5

TECHNICAL MANUAL EROS

Should any damage and/or a system malfunction be detected, do not continue with the installation.

The manufacturer will not be liable for damage caused during the installation due to non-compliance with these

recommendations.

In order to ensure the safe assembly, use and main-

tenance of this product, a number of precautionary

measures must be taken. Please observe the following

warnings and instructions, for the safety of all con-

cerned.

Please contact your distributor with any queries.

- This manual is intended as a reference for experi-

enced professionals and should therefore not be used

by DIY amateurs or trainee fitters.

- This manual describes the installation of the product

assembly components, and refers to the electrical

control installation manuals. if necessary, this manual

should be supplemented with instructions for any ad-

ditional components not described herein.

-Please read this manual carefully before starting work.

- Some components may be sharp or have jagged edg-

es. It is therefore advisable to wear safety gloves.

- All parts supplied have been designed specifically

for this product. The replacement or addition of oth-

er parts may have a negative eect on the safety of

the product and its warranty. In addition, the CE certi-

fication of this product will become invalid if any parts

are replaced or if the installation is not carried out in

accordance with the instructions in this manual. The

installer shall accept full responsibility in this regard.

- Ensure that the assembly area is suciently illumi-

nated. Remove any obstacles or dirt. Make sure no-

body is present besides the fitters. Unauthorised

persons (especially children!) may interfere or cause

hazards during installation.

Before assembly, it is very IMPORTANT for your safety

and that of the product to follow all the recommentions

listed below. A poor-quality installation may cause

harm to people or damage to the installation itself.

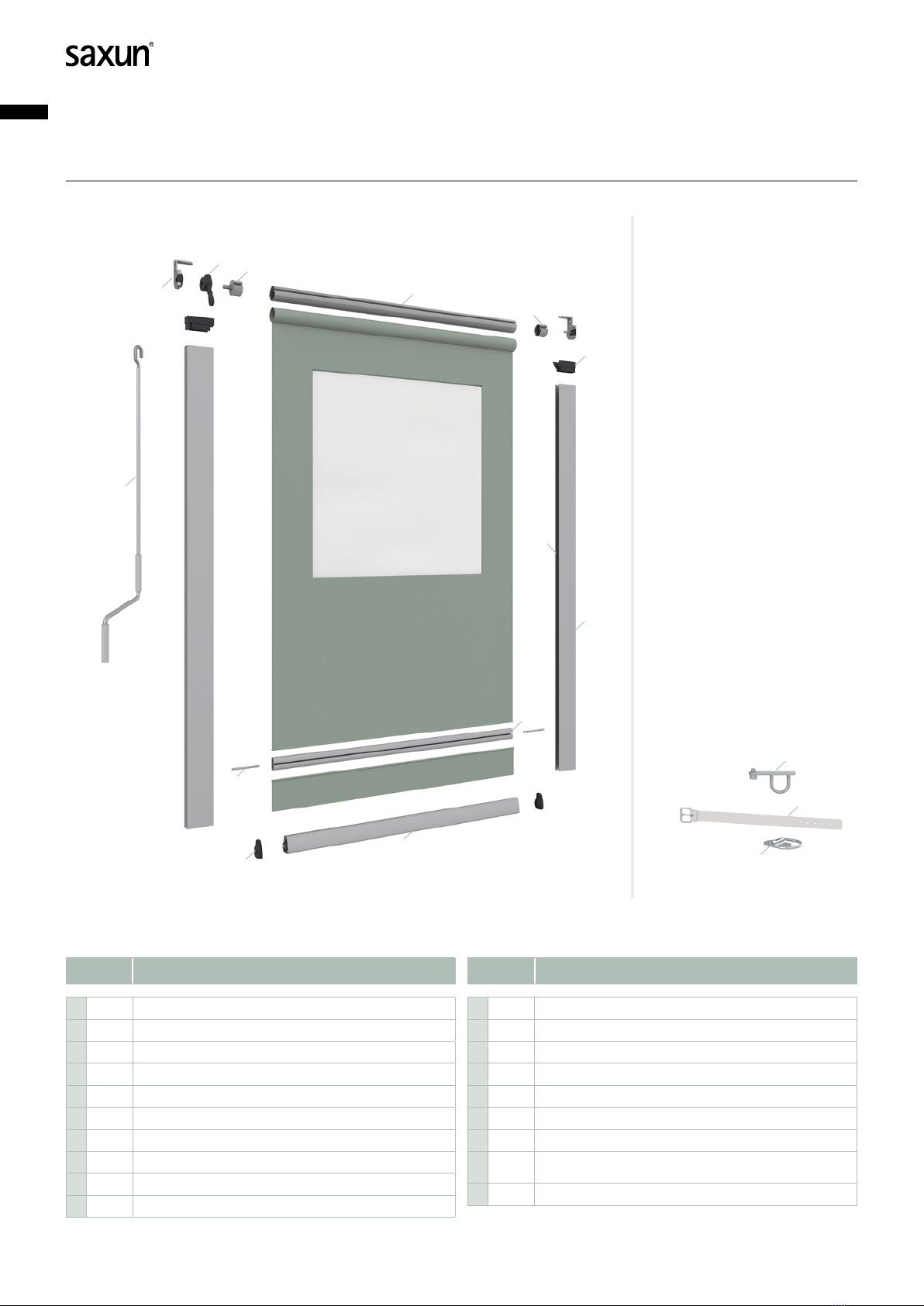

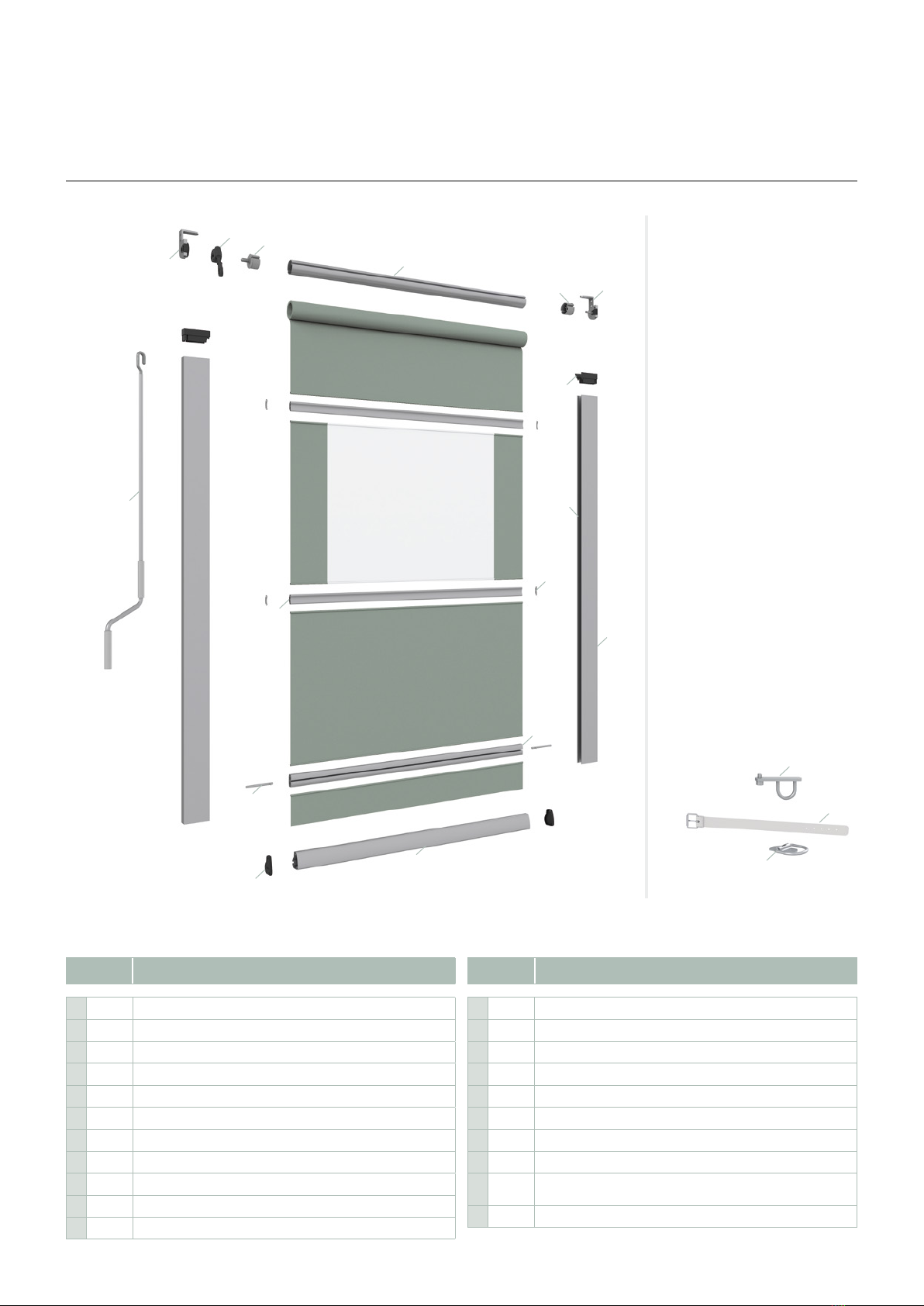

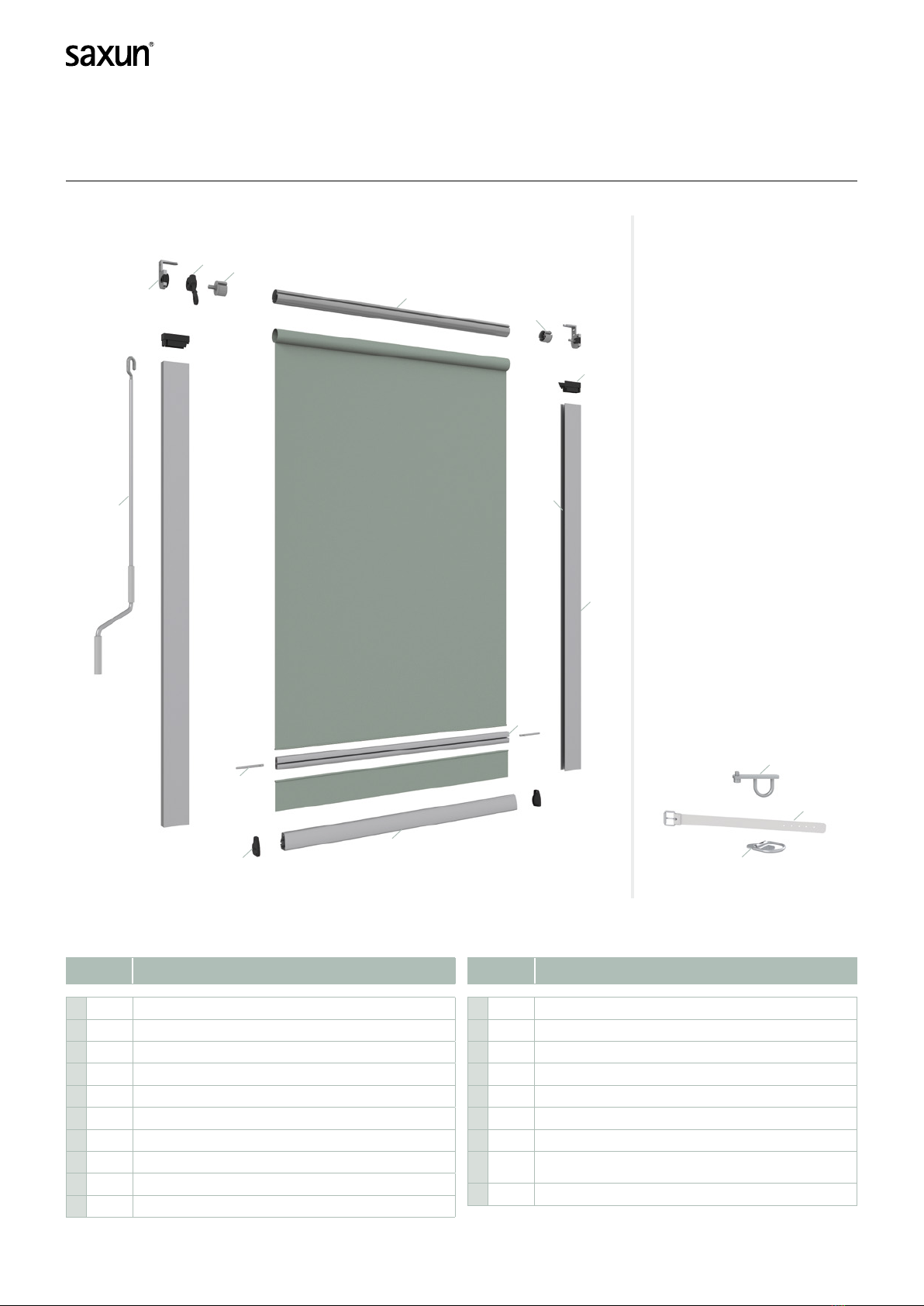

Once the product has been unpacked, the professional

fitter has to check its integrity. Before starting the in-

stallation, the arrangement of all components and tools

must be checked in order install the product correctly.

In case of doubt, contact Giménez Ganga´stechnical

department.

Under no circumstances should a damaged product be

installed, as it may damage the equipment and create

situations that are dangerous for people.

These systems are exclusively intended for the use for

which they were designed. Any other use is inappropri-

ate, and therefore dangerous.

The system installation must always be performed by a

professional fitter, respecting the manufacturer´s indi-

cations, as well as knowing and applying all the regula-

tions in force.

IMPORTANT

For power operated products, the existing voltage must be checked before installation.

The connection must always be a grounded connection. Otherwise, do not continue the installation as it may

be dangerous.

1. GENERAL RECOMMENDATIONS REGARDING SAFETY, USE AND RESTRICTIONS