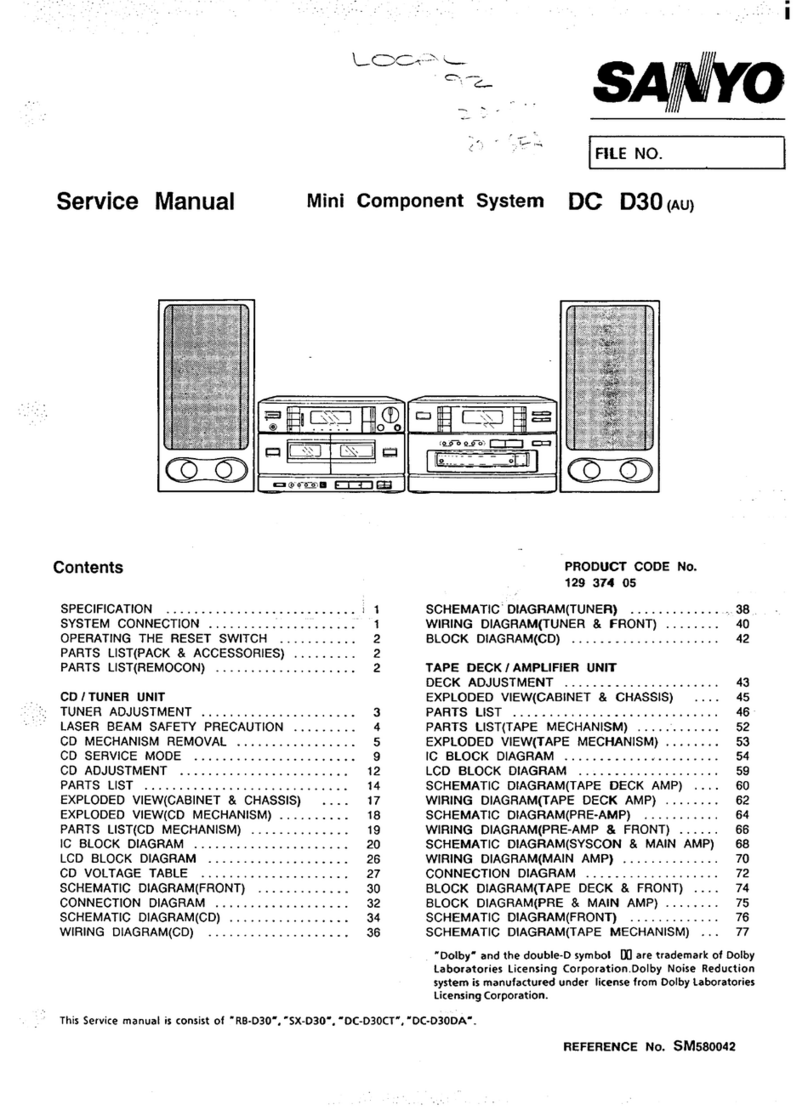

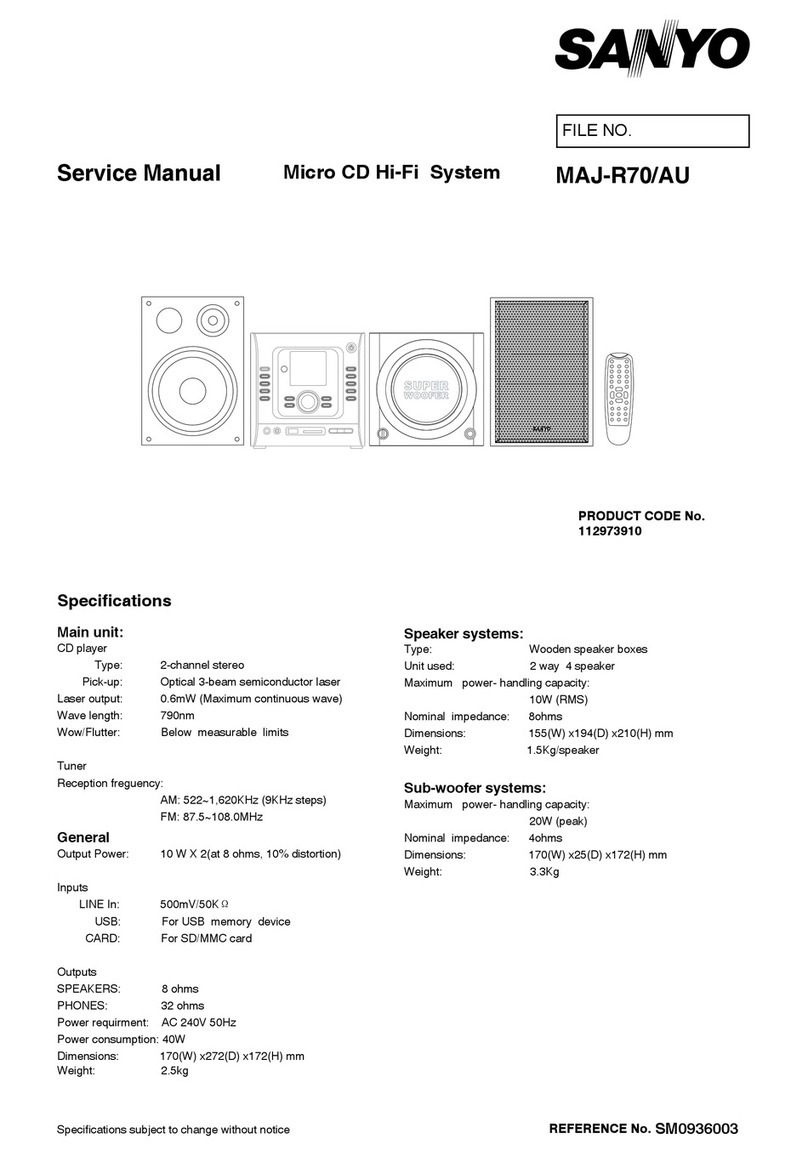

SPECIFICATIONS

Note:

The below mentioned specifications are mainly based on the IHF measurements standard. They can therefore not directly be

compared with specifications based on the DIN standard or other standards.

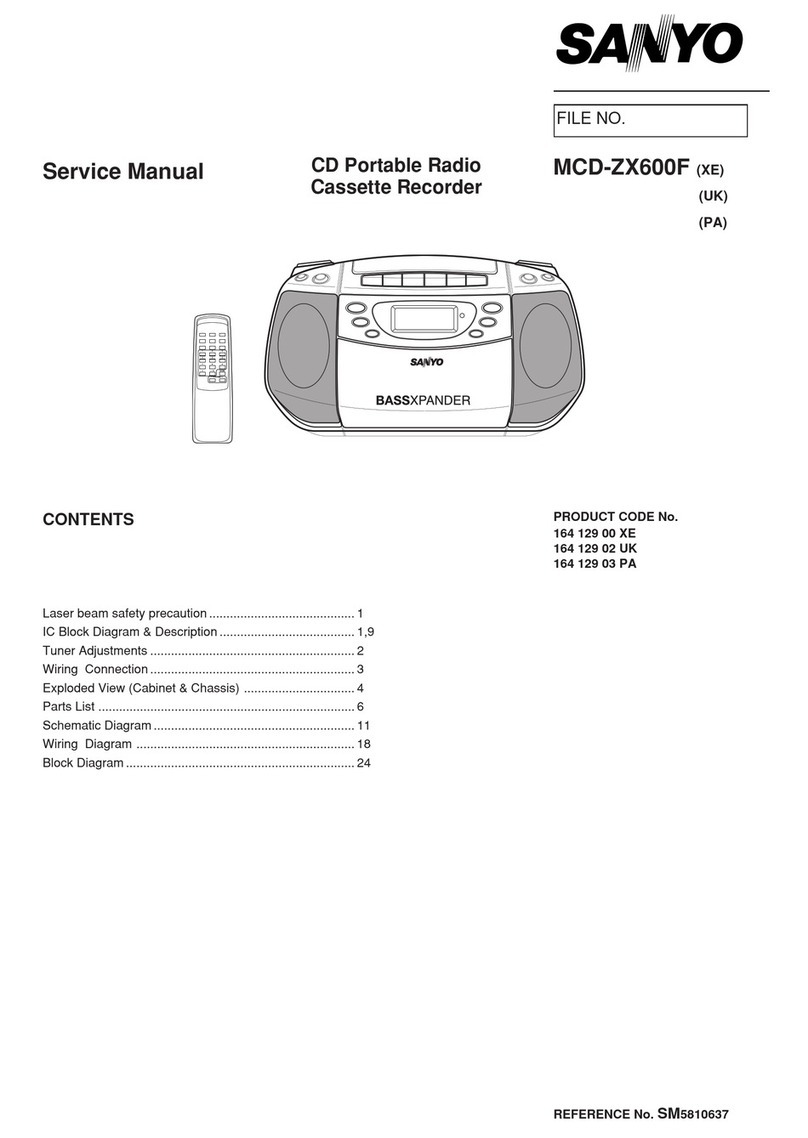

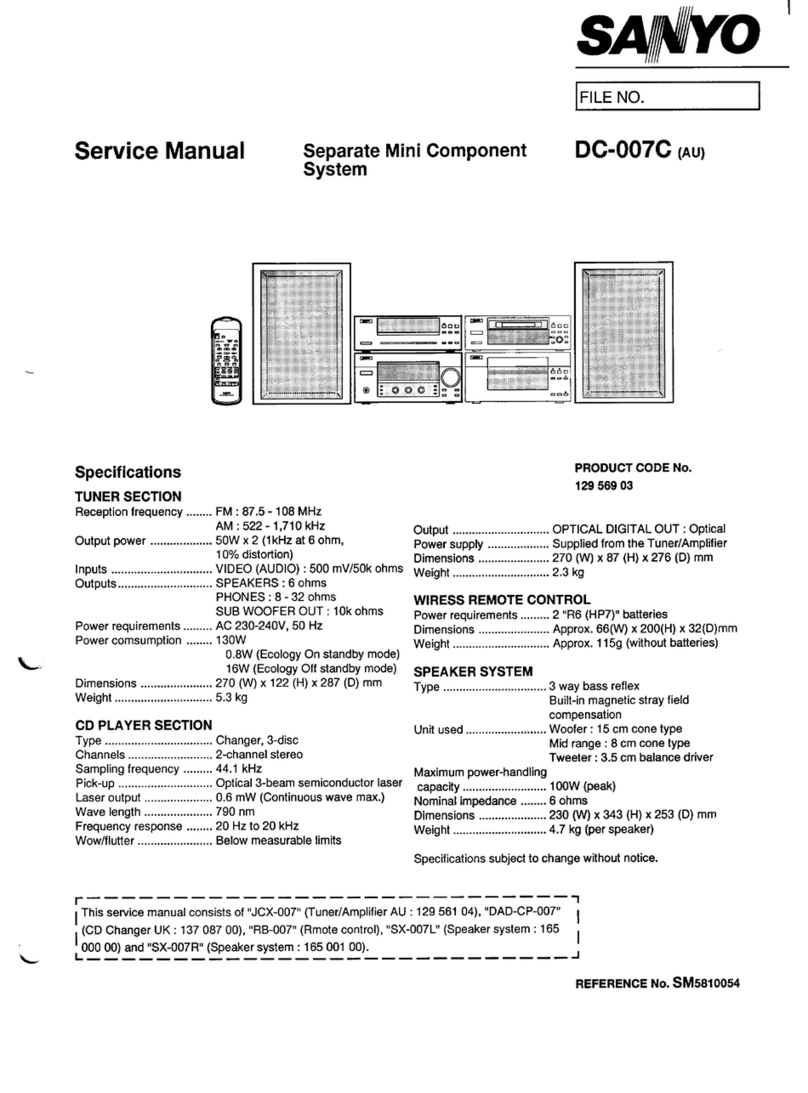

Tuner section

L%.

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

LW

...................................

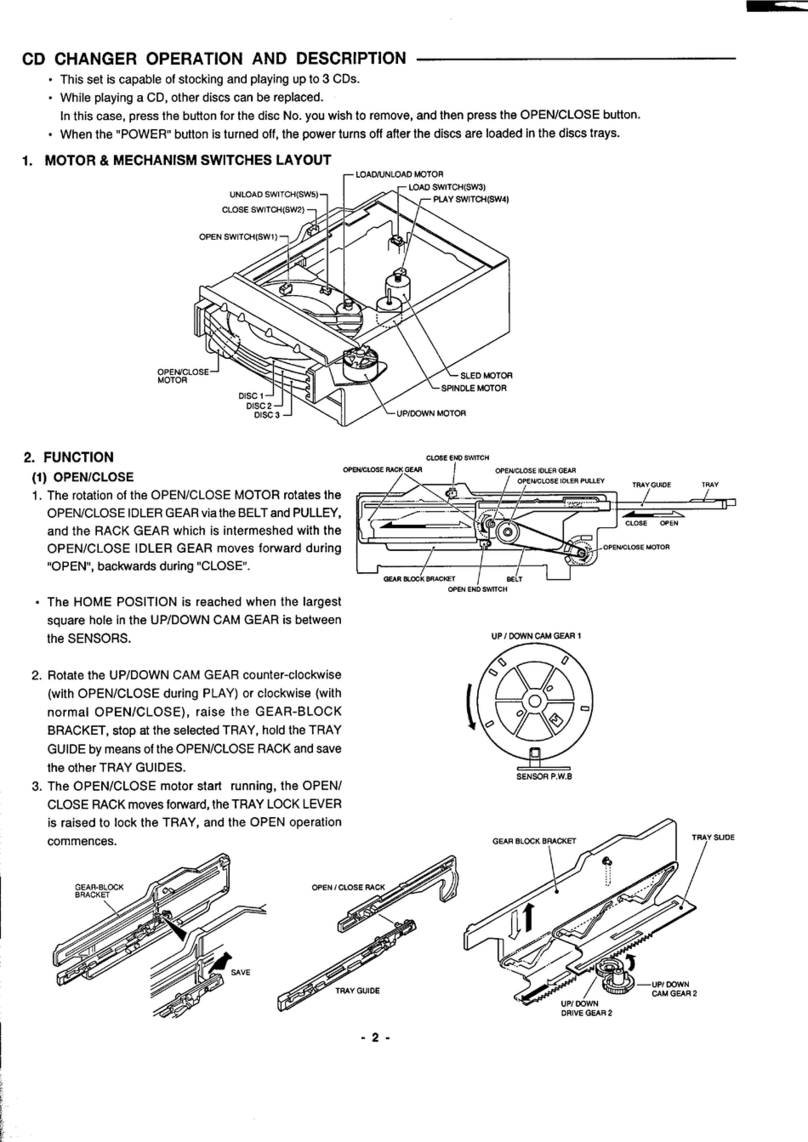

CD changer section

Type

.................................

Channels..........................

Sampling frequency

.........

Pick-up

.............................

Laser output.....................

Wavelength

.....................

Frequency response

........

Wow and flutter................

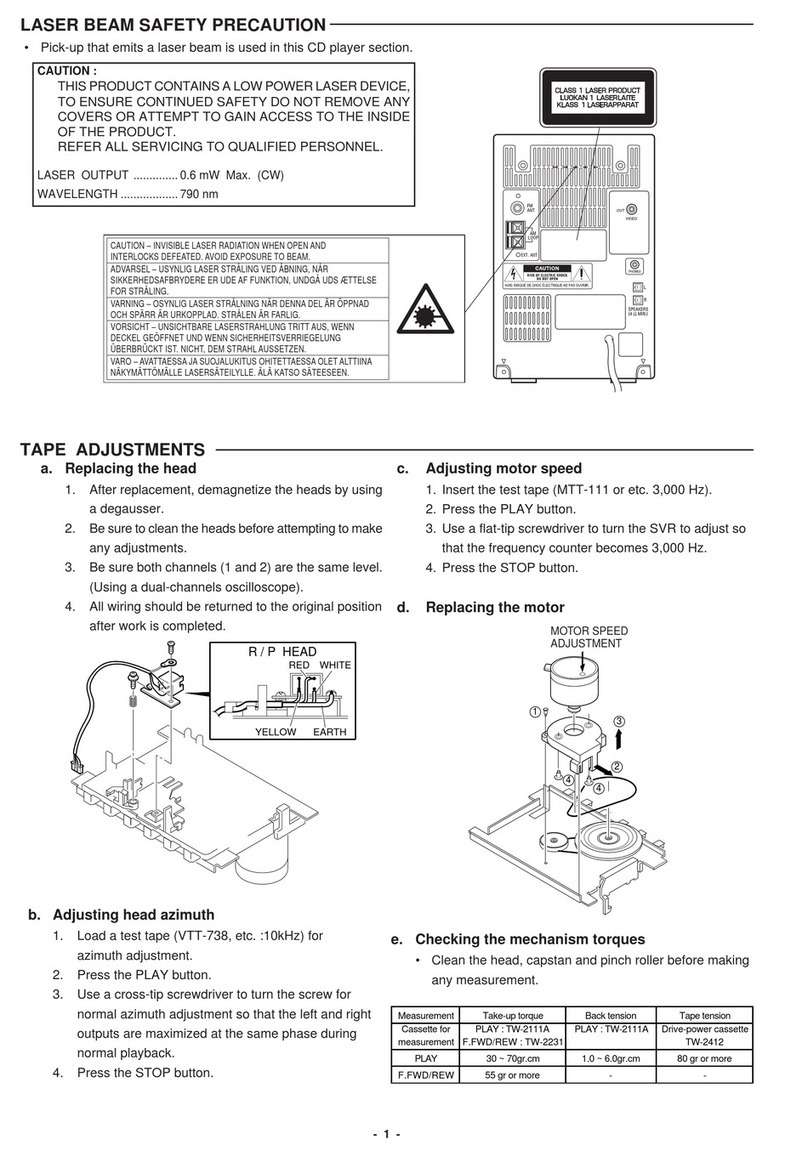

Cassette deck section

Track system:..................

Frequency response

........

Signal-to-noise

ratio.........

Wow and

flutter................

Fast forward and

rewind time......................

Amplifier section

Output

power..................

Inputs

VIDEO/DVD

.....................

MULTIMEDIA

IN

..............

outputs:...........................

87.5 MHz

-

108 MHz

522

kHz

-

1611

kHz

144

-

288

kHz

Changer,

3-disc

2-channel stereo

44.1

kHz

Optical

3-beam

semiconductor laser

O.GmW(Continuous

wave max.)

790 nm

20 Hz to 20

kHz

Below measurable limits

4-track, 2-channel stereo

50 Hz to 14kHz

52

dB

0.12% (WRMS)

Approx. 110 sec. (C-60)

55 W x 2 (at

6ohms,

10% distortion)

400

mVI50

kohm

400mV/50 kohm

SPEAKERS

:6

ohm

PHONES

:8

-

32 ohm

SUB WOOFER

:I0

kohm

Speaker systems

FRONT SPEAKER SYSTEM(SX-F430)

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

wa

Y

bass reflex

Unit

used . . . . . . . . . . . . . . . . . . . . . . . . . .

Woo

er

:

16 cm cone type (UK)

Woofer

:

13 cm cone type (XE)

Midrange

:

5

cm cone type

Tweeter

:

piezoelectric

Maximum power-handling

capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . .

100 Watts(peak)(UK)

120 Watts (peak) (XE)

Nominal impedance . . . . . . . . .

6 ohms

Dimensions (W x H x D) . 240 x 330 x 270 (mm) (UK)

220 x 330 x 230 (mm) (XE)

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9

kg

(UK)

3.5 kg (XE)

General

Power requirements . . . . . . . . .

230 V AC, 50 Hz

Power consumption . . . . . . . . .

105 Watts

Dimensions (W x H x D) .

270(W)

x 330(H) x 290(D) (mm)

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5

kg

Specifications subject to change without notice.

To achieve the best sound performance, select music sources which have

the 001

DOW

SURROUND]~

mark.

Manufactured under license from Dolby Laboratories Licensing

Corporation.

DOLBY, the double-D symbol

00

and “PRO LOGIC” are trademarks of

Dolby Laboratories Licensing Corporation.

WHAT TO DO IF

lIf the operation of the unit or display is not normaLor you

wish to clear the contents of the memory.

1. Disconnect the power cord’s plug from the electrical outlet.

2. Press the RESET button for at least 20 second.

3. Connect the power cord.

4. Press the POWER button to turn the power on.

-l-