I

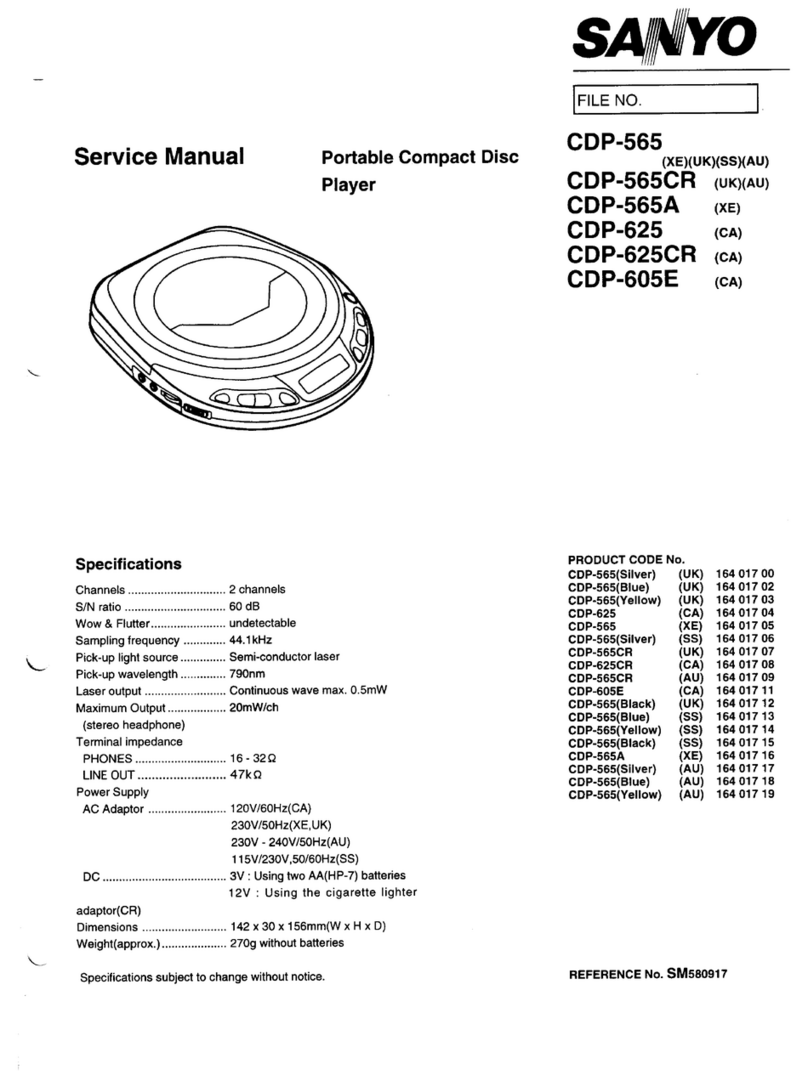

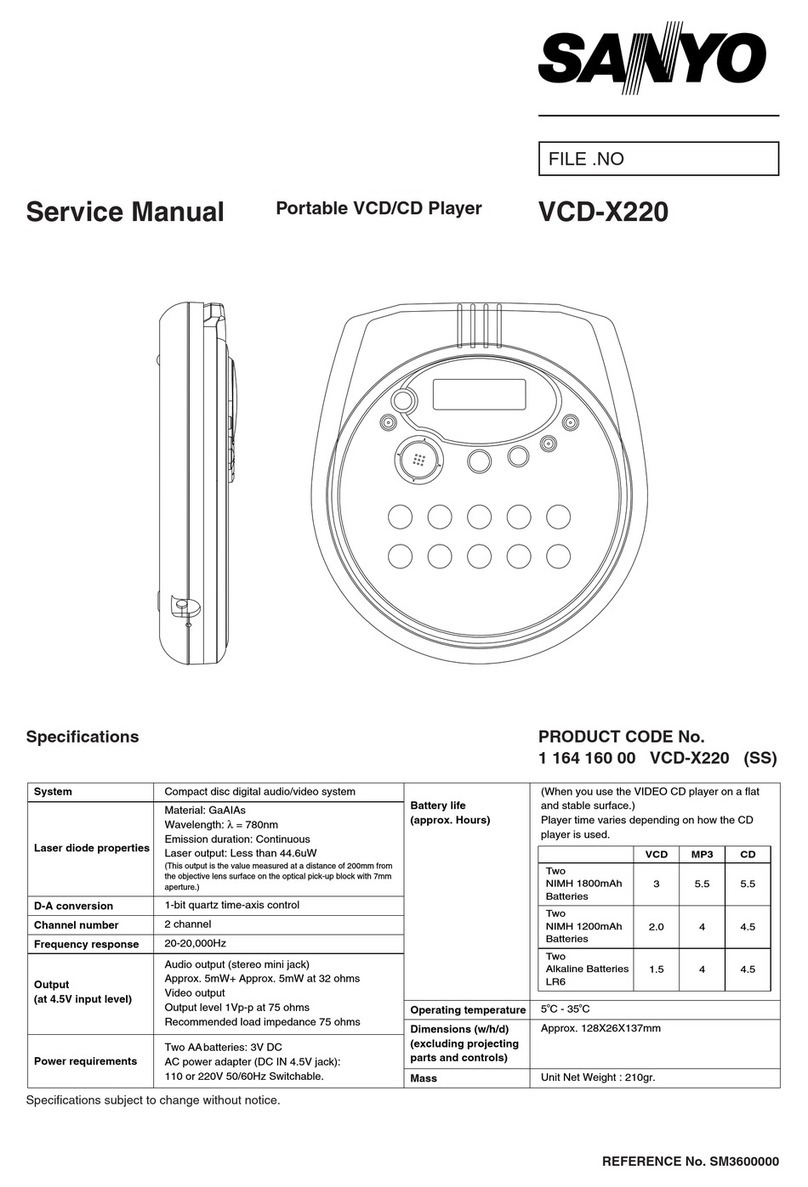

REPLACEMENT OF CD MECHANISM .. . .

CY2 CJ-CY3

\3

3. Replacement and lubrication of the pickup

●Before replacement of the pickup, be sure to carefully read

the section regarding the pickup when the unit is moved or

transported.

(1) Remove the apickup rail (CM2) with care fixing the latch

with way driver from bottom part of chassis (CM3-1 ).

(2)The pickup (CM9) can now be remove once the apickup

rail (CM2) have been taken out.

●When removing or inserting the apickup rail from or into

chassis, take care not to exert excessive force.

●If the pickup is reconditioned of replaced, be sure to wipe

the rails clean and also apply acoating of FLOIL (G-474B)

to there entire circumference and entire length. When ap-

plying the grease, do not ailow any grease to adhere to

any other parts.

(3) Pass the apickup rail (CM2) through the new pick up

(CM9).

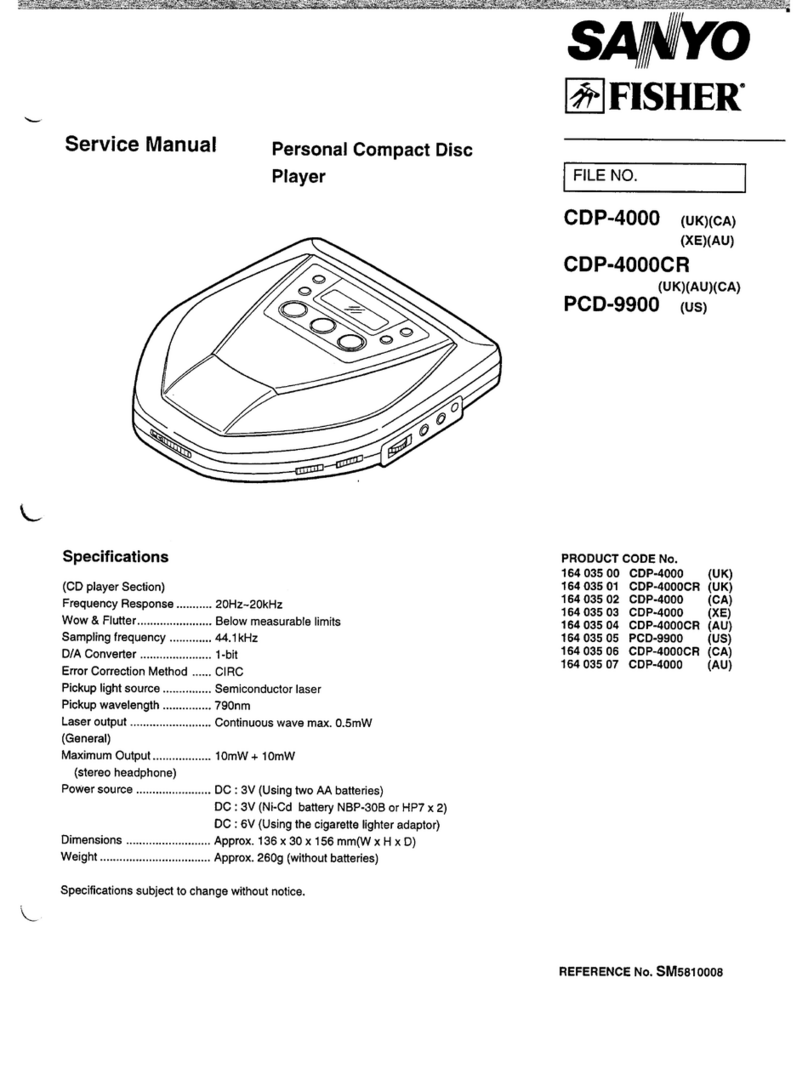

●The pickup P. W. Board pattern is “shorted”, as shown in

the figure, so that the new pickup will not be susceptible

to the effects of static.

●

)

P

&–CM8

/0

3

CM3-1

Set the pattern to “open” after the pickup has been re- 7/ 11-ll\

placed.

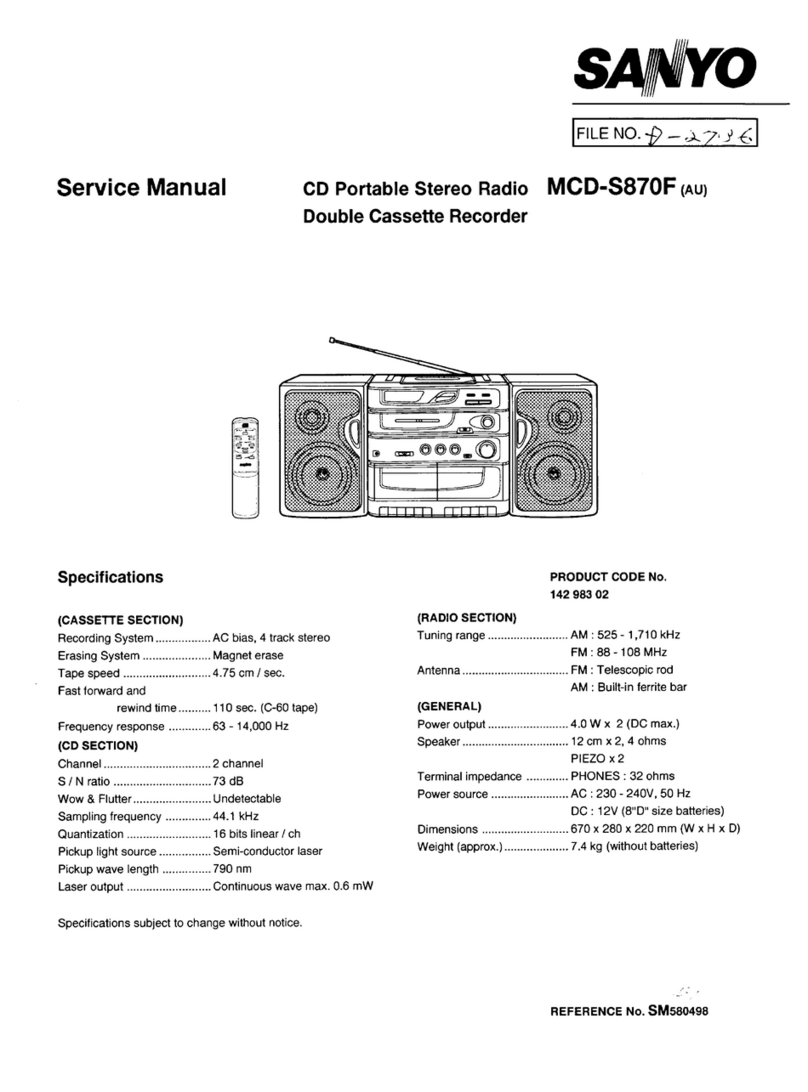

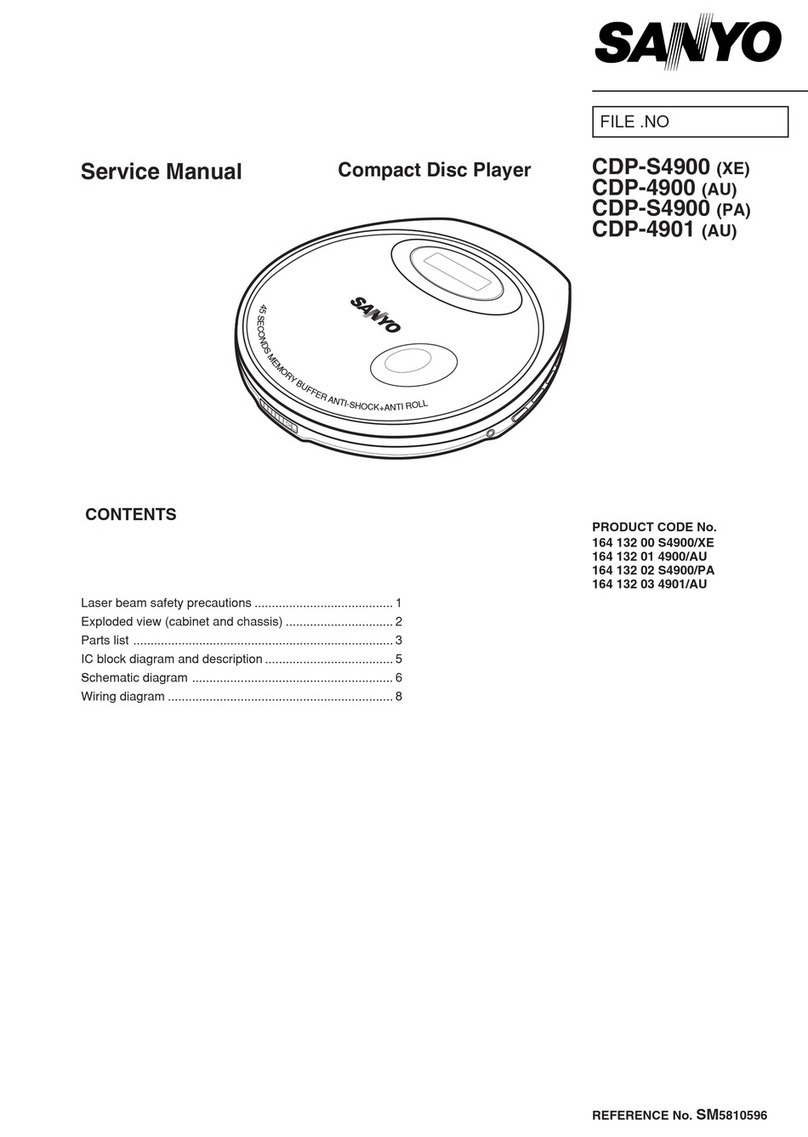

4. Checking the action of the CD mechanism 5. Replacement of the sled motor

(1)

Disconnect the socket (for the sled motor power supply) (1) Remove the two screw (CY1 )and remove the sled motol

from the P. W. Board. (CM5).

(2) Apply avoltage of DC 2.0 Vto the sled motor’s terminal.

(3) Measure the current during sled motor operation.

.The direction of movement of the pickup (outer groove or

inner groove) can changed by changing the battery polar-

ity. CM3-1

(4) The current during sled motor action varies according to

the positional relationshiping of gears (CM7 and CM8).

(5) If the current exceeds 40 mA, remove the gears (CM7 and

CM8).

(6) Apply asmall amount of aFLOIL (G-474B) bonding materi-

als to the chassis shafts.

CYI

$9

,U

CM5 ““”

-6-