6

1.3. GENERAL SAFETY RULES.

The use of this ma hine is demanding, so it requests a good instru tion of the

operators, moreover the ma hine is manufa tured with high te hnology

omponents that require assistan e operators with spe ifi preparation.

So, the use and maintenan e of the press, request a ertain attention for the

interventions in the following zones:

-working zone

-infeed zone

-ele tri devi es

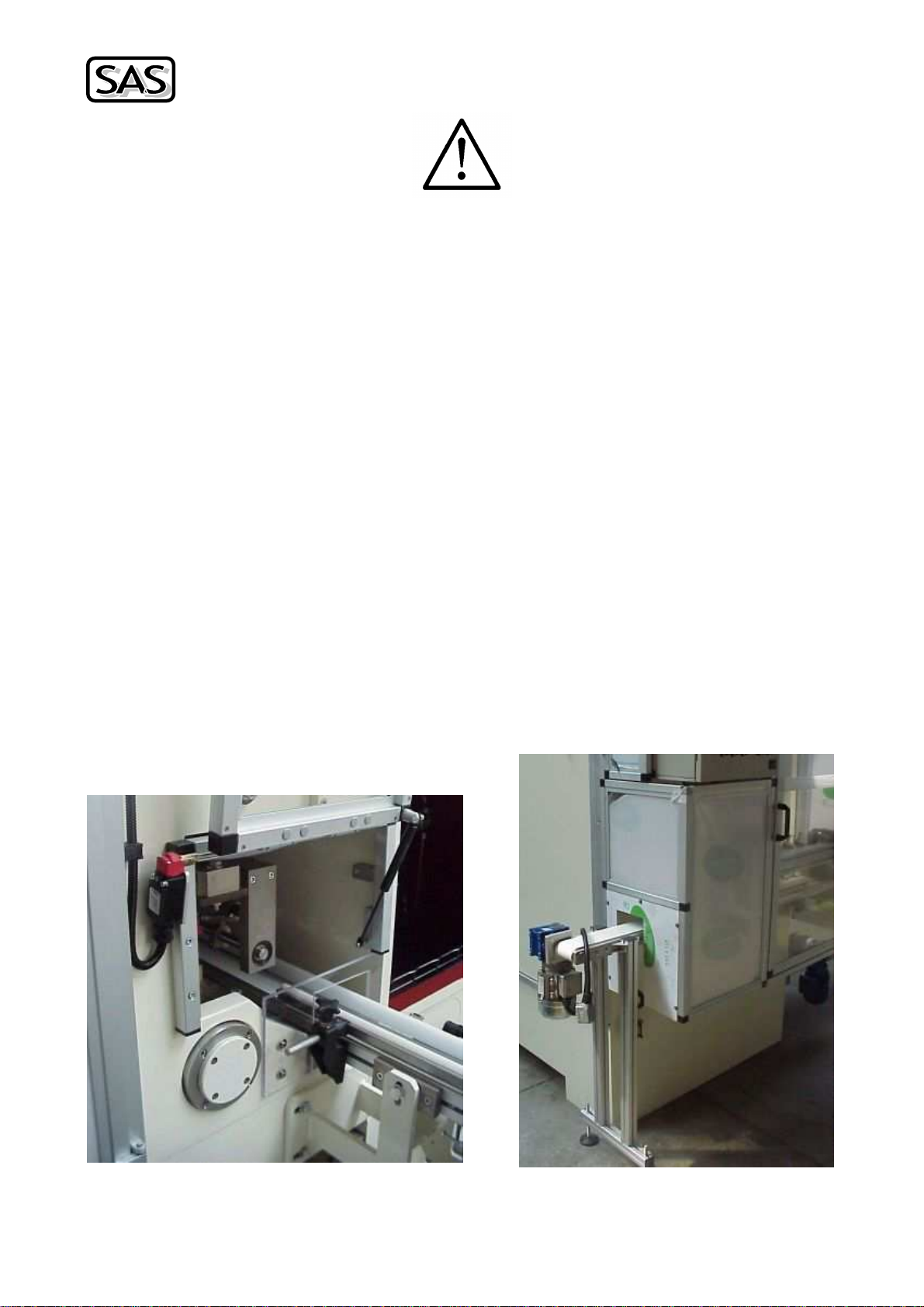

THE FIRST TWO ZONES CAN BE REACHED ONLY BY OPERATORS WHICH HAVE BEEN

EDUCATED TO THE SYSTEM USE AND ALSO INFORMED ON THE CONSEQUENCES DUE

TO AN IMPROPER USE AND INTERVENTION ON THE SYSTEM, WHILE:

INTERVENTIONS INTO THE ELECTRIC DEVICES ARE ALLOWED ONLY TO QUALIFIED

EXPERTS.

THE FOLLOWING PREVENTIONS RULES FOR CUSTOMER’S CARE ARE COMPULSORY:

-Maintain a urately free and lean the pla e of work;

-wear always personal prote tions means (CEE 89/686 e CEE 89/656);

-before starting to work, ontrol that all safety devi es are on and effi ient;

-during work, prote tions or guards have to be onne ted;

-IT’S ABSOLUTELY FORBIDDEN TO CLEAN THE ELECTRIC CONTROL PANEL OR ANY

ELECTRICAL EQUIPMENT UNDER VOLTAGE, WITH JET OF WATER;

-operators are obliged to signal to person in harge any defi ien y and/or

potential situation of danger that ould happen;

-the Customer has the duty to inform immediately the supplier in ase any

defe t and/or malfun tion of prote tion safety system are found. Same goes

for every situation of presumed danger that he dis overs;

-the ma hine an not be use in pla es with high ele tromagneti fields that

an ause an storage of stati harge;

-the level of ambient lighting should be su h to guarantee full fun tionality of

the plant with maximum safety. When performing maintenan e and related

a tivities limited to se tions and/or parts of the plant not suffi iently illuminated

it is obligatory to provide for a portable sour e of light, taking are to avoid

shadow zone that an interfere with above mentioned a tivities.