Schako RMS User manual

Ferdinand Schad KG

Steigstraße 25-27

D-78600 Kolbingen

Telephone + 9 (0) 7 63 - 980 - 0

Fax + 9 (0) 7 63 - 980 - 200

info@schako.de

www.schako.de

Smoke detection system

Model RMS

Contents

Construction subject to change. No return possible!

Smoke detection system RMS

09/11 - 2 27.03.2019Version:

Description ........................................................................................................................................3

Application .................................................................................................................................................................................3

Advantages .............................................................................................................................................................................3

RMSII-L .....................................................................................................................................................................................

Function (special scattered light method) ..................................................................................................................................

Construction ..............................................................................................................................................................................5

Accessories ................................................................................................................................................................................5

Fastening ...................................................................................................................................................................................5

Dimensions ........................................................................................................................................5

Technic l d t ....................................................................................................................................8

Smoke detection system (-RMS) ...............................................................................................................................................8

Relay module (-RM) ..................................................................................................................................................................8

M inten nce / Inspection ..................................................................................................................... 10

Order det ils .................................................................................................................................... 11

Specific tion texts .............................................................................................................................. 11

Smoke detection system RMS

09/11 - 3

Construction subject to change. No return possible!

27.03.2019Version:

Description

Applic tion

The SCHAKO smoke detection system consists of the smoke

detector RMSII-L nd the rel y module RM V4.00 nd is used

in pl ces where, t the e rliest possible st ge of fire (upon

occurrence of cold smoke of < 72°), triggering nd switching

oper tions re to be controlled utom tic lly. It c n be fitted

to ventil tion ducts. If detected, the prop g tion of smoke in

the ir duct system is prevented for the most p rt by closing

the fire or smoke d mpers. The alarm message is transmitted

via a potential-free contact and interrupts the electric circuit to

the electric trigger devices (magnetic clamps, spring return ac-

tuators) or to pneumatic drives. The connected fire d mpers

nd smoke d mpers re closed. Only trigger devices working

by the "zero-current closed/ depressurised closed" working

principle must be connected to the RMS system. The smoke

detectors and the connected trigger and switch devices are sup-

plied jointly with power from a relay module 230 AC and a sec-

ondary 2 V DC within a protection area.

The smoke detectors remain in alarm condition after being trig-

gered, even after the normal ambient conditions have been re-

stored. The smoke detectors will not return to their monitoring

status until the relay module is reset.

The measurement takes place outside the smoke detector hous-

ing, thus not requiring ny detection ch mber. Approved for

ventilation ducts of air velocities between 1 m/s and 20 m/s.

Adv nt ges

Industrial property rights owned by SCHAKO:

Extern l monitoring is done by

the VdS Sch densverhütung GmbH Köln (VdS D m ge Pre-

vention Br nch, Cologne)

When integr ting SCHAKO components into customer f cili-

ties, ny comp tibility problems re not our responsibility

nd must be elimin ted by the customer.

Inst ll tion nd mounting

Inst ll tion in duct

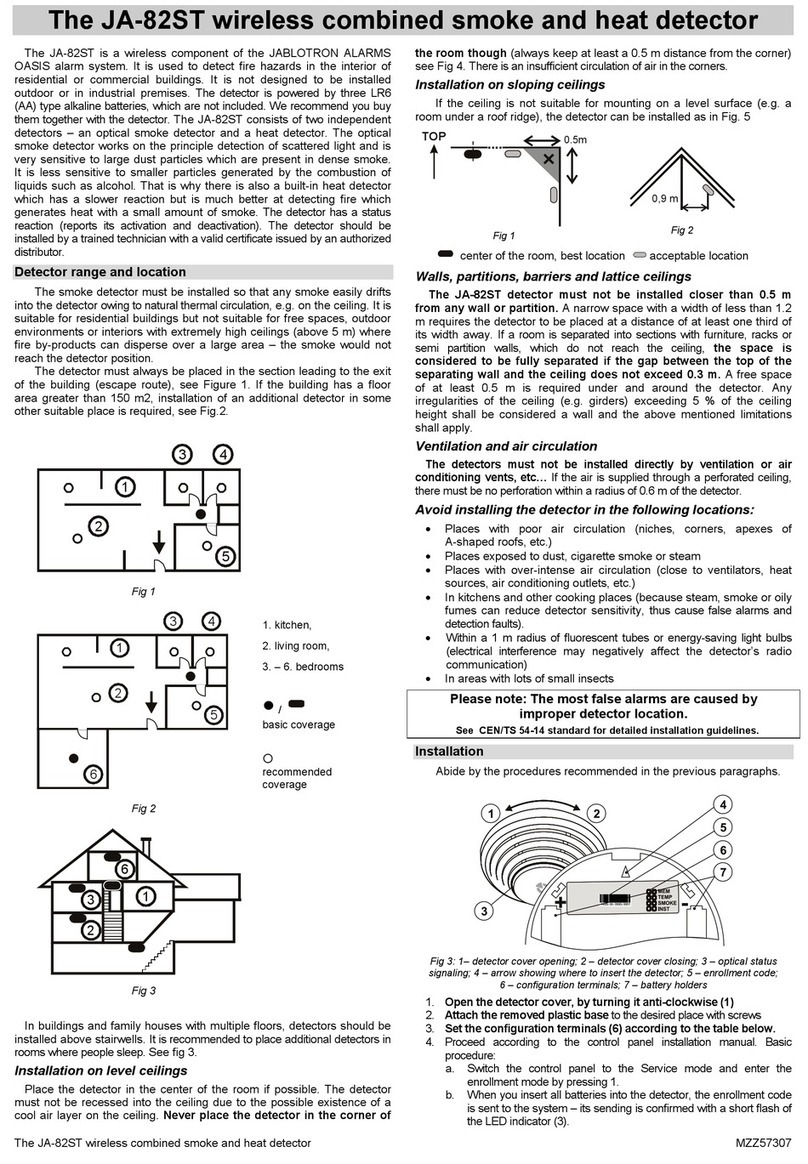

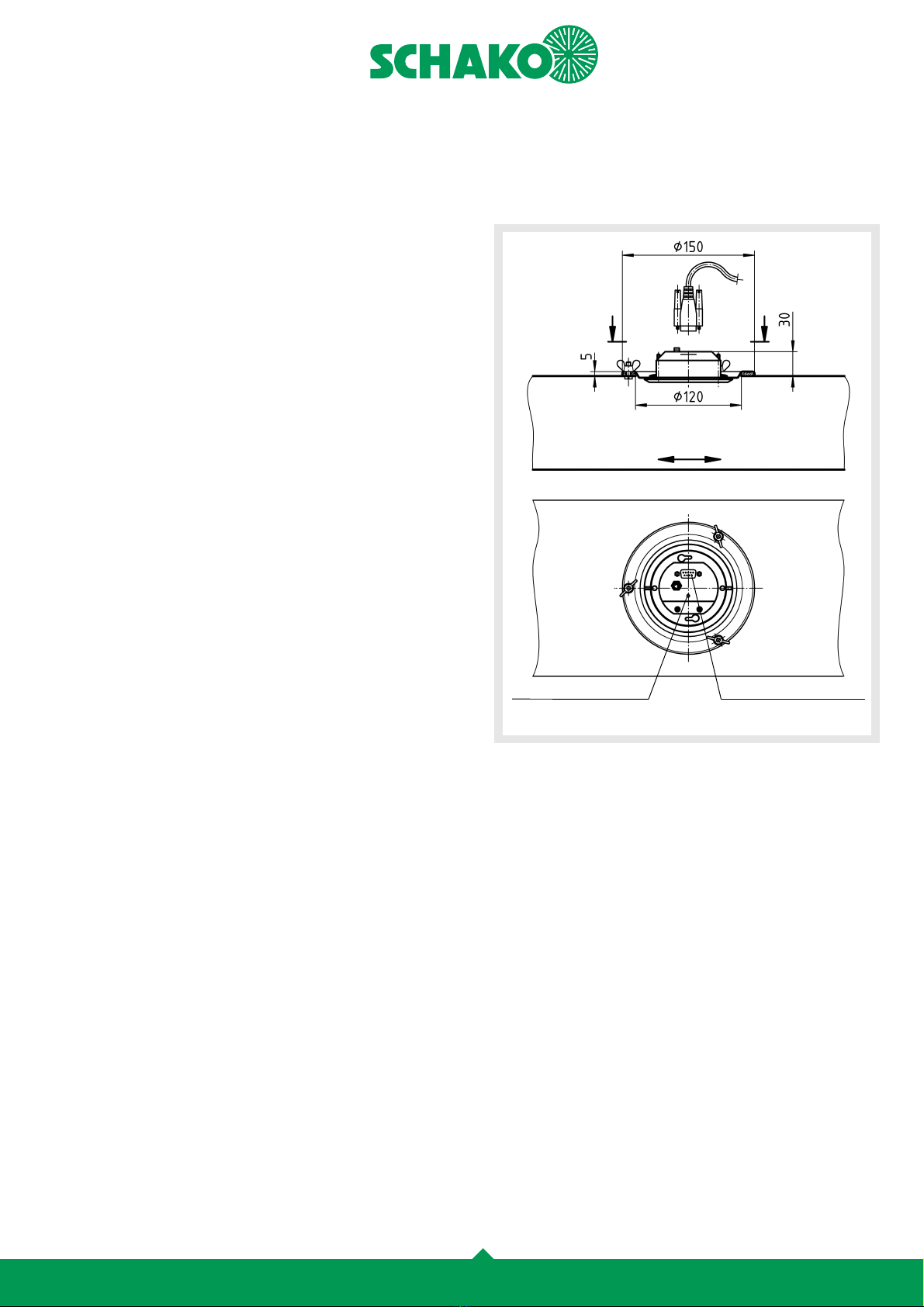

Fig. front side

Fig. lateral side

The smoke detector must be installed such that it is permanently

located in the air flow (not in the inspection opening of the fire

d mper).

- As no detection chamber is required for measurements, no

medium flows through the smoke detector and deposits can

only be formed on the safety glass, allowing easy cleaning.

- Fitted flush with the duct.

- Automatic tampering detection.

- Self-function test of the transmitter and receiver sensors. A

defect is displayed.

- When a power, processor or system failure occurs, a fault

message is displayed simultaneously with an alarm message.

- Includes system monitoring (watchdog).

- Bus connection possible via potential-free contacts.

- Connection to the communicative Signalling and Switching

Bus System + Easy Bus possible.

- Maintenance required once a year

- Patent: DE 199 51 03 A1

- Registered utility model: 20023533.8

- Patent: EP 122 6 1

- VdS Approval: G209206

Air flow direction in duct

Air flow direction in duct

Smoke detection system RMS

09/11 - 4

Construction subject to change. No return possible!

27.03.2019Version:

Inst ll tion rr ngement nd mounting

The smoke detector must be fitted free of vibration if possible.

When charged with steam, disinfectant, dust, soot (exhaust

gases) or dew, an alarm or fault message is triggered.

Assembly in ducts

When fitting the RMS

ΙΙ

-L smoke detector, c re must be t ken

th t in 100 mm r dius round the detector, nothing c n re-

flect the emitted sensor sign l.

Connection

Connecting the power supply. When the output voltage is active,

the orange operating indicator lamp will flash.

Note

Before the first startup of the smoke detector, the ducts must be

cleaned so as to avoid any accidental alarm message.

The relay modules are equipped with a controller with power

limiter and thermal protection. When a short-circuit occurs, the

controller switches off the output voltage. An interruption in the

mains supply voltage or the "+" output line will restore the func-

tion of the smoke detector.

After fitting the smoke detector RMSΙΙ-L on site ready to oper-

ate, an acceptance test immediately prior to putting the fire

damper or smoke detector into operation must establish that the

installation conforms to the regulations and that the smoke de-

tector functions properly, especially that all components inter-

act correctly. The acceptance test must be documented by the

building owner of the ventilation system. The documents must

be filed by the building owner/operator of the ventilation sys-

tem.

For maintenance, service, retrofitting, etc., inspection openings

in sufficient number and size must be provided on site.

RMSΙΙ-L

Function (sc ttered light principle)

Two sensors in the smoke detector send out a light beam and

measure if the air on the front of the safety glass is contaminat-

ed with smoke or other particles. Before triggering an alarm,

various measurement cycles must be carried out, during which

the contamination in the air must be measured. If the contami-

nation is not permanently present, then the internal measure-

ment cycle counter is reset. The response sensitivity of the

smoke detector is set inalterably ex works. The alarm output is

a potential-free change-over contact. The smoke detector can be

reset to the ready-to-operate mode by remote control.

A power failure at the smoke detector can be displayed at the

central unit. In this case, the electric circuit for the release de-

vice is interrupted on the connected fire dampers, and the

dampers are closed. Tampering with the smoke detector, for ex-

ample by taping the sensors, is detected and, if required, report-

ed to the central unit via a potential-free contact (error output).

Deposits on the safety glass of the smoke detector are detected

and evaluated. When a certain degree of soiling is exceeded, it

is reported as a fault message to the switchboard via a potential-

free contact. In this way, the smoke detection system monitors

itself.

1. Establish smoke detector position (not in the inspection

opening of the fire damper), and mark the middle.

2. Cut out a hole of 120 mm in diameter.

3. Drill mounting holes (only when installed on site in the ven-

tilation duct).

. Insert the delivered insulating sleeves into the mounting

holes.

5. Fit smoke detector with mounting frame and seal, fasten with

thumb nuts or Parker screws.

6. During installation, observe air flow direction.

7. Carry out electrical wiring according to wiring diagram.

8. Before putting the RMS

ΙΙ

-L into operation, the duct system

must be cleaned completely. Care must be taken that the

glass front is sprayed again with an antistatic spray after wip-

ing it clean with a damp cloth.

Smoke detection system RMS

09/11 - 5

Construction subject to change. No return possible!

27.03.2019Version:

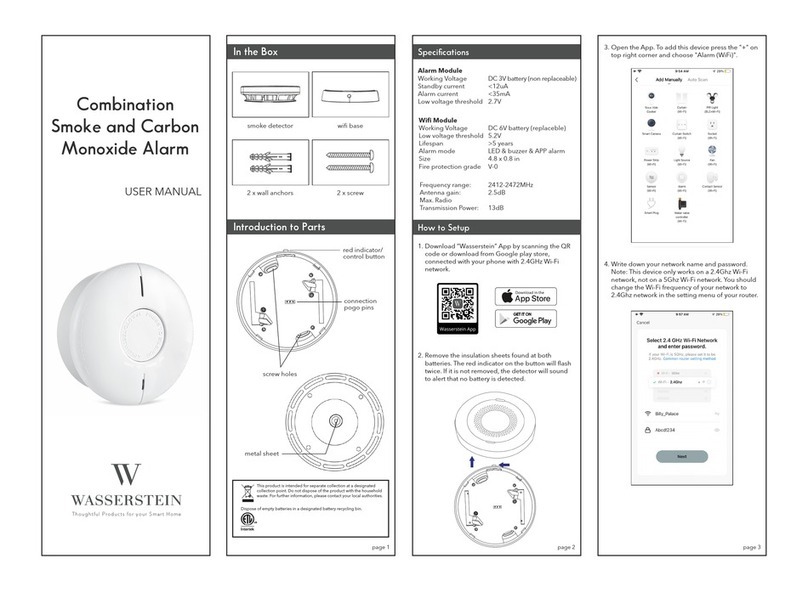

Construction

Accessories

F stening

Dimensions

Smoke detection system RMS

ΙΙ

-L

for installation in rectangular ducts without assembly part!

Smoke detector base

- Polycarbonate

Connecting cable

- 2.0 m with 9-pin Sub D plug. The 9-pin Sub D terminal for

the electric supply and trigger lines is located inside the

base.

Individual display

- LED on duct exterior

Mounting frame

- Sheet steel, with seal

Assembly part type EBT

- for installation flush with the duct, made of galvanised

sheet steel.

- Housing leakage according to DIN EN 1751, class B, at a

duct pressure of up to 1000 Pa.

Assembly part (-REBT / -REBTF)

- for installation in round ducts, made of galvanised sheet

steel.

- Housing leakage according to DIN EN 1751, class B, at a

duct pressure of up to 1000 Pa.

- model

- without flange (-REBT), with rubber lip seal made of

special rubber.

- with flange (-REBTF), on both sides, to EN 12220.

Screw connection

- with thumb nuts or Parker screws

SUB-D plug

9-pin + correspondence

LED for displaying

functional, fault and

alarm message

AIR FLOW DIRECTION

(Duct opening)

ca.

Smoke detection system RMS

09/11 - 6

Construction subject to change. No return possible!

27.03.2019Version:

Accessories

with ssembly p rt (-EBT), for fire damper installation

- Inst ll tion in duct topside

The smoke detector must always be assembled in the assembly

part type EBT on the operator side (trigger device, drive) (not in

the inspection opening of the fire damper).

- Inst ll tion in duct side w ll

The dimension L depends on the height H (mm).

Section A-A / off-centre ssembly

for B > 700

Duct topside

Min. space required

Section A-A / centre ssembly

for B < 700

EBT

1.) min. 100

H

(mm)

L

(mm)

200 - 750 180

800 210

Section C-C

Duct topside

EBT

1.) min. 100

Smoke detection system RMS

09/11 - 7

Construction subject to change. No return possible!

27.03.2019Version:

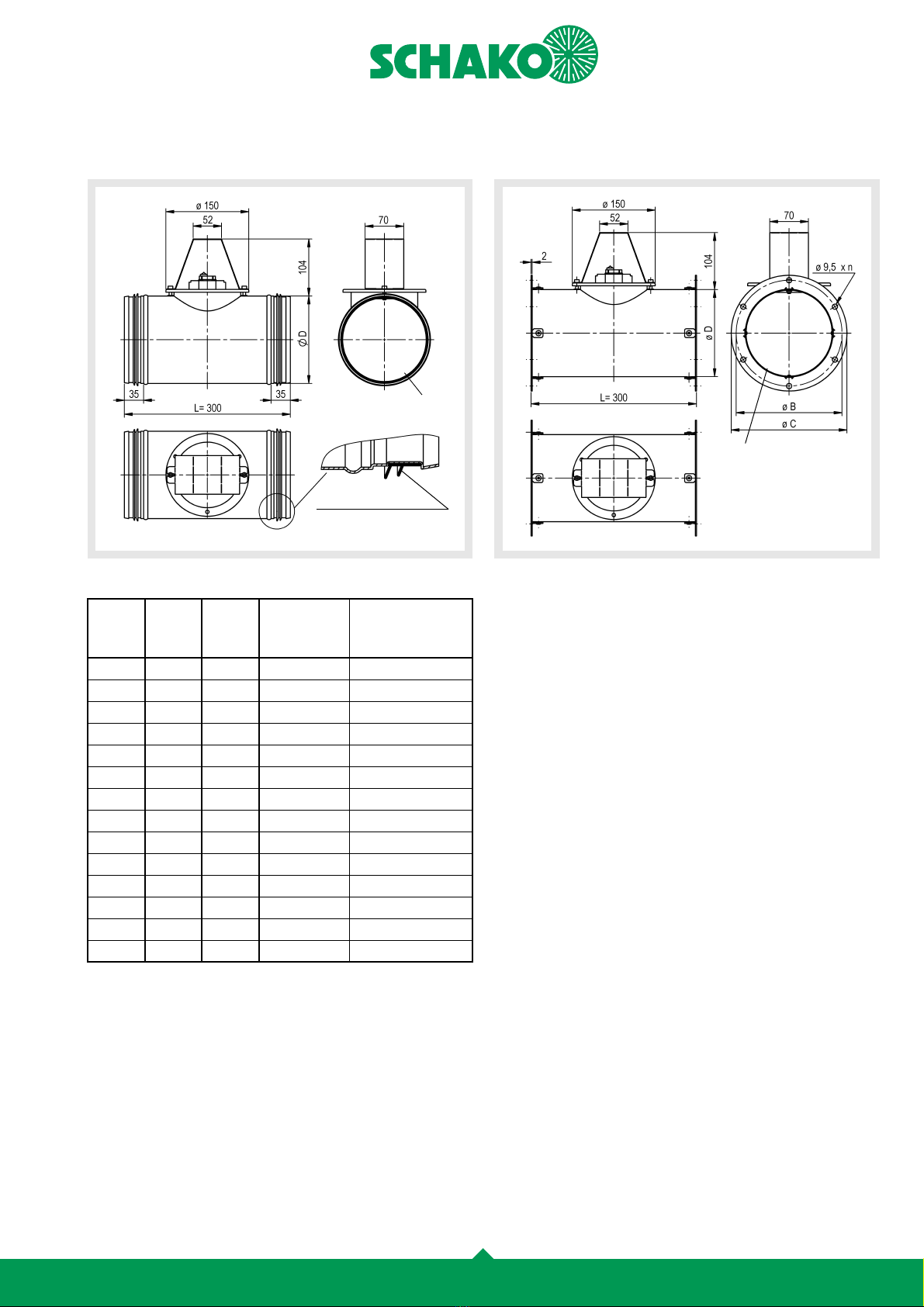

with ssembly p rt (-REBT), for installation in round ducts

- without fl nge, with rubber lip seal.

Av il ble sizes REBT / REBTF

1.) painted black matt on the inside

with ssembly p rt (-REBTF), for installation in round ducts

- with fl nge on both sides, to EN 12220.

NW øD

(mm)

øC

(mm)

øB

Bolt circle

(± 0.5mm)

n

Number of bores

ø9.5 (± 0.5mm)

100 98 150 132

125 123 175 157

140 138 190 172 6

160 158 210 192 6

180 178 230 212 6

200 198 250 233 6

224 222 27 257 6

250 2 8 300 283 6

280 278 3 0 317 8

315 313 375 352 8

355 353 15 392 8

400 398 60 38 8

450 8 510 88 8

500 98 560 538 8

with rubber lip seal as a

standard

1.)

1.)

Smoke detection system RMS

09/11 - 8

Construction subject to change. No return possible!

27.03.2019Version:

Technic l d t

Smoke detection system (-RMS)

Individu l displ y - LED displ y:

Connection ssignment of the 9-pin SUB-D plug:

The rel ys drop off when n l rm / f ult or power cut oc-

curs.

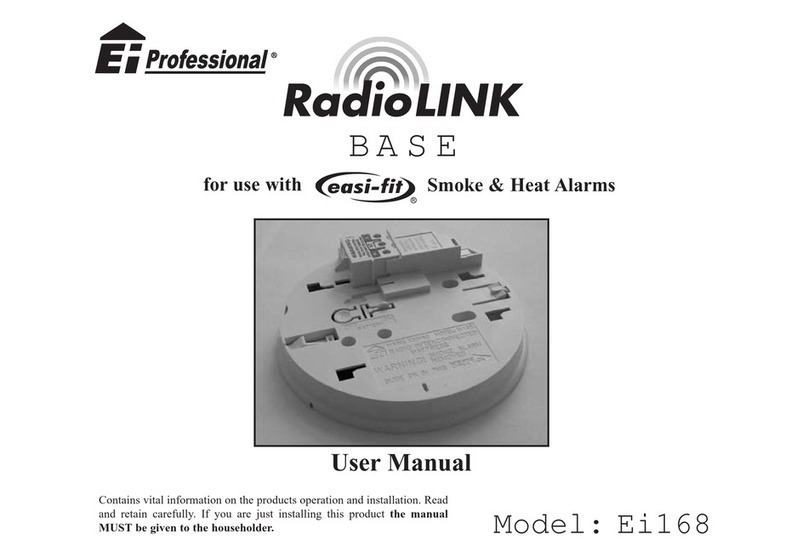

Rel y module (-RM)

The RMS

ΙΙ

-L is connected to the power supply by means of a

relay module (9-pin SUB-D socket). Moreover, the reset button

RST and the test switch have already been mounted on the relay

module. This makes it easier to check the fire damper closing

function via the test switch and/or to reset the alarm message

via the reset button RST. Additional terminal strips for spring re-

turn actuator and / or fan disconnection or other switching op-

erations will shorten the installation time and prevent wrong

wiring.

A 2 V spring return actuator can be activated via the 3-pin AMP

plug (standard Belimo BLF, BF, BFG).

RM V 4.00

Operating voltage: 2 V DC (+15% -20%)

Residual ripple: < 20%

Max. current consumption: 25 mA

Switching contacts: - 1 alarm output (potential-free

change-over contact)

- 1 fault output (potential-free

change-over contact)

Max. switching voltage: 100 V DC / 125 V AC

Max. switching current: 1.0 A

Max. switching power: 30 W / 62.5 V A

Operating temperature and

ambient temperature:

0 °C to +60 °C

Protection type according

to DIN 0050:

IP 0

Weight: 0.2 kg

Storage temperature: max. 75°C

Relative humidity: 10 - 90%

flashing orange = Function

permanently red = Alarm

permanently orange = Fault / Soiling

Assign-

ment Rel y Me ning

de-energised

oper ting

1 - - GND

2 Relay contact work contact fault

3 Relay contact centre contact fault

Relay contact rest contact fault

5 - - Test switch to GND

6 Relay contact rest contact alarm

7 Relay contact centre contact fault

8 Relay contact work contact alarm

9 - - +2 V

Operating voltage: 230 V AC, 50 Hz

Dimensioning: 23 VA

Ambient temperature: 0- 0°C

Relative humidity: 0-90%

Degree of protection: IP30

Connection

LED fault

F1 fuse

secondary

LED operation

Button reset

LED alarm

Manual release button

Smoke detection system RMS

09/11 - 9

Construction subject to change. No return possible!

27.03.2019Version:

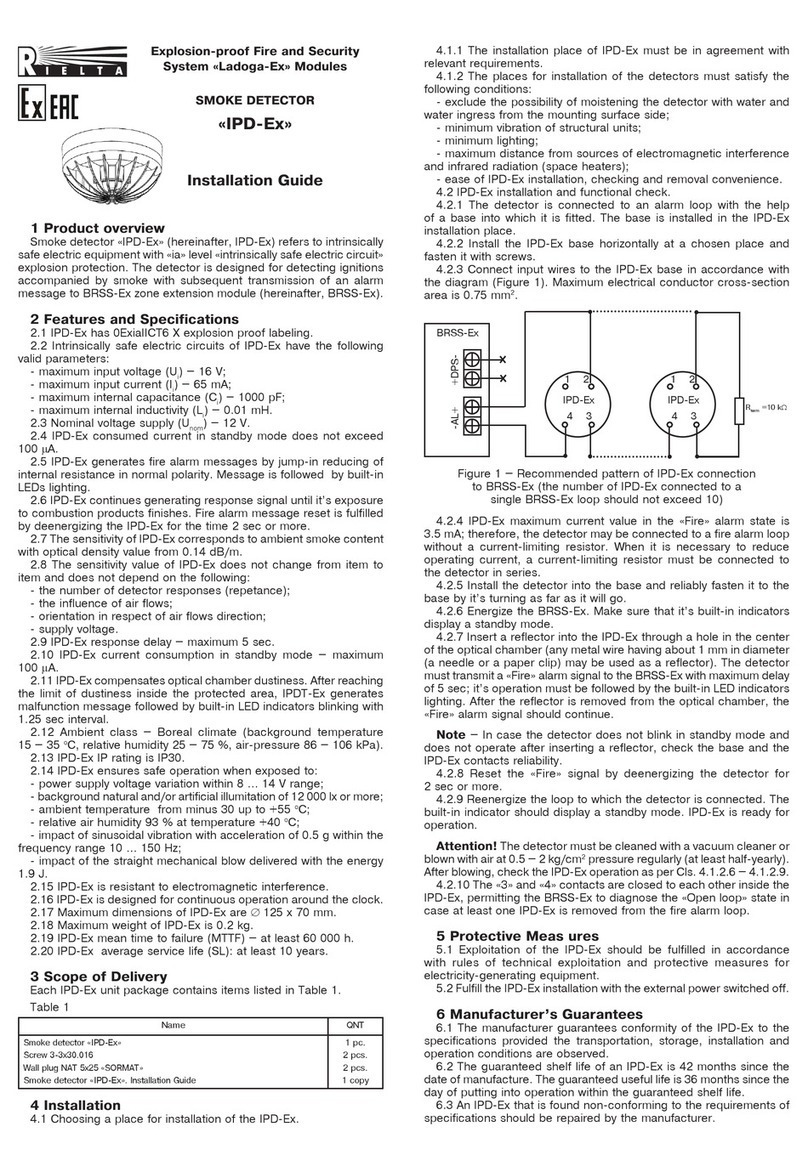

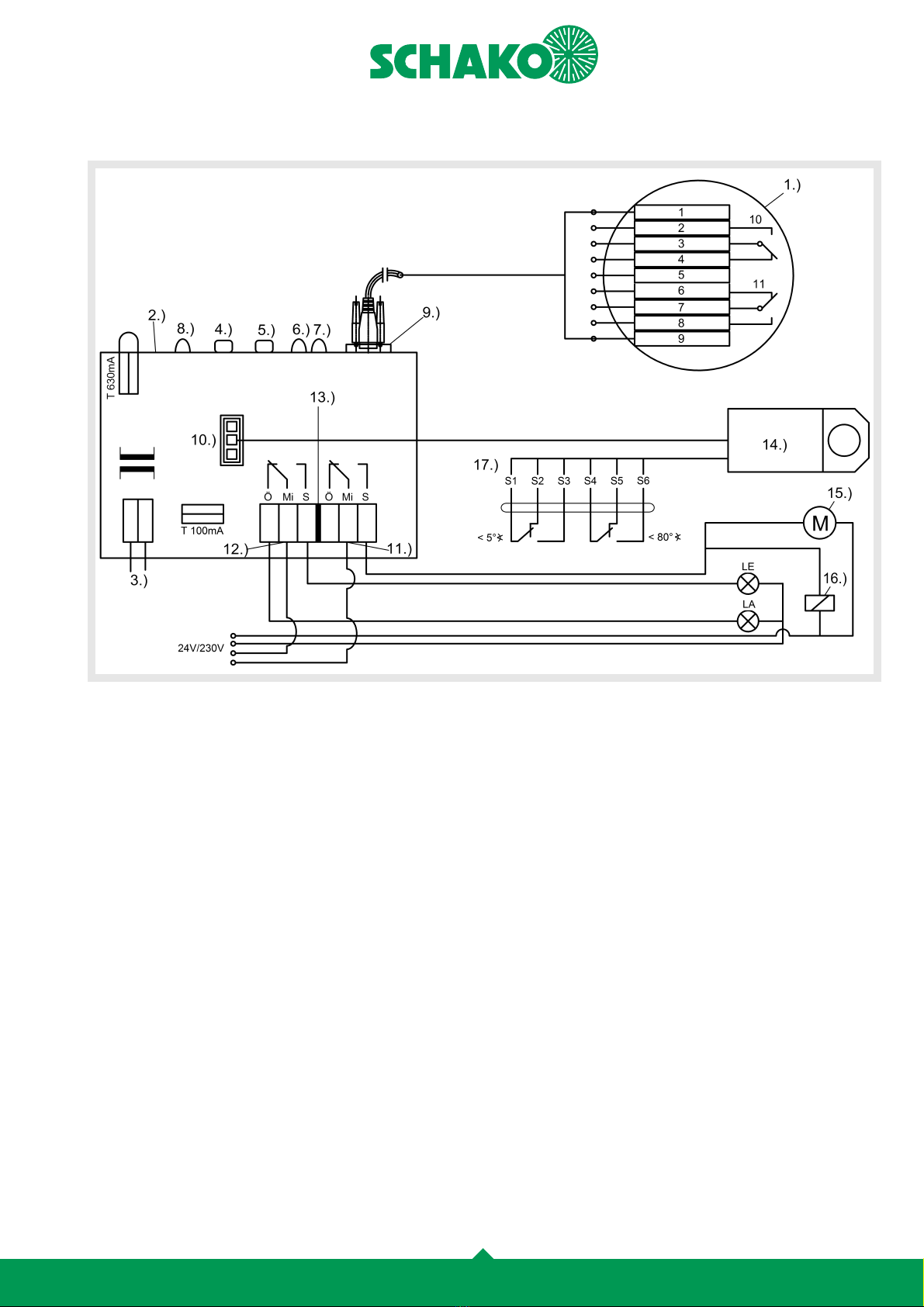

Circuit di gr m of rel y module

Cont ct ssignment RMS-L:

The de-energised state is shown. For relay module, also the

alarm or fault condition.

2 V AC/DC

2 V DC 5A

250 V AC 5 (1)A

230 V AC 50 Hz

Primary

2 V AC

230 V AC

Second-

1.) Smoke detectors

2.) Relay module

3.) Mains connection

.) Reset button

5.) Manual release

6.) LED fault

7.) LED alarm

8.) LED operation

9.) Connection RMS

10.)

AMP plug for 2 V AC/DC actuators (max. 10 VA)

11.) Selector switch 1, e.g., actuator

12.) Selector switch 2, e.g., light

13.) Contact load of the selector switches

1 .) Spring return actuator 2 V AC/DC for fire damper.

SCHAKO product or external product (for the techni-

cal data, please refer to the motor data sheet)

15.) Spring return actuator 2 V AC/DC / 230 V AC SCHA-

KO product or external product (optional) (for the

technical data, please refer to the motor data sheet)

16.) Magnetic clamp / pneumatic valve (optional)

17.) Limit switch spring return actuator

(connection is fitted in a T-piece socket on-site)

1 GND

2 Work contact

3 Centre contact

Rest contact

5 Test switch / RST

6 Rest contact

7 Centre contact

8 Work contact

9 +2 V

10 FAULT

11 Alarm

Ö = NC contact

Mi = Centre contact

S = NO contact

LA = Ventilation OFF (option)

LE = Ventilation ON (option)

Smoke detection system RMS

09/11 - 10

Construction subject to change. No return possible!

27.03.2019Version:

M inten nce / Inspection

Maintenance of the smoke detection device for fire and smoke

dampers must be carried out once a year or after a fault mes-

sage, due to contamination.

Note

Installation and wiring must be carried out by authorised elec-

tricians only. The agreed regulations of the technic, safety and

accident prevention regulations as well as the VDE guidelines,

regulations of the local EVU's and the wiring instructions and

connection plans of the manufacturer, must be adhered to when

installing, wiring and commissioning. When wiring the junction

boxes, make sure to earth the shielding. The smoke detector

must be used according to this brochure description.

M inten nce instructions

The SCHAKO smoke detector type RMS

ΙΙ

-L permanently moni-

tors itself and gives an error warning to the central unit if there

is a mechanical or electrical defect or if it is too heavily soiled.

In case of a power failure of the smoke detector, a fault message

is also sent to the central unit. This permanent self-monitoring

allows a yearly maintenance interval.

M inten nce includes the following ctions:

Inspection instructions

The SCHAKO smoke detector type RMS

ΙΙ

-L permanently moni-

tors itself and gives an error warning to the central unit if there

is a mechanical or electrical defect or if it is too heavily soiled.

When a power failure of the smoke detector occurs, a fault mes-

sage is also sent to the central unit.

1. The type of use and installation situation must be checked

for the first time during commissioning and then after mod-

ification.

2. The electrical connections must be checked for correct con-

nection and perfect condition.

3. Checking whether the diode on the fitted smoke detector or

relay module flashes orange, thus signalling ready operat-

ing state.

. Electrical functionality control

The power supply of the smoke detector must be discon-

nected by removing the 9-pin Sub-D plug or by pressing the

reset button on the relay module. This causes the smoke de-

tector to send an alarm to the connected locking device,

which will close automatically. The diode on the smoke de-

tector or relay module is no longer lit. As soon as the power

supply has been restored and the alarm has been acknowl-

edged by pressing the reset button, the smoke detector

must return to the ready operating state, and the diode on

the smoke detector and / or relay module must flash orange

5. Fault control

On the smoke detector RMS

ΙΙ

-L, the transmitter and receiv-

er sensors must be covered. The diode on the smoke detec-

tor lights up permanently in orange. The fault contact

reports a fault. After that, the cover must be removed again.

The smoke detector must again return to the ready operat-

ing state, and the fault message is reset at the central unit.

6. Functionality control using test aerosols

When the smoke detector is fitted to ducts, a test aerosol

must be applied to the smoke detector through an inspec-

tion opening.. This must be done by applying the test aero-

sol to the smoke detector increasingly in pulsed form for

about 10 sec. When the alarm threshold values is exceeded,

an alarm message will be triggered, and the connected lock-

ing devices must close automatically. The diodes on the

smoke detector and on the relay module must light up in

red. After the test aerosol components in the surrounding

air of the smoke detector have decomposed to such an ex-

tent that the value drops again below the alarm threshold

value, the alarm message is still displayed on the smoke de-

tector and on the relay module. This is why the smoke de-

tector must be activated again by pressing the reset button

on the relay module. As soon as the diode on the smoke de-

tector type RMS

ΙΙ

-L flashes in orange again and the red LED

on the relay module goes out, the smoke detector is ready

to operate again.

7. Elimination of defects

If defects have been detected during maintenance, they

must be eliminated immediately. Defective components

may only be replaced with original parts delivered by SCHA-

KO. Repair of the smoke detector and of the relay module

must be carried out only by the appliance manufacturer.

If any of the connected shut-off devices are not closing,

even when the smoke detector and the relay module operate

faultlessly, then the shut-off devices themselves must be

checked.

8. If the maintenance and inspection instructions of this tech-

nical documentation are used for the annual check of the

functioning of the SCHAKO smoke detection system (RMS),

the smoke detector can remain in use until an inadmissible

deviation is detected.

Smoke detection system RMS

09/11 - 11

Construction subject to change. No return possible!

27.03.2019Version:

Order det ils Specific tion texts

Smoke detection system type RMS, with annual maintenance,

for installation flush with the duct or fire damper installation

with assembly part type EBT (extra charge), with maintenance

cover. Consisting of a housing, base, cover plate, similar to RAL

9010 (white), a mounting frame made of sheet steel with seal

and with connecting cable 2.0 m long with Sub-D 9-pin connec-

tion. For use on fire and smoke dampers, with electric or pneu-

matic release devices working by the zero-current closed /

depressurised closed functional principle, and with magnetic

clamp and lifting magnet.

Two sensors self-monitoring permanently for correct function-

ing measure the air contamination due to smoke with a special

scattered light procedure outside the housing, without using a

detection chamber. They measure the degree of contamination

at two points on the surface of the safety glass. Alarm and fault

messages each take place via a potential free change-over con-

tact. Manual triggering of the smoke detector possible via a re-

set button (at an extra charge).

Fastening with screw mounting (SM) (with thumb nuts or Park-

er screws).

Includes relay module (-RM) for supplying power and for alarm

transmission incl. test switch and reset button

- with transformer for connection to 230 V AC, 50 Hz

Connection 2 V DC.

Product: SCHAKO type RMS

Accessories:

Accessories:

Order ex mple

RMS

ΙΙ

-L-RM

Unless st ted otherwise, the thick-fr me model will be

delivered!

Assembly part

for duct installation

-EBT

Relay module

-RM

incl. RST

Smoke detection system

Type RMS

ΙΙ

-L

without flange

with rubber lip seal

-REBT

Assembly part

for duct connection

with flange, on both sides

according to EN 12220

-REBTF

- Assembly part (-EBT) for simple duct installation in front of

the fire damper. Consisting of galvanised sheet steel with

connection flanges. Housing leakage according to DIN EN

1751, class B, at a duct pressure of up to 1000 Pa

- Assembly part (-REBT / -REBTF) for simple installation in

round ducts in front of the fire damper. Consisting of galva-

nised sheet steel. Housing leakage according to DIN EN 1751,

class B, at a duct pressure of up to 1000 Pa.

- without flange (-REBT), with rubber lip seal made of spe-

cial rubber.

- with flange (-REBTF), on both sides, to EN 12220.

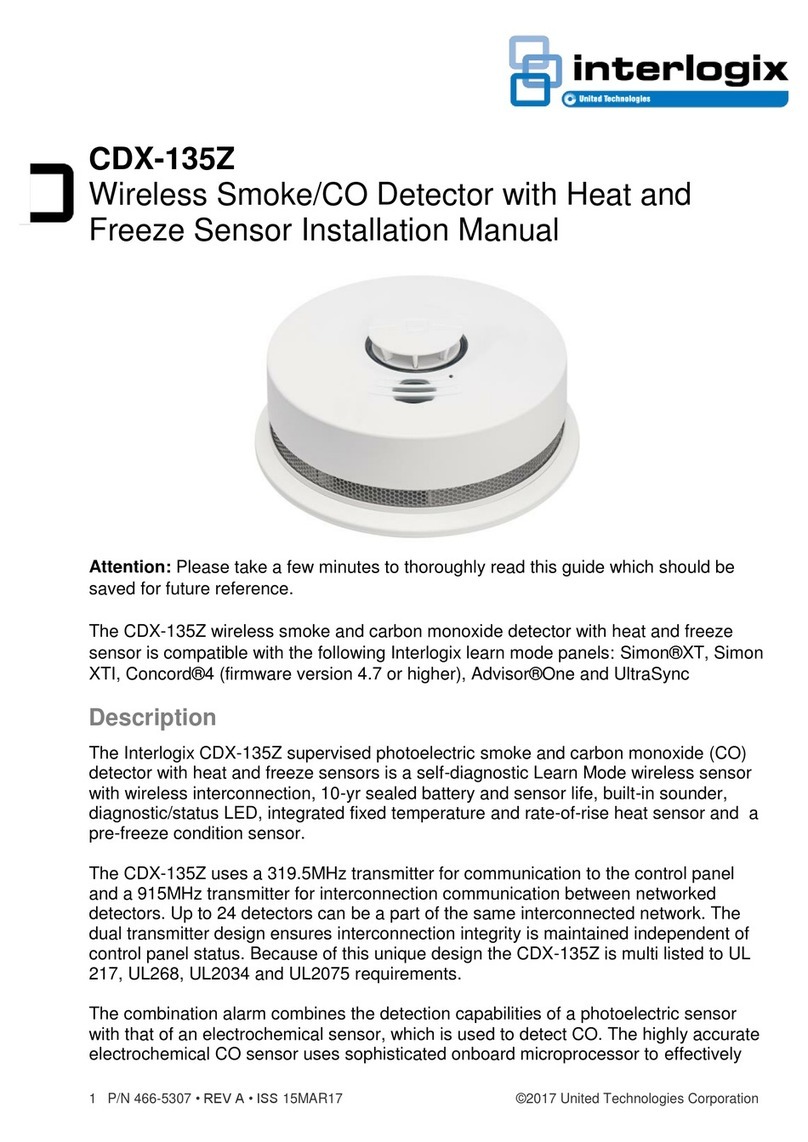

This manual suits for next models

1

Table of contents

Popular Smoke Alarm manuals by other brands

Interlogix

Interlogix CDX-135Z installation manual

Tyco

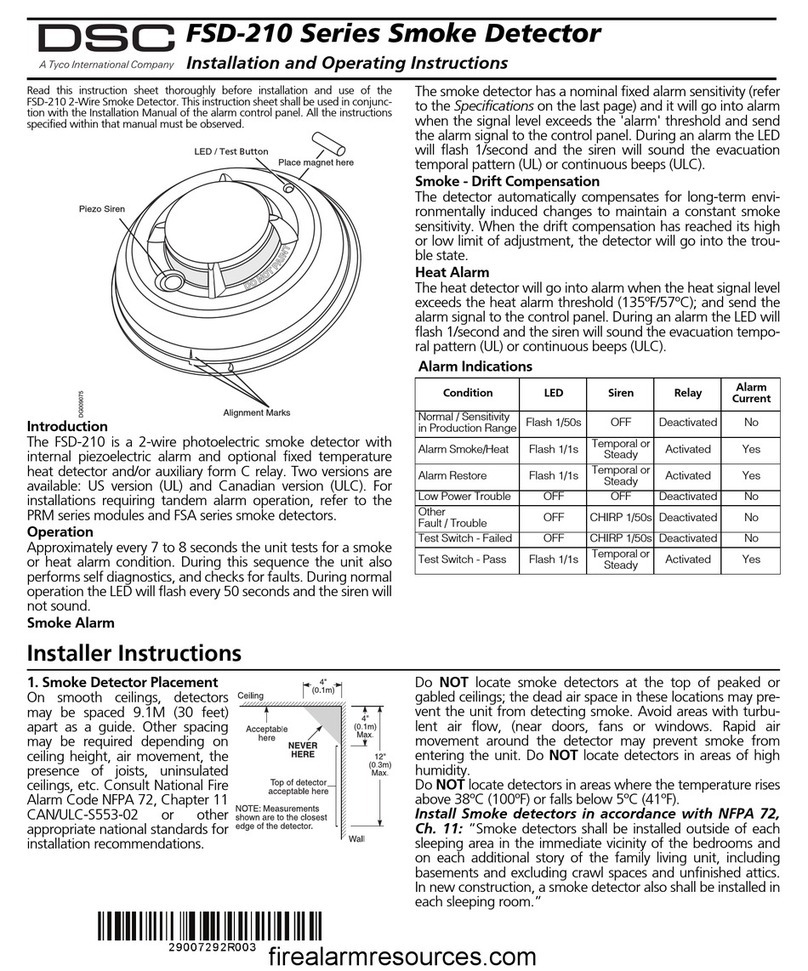

Tyco DSC FSD-210 Series Installation and operating instructions

Smartek

Smartek NUBI 4.0 manual

Ei Electronics

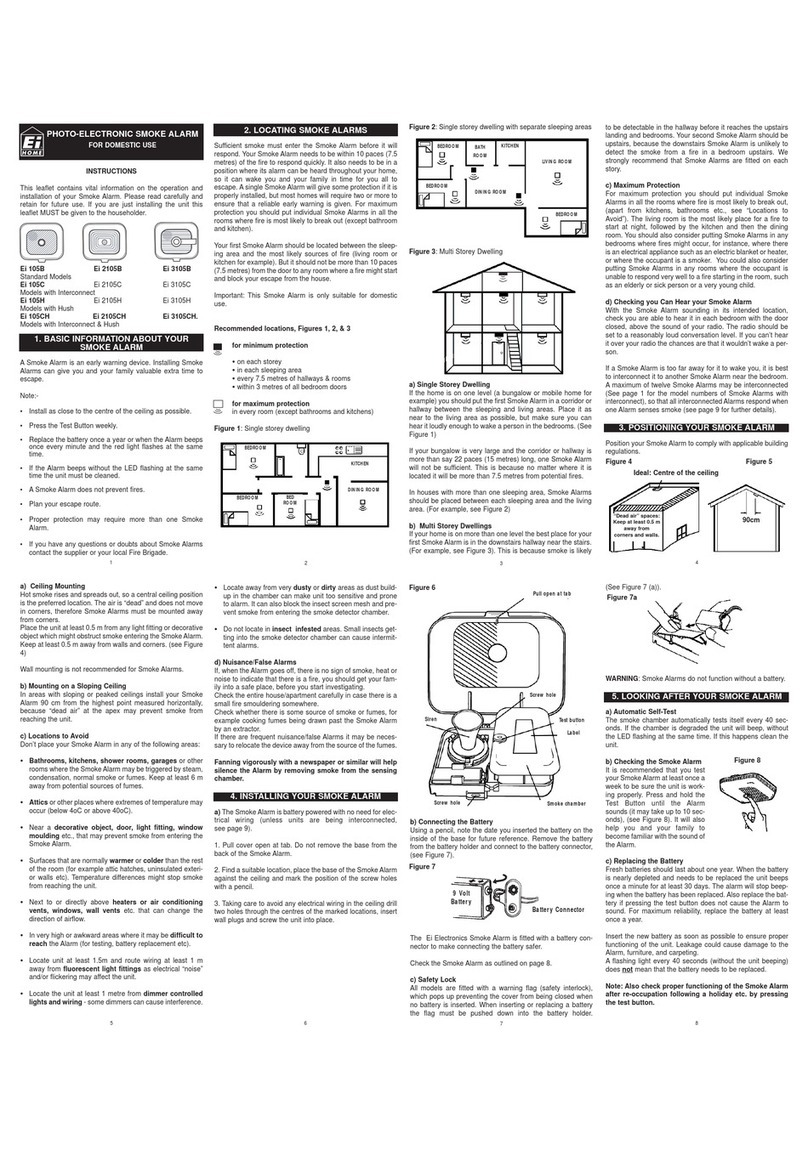

Ei Electronics Ei 105B instructions

Teletek electronics

Teletek electronics SensoIRIS T110IS installation instructions

Honeywell

Honeywell 5800COMBO Installation and setup guide