Instructions for use of etc-12/etd G Series Direct Replacement Trip Unit

page 4 of 13

revision B,

8/20/10

Introduction:

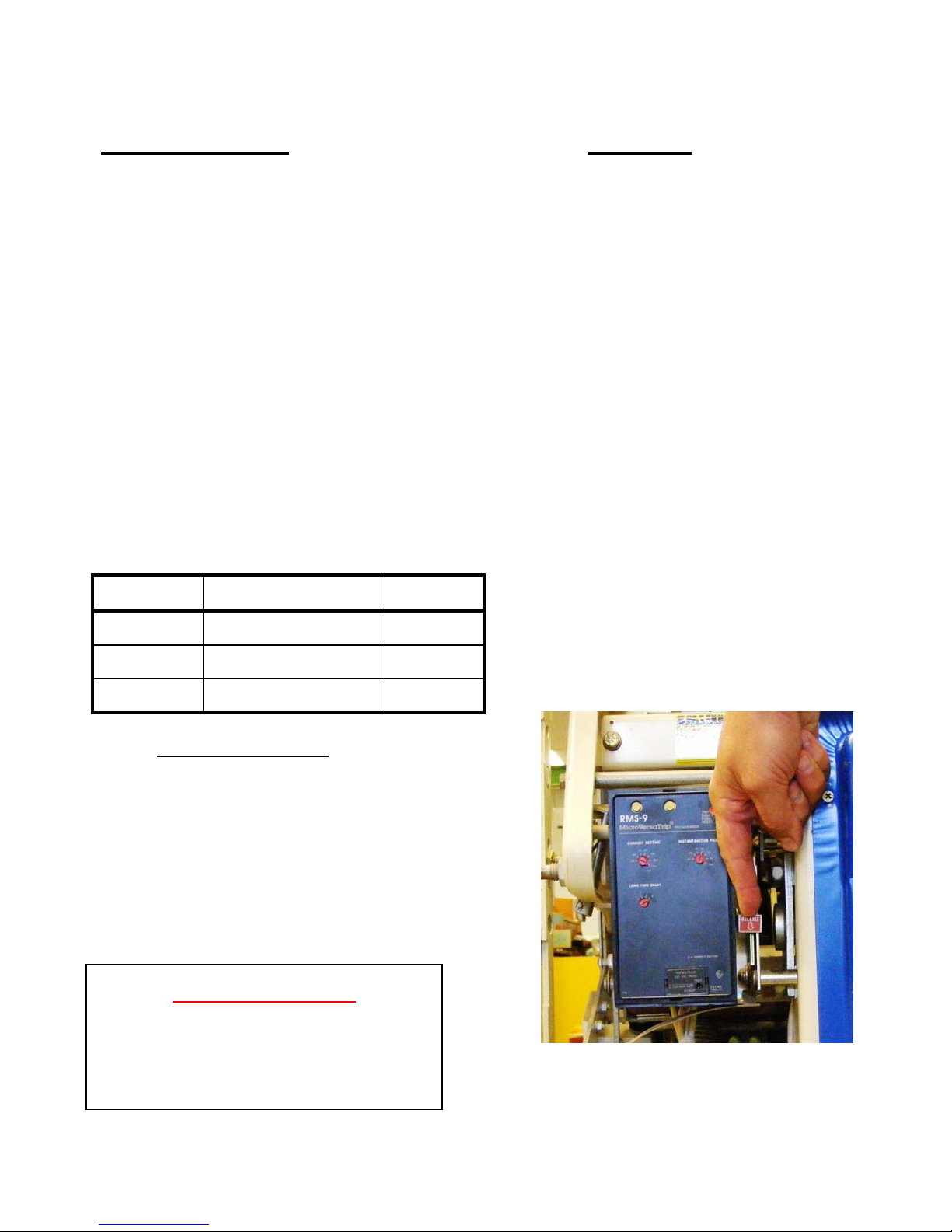

The Satin American etc-12 G series can be

used to replace various OEM trip units while

utilizing current sensors and flux trip devices

that are already on the circuit breaker. The

G-series trip unit contains the same

hardware and operates using the same

curves as the etc-12 trip unit but is packaged

in an enclosure that makes it plug-in

compatible with several original General

Electric trip units.

This manual provides instructions for

individuals with circuit breaker maintenance

experience to use the etc-12 to replace

General Electric MicroVersaTrip,

MicroVersaTrip RMS-9 MicroVersaTrip Epic,

MicroVersaTrip Plus and MicroVersaTrip PM*

The etc-12 trip unit is supplied with all

protective functions. Unneeded protection

bands can be shut off. The unit is adaptable

to all frame sizes without the need for ratings

*The etc-12 / etd G series is compatible with current

transformers and flux trip device on breakers retrofitted

with MicroVersaTrip PM but advanced features such as

voltage / power monitoring and plug-in compatible

communications are not available.

plugs. The etc-12 is compatible with

residual-sensing ground fault for 3 and 4 wire

applications.

In the special instance when ground fault

protection is being added on a 4-wire

system, an additional neutral sensor, copper

details and secondary disconnects may be

required. Contact the factory before

beginning a conversion of such a system

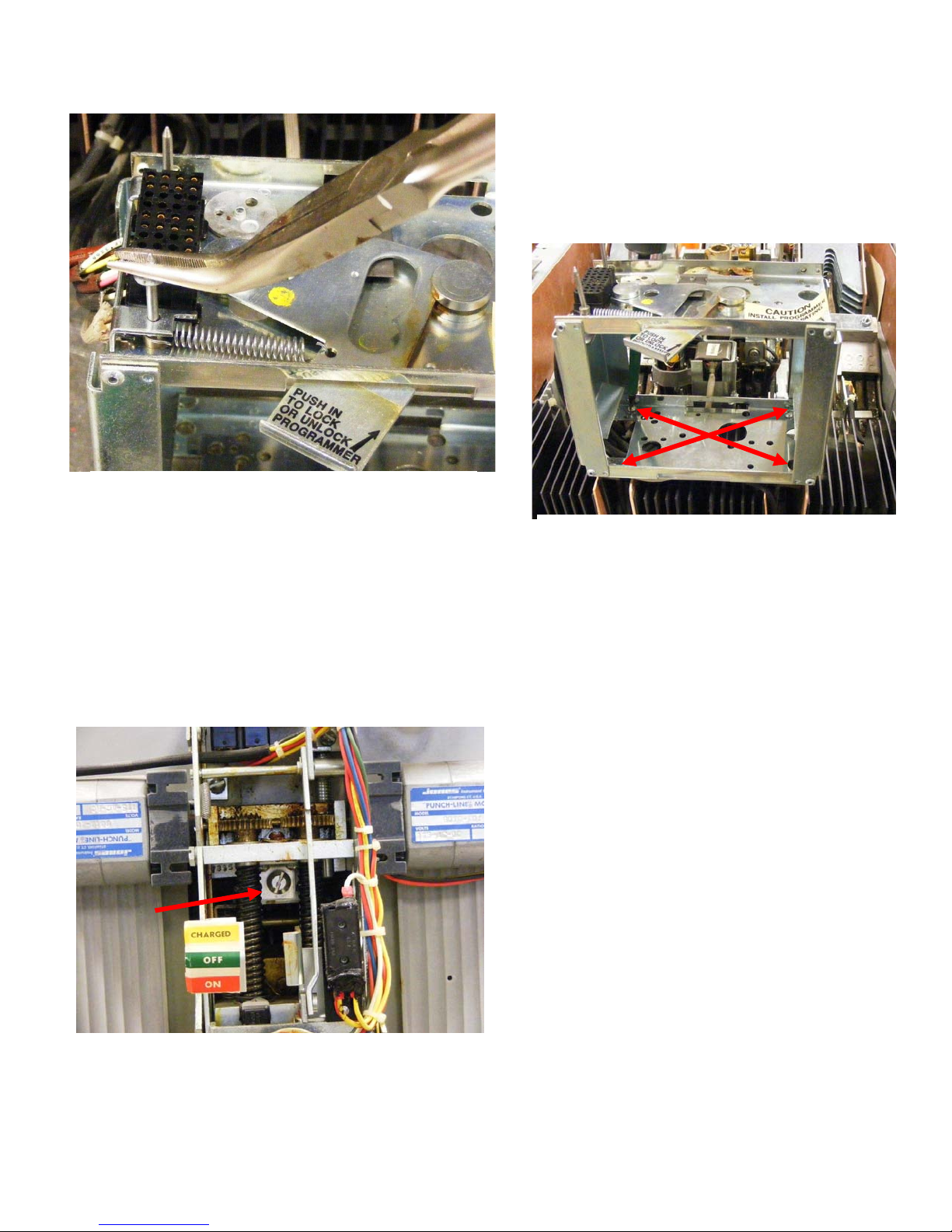

Installation requires familiarity with circuit

breaker operation and maintenance, careful

workmanship and compliance with

instructions. Conversion requires removal of

the original trip unit, installation of the new

trip device and minor rewiring. In the event

that any of the original components are found

to be defective, Satin American can provide

compatible replacements. Qualified

individuals can usually accomplish the

upgrade in less than an hour.

IMPORTANT!!

RETROFITTED BREAKERS MUST BE PERFORMANCE TESTED BEFORE BEING RETURNED

TO SERVICE. PRIMARY INJECTION TESTING IS STRONGLY RECOMMENDED. REFER TO

THE

TESTING

SECTION IN THE

SECTION II

MANUAL FOR DETAILED INSTRUCTIONS.

WARNING!!

TO PREVENT ELECTRICAL SHOCK AND INJURY, DISCONNECT THE BREAKER FROM ALL

PRIMARY AND SECONDARY POWER SOURCES AND CONFIRM THAT THE BREAKER IS

OPEN AND CHARGING SPRINGS ARE DISCHARGED BEFORE BEGINNING WORK.

REFER TO NFPA-70E FOR COMPREHENSIVE ELECTRICAL SAFETY