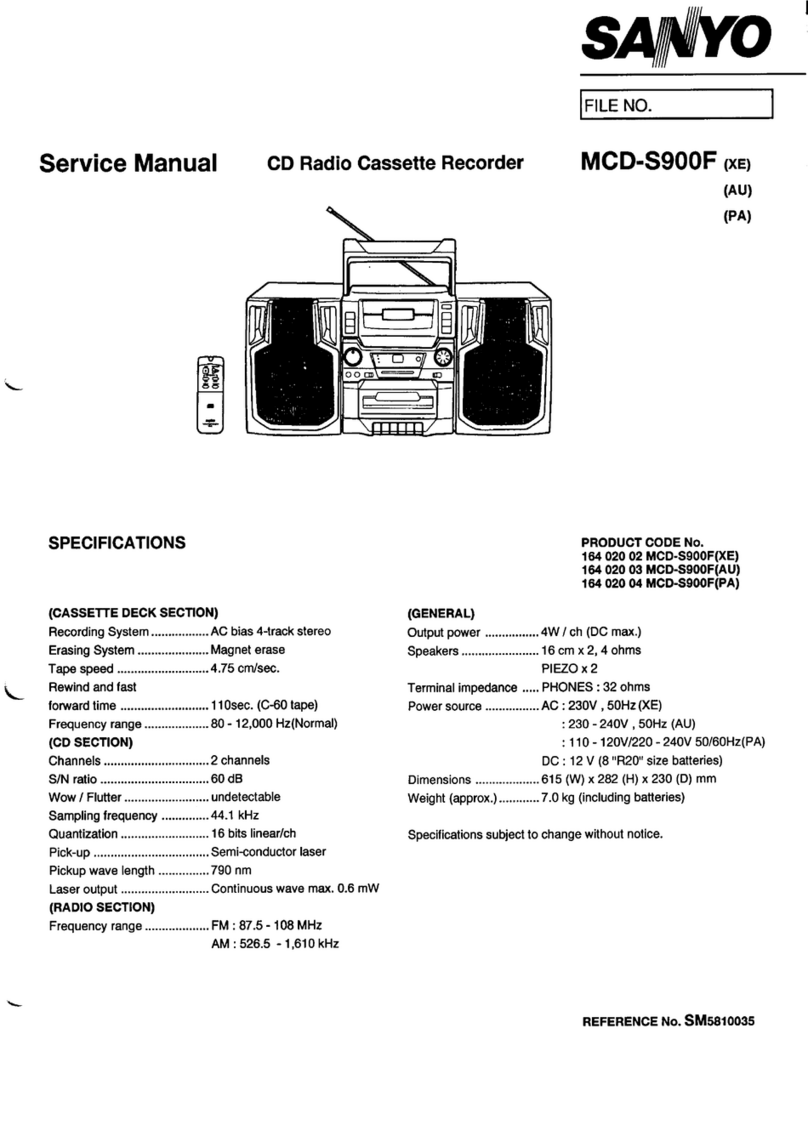

Sanyo MCD-s900F User manual

Sanyo

Sanyo MG-3 User manual

Sanyo

Sanyo M-1060C User manual

Sanyo

Sanyo MGP17 User manual

Sanyo

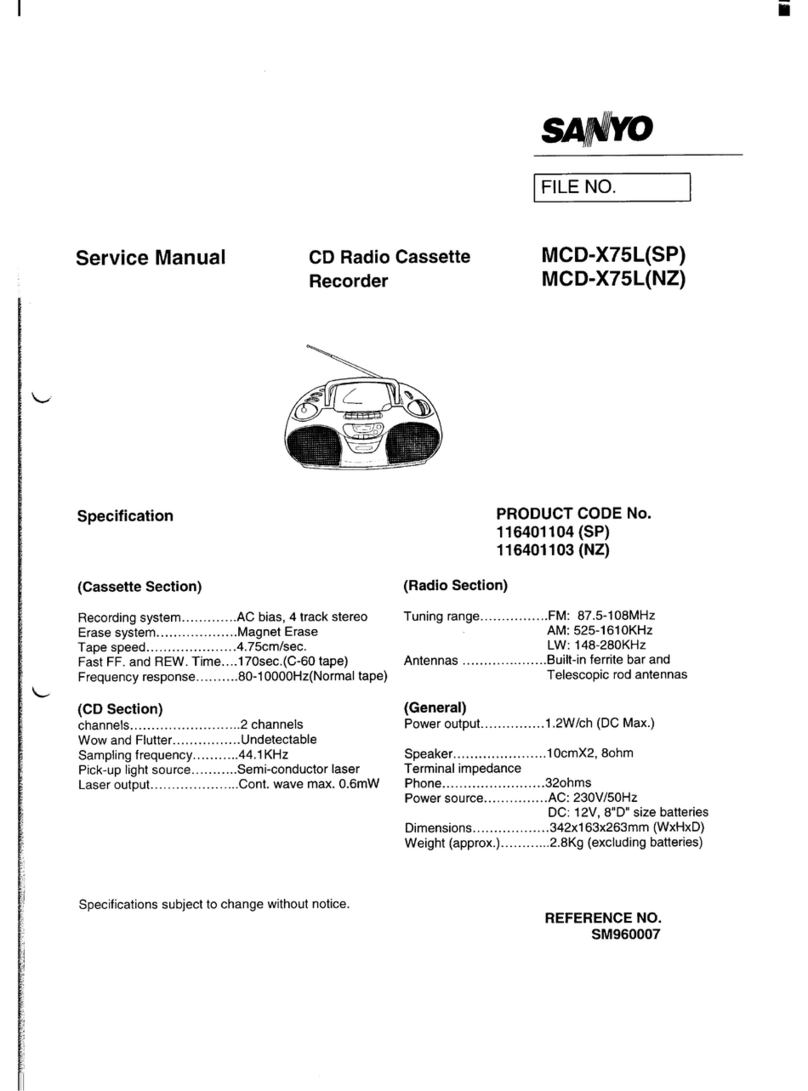

Sanyo MCD-X75L User manual

Sanyo

Sanyo MCD-ZX700F User manual

Sanyo

Sanyo VHR-550 User manual

Sanyo

Sanyo MCD-S660F User manual

Sanyo

Sanyo MCD-S860F User manual

Sanyo

Sanyo MCD-UB575M User manual

Sanyo

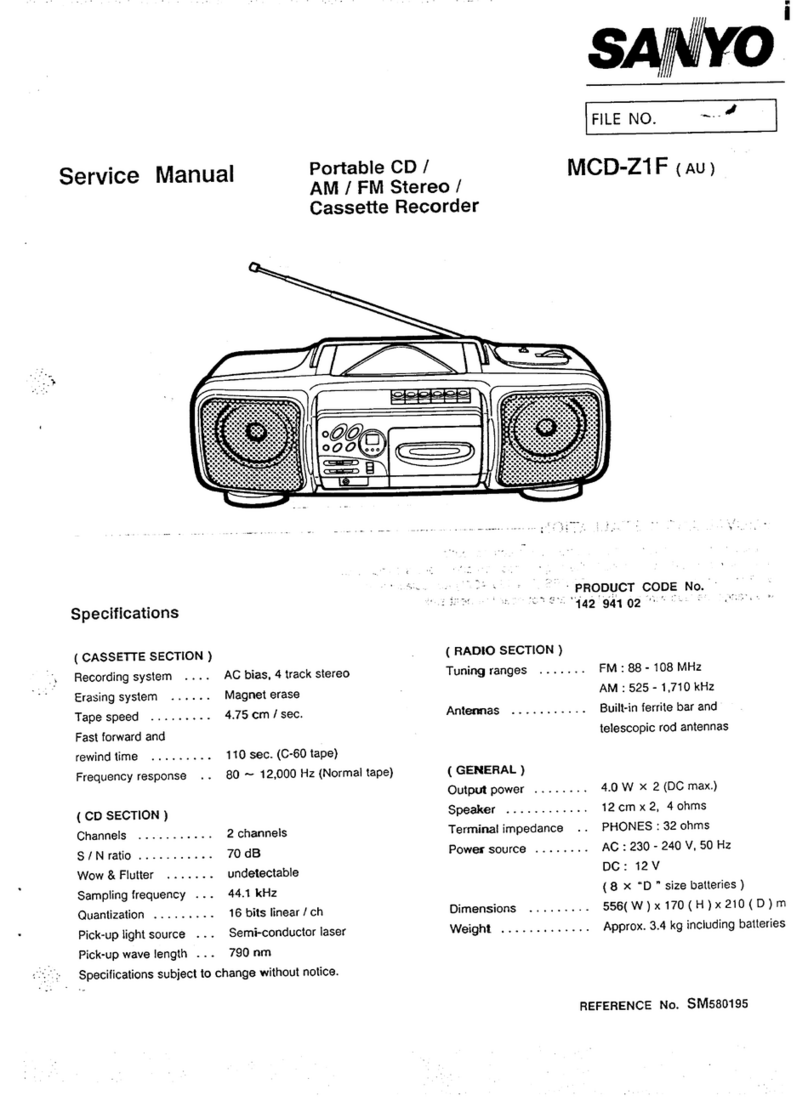

Sanyo MCD-Z1F User manual

Sanyo

Sanyo M9998 User manual

Sanyo

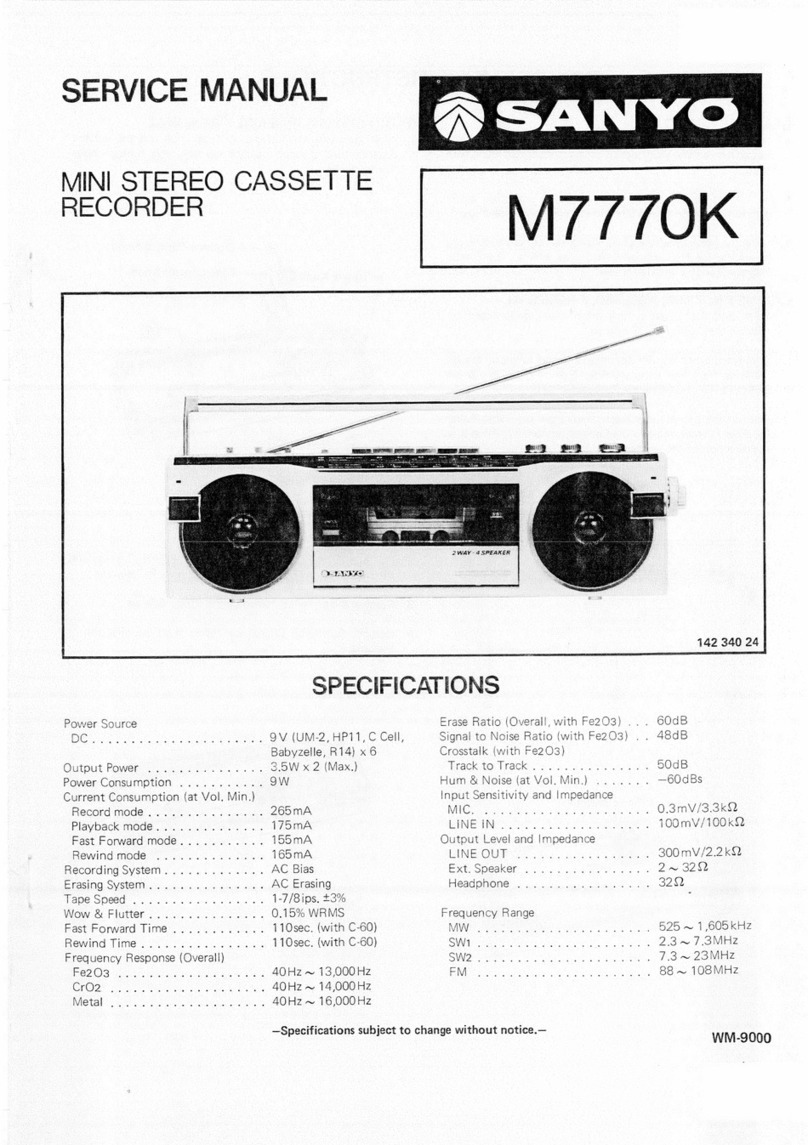

Sanyo M7770K User manual

Sanyo

Sanyo MCH-S970F User manual

Sanyo

Sanyo VHR-510 User manual

Popular Cassette Player manuals by other brands

Sony

Sony CFS-B15 - Am/fm Stereo Cassette Recorder operating instructions

Sony

Sony WMFS220 - Portable Sports AM/FM Cassette... operating instructions

Aiwa

Aiwa HS-TA21 operating instructions

Aiwa

Aiwa CS-P77 Service manual

Sony

Sony Pressman TCM-465V operating instructions

Sony

Sony WALKMAN WM-GX808 operating instructions