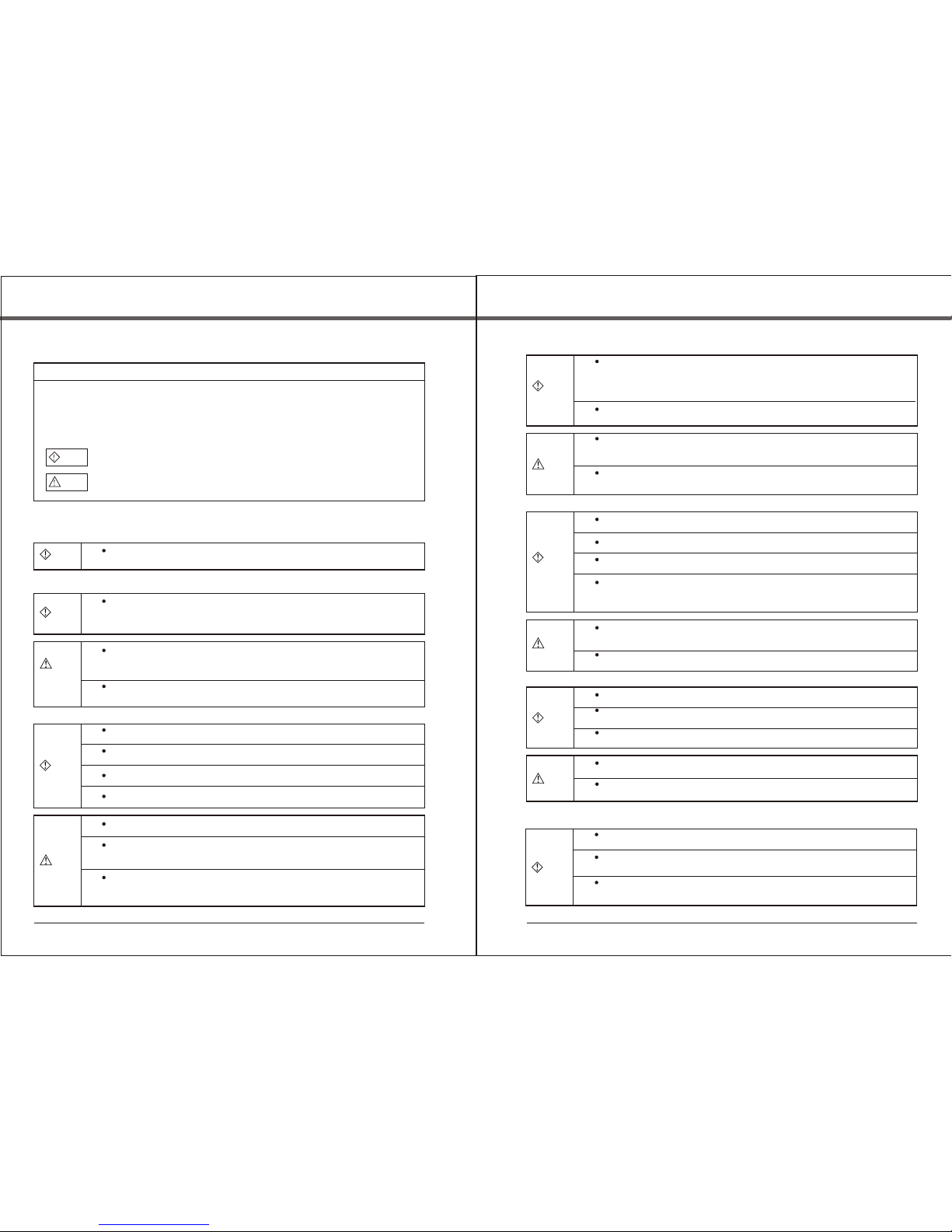

Chapter 1 Safety points and precautions Chapter 1 Safety points and precautions

1.1.7 In maintaining:

Don't install or operate the damaged inverter or the inverter lack of

the parts, otherwise, the accident will cause any personal injury.

Caution

1.1 Safety points:

1.1.1 Before installing:

1.1.2 In installing:

1.1.3 In wiring:

1.1.4 Before energizing:

1.1.5 After energizing:

1.1.6 In running:

This manual includes the operation instructions and attention.

In addition, please submit this manual to the end user.

Safety points

Before installing, operating, maintaining or examining the inverter, please read

this manual and attached documents carefully for correct use. Only you fully

understand the knowledge, safety information and all precautions about this

inverter, you can use it, in this manual, the safety points are classified into

“Danger” and “Caution”.

Caution

Danger The danger caused by the operation not according to the requirements

may result in severe injury, even the death.

The danger caused by the operation not according to the requirements

may result in medium or light injury and equipment damage.

Danger

Mount the inverter at the flame-retardant material (such as the metal),

and keep it away from the combustible material, otherwise, the fire will

be caused.

If more than two inverters are installed in a cabinet, please keep the

good heat emission for the installation position (refer to Chapter 3

Mechanical and electrical installation)

Don't let the conductor head or screw drop into the inverter, otherwise,

the inverter may be damaged.

The inverter shall be operated by the professional electrician,

otherwise, any electric shock will happen!

There must be a circuit breaker for isolating between inverter from

power supply, otherwise, the fire will happen!

Before connecting, please make sure that the power is switched

off, otherwise, you will suffer from the electric shock!

Please accord with the standard to perform the earthing operation,

otherwise, you will suffer from the electric shock!

Don't connect the input power line to the output terminals U, V and W,

otherwise the inverter will be damaged!

Make sure the provided circuit reaches EMC requirements and

local safety standard. Please refer to the suggestions in this manual

for the diameter of used conductor, otherwise, any accident will happen!

The braking resistor can't be directly connected between(+)

terminal and(-)terminal of DC bus, otherwise, the fire may

happen!

Please make sure that the supply voltage is consistent with the rated

voltage of inverter, the connection positions of input and output are

correct, the peripheral circuits have no short circuit, and all circuits

are connected firmly, otherwise, the inverter may be damaged!

Only the cover plate is closed, the inverter can be energized, otherwise,

you will suffer from the electric shock!

The inv erter h as been given t he with stand v oltage test bef ore

leaving the ma rket, so, it need n't to be tested aga in, otherw ise,

some accide nts may happe n!

After the inverter is energized, don't open the cover plate, otherwise,

you will suffer from the electric shock!

Never touch the inverter and peripheral circuits with the wet hands,

otherwise, the accident of electric shock will happen.

Don't touch the terminal of inverter, otherwise you will suffer from

the electric shock!

At the beginning of being electrified, the inverter can conduct the

safety check for the external strong current circuit automatically,

at this moment, don't touch the terminals U, V and W of inverter or

motor terminals, otherwise, the accident of electric shock will happen!

If needing the parameter identification, please notice the danger

that may be resulted from the motor rotation, otherwise, some injury

accidents will happen!

When the inverter is running, anything is not allowed to drop into,

otherwise, it may be damaged!

Never adopt the making and breaking methods for contactor to control

the start and stop of inverter, otherwise, it may be damaged!

Neve r mai nta in th e equi pme nt wh en th e pow er is sw itc hed o n,

othe rwi se, y ou ma y suf fer fr om th e ele ctr ic sho ck!

12

Danger

Danger

Caution

Caution

Danger

All periphery parts should be connected correctly according to

this manual, otherwise, any accident may happen!

Danger

Caution

Don't change the inverter parameters set by manufacturer randomly,

otherwise, the equipment may be damaged.

Danger

Caution

If selecting the restart function, please keep away from the mechanical

equipment, otherwise, the human injury accident may happen!

Never touch the cooling fan and discharge resistor to sound the temperature,

otherwise, you may be burned!

No layman is allowed to detect the signal when the equipment is running,

otherwise, the human injury or equipment damage may happen!

Danger

Only the “Charge” lamp of inverter goes out, the inverter can be maintained,

otherwise, you may be injured by the residual capacitance of capacitor!

No layman is allowed to maintain the inverter, otherwise, the human

injury or equipment damage may happen!