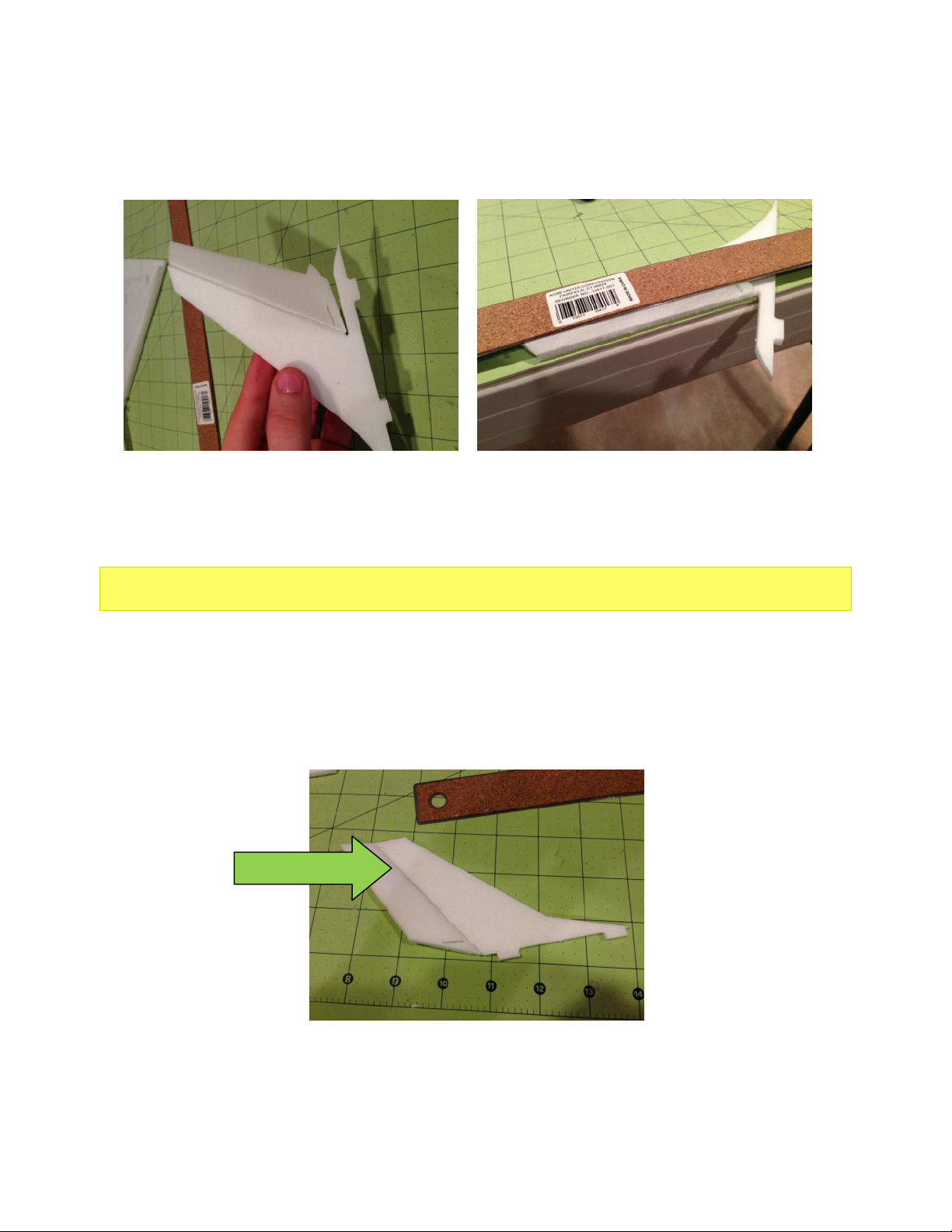

Sawn Craft Micro B-58 User guide

Other Sawn Craft Toy manuals

Sawn Craft

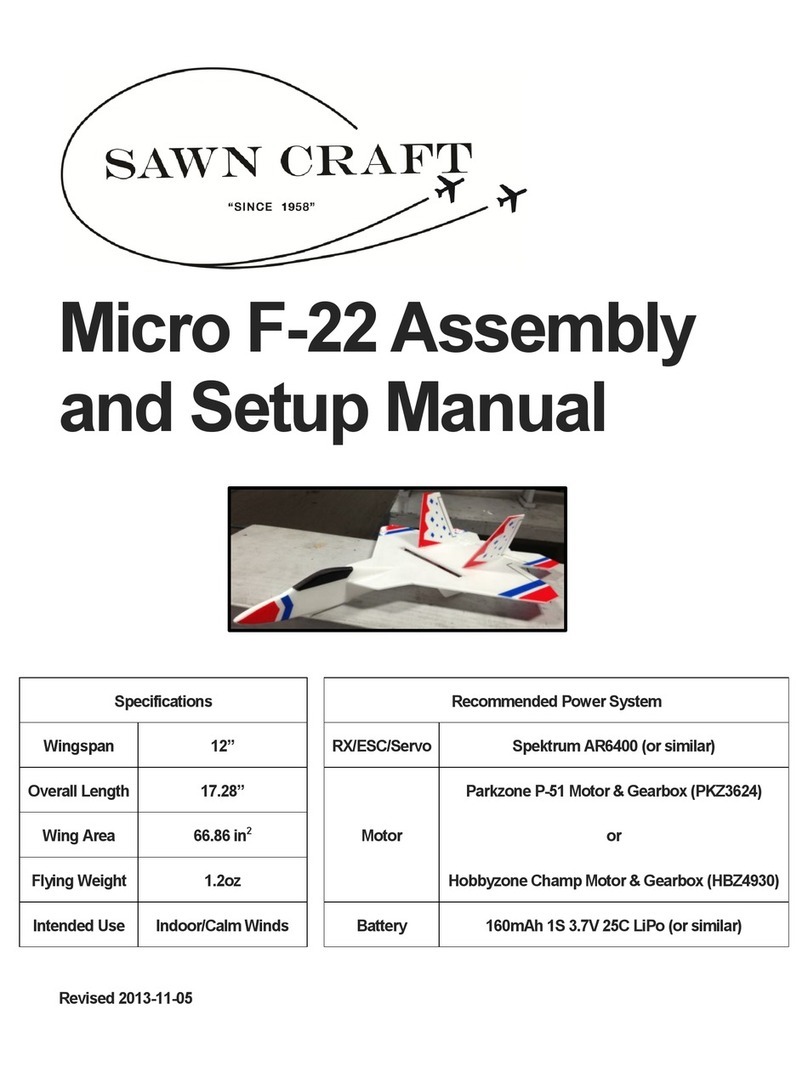

Sawn Craft Micro F-22 User guide

Sawn Craft

Sawn Craft Micro Eurofighter User guide

Sawn Craft

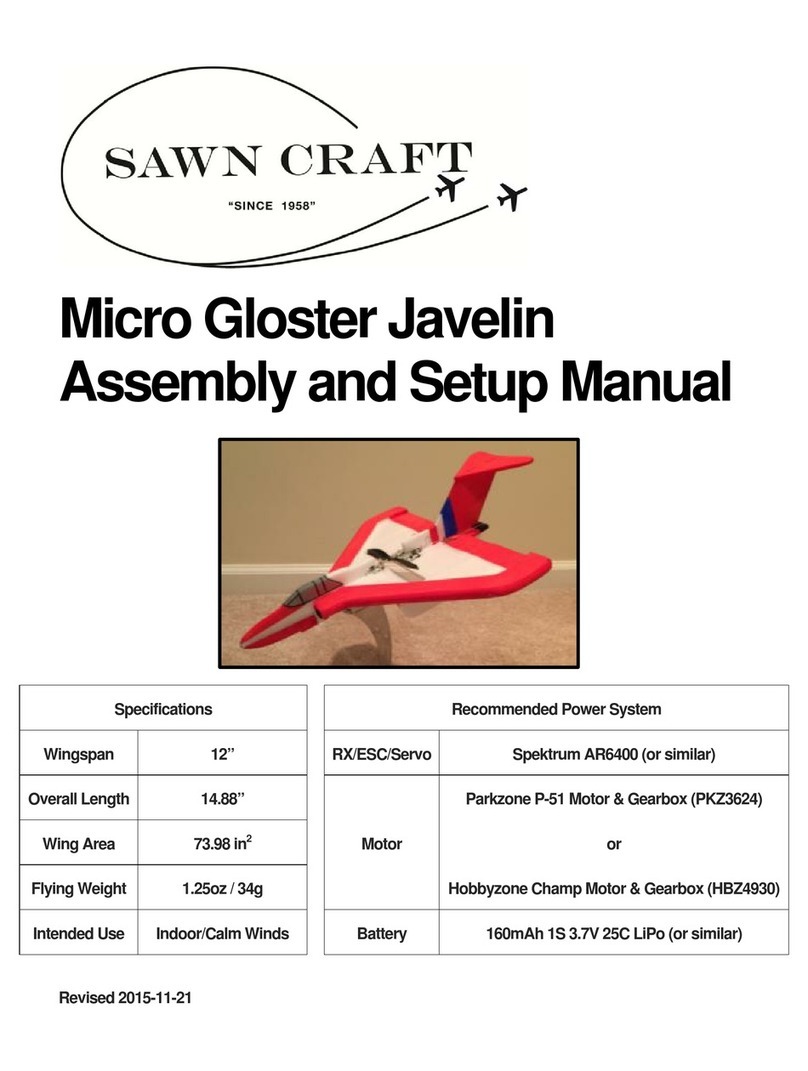

Sawn Craft Micro Gloster Javelin User guide

Sawn Craft

Sawn Craft Cherokee 24 User guide

Sawn Craft

Sawn Craft Micro F-4D Skyray User guide

Sawn Craft

Sawn Craft Mana-Tee User guide

Sawn Craft

Sawn Craft Micro F-16 User guide

Sawn Craft

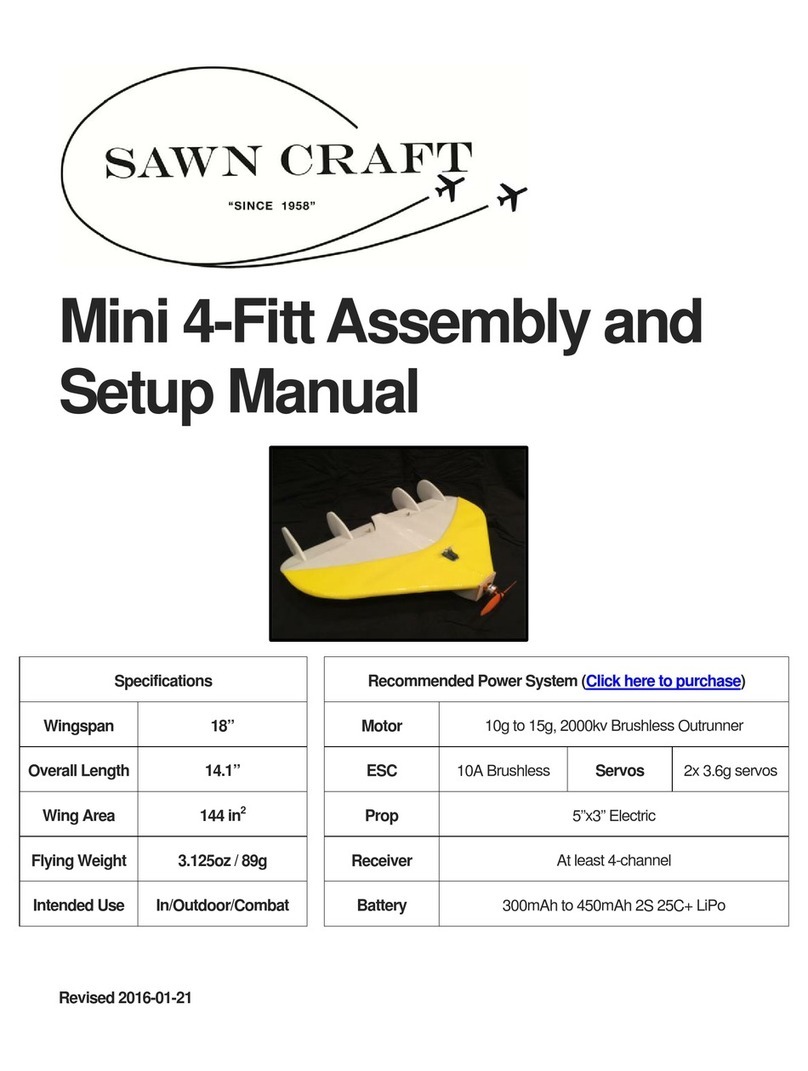

Sawn Craft Mini 4-Fitt User guide

Sawn Craft

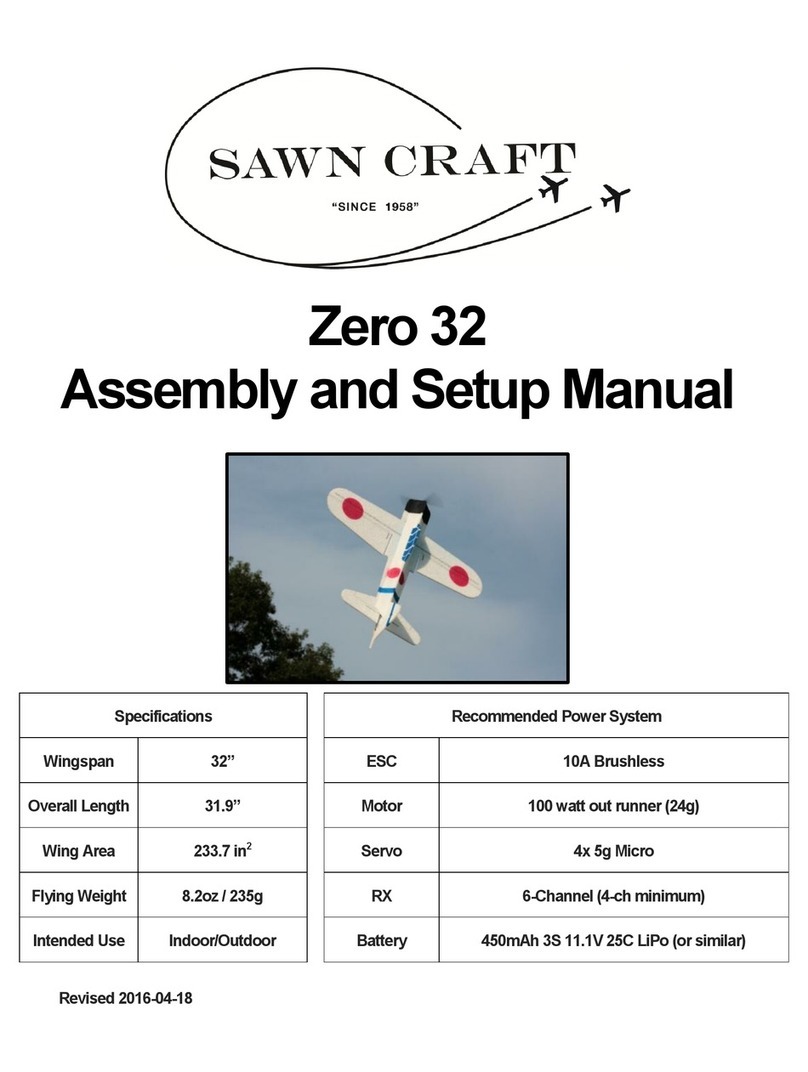

Sawn Craft Zero 32 User guide

Popular Toy manuals by other brands

FUTABA

FUTABA GY470 instruction manual

LEGO

LEGO 41116 manual

Fisher-Price

Fisher-Price ColorMe Flowerz Bouquet Maker P9692 instruction sheet

Little Tikes

Little Tikes LITTLE HANDIWORKER 0920 Assembly instructions

Eduard

Eduard EF-2000 Two-seater exterior Assembly instructions

USA Trains

USA Trains EXTENDED VISION CABOOSE instructions