Sawyer Manufacturing Company

7799 S. Regency Dr., Tulsa, OK 74131 USA

F918.834.0318

info@sawyermfg.com

P918.834.2550

sawyermfg.com

V1

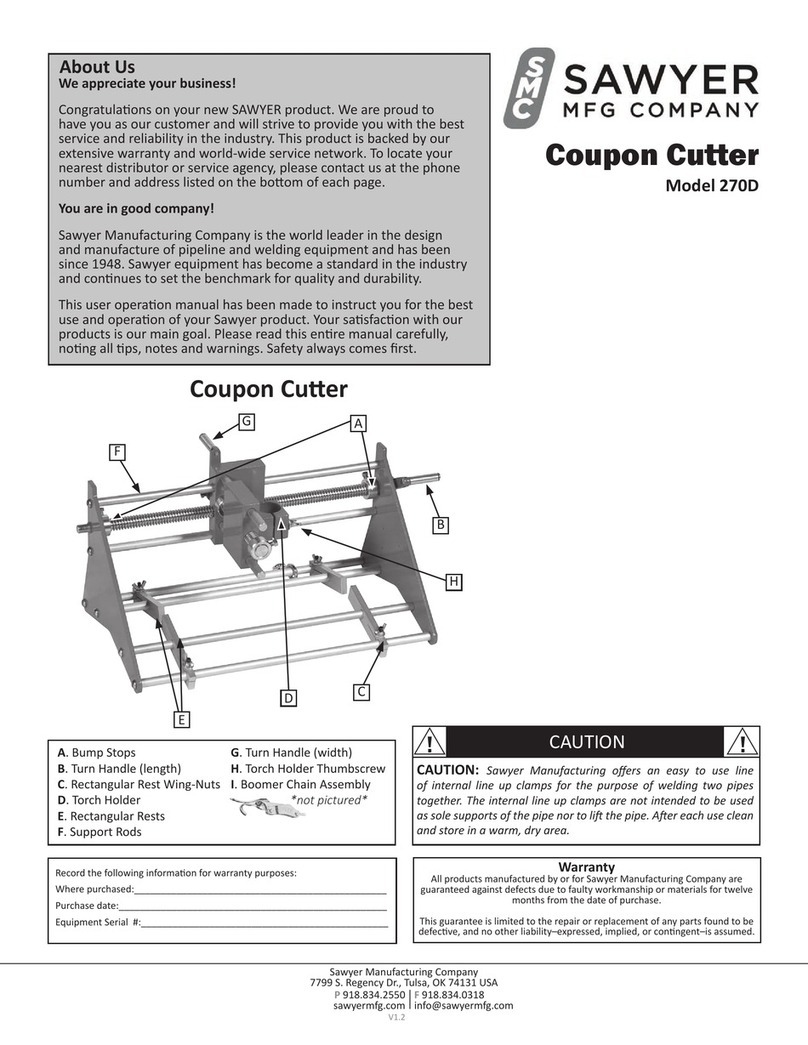

2. Seng Guide Wheels for the pipe diameter to be cut

A. Li machine and verify the wheel holders holding the Guide

Wheels (Q, Fig. 5) are aached in the correct Guide Wheel Tracks (R) for

the diameter of pipe to be cut.

Tip: If a posion change is required, remove the four Socket Head Cap Screws (S, Fig. 6), t wheel

supports in the proper slots for the diameter being cut and reinstall the screws.

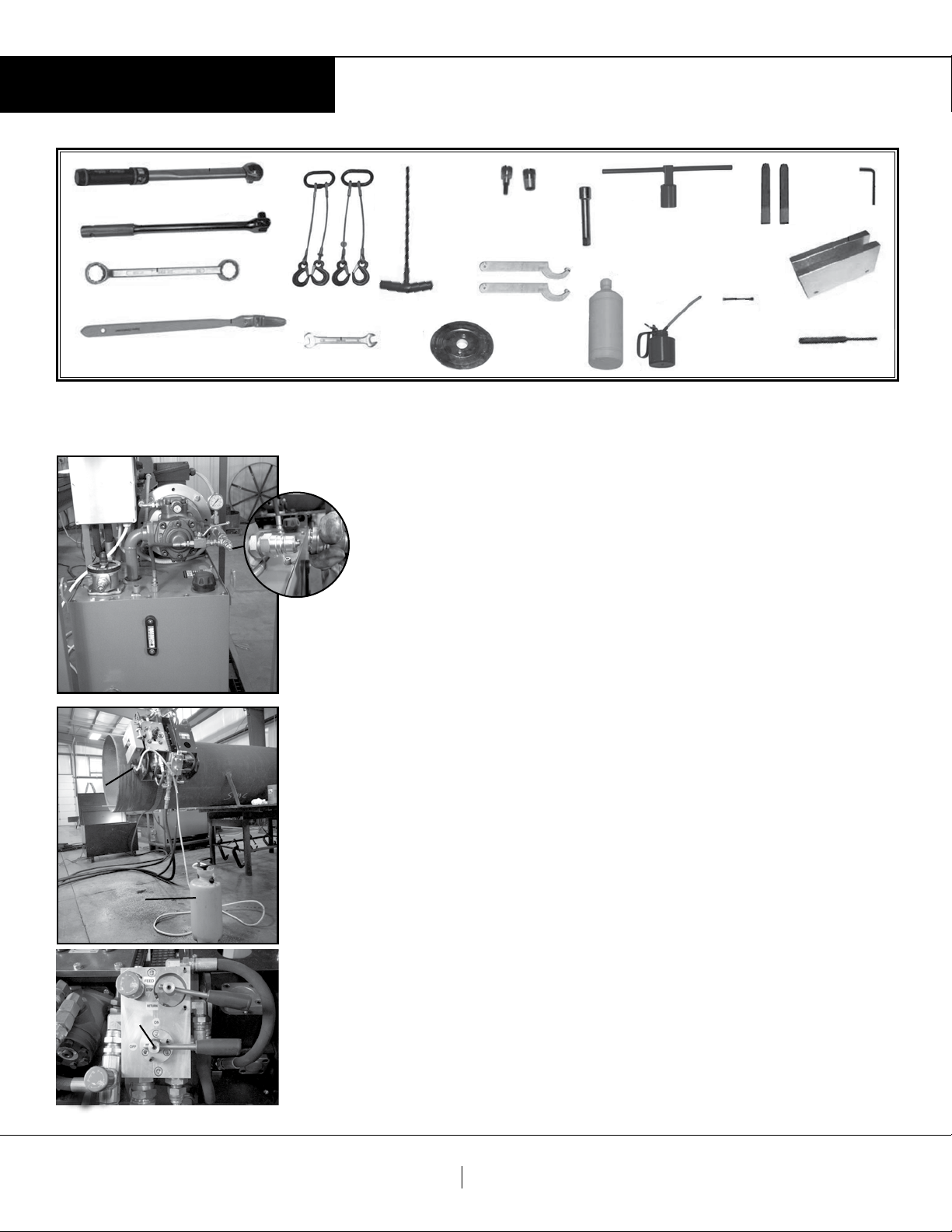

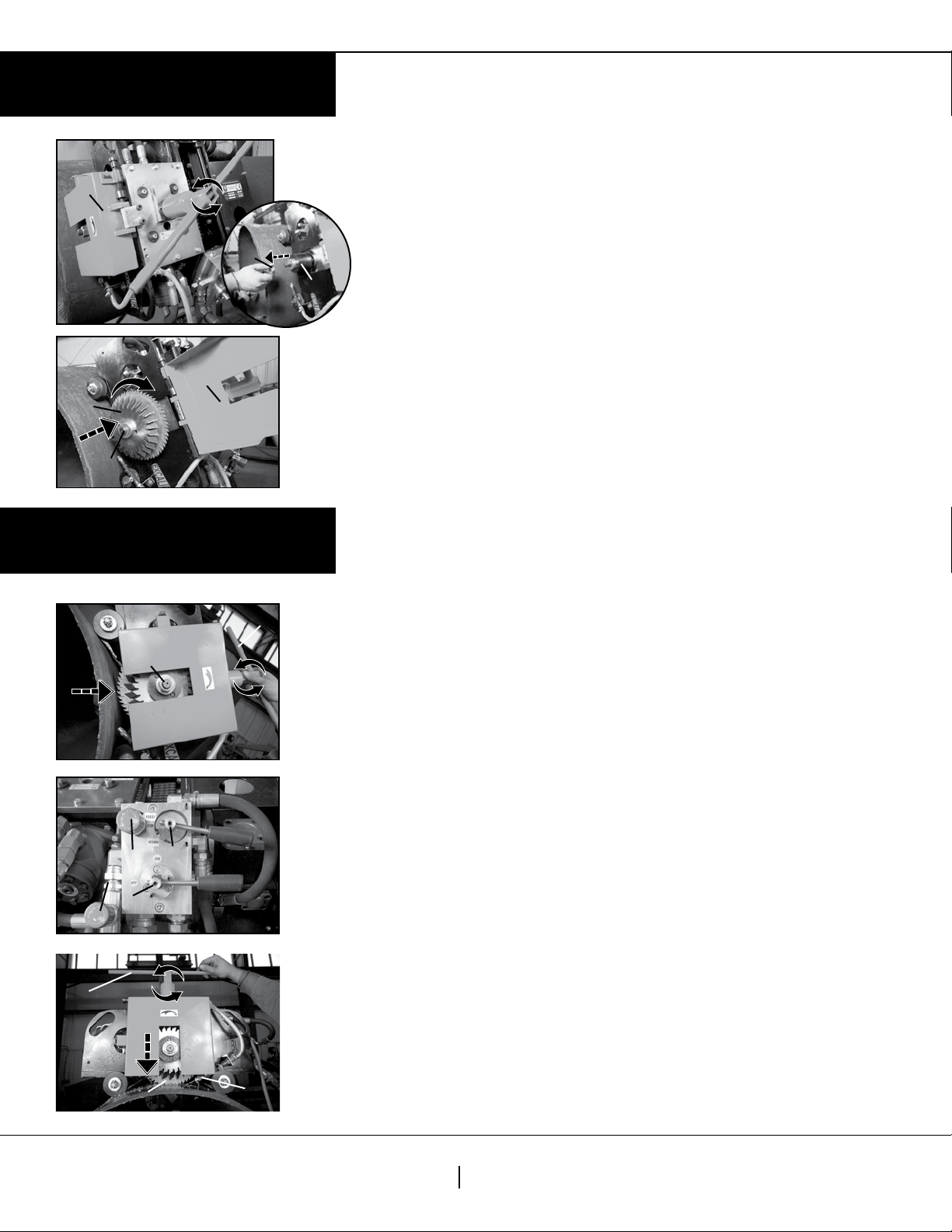

3. Installing the Drive Chain

A. Thread the Drive Chain (U) through the machine and onto the Drive Chain

Sprockets (V, Fig. 6). Refer to Table 1, page 6

B. The required Drive Chain length is determined by the diameter of the

pipe to be cut.

C.Lengthen the Drive Chain.

1. Select the chain segments required to lengthen the chain

2. If the chain is unjoined, proceed to the next step. If chain is joined,

then remove a single chain pin (X, Fig. 7a).

Tip: Use a pin hammer

3. Add the required amount of addional chain to the ends and secure

(Fig. 7) using a Chain Link Kit (oponal).

D.Shorten the Drive Chain.

1. Select the chain segments required to shorten the length.

2. If the chain is unjoined, proceed to the next step. If chain is joined,

then remove a single chain pin (X, Fig. 7a).

Tip: Use a pin hammer

3. Measure from the unlinked chain point to the correct length and

remove the excess chain. Repeat previous step and secure (Fig. 7)

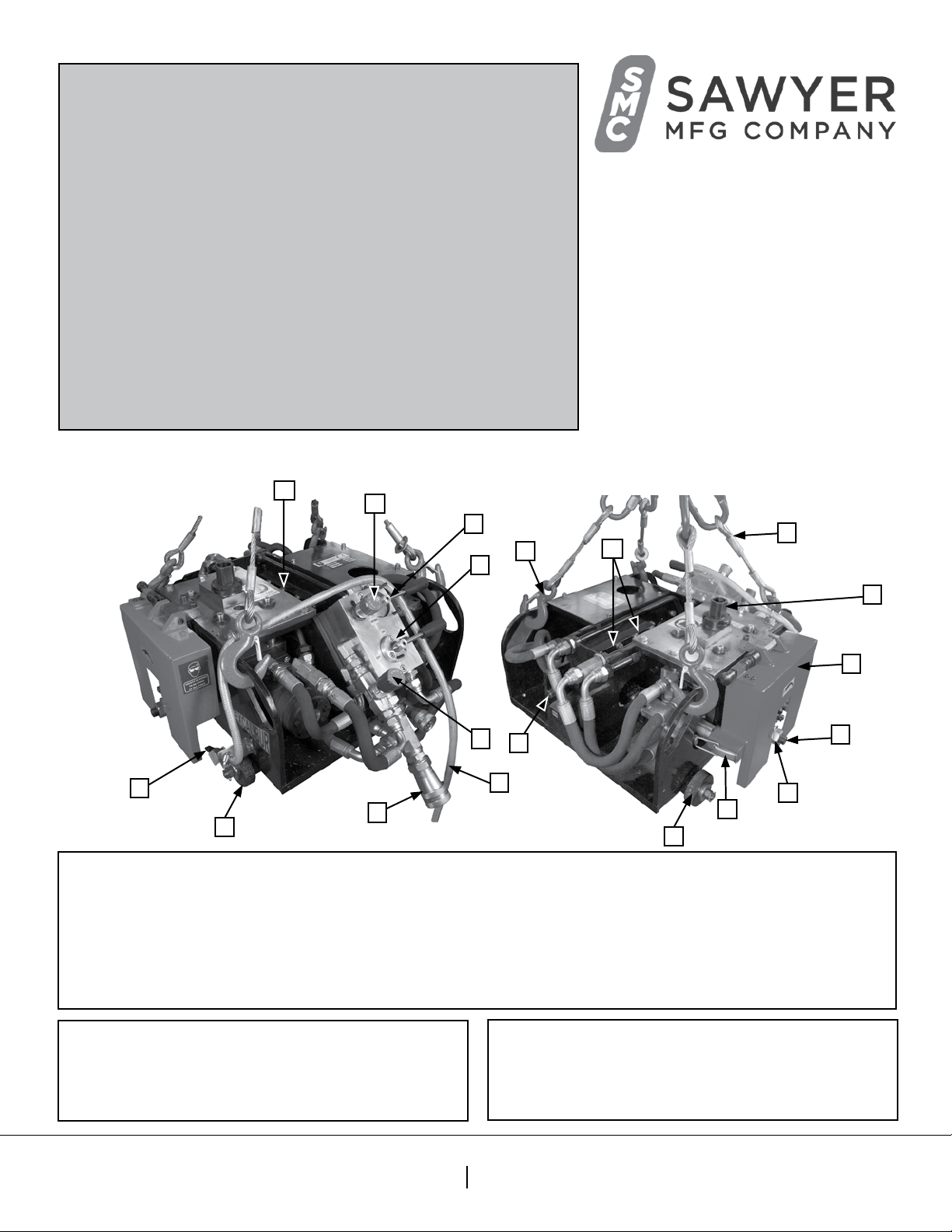

4. Installing the Excalibur on the pipe

A. Using the two liing cables (F, Fig. 8), li the Excalibur onto the pipe.

B. Release the liing mechanism, ensuring the machine is sll supported on

the pipe unl the chain is ghtened and secured.

C.

Tighten the mesh chain by rotang the Chain Tensioning Screw

(W, Fig. 9)

counterclockwise with the 16 mm Swivel T Handle.

D. Torque the Chain Tensioning Screw (W) to 96 ./lb. (130NM).

1. Release the tension on the two Liing Cables (F) and unhook the Liing

Spring Clips (G) from the machine.

E.

Connect the supplied air/hydraulic hoses to the relevant connectors on the

Excalibur machine, and start the power source

Hose Connector (T, Fig. 10) on the Excalibur, and start the power source.

1. Turn the Start/Stop Control to the ON posion. (B, Fig. 10a)

Note: Hydraulic Model only – If this is the rst me the hydraulic power supply is being run, let the

hydraulic uid circulate through the machine 15-20 minutes to remove air bubbles from the uid.

2. Move the Machine Direconal Control (C, Fig. 10a) to the forward posion.

3. Turn the Machine Speed Control (D, Fig. 10a) valve counter-clockwise.

4.

Rotate the Excalibur one full turn around the pipe to align the chain. (Fig. 11)

Note: Verify there is enough clearance for the machine to travel around the pipe.

5. Re-torque the Chain Tensioning Screw (W, Fig. 9) to 96 ./lb. (130NM).

6. Turn o the air/hydraulic power source.

Tip: Open pressure bypass valve before turning o power to the Excalibur.

Fig. 10

Fig. 5

Fig. 9

Fig. 6

Fig. 11

Installation

Fig. 7

X

T

Q

R

S

U

V

Fig. 8

Fig. 7a

F

Fig. 10a

D

C

B

X

W