2

1. TECHNICAL SPECIFICATIONS

Refer to the rating plate on the filter box holder

(see example opposite)

230V (+10% -15%) / 50Hz - 60Hz / 2 x 0.1A

0 to 180 mbar (nominal 148 mbar)

certificate number 1312 AR 1201

Nominal capacity (inlet pressure = 148 mbar) ∑Qn (Hs)

(Nominal heat input) ∑Qn (Hi) 7.452

10.580

14.260

kW

Maximum capacity (inlet pressure = 180 mbar) ∑Qm (Hs) 8.932

12.682

17.093

kW

(Maximal heat input) ∑Qm (Hi) 8.218

11.668

15.726

kW

Gas consumption (inlet pressure = 148 mbar) M

(Mass flow rate) (inlet pressure = 180 mbar) M 0.649

0.912

1.237

kg/h

Ø orifices (1/100e mm) primary orifice (restrictor) none

none

secondary orifice (injector) 2 x 70

2 x 78

2 x 95

Combustion air 7.452

10.580

14.260

m

/h

Inlet pressure 60 to 180 mbar (nominal 148 mbar)

certificate number 1312 AR 1201

Nominal capacity (inlet pressure = 148 mbar) ∑Qn (Hs)

(Nominal heat input) ∑Qn (Hi) 7.293

10.355

13.957

kW

Maximum capacity (inlet pressure = 180 mbar) ∑Qm (Hs) 8.932

12.682

17.093

kW

(Maximal heat input) ∑Qm (Hi) 8.043

11.420

15.392

kW

Gas consumption (inlet pressure = 148 mbar) V

(Volumetric flow rate) (inlet pressure = 180 mbar) V 0.852

1.210

1.629

m

/h

Ø orifices (1/100e mm) primary orifice (restrictor) 1 x 135

1 x 180

secondary orifice (injector) 2 x 115

2 x 135

2 x 150

Combustion air 7.293

10.355

13.957

m

/h

Hi = Net calorific value - Hs = Gross calorific value

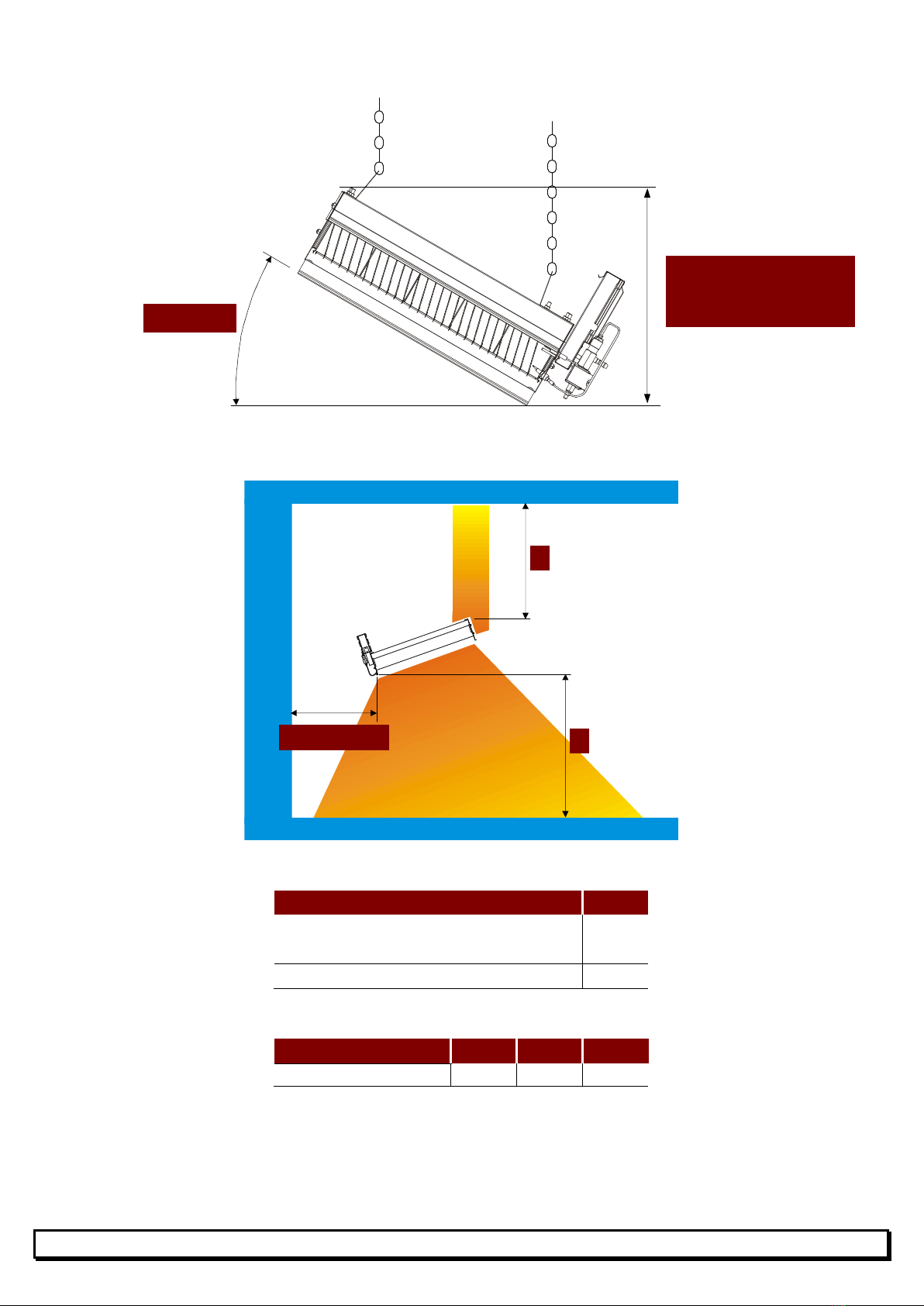

The proper operation of the heaters requires the renewal of 1 m3/h fresh air per kW of

operating capacity.

X (mm) 272 398 522

Weight (kg)

7.00 8.00 9.00