Safety and General Instructions

77855 Achern-Gamshurst Tel.: +49 7841/2052-0 No.: 77 SI01 E

Oststrasse 17 Germany Fax: +49 7841/2052-52 Rev. A Page

of

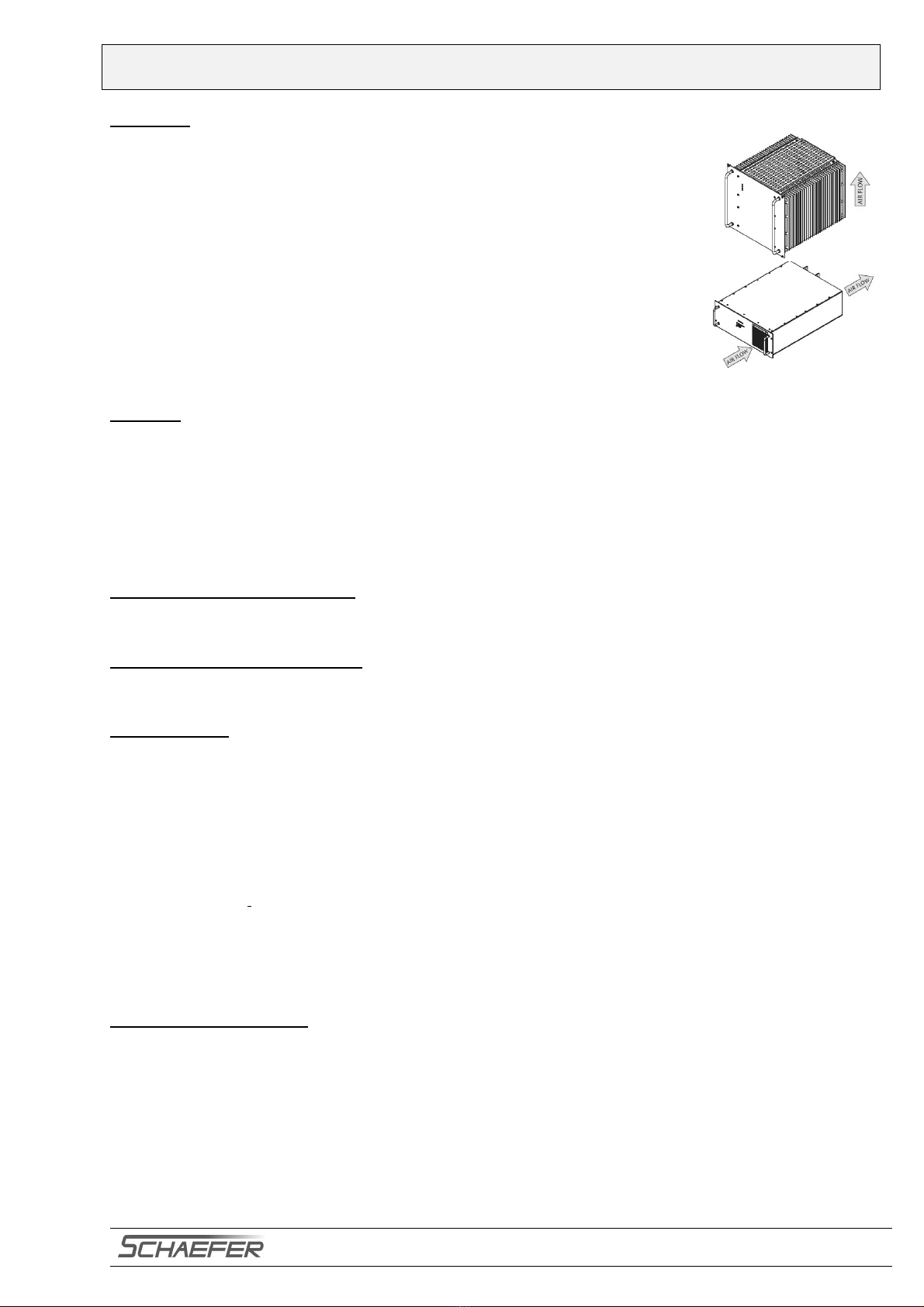

AIR FLOW

It is preferable that the airflow to the power supply is filtered and below 55°C. An airflow

resistivity (pressure drop) of below 20 kPa is required to comply with EN60950 pollution category

II. Diffused thermal energy is required to be exhausted and replaced by air as detailed above.

Thermal management is required where the air provided to a power

supply complies with the power supply’s design parameters. The use of fans requires an

increase in airflow to a minimum rate of 120m³/h (corresponding to 70 cfm). The airflow

resistivity and respective pressure drop should be considered when a fan is required.

DIRECTION OF AIR FLOW

Typically, Schaefer modules and systems are cooled through air supply entering from

below and exiting above, with the exception of models of series C/B 5100, 5200, 5300,

5400, 6400 and 6600 whose airflow is from front to back. Custom designs also offer

lateral cooling. Such details however, are project specific

.

CABINET

A cabinet may be employed to enhance a module / system,.

•This may be required to fulfill the increased IP / NEMA rating, due to a negative effect of the solution on the

environment.

•Specifically, with unclean, saturated, corrosive or otherwise aggressive air quality it may be required to employ a

cabinet with a combination of features such as hermetical sealing and air exchange amongst others.

•The enclosure must be capable of sustaining the weight of the modules, specifically if module support rails are used.

•Stationary cabinets should be fastened to the ground.

•The center of gravity must be as low as possible with portable systems.

TRANSPORTATION OF MODULE

The grips on the front of the modules are to assist in module insertion into a sub-rack, and not for supporting the weight of the

module.

WALL MOUNT / CHASSIS MOUNT

Modules with a mounting plate or angle are designed for integration into the host equipment. They are not for employment

outside of an enclosure.

MAINTENANCE

Check the applied voltages and screw connections at periodic intervals in order to recognize any irregularities in the performance

of the power supply. If necessary, correct through adjustments and calibration.

Clean the power supply at certain intervals from dirt and dust which may have accumulated.

Record technical, operational and environmental data, that is to be used as a reference for evaluation.

Due to storage conditions, the following maintenance may be necessary:

a. A reforming procedure has to be done after 3 years of voltage-free storage under normal temperatures (+5° …+35°C)

b. A reforming procedure has to be done after 1 year of voltage-free storage under extended temperatures

(-40° ...+5°C and +35° ... +85°C).

Reforming procedure:

Due to increased leakage current of the internal electrolytic capacitors after voltage-free storage, the capacitors have

to be reformed. For this purpose, the rated input voltage has to be applied to the terminals.

Leave the input voltage applied for a period of 1 hour. Subsequently, the unit is stored under no voltage conditions for 12 to

48 hours at a temperature between 15°C and 35°C.

Afterwards the capacitors are reformed and meet the specified values.

STORAGE INSTRUCTIONS

Storage temperature: -40°C ... +85°C

We recommended the following conditions for storage:

- Do not store the unit at a high temperature ( at higher temperatures the ageing process is increased ) or in high humidity.

Store the unit indoors at a temperature of +5 …+35°C and a humidity of less than 75% RH.

- Keep the unit in the original package.

If the units are stored below the operating temperature, then they have to be left for at least 5 hours at operating temperature

conditions to ensure there is no condensing water present before operation.