INDEX

REFERENCE GUIDE ............................................................................................ 1

GENERAL .............................................................................................................. 2

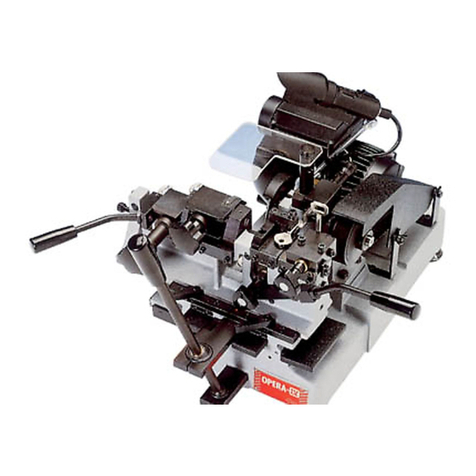

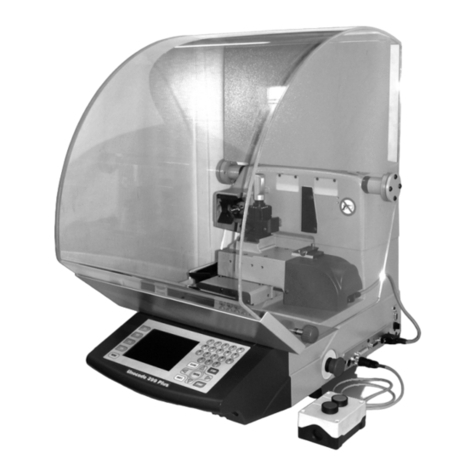

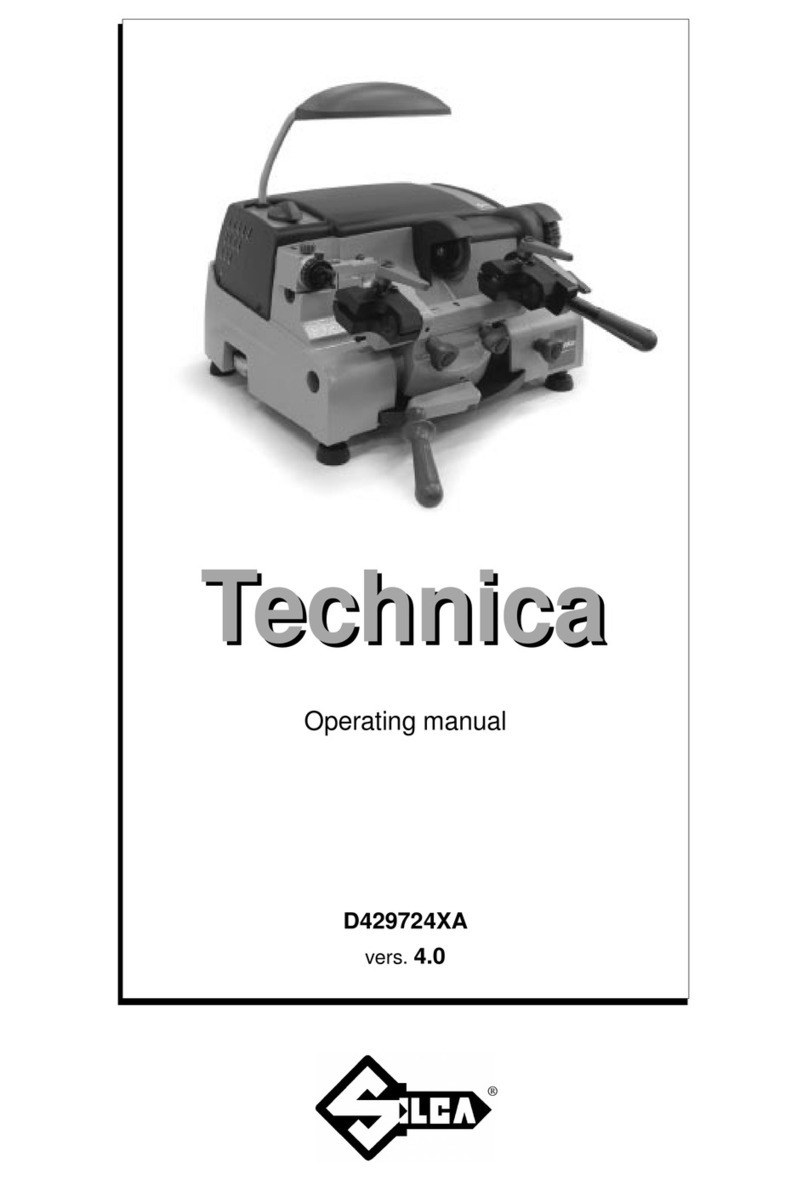

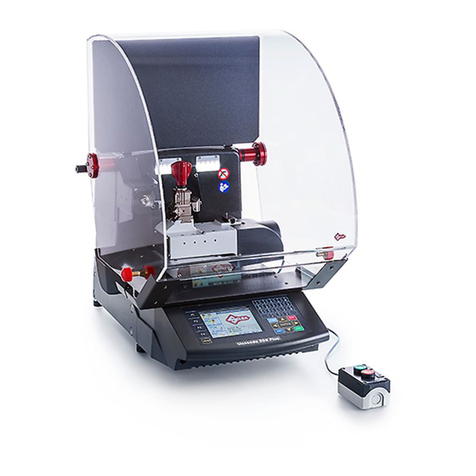

1 MACHINE DESCRIPTION ..................................................................................... 3

1.1 MAIN CHARACTERISTICS ................................................................................ 3

1.2 SAFETY ........................................................................................................ 4

1.3 MAIN WORKING PARTS .................................................................................. 5

1.4 TECHNICAL DATA .......................................................................................... 6

1.5 ACCESSORIES PROVIDED .............................................................................. 7

2 TRANSPORT ......................................................................................................... 8

2.1 PACKING ...................................................................................................... 8

2.2 UNPACKING .................................................................................................. 9

2.3 MACHINE HANDLING ...................................................................................... 9

3 MACHINE INSTALLATION AND PREPARATION ............................................. 10

3.1 CHECKING FOR DAMAGE ............................................................................. 10

3.2 ENVIRONMENTAL CONDITIONS ..................................................................... 10

3.3 POSITIONING AND INSTALLATION .................................................................. 10

3.4 DESCRIPTION OF WORK STATION ................................................................. 11

3.5 GRAPHICS .................................................................................................. 11

4 “SET UP” AND USE OF THE MACHINE ............................................................ 12

4.1 KEYBOARD AND FUNCTIONS ........................................................................ 12

4.2 USE OF THE CLAMP .................................................................................... 13

4.3 CUTTING BY ELECTRIC CONTACT ................................................................. 15

4.4 FITTING THE CLAMP TO THE MACHINE .......................................................... 16

4.5 CUTTER ..................................................................................................... 16

4.6 CHANGING THE CUTTER .............................................................................. 16

4.7 INVERTING THE PULLEYS ............................................................................. 17

5 OPERATING GUIDE ............................................................................................ 18

5.1 INITIAL OPERATIONS .................................................................................... 18

5.2 [1] COPY BY CODE .................................................................................... 19

5.2.1 SPECIAL CASES ......................................................................................20

5.2.2 LIMITED ACCESS TO DATA (PROTECTED SYSTEMS) ...................................24

5.3 [2] LIST OF CODES ..................................................................................... 24

5.4 USE OF THE MACHINE WITH A PERSONAL COMPUTER ................................... 25

5.4.1 [3] QUEUE FROM PC .............................................................................25

5.5 [4] CALIBRATIONS ...................................................................................... 26

5.5.1 CALIBRATING THE V100 CLAMP ..............................................................26

5.5.2 CALIBRATING CUTTERS ...........................................................................29

5.5.3 MANUAL ADJUSTMENTS ..........................................................................30

5.6 [5] MAINTENANCE ..................................................................................... 31

5.6.1 TESTS ...................................................................................................31

5.6.2 MACHINE ZERO POINTS ..........................................................................33

5.7 OPTIONS [6] ............................................................................................... 36

5.8 ERROR MESSAGES ...................................................................................... 40

6 CLEANING ........................................................................................................... 42

7 MAINTENANCE ................................................................................................... 43

7.1 TROUBLE SHOOTING ................................................................................... 43

7.2 MAINTENANCE OPERATIONS ........................................................................ 45

7.3 CUTTER REPLACEMENT ............................................................................... 45

7.4 BELT REPLACEMENT AND TENSION ADJUSTMENT .......................................... 46

7.5 CHECKING AND/OR REPLACING FUSES ......................................................... 47

7.6 ELECTRONIC CIRCUIT BOARD REPLACEMENT ................................................ 48

7.7 KEYBOARD/DISPLAY REPLACEMENT ............................................................. 49

7.8 ACCESS TO BACK COMPARTMENT ................................................................ 50