3

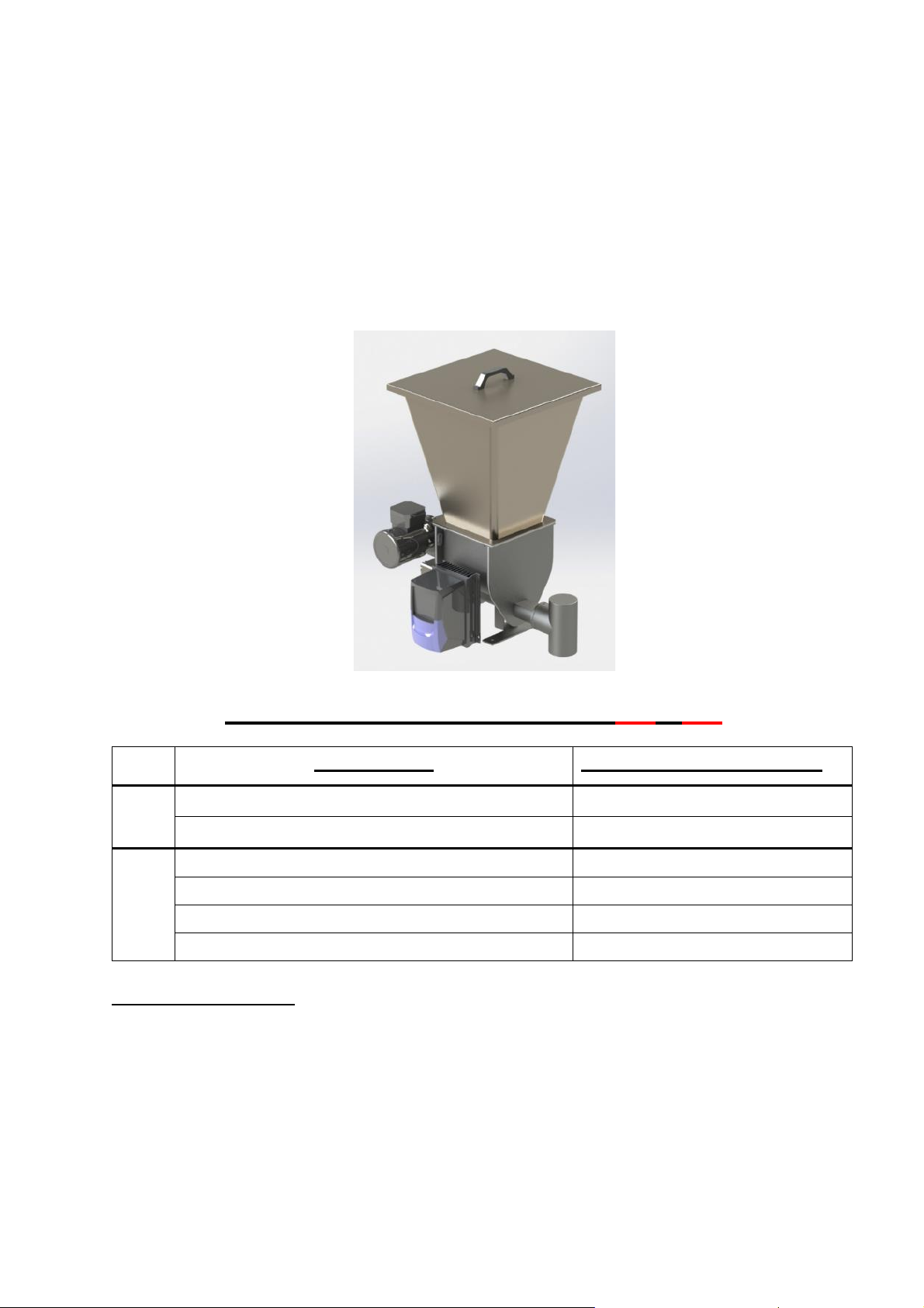

SAS 1SF - Twin Screw Feeder Assy & Control - APRIL 2020

WARNINGS OVERVIEW

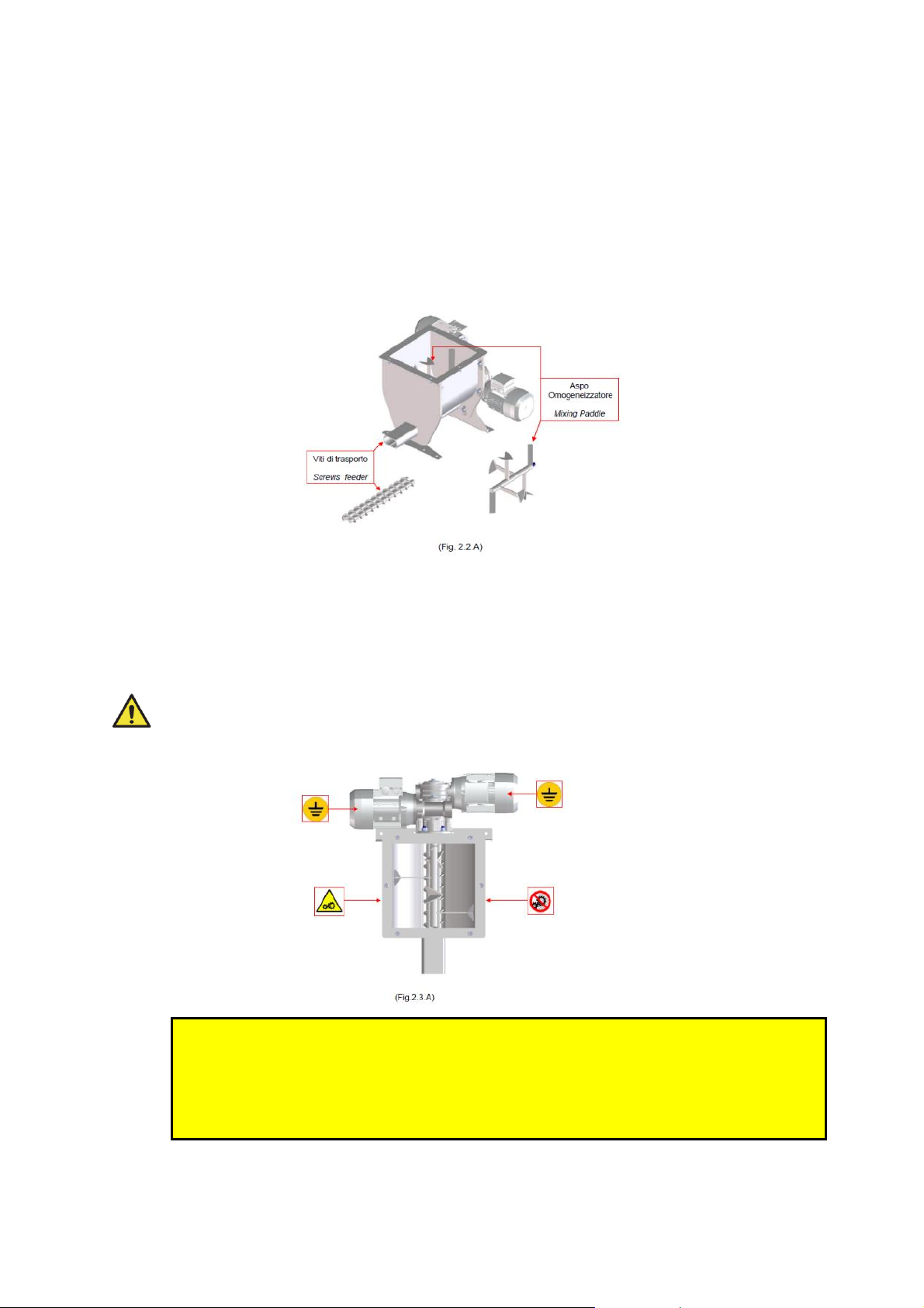

•Notes for screw feeders assigned at the transport of food, pharmaceutical

and zoo-technical products:

oPeriodically clean the screw feeders; the cleaning frequency depends

on the type of product processed and on the nature of the system. It

must be fixed by the people responsible for the use of the machine.

oGreat attention must be paid to the cleaning of the dispenser body, the

dispensing screw, the protections, etc.

oIf it is necessary to clean with other products that are difficult or

impossible to list because of their nature, it is necessary that the

customer previously informs our technical office.

IT IS STRICTLY FORBIDDEN

the use of the equipment if some anomalies occurs

(excessive noise, vibrations, etc).

WARNING:

The failure of the safety standards observance and advices for corrected

machine maintenance or the possible tampering of safety standard relieves

Spice Application Systems Ltd and their suppliers in case of responsibility of

fire, damage or plant/line/machine malfunctioning.

INAPPROPRIATE USE

An inappropriate use of the machine may have serious risks for people and/or

the environment as well as causing damages to the equipment itself.

The equipment must be used only for the purposes specifically expected by the

manufacturer:

•Do not use the equipment if it’s not correctly installed, do not start it up if

the engine group is not mechanically fixed to the rest of the machine.

•Do not use the equipment if the rotating part are not intact or perfectly

cleaned. In this case the dosing power and the capacity are not

guaranteed.

•Do not use the screw feeders with a screw exceeding the length of the

exhaust pipe.

•Do not use the equipment as a supporting point even if it is not working.

There is the danger to fall or to damage the machine itself.

•Do not work on the electric engine or on any other electric component if

the power supply is on, in order to avoid electrocution.

•Do not wash the machine with a water jet. The electric motor is not

shielded from dust and water.

•Do not use products that do not have a clear composition, chemically

aggressive, flammable or dangerous for the machine or the operator

•Do not operate the machine outside, exposed to weather and sudden

changes of temperature.