3

Contents

1Read First.............................................................................................................................................. 4

1.1 Safety and Caution Symbols.......................................................................................................... 4

1.2 Intended Use.................................................................................................................................. 4

1.3 Dangers.......................................................................................................................................... 4

1.3.1 Neglecting of Safety Notes..................................................................................................... 4

1.3.2 Remaining Dangers................................................................................................................ 4

1.4 Reconstructions and Modifications................................................................................................ 4

1.5 Personnel....................................................................................................................................... 4

1.6 Warning Notes ............................................................................................................................... 4

2Term Definitions.................................................................................................................................... 5

2.1 Terms............................................................................................................................................. 5

2.2 Definition of the Pictograms on the Torque Sensor....................................................................... 5

3Product Description............................................................................................................................... 5

3.1 Mechanical Setup ......................................................................................................................... 5

3.2 Electrical Setup.............................................................................................................................. 5

4Mechanical Assembly............................................................................................................................ 6

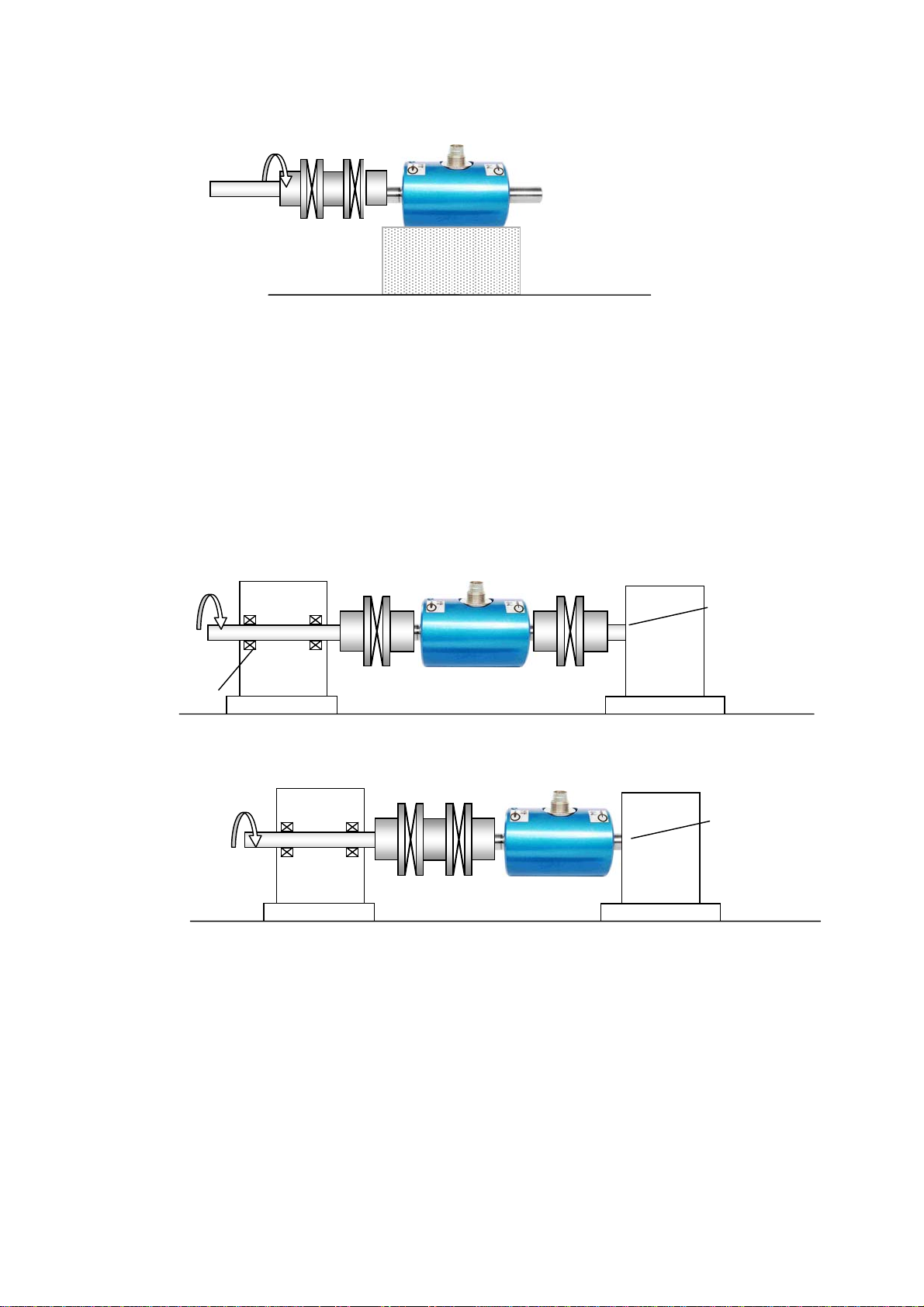

4.1 Couplings....................................................................................................................................... 6

4.1.1 Examples for Single-Jointed Couplings.................................................................................. 6

4.1.2 Misalignment Possibilities of Single-Jointed Couplings......................................................... 6

4.1.3 Double-Jointed Couplings....................................................................................................... 7

4.1.4 Alignment of the Measurement Arrangement......................................................................... 7

4.2 Shaft Connection............................................................................................................................ 7

4.2.1 General................................................................................................................................... 7

4.2.2 Torque Sensors of 0,005 N·m to 0,02 N·m............................................................................. 7

4.2.3 Torque Sensors of 0,03 N·m to 15 N·m.................................................................................. 8

4.2.4 Torque Sensor from 20 N·m................................................................................................... 9

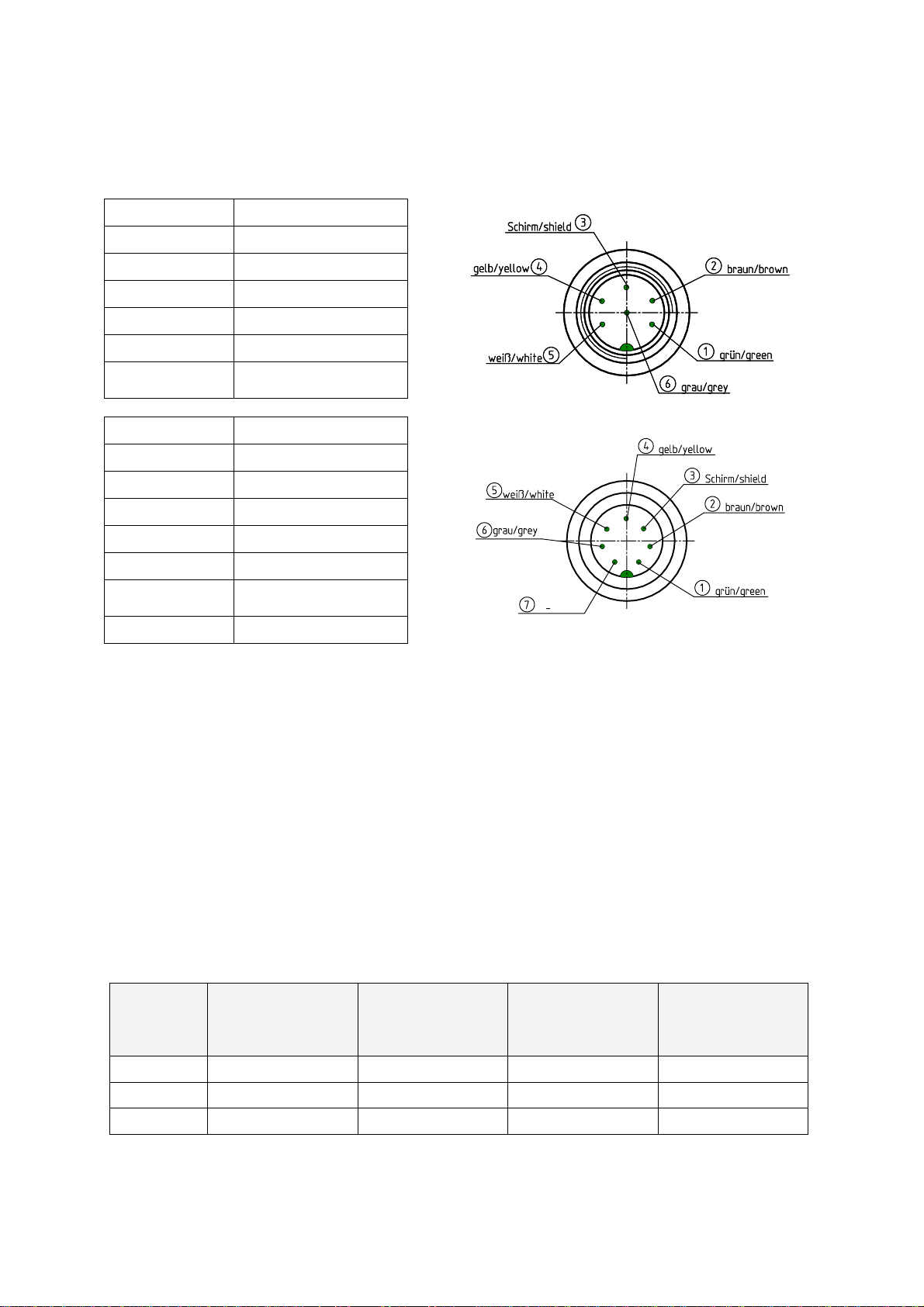

5Electrical Connection........................................................................................................................... 10

5.1 Pin Connection............................................................................................................................. 10

5.2 Cable............................................................................................................................................ 10

5.3 Shielding Connection................................................................................................................... 10

5.4 Extension Cable........................................................................................................................... 10

5.5 Running of Measuring Cables...................................................................................................... 11

6Measuring............................................................................................................................................ 11

6.1 Engaging...................................................................................................................................... 11

6.2 Direction of Torque....................................................................................................................... 11

6.3 Static / Quasi-Static Torques....................................................................................................... 11

6.4 Dynamic Torques......................................................................................................................... 11

6.4.1 General................................................................................................................................. 11

6.4.2 Natural Resonances............................................................................................................ 11

6.5 Disturbance Variables.................................................................................................................. 12

6.6 Calibration Control (Option)........................................................................................................ 12

7Maintenance........................................................................................................................................ 13

7.1 Maintenance Schedule ................................................................................................................ 13

7.2 Trouble Shooting.......................................................................................................................... 13

8Decommission..................................................................................................................................... 13

9Transportation and Storage ................................................................................................................ 13

9.1 Transportation......................................................................................Erreur ! Signet non défini.

9.2 Storage......................................................................................................................................... 13

10 Disposal...................................................................................................Erreur ! Signet non défini.

11 Calibration................................................................................................Erreur ! Signet non défini.