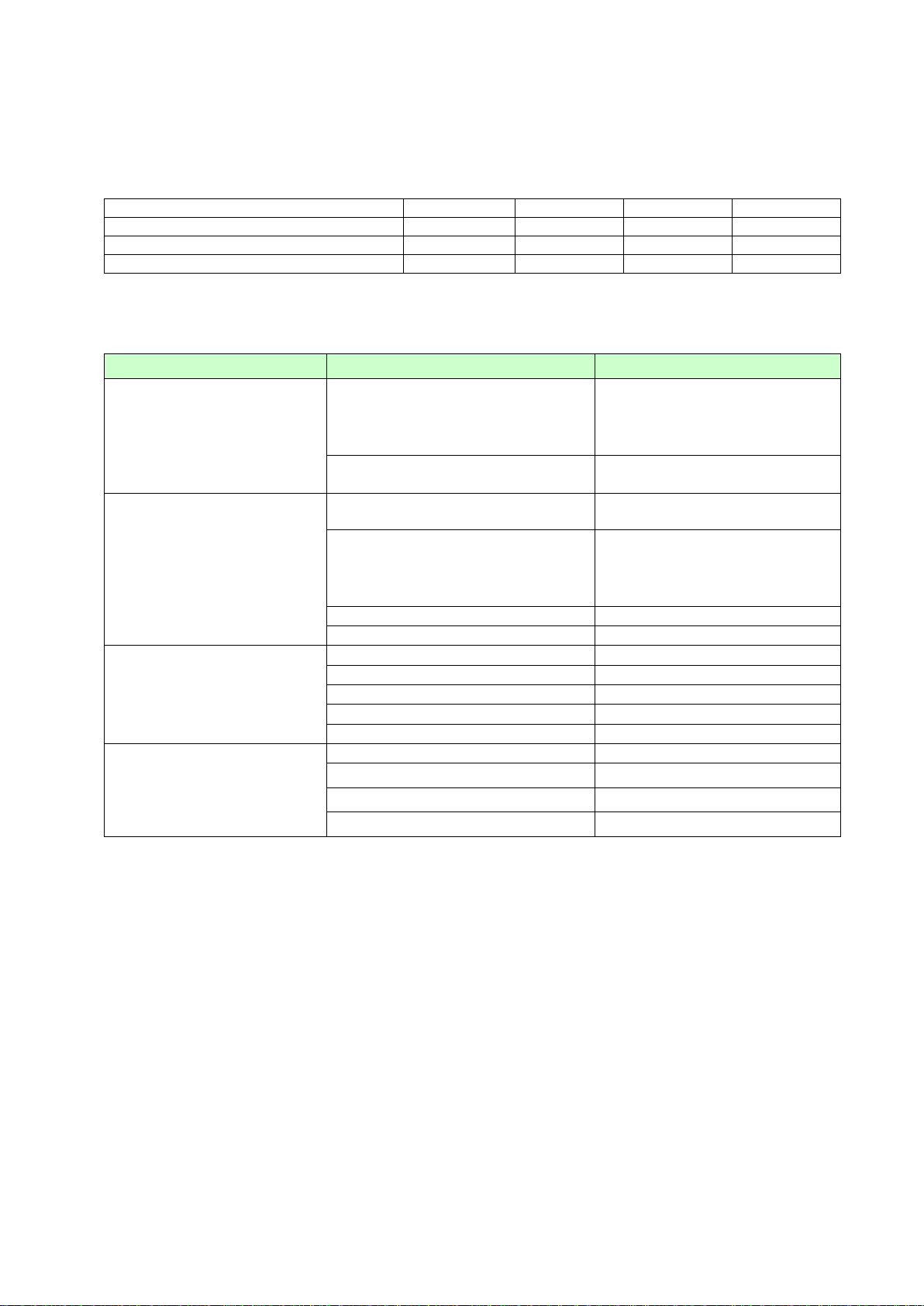

Contents

1Read First.............................................................................................................................................. 4

1.1 Safety and Caution Symbols.......................................................................................................... 4

1.2 Intended Use.................................................................................................................................. 4

1.3 Dangers.......................................................................................................................................... 4

1.3.1 Neglecting of Safety Notes..................................................................................................... 4

1.3.2 Remaining Dangers................................................................................................................ 4

1.4 Reconstructions and Modifications ................................................................................................ 4

1.5 Personnel....................................................................................................................................... 4

1.6 Warning Notes ............................................................................................................................... 4

2Term Definitions .................................................................................................................................... 5

2.1 Terms............................................................................................................................................. 5

2.2 Definition of the Pictograms on the Torque Sensor....................................................................... 5

3Product Description............................................................................................................................... 5

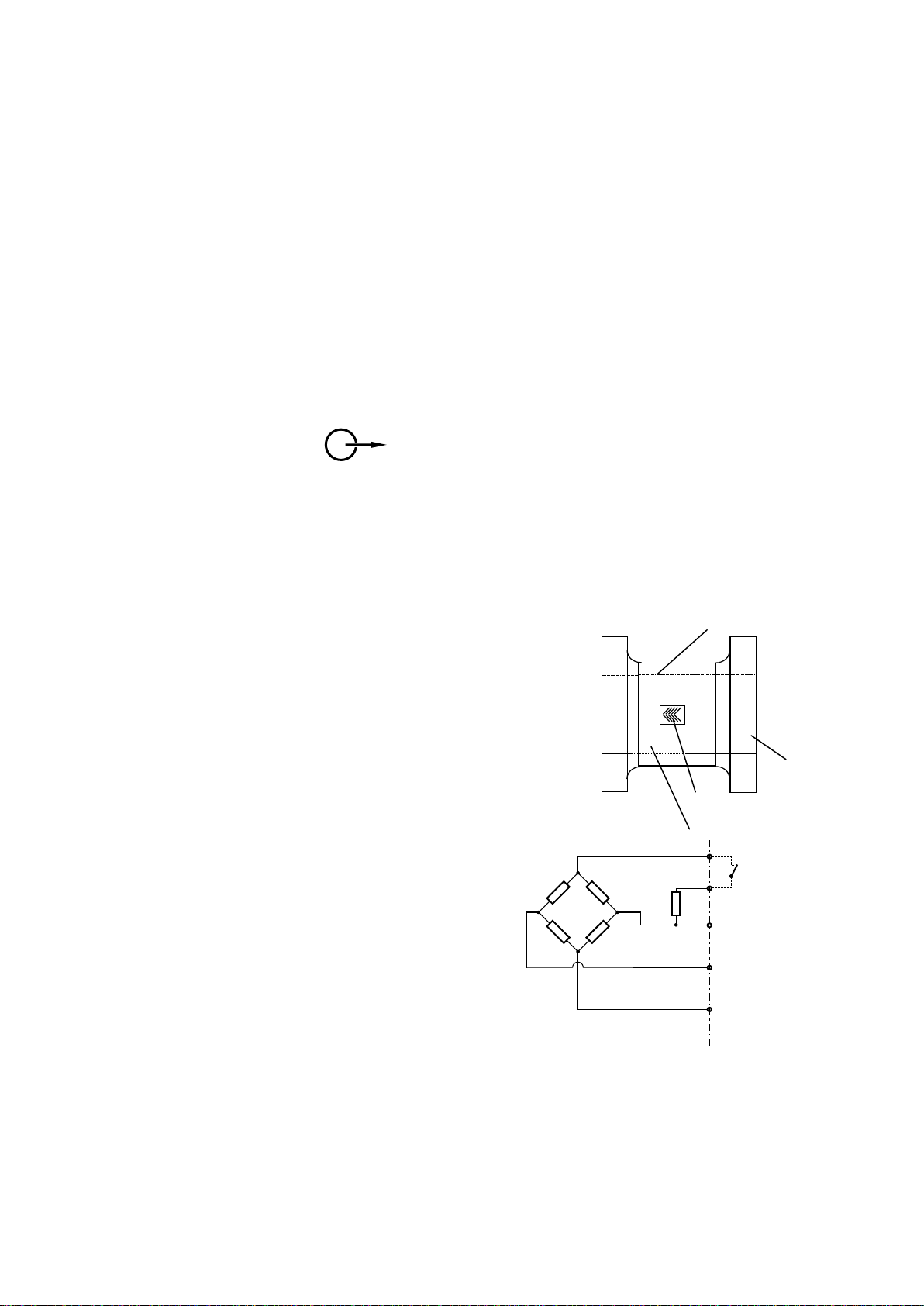

3.1 Mechanical Setup........................................................................................................................... 5

3.2 Electrical Setup.............................................................................................................................. 5

4Mechanical Assembly............................................................................................................................ 6

4.1 Sensors up to 15 N·m .................................................................................................................... 6

4.2 Flange Connection......................................................................................................................... 6

4.3 Shaft Connection............................................................................................................................ 6

4.4 Inside Square and Outside Square................................................................................................ 6

5Electrical Connection............................................................................................................................. 7

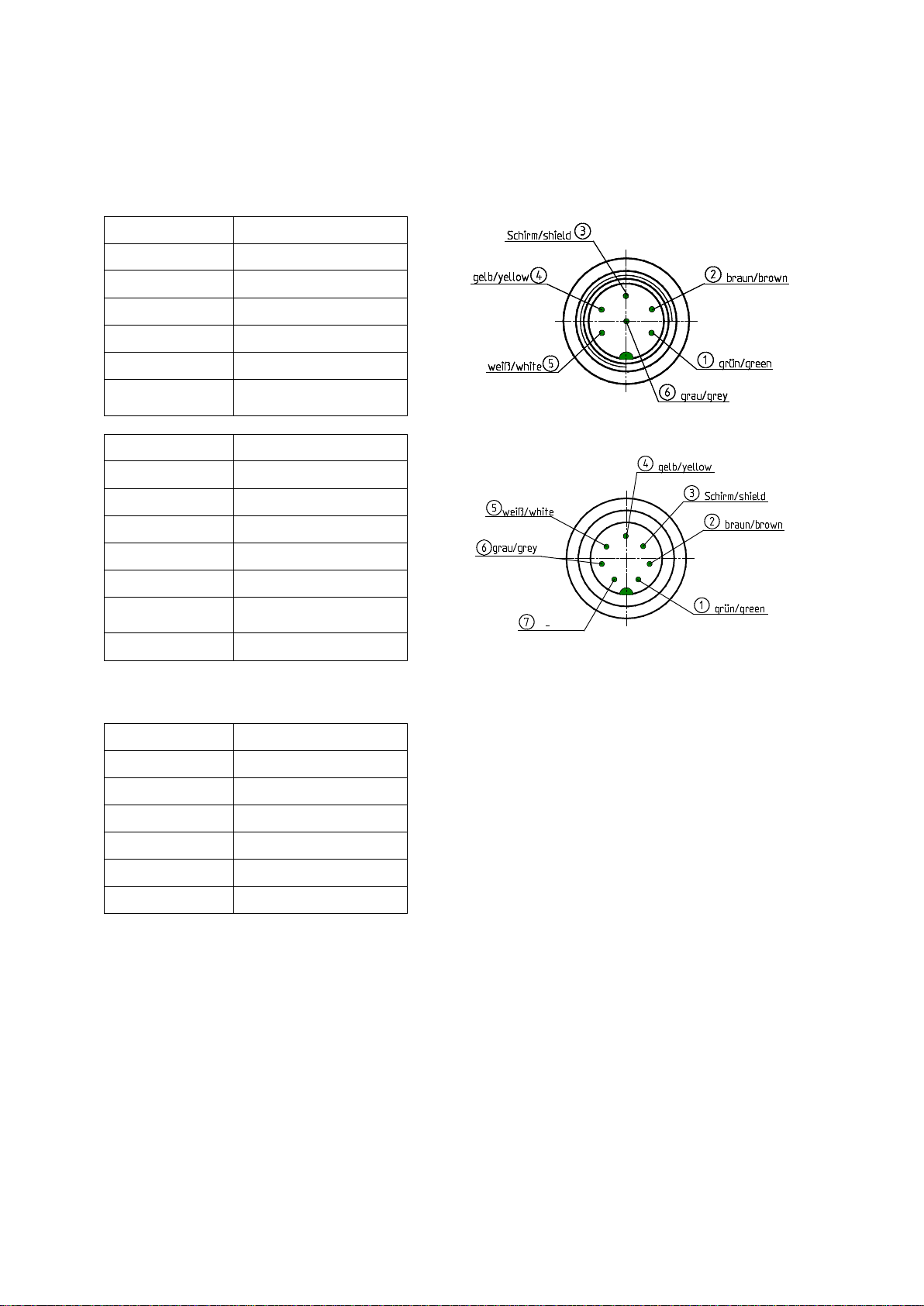

5.1 Pin Connection............................................................................................................................... 7

5.2 Free Cable Ends............................................................................................................................ 7

5.3 Cable.............................................................................................................................................. 7

5.4 Shielding Connection..................................................................................................................... 7

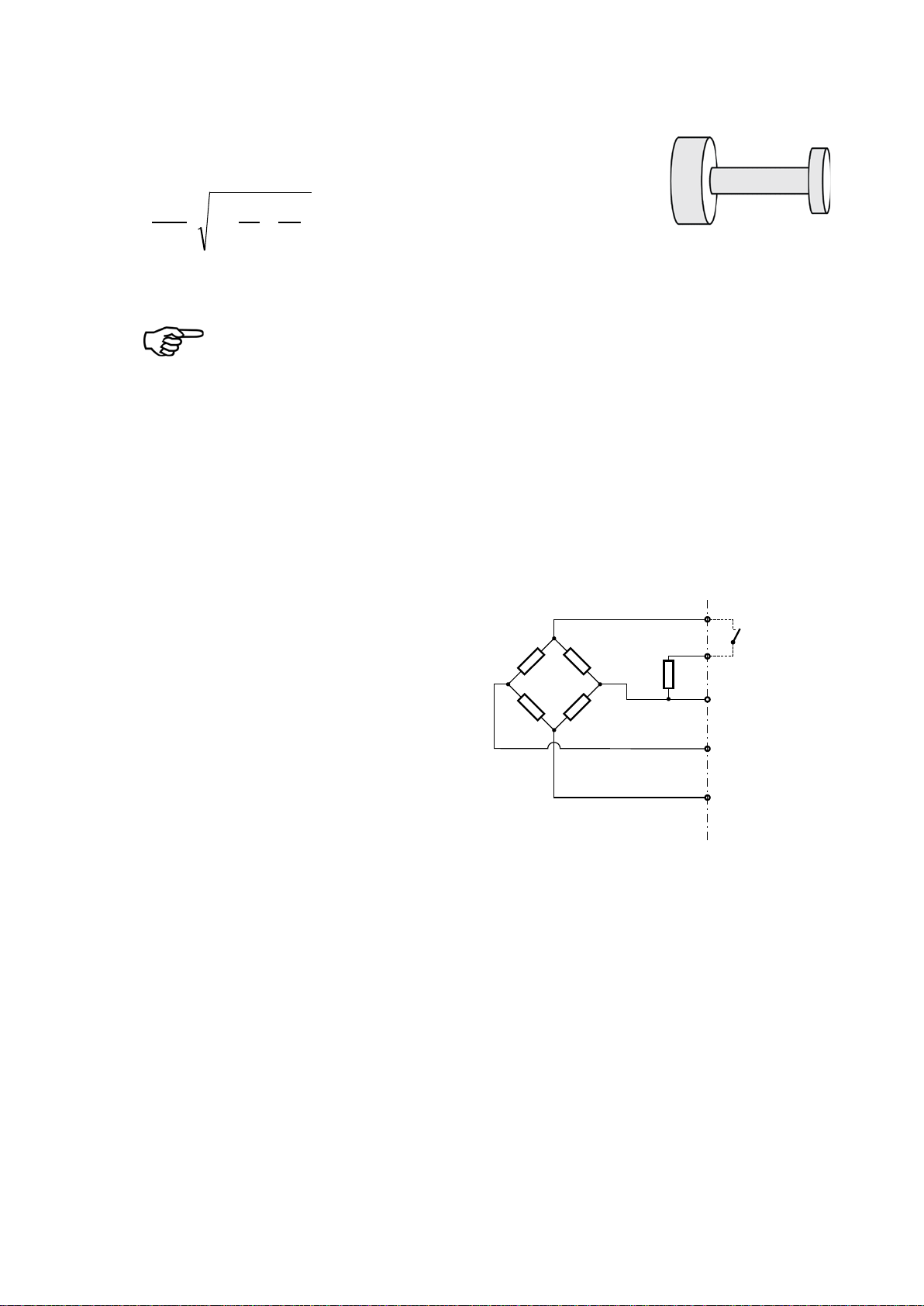

5.5 Extension Cable............................................................................................................................. 8

5.6 Running of Measuring Cables........................................................................................................ 8

6Measuring.............................................................................................................................................. 8

6.1 Engaging........................................................................................................................................ 8

6.2 Direction of Torque......................................................................................................................... 8

6.3 Static / Quasi-Static Torques......................................................................................................... 8

6.4 Dynamic Torques........................................................................................................................... 8

6.4.1 General ................................................................................................................................... 8

6.4.2 Natural Resonances ............................................................................................................... 9

6.5 Disturbance Variables.................................................................................................................... 9

6.6 Calibration Control (Option) .......................................................................................................... 9

7Maintenance........................................................................................................................................ 10

7.1 Maintenance Schedule ................................................................................................................ 10

7.2 Trouble Shooting.......................................................................................................................... 10

8Decommission..................................................................................................................................... 10

9Transportation and Storage ................................................................................................................ 10

9.1 Transportation......................................................................................Erreur ! Signet non défini.

9.2 Storage......................................................................................................................................... 10

3