Page 3 of 12

Notes:

–This is a two person installation.

1

2

3

4

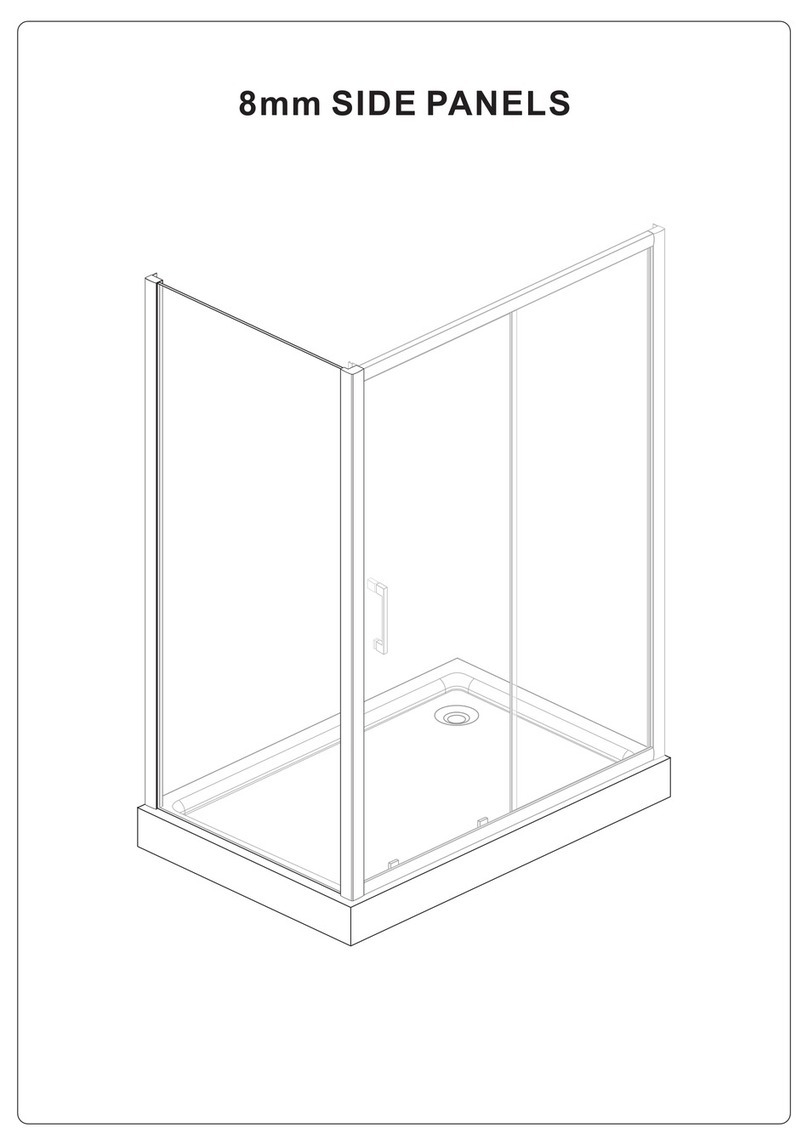

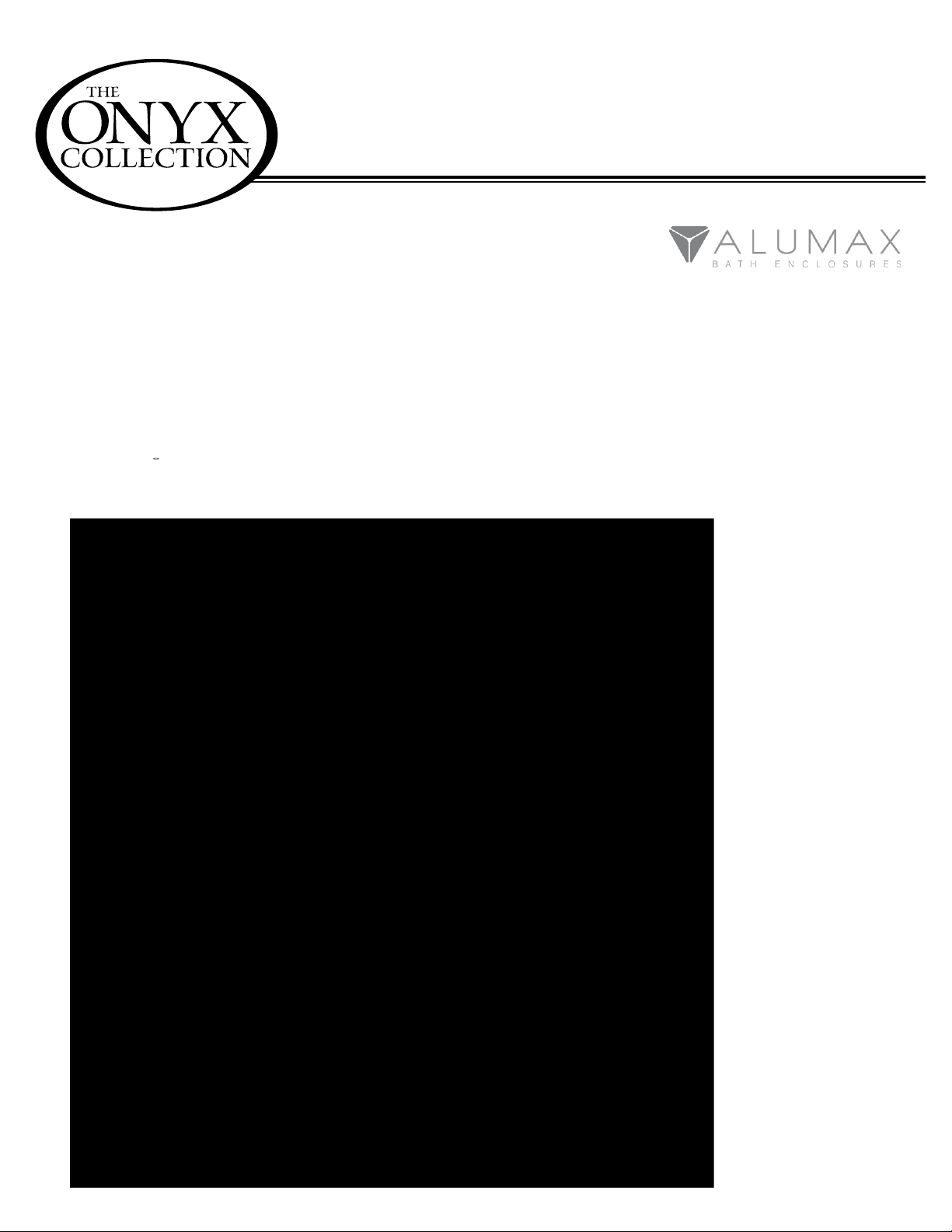

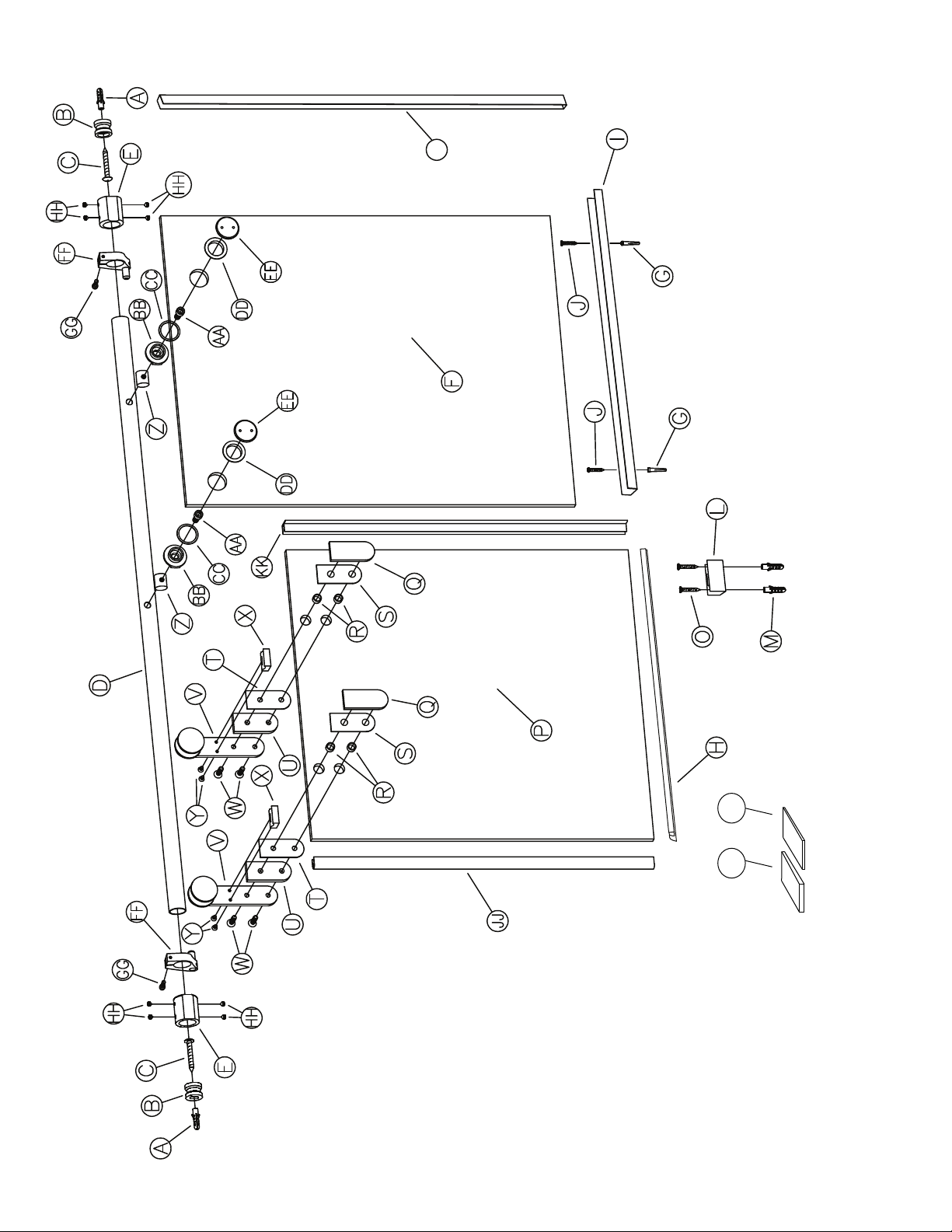

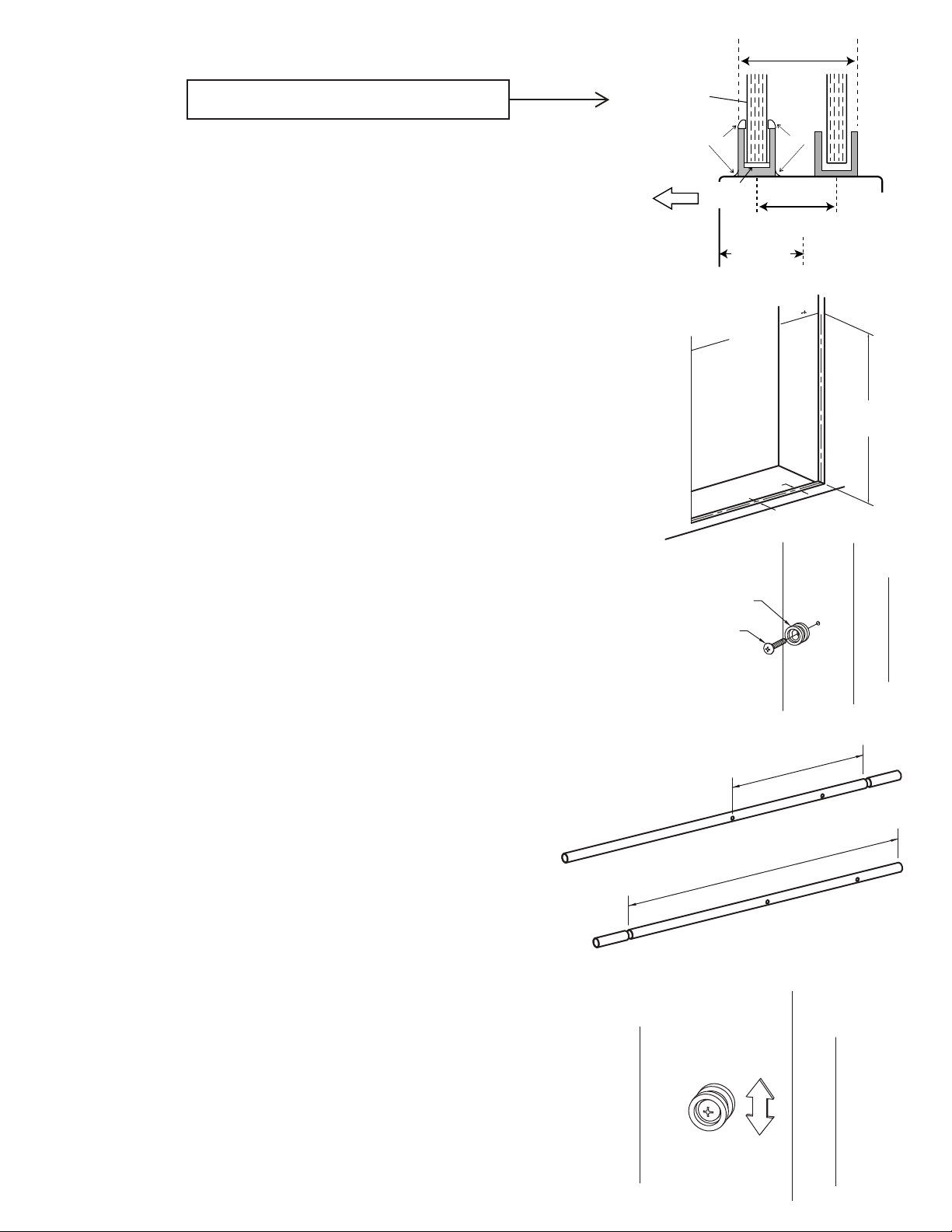

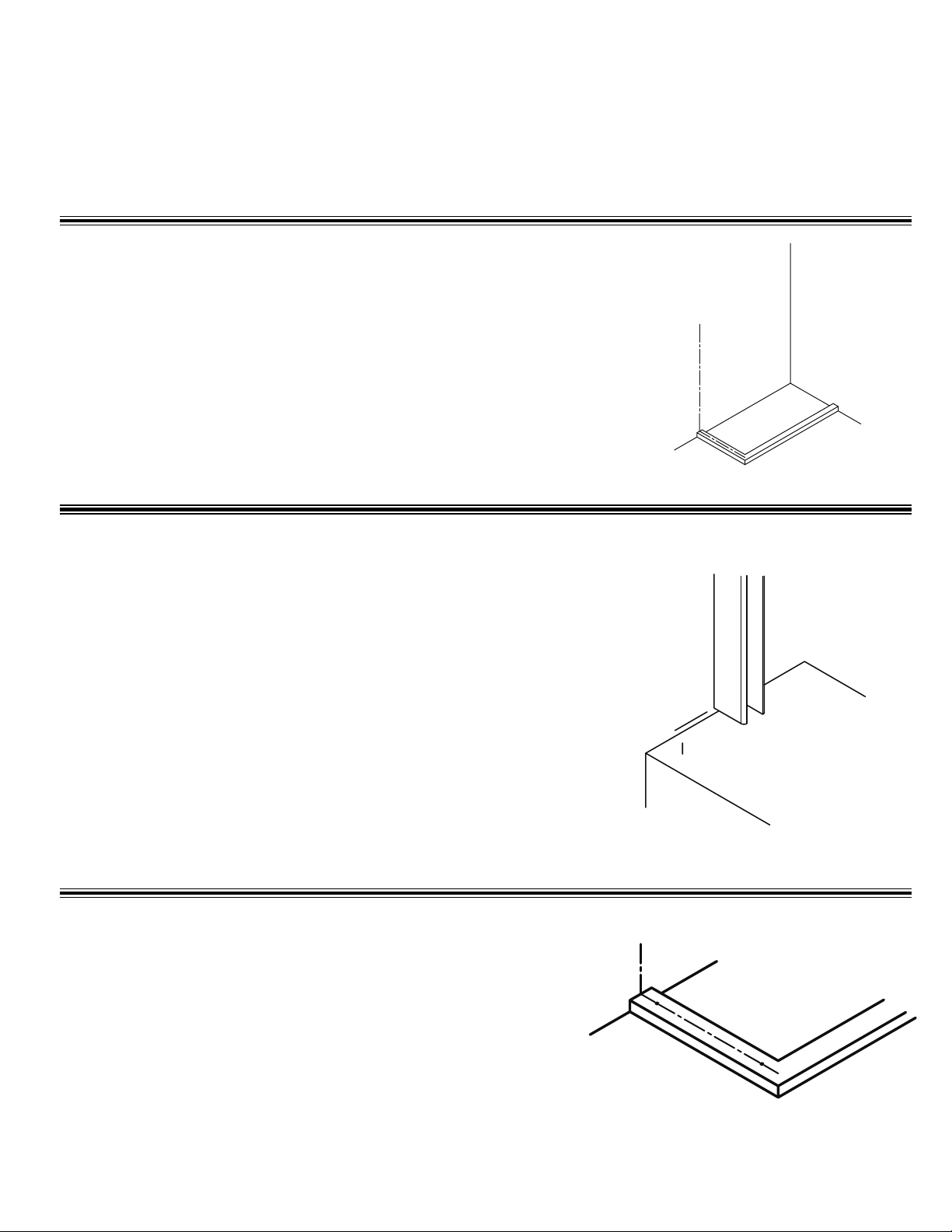

FOOT PRINT - The width of the Door unit's base is 2 1/16"

Consider these measurements before drilling.

Fixe Panel (F)

15/16”

1

7/8”

Total width of shower door unit

From door panel centers

Outside

of curb

Establish Centerlines

c

L

1

1/2” Min.

of sliding door

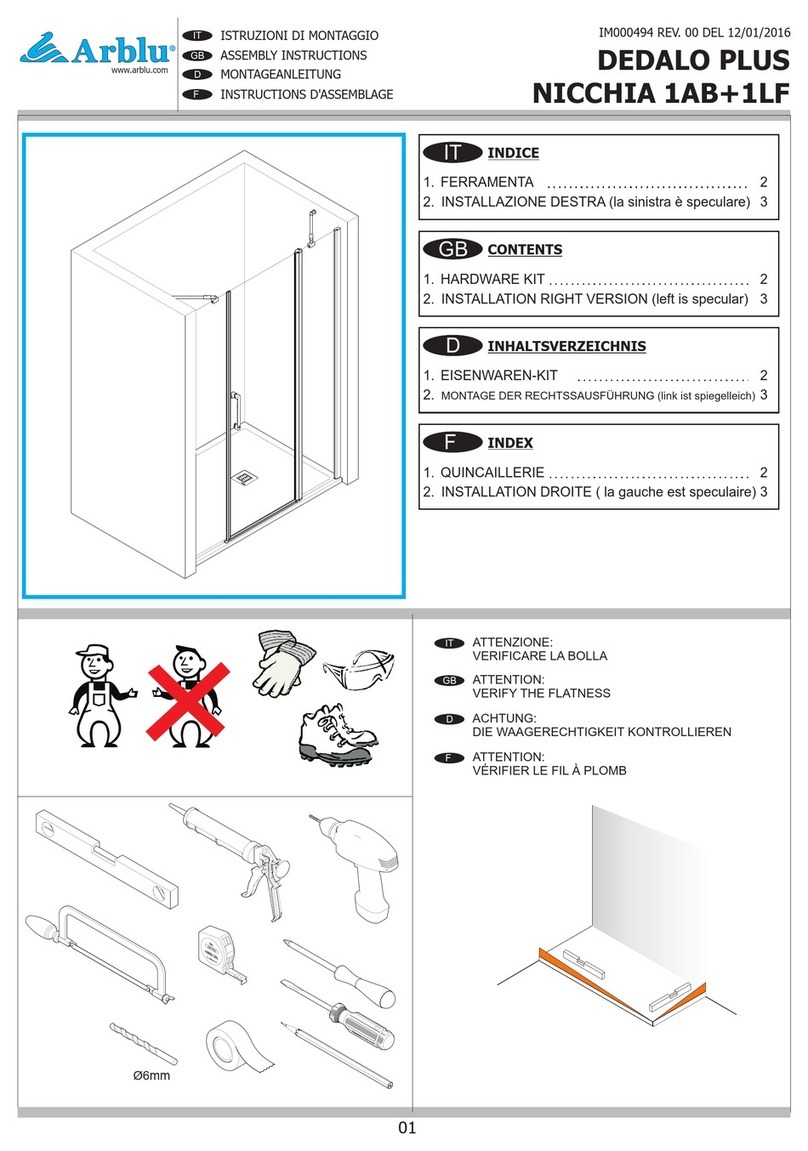

All marks made on tile, marble or berglass should be made lightly in

pencil so they can be removed after the installation is complete.

An optional method is to use masking tape on the walls and sill that can be

removed as the installation progresses.

• The centerlines of the door must be established on the shower sill and on the

walls as well. (See diagram top of page)

• Measure the width of the shower sill and mark the centerline down the middle.

(This needs to be at least 1½” from outside of curb edge)

• Transfer the centerline to the walls using a level. Mark Header Bar [D] location

at 2” less than the unit height, on the centerline. (Unit height on Box Label)

• Measure, and write down, the distance between the two Wall Mount marks.

Note: Unit Height is Stationary Panel Height Plus ¼"

MEASURE

UNIT HEIGHT

- 2”

SILL÷2

CENTERLINE

SILL

Wall Mount Block

Wall Mount Screw

FIXED PANEL

WIDTH - 2 3/8”

UNIT WIDTH - 1 3/4”

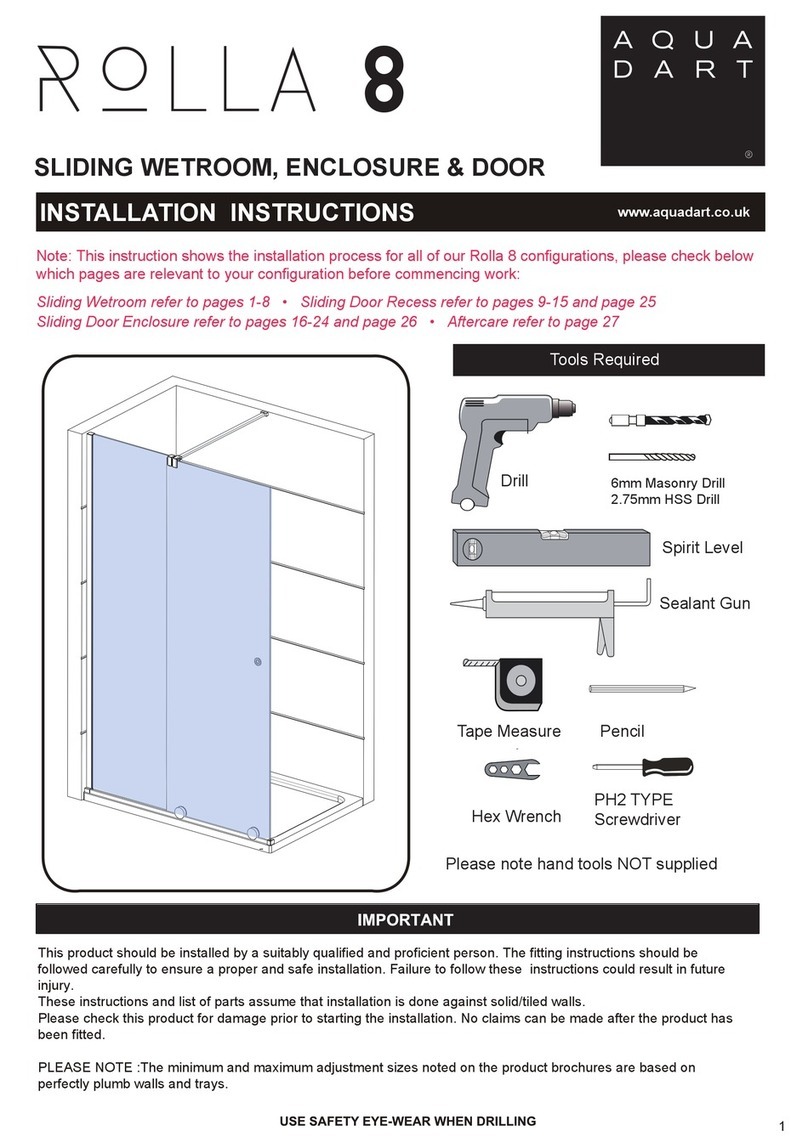

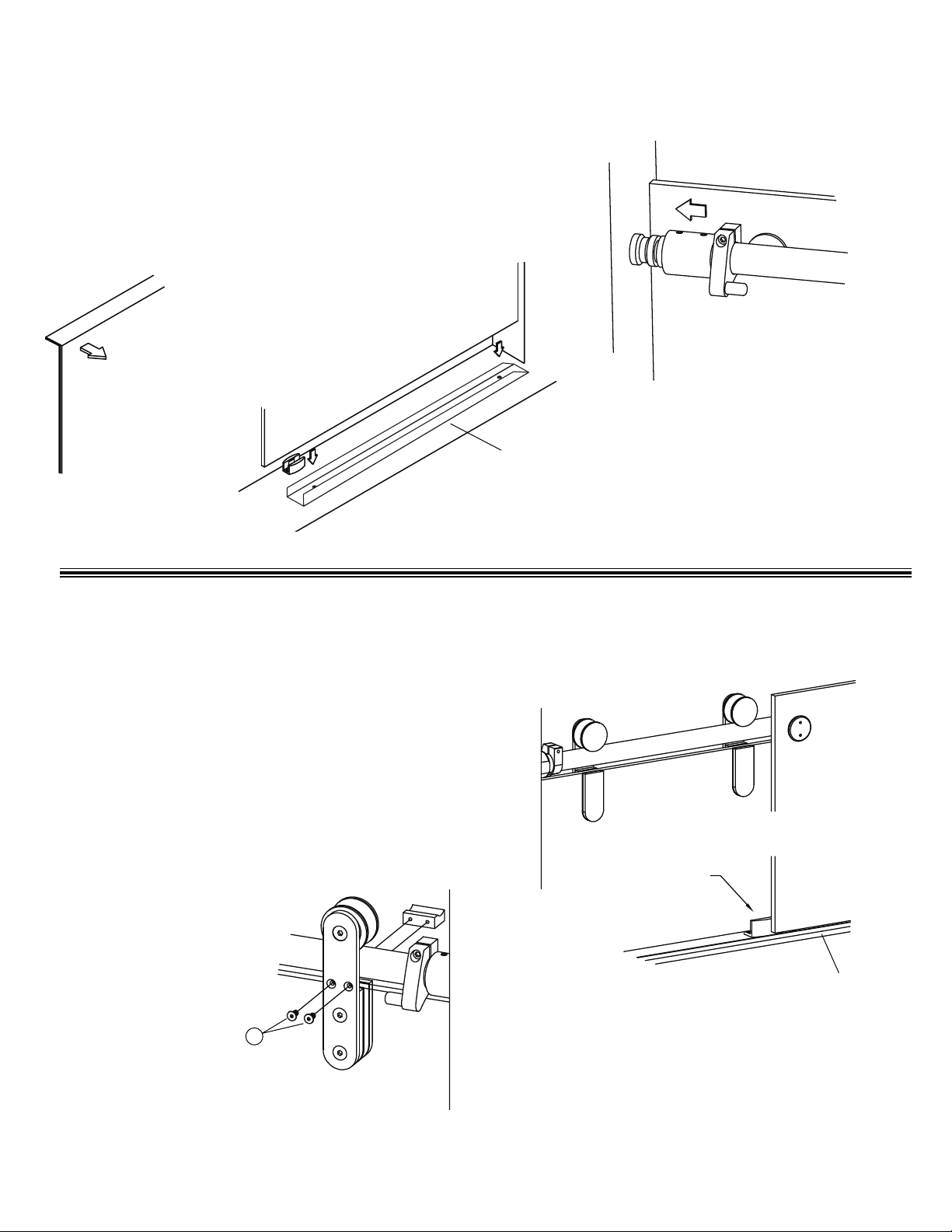

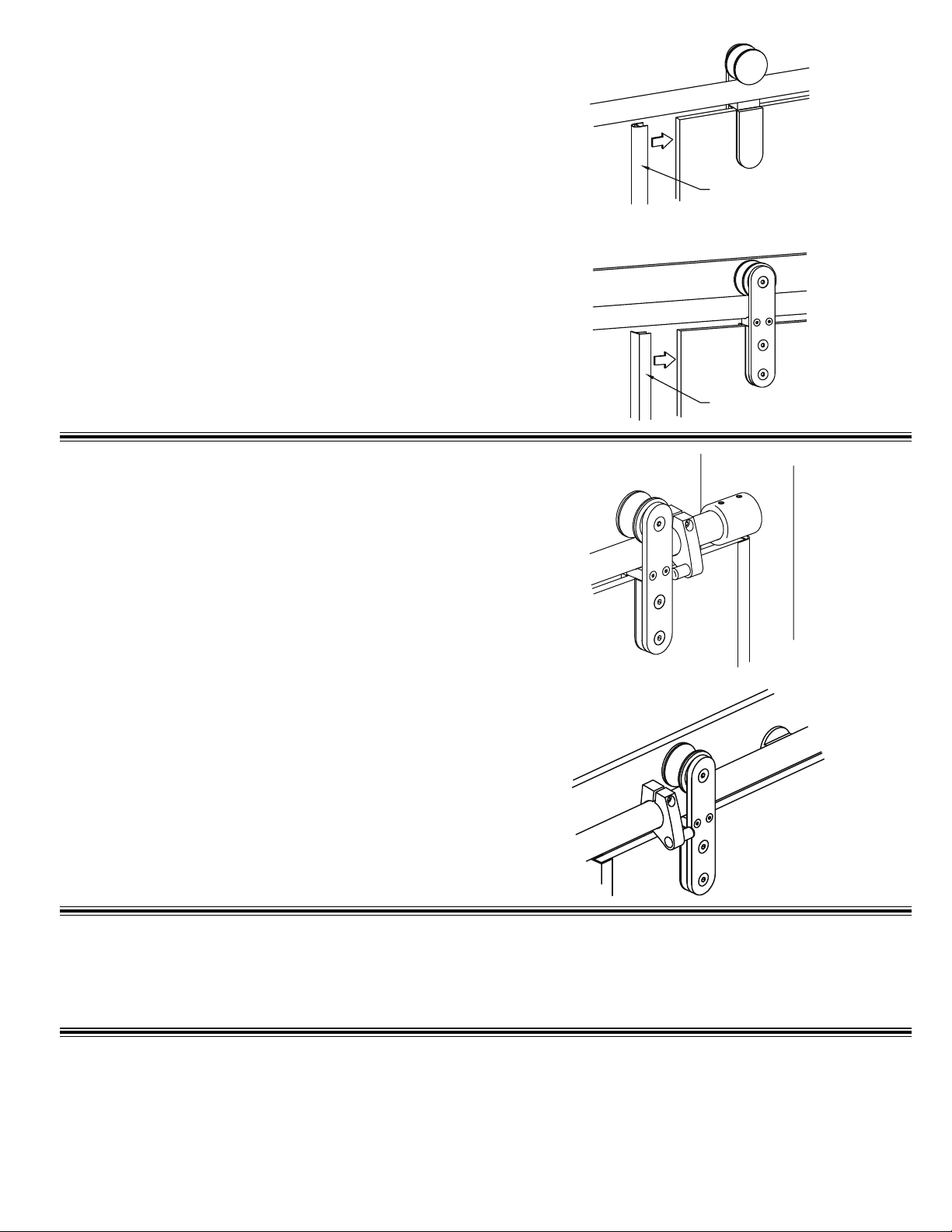

Bar Mount – Drill the Wall Mount holes 5/16”. Insert the Wall Anchors

[A] fully into the holes. Place the Wall Mount Blocks [B] against the

wall with the counter bore to the middle of the enclosure. Using the 1/4 x

2½” Truss head screws [C], attach the Wall Mount Block to the wall, with the

slot in a vertical position and the screw centered in the block.

Bar Length - Measure the width of the xed glass panel [F]. Subtract

2 3/8” from that dimension. Measure from the center of the middle

hole in the bar to the xed panel end of the bar and cut that end o (The

xed panel end is the one with the second hole in it). Now subtract

1 3/4” from the measurement taken in step 1, which is the overall

width of the shower opening at the top. Then take that measure

from the newly cut end of the bar to the uncut end and cut that

end o of the bar.

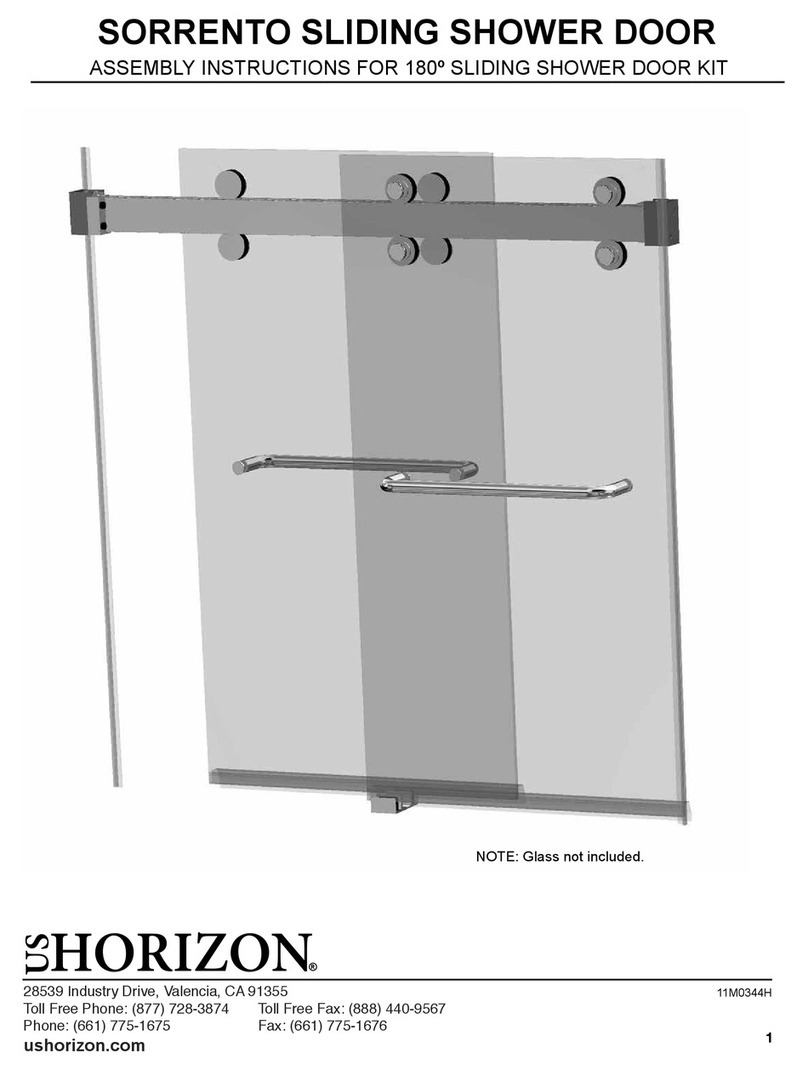

Level the Bar – Temporarily place the Wall Mount Sleeves [E] on each

end of the Header Bar. Align the Header Bar with the Wall Mount.

Place Block, and slide the Wall Mount Sleeves over the Wall Mount Blocks.

a level on the center of the Header Bar and check for level. If needed the

Wall Mount Blocks can be raised, or lowered to make the Header Bar level.

Once leveled, remove the Header Bar from the Wall Mount Blocks, and the

Wall Mount Sleeves from the Header Bar.

SILICONE SILICONE

CLEAR

SETTING

BLOCKS