- 4 -

1600_GB-INHALT_2740

GB

TABLE OF CONTENTS

Observe

Safety

Hints in the

supplement!

Table of contents

TABLE OF CONTENTS

CE sign ...................................................................... 5

Meaning of warning signs.......................................... 5

GENERAL SAFETY TIPS

Travelling with implement in tow ................................ 6

Coupling and uncoupling the implement ................... 6

Regulations for Use ................................................... 6

Travelling on roads..................................................... 6

Before starting work................................................... 6

Checking before operation......................................... 6

Overview.................................................................... 7

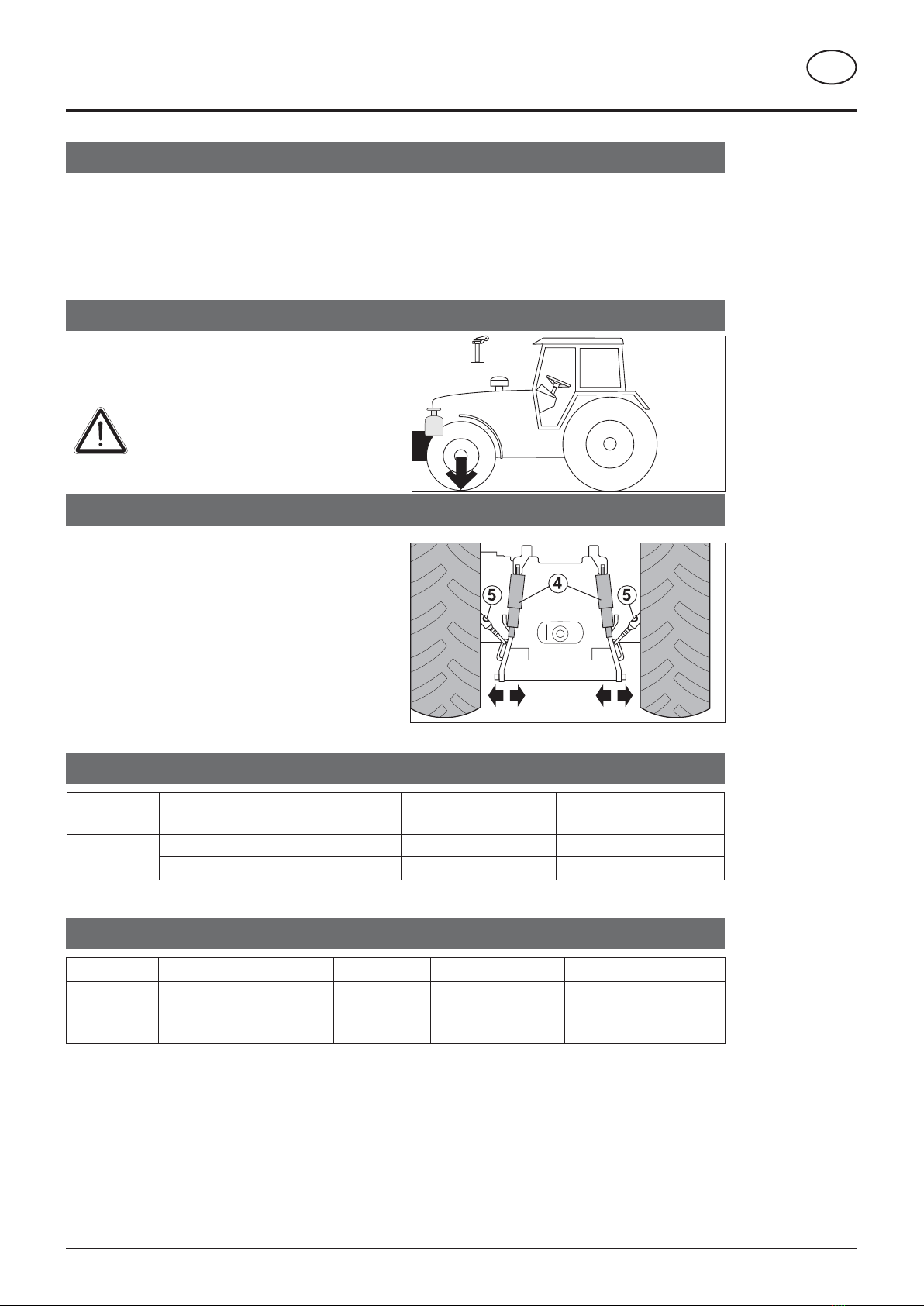

SPECIFICATION

TRACTOR REQUIREMENTS

Tractor........................................................................ 8

Ballast weights........................................................... 8

Lifting gear (three-point linkage)................................ 8

Necessary hydraulic connections .............................. 8

Power connections required ...................................... 8

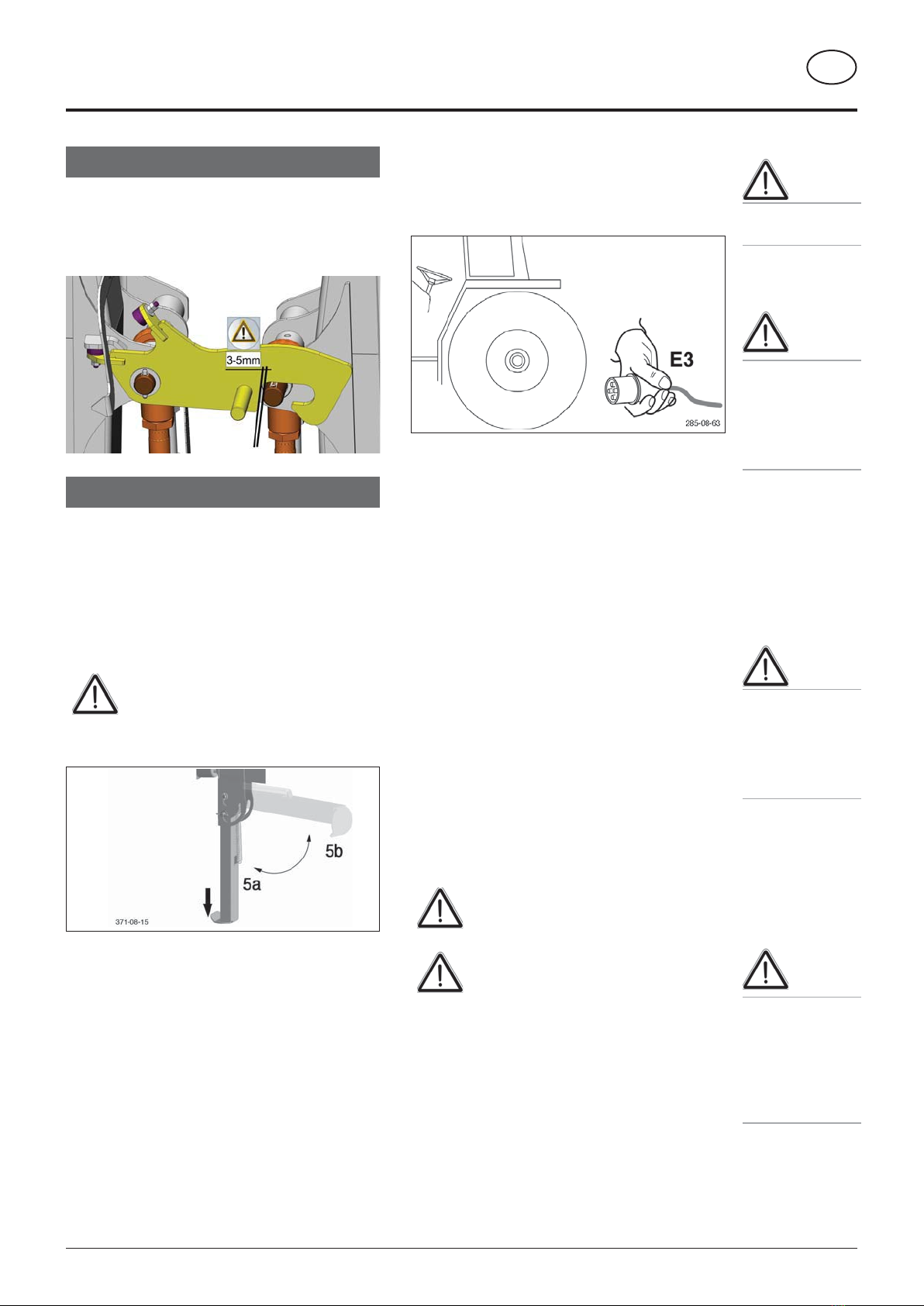

ATTACHING THE MACHINE

Before initially attaching the machine ........................ 9

Attaching the machine ............................................... 9

Parking the machine ................................................ 10

OPERATION

General guidelines on working with the machine .....11

From transport position to working position ..............11

From headland position to working position............. 12

From working position to headland position............. 12

Settings on rotor chassis.......................................... 12

1. Set lateral incline.................................................. 12

2. Adjusting rake height ........................................... 13

3. Aligning the indicators...........................................14

Example - left rotor with tandem chassis: ................ 15

Cardan shaft speed ................................................. 16

Swath apron (optional equipment)........................... 16

Single rotor operation (variant) .................................17

Hydraulic working width adjustment .........................17

Setting the curved track........................................... 18

Setting the headland height (both sides) ................. 18

TRANSPORT

From working to transport position........................... 19

From headland to transport position ........................ 19

Tine arm holder operation........................................ 20

Driving on public roads ............................................ 20

Machine dimensions in transport position................ 21

Reducing the transport height.................................. 21

Tine covering ........................................................... 22

WORKING ON SLOPES

Take care when turning on slopes! .......................... 24

Safety advice ........................................................... 25

General maintenance information............................ 25

Cleaning of machine parts....................................... 25

MAINTENANCE

Parking in the open.................................................. 25

Winter storage.......................................................... 25

Cardans ................................................................... 25

Hydraulic unit........................................................... 25

MAINTENANCE

Transmission............................................................ 26

Chassis.................................................................... 26

Set tyre tracking ...................................................... 27

Tyres ........................................................................ 27

Tine arms................................................................. 27

Rotor unit ................................................................. 28

Lubrication diagram ................................................. 30

Spring tines.............................................................. 32

Maintenance Setting the working width ................ 32

Lubrication chart ...................................................... 33

TOP 842 C/ TOP 962 C hydraulic plan................... 34

HYDRAULIC PLAN

TOP 842 C/ TOP 962 C hydraulic plan with single

rotor operation ......................................................... 35

TECHNICAL DATA

Technical data.......................................................... 36

Connections required .............................................. 37

Optional equipment:................................................. 37

Variations:................................................................ 37

Use of the swath rotor as intended .......................... 37

Type plate ................................................................ 37

Tyres ........................................................................ 38

SUPPLEMENT

Lubricants ................................................................ 48

Combination of tractor and mounted implement.......51