Stand: März 2013 C.F. Maier Europlast GmbH & Co KG Seite 9 von 16

Thoroughly remove excessive Sika after

riveting by using a particular Sika remov-

ing agent and seal then the cutting

edges. Now, any fixtures used can be

removed, too.

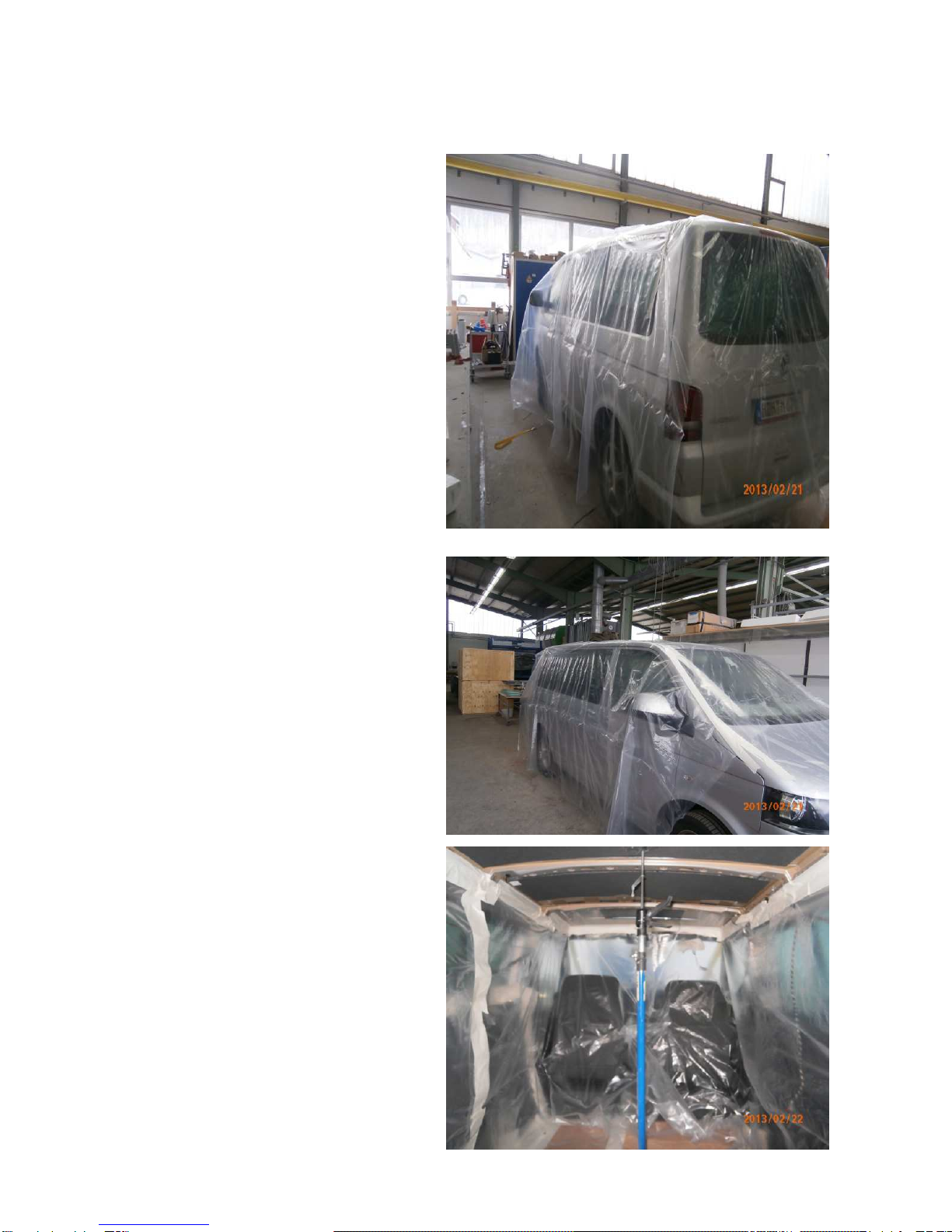

Rivet the fixing plates (article no.

111978) laterally below the cut reinforc-

ing clips (see page 5 / image in the mid-

dle). The plates for which boreholes

have already been prepared must only

by aligned centrally to the reinforcing clip

and the drilling template must be trans-

ferred to the car body and the reinforcing

frame, bore diameter 5 mm, rivets with

4.8 x 16.9 mm aluminium/steel. The ve-

hicles with a short wheel base (SCA

194/195) have four fixing plates on the

left side, three plates on the right side

due to the sliding door..

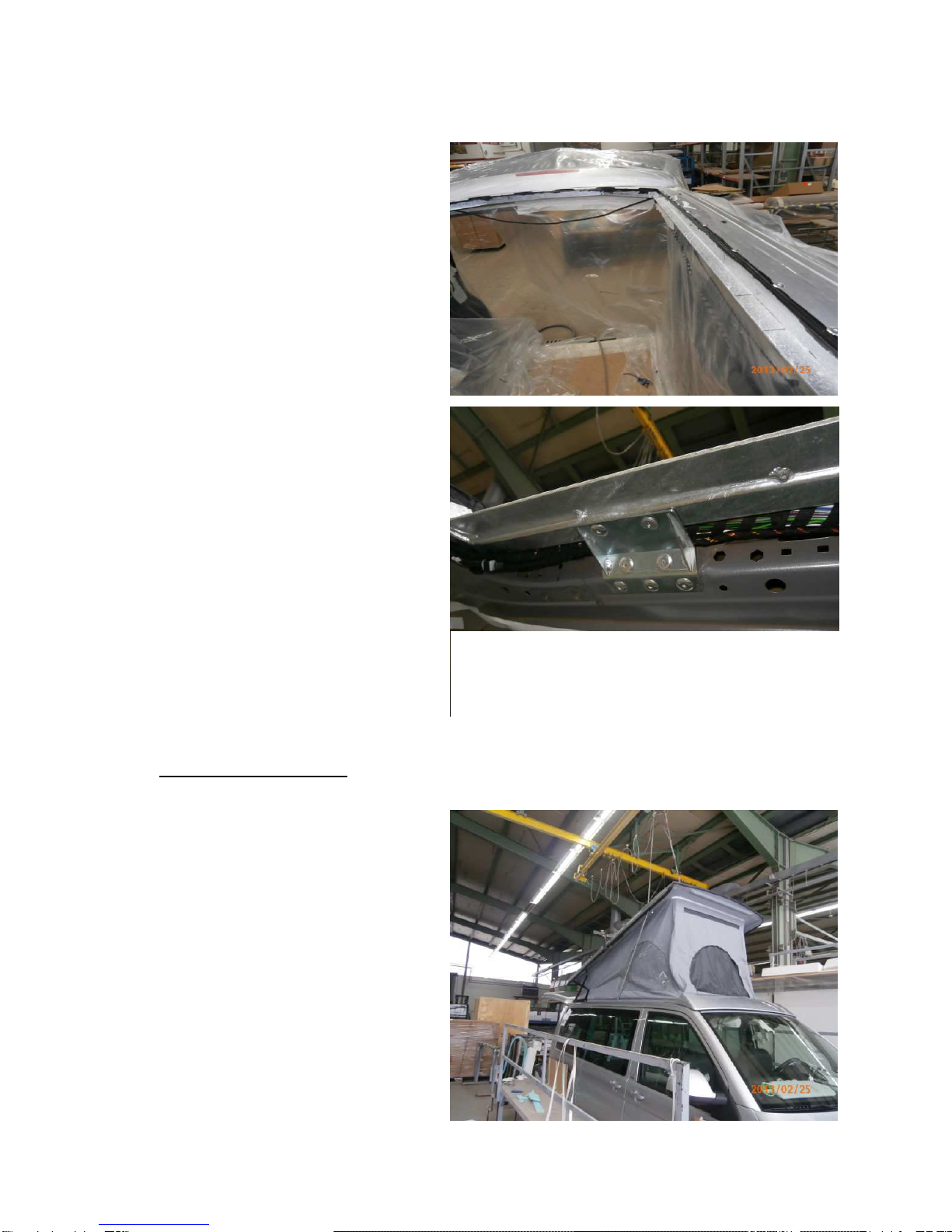

5. Sleeping Roof Assembly

Position the assembled sleeping roof

(condition at the time of delivery) onto

the vehicle and open the roof. Support

the roof shell in front. After that, align the

spoiler of the platform with the contours

of the windscreen as well as with the

lateral drip rail. Now, the sleeping roof

must be secured against shifting. Please

pay attention to fasten the screw clamps

in a way to prevent a collision with the

roof shell when closing the roof. Finally,

check the roof for proper functioning.