ISD8001: Industrial ScentDirect

Diffusion System

Wall Mount Instructions

ISD (Industrial Direct Diffusion System)

Congratulations on the purchase of your ISD fragrance

delivery

system. Please take

a

moment

to read the provided instructions and familiarize yourself

with

the

operation

of the system.

Understanding how the system works is vital in ensuring

i

deal

scent

delivery.

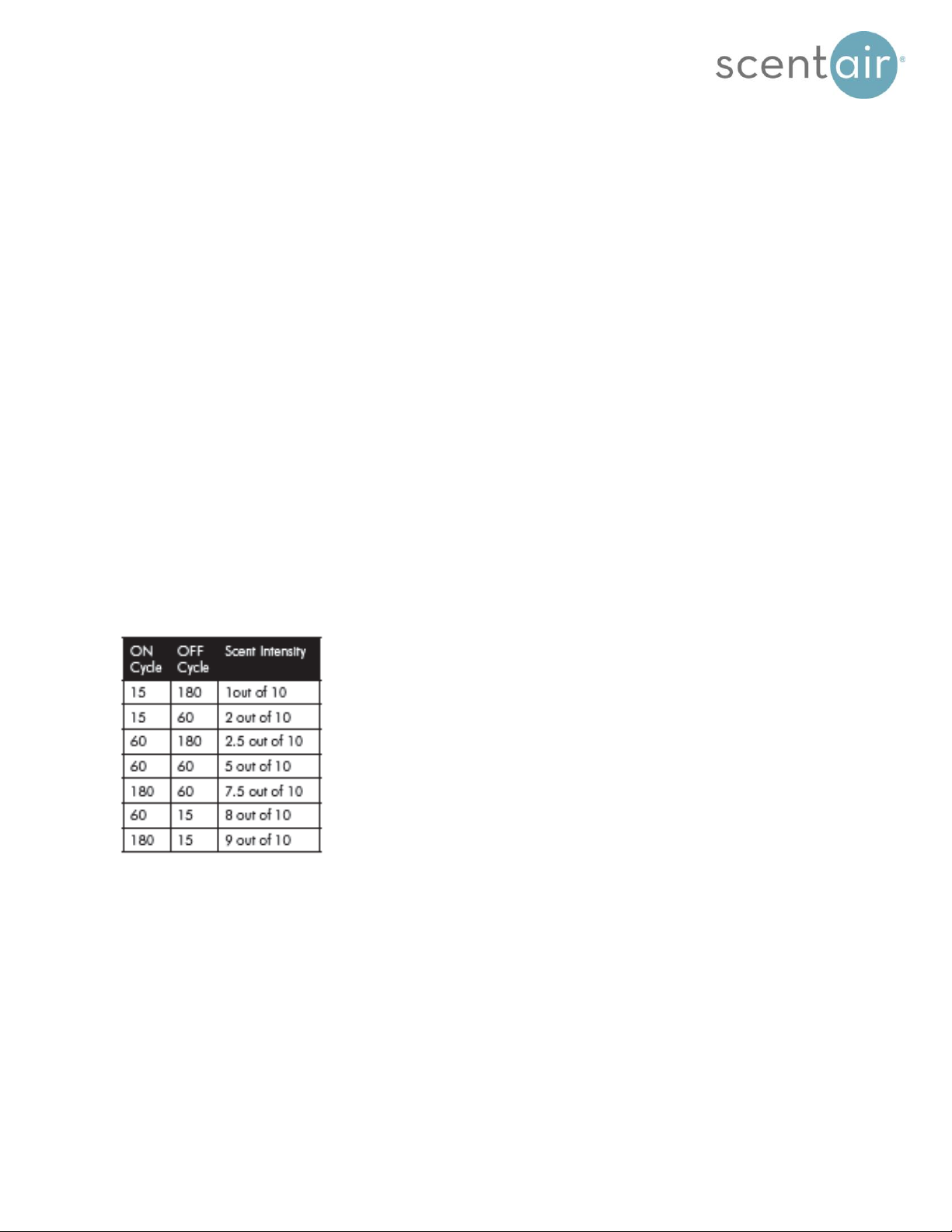

The ISD scent diffusion system is designed to deliver a dry vapor fragrance directly into the air

in any enclosed space. This unit uses air at low pressures to atomize liquid fragrance into a

dry vapor. The atomization occurs inside the machine and the scent is delivered from the unit

with a fan. The ISD is able to adjust the fan speed and the pump pressure to cover a wide

range of applications.

INSTALLATION INSTRUCTIONS

DETERMINE

MOUNTING

L

OCA

TION

Always review the air flow characteristics of the property before starting an installation.

Identify the location to be scented and locate a surface nearby to mount the machine. The

unit should be mounted so that the output crosses the location to be scented.

Be sure to mount the ISD out of the reach of children. The system can be mounted anywhere

from ground level to 12 feet high. A good rule of thumb is to mount it above or below nose

level and allow fragrance to disperse into the space.

System

must

be upright and level to

function

correctly

. Please use in a dry

environment for best results.

Wall Mount Installation instructions

The articulating wall mount MUST BE installed directly over wall studs when used on a

finished interior wall. The wall mount bracket is installed on the wall first and then the

ISD8001 is hung and secured. The mount is supplied with 6mm dia coarse thread screws that

can be used in wood framing or (with plastic anchors ) concrete or masonry walls. Please

refer to the instructions provided with the Mount itself ( pages 1-5 ) for attaching the mount

to these materials. Always use a studfinder to determine the center of a wall stud before

finalizing the placement of the wall mount. Whenever the mount is to be installed into metal

framed walls with thin gauge sheet metal studs the special ¼-20 screws and special

snaptoggle anchors must be used according to the following directions. The snaptoggle

anchors are also to be used when installing the mount onto thin walled cinderblock wall.