Sanyo VHR-350ES User manual

Other Sanyo Cassette Player manuals

Sanyo

Sanyo MCD-Z18F User manual

Sanyo

Sanyo MCD-S860F User manual

Sanyo

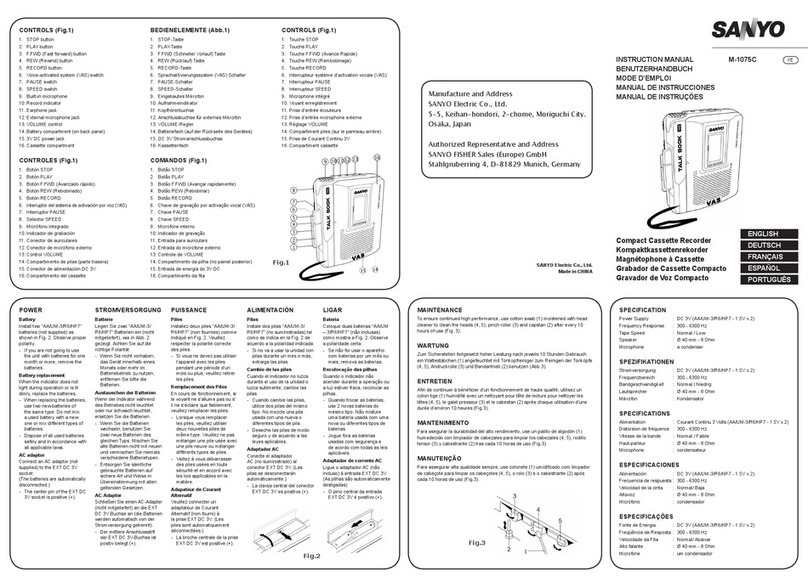

Sanyo M-1075C User manual

Sanyo

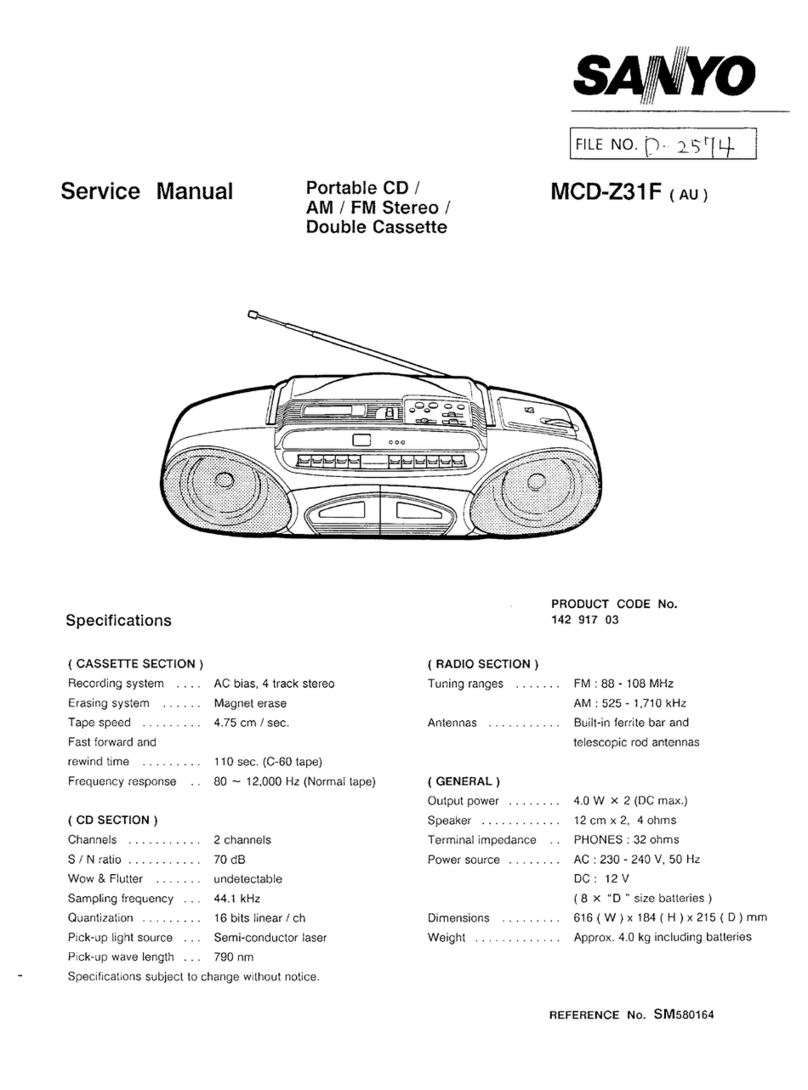

Sanyo MCD-Z31F User manual

Sanyo

Sanyo MCD-S670F User manual

Sanyo

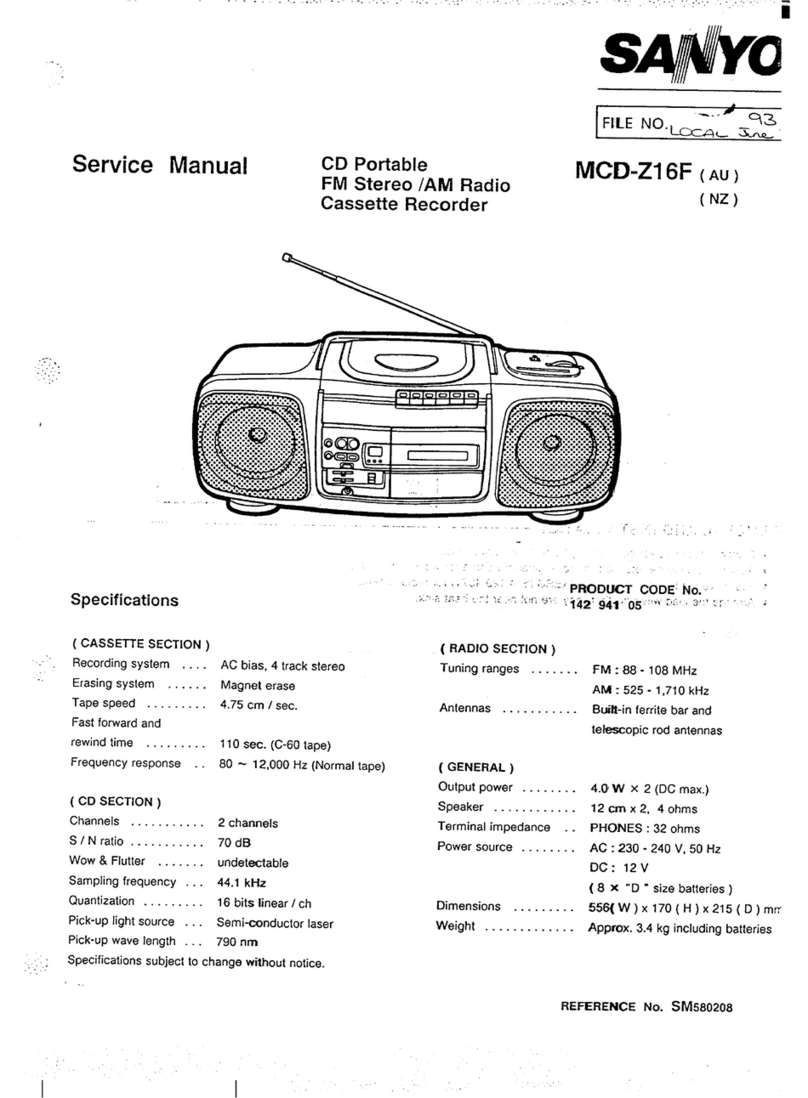

Sanyo MCD-Z16F User manual

Sanyo

Sanyo TRC-960C User manual

Sanyo

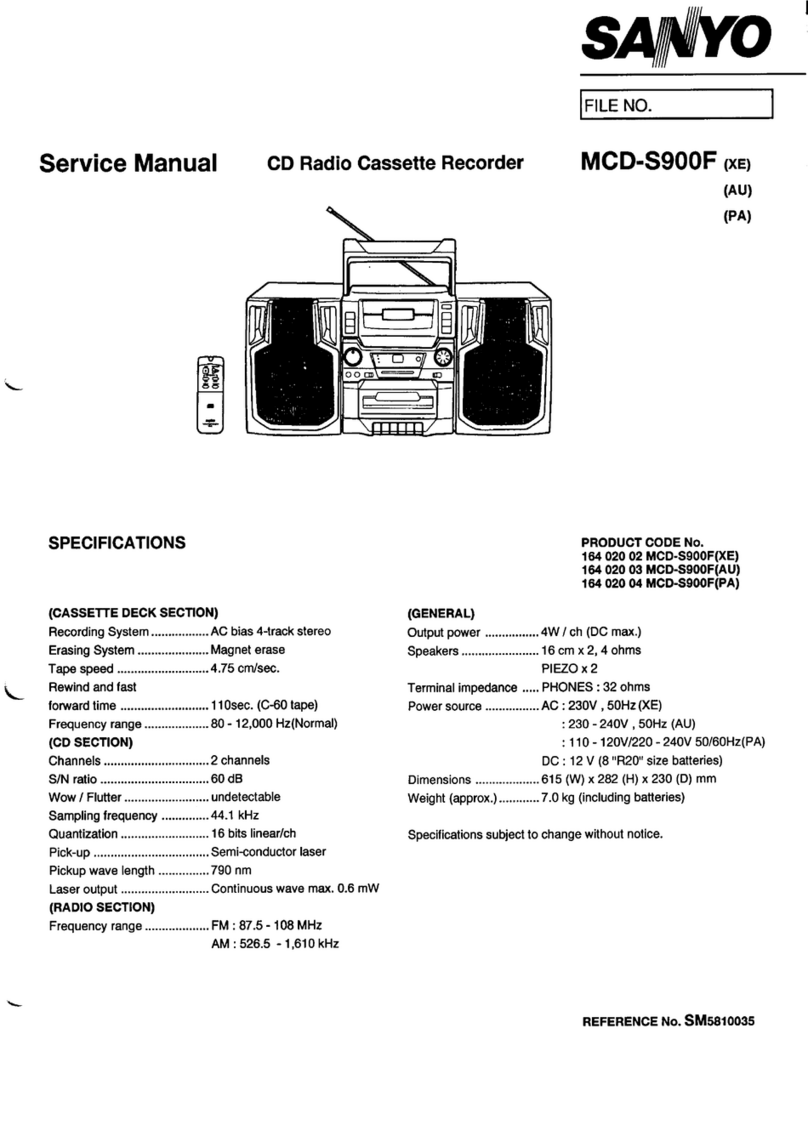

Sanyo MCD-s900F User manual

Sanyo

Sanyo MCD-ZX700F User manual

Sanyo

Sanyo M9998K User manual

Sanyo

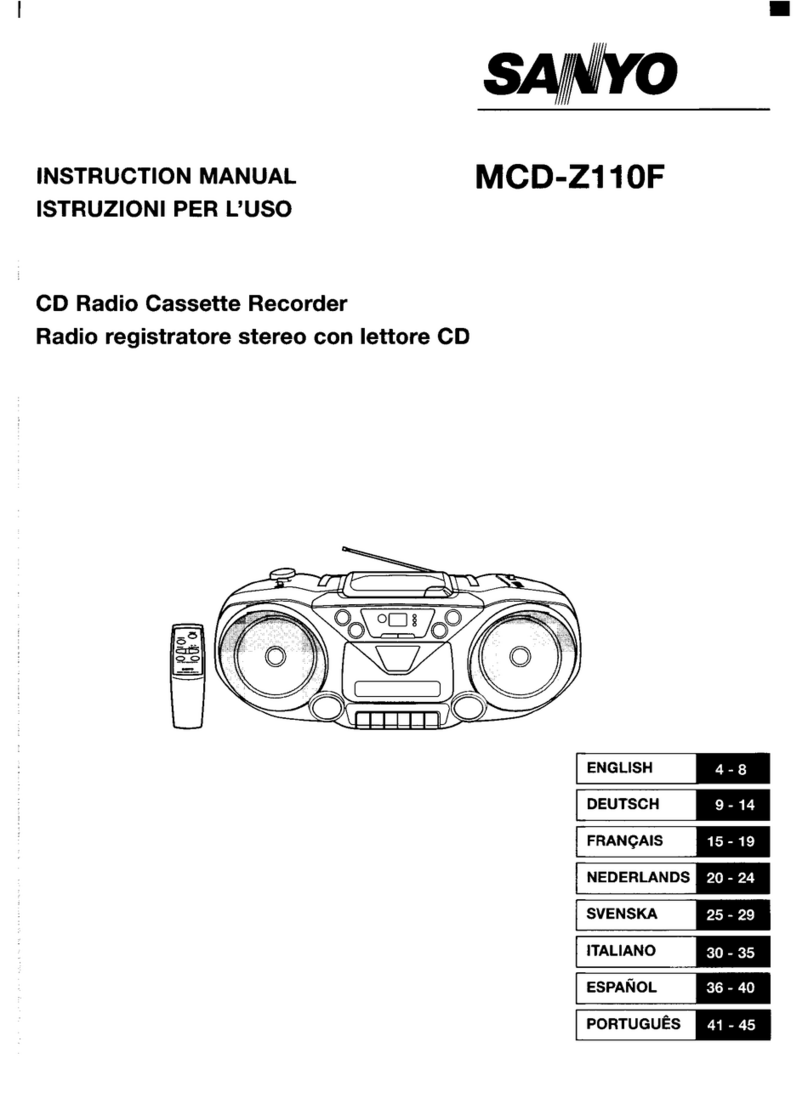

Sanyo MCD-Z110F User manual

Sanyo

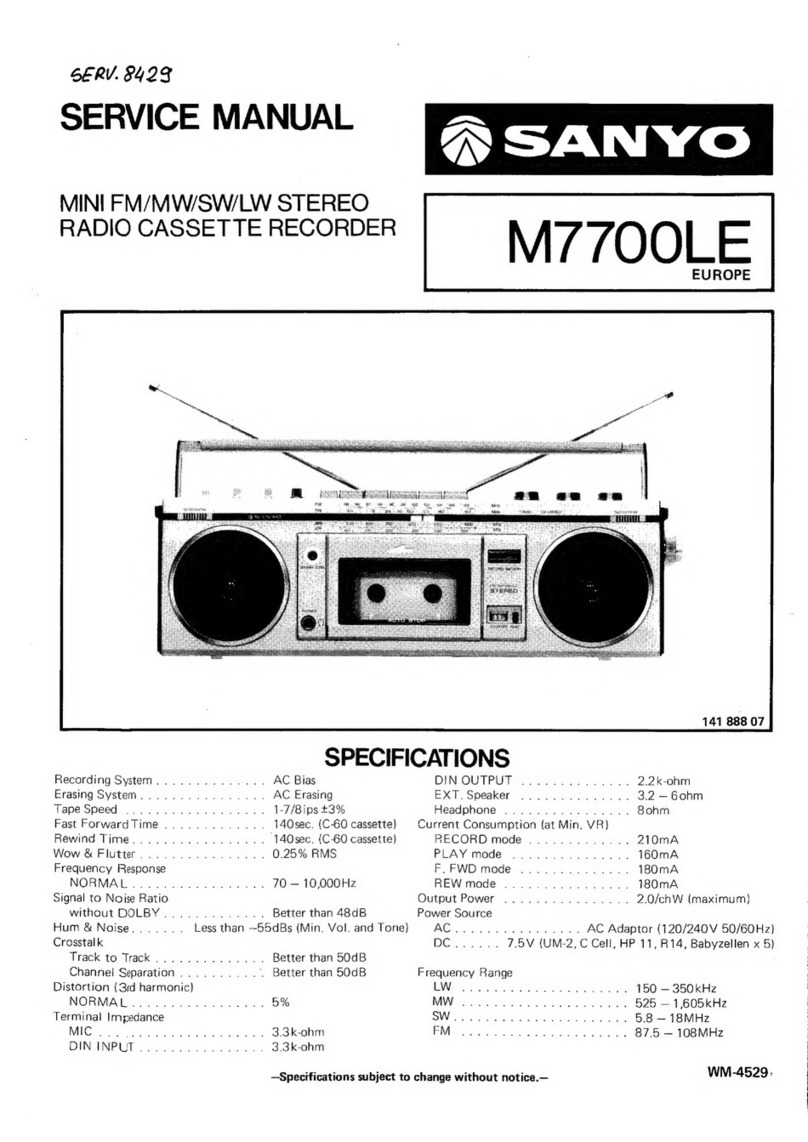

Sanyo M7700L User manual

Sanyo

Sanyo M1990FE User manual

Sanyo

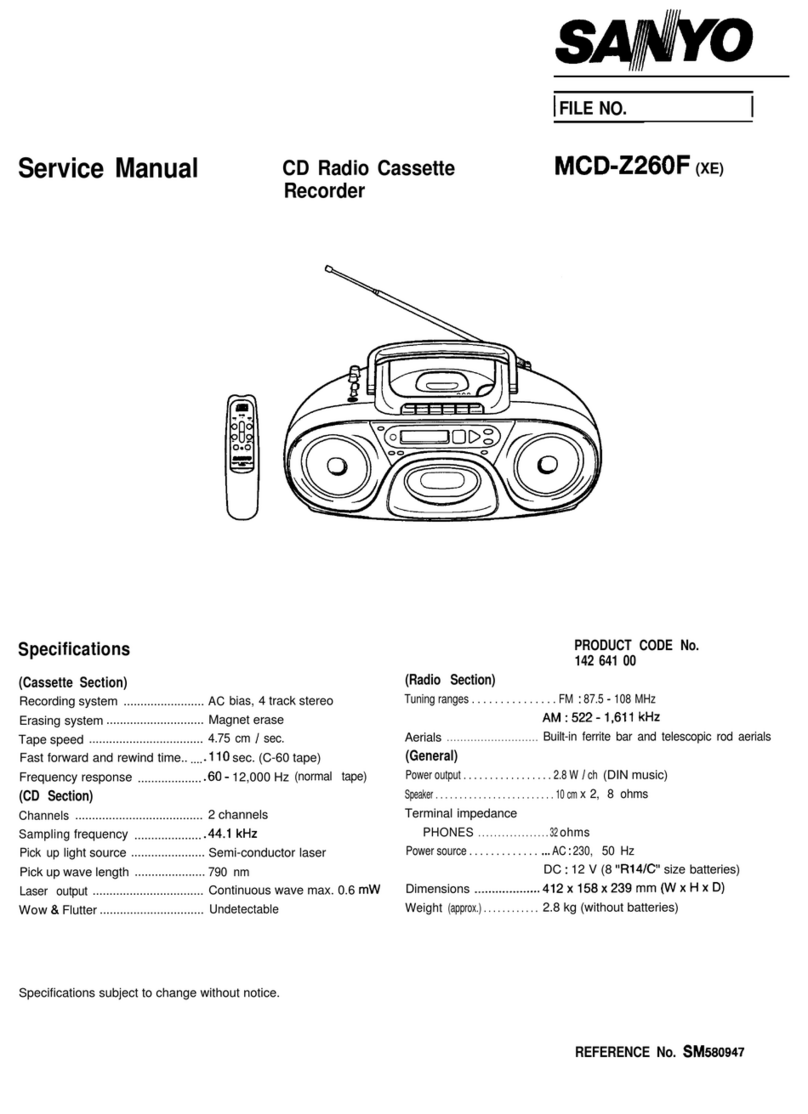

Sanyo MCD-Z260F User manual

Sanyo

Sanyo MCD-Z160F User manual

Sanyo

Sanyo TLS-S8000P User manual

Sanyo

Sanyo MCD-Z1F User manual

Sanyo

Sanyo MCD-Z38F (AU) User manual

Sanyo

Sanyo MCD-S665F User manual

Sanyo

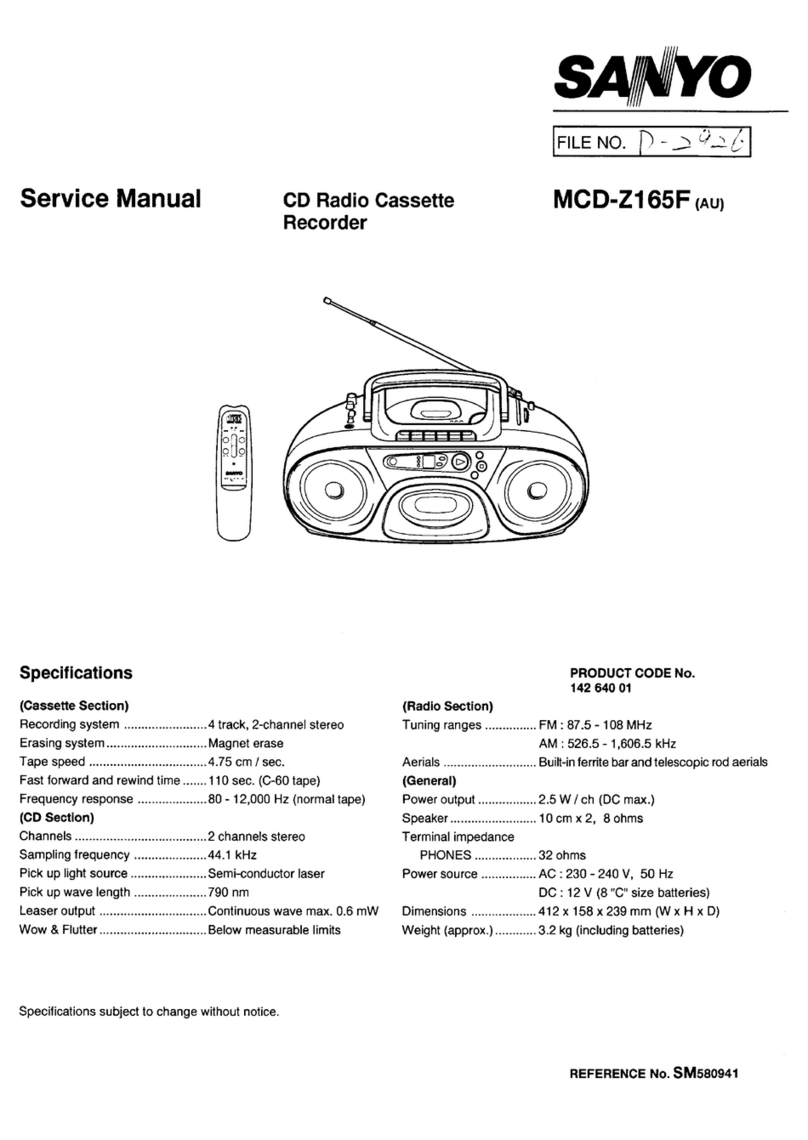

Sanyo MCD-Z165F User manual

Popular Cassette Player manuals by other brands

Sony

Sony CFS-B15 - Am/fm Stereo Cassette Recorder operating instructions

Sony

Sony WMFS220 - Portable Sports AM/FM Cassette... operating instructions

Aiwa

Aiwa HS-TA21 operating instructions

Aiwa

Aiwa CS-P77 Service manual

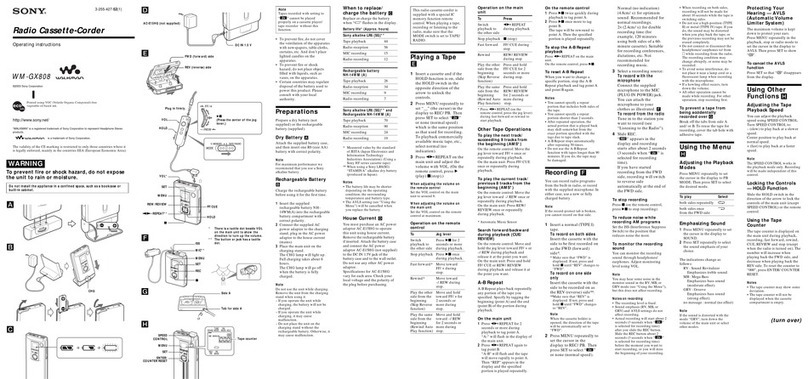

Sony

Sony Pressman TCM-465V operating instructions

Sony

Sony WALKMAN WM-GX808 operating instructions