Seite 3

1. General Information

1.1. Notes regarding the operating instructions

Read the following hints before installing and operating this machine!

Make yourself familiar with this machine by reading this operating instructions carefully.

Within these operating instructions there are indicated the following safety notes and hints:

means Attention. Notes for probable danger and for avoiding mistakes.

means notes and hints regarding certain operation procedures.

1.2. Notes regarding warranty

The installation and initial operation has to be done by an authorised supplier or service technician.

Only trained persons are allowed to operate this machine. When required, the training has to be repeated.

Supervisory and operating staff have to read the operating instructions carefully before initial

operation of this machine. Starting, operating and cleaning have to be done according the

operating instructions and are only allowed after having been introduced to the way of working.

In case of

-unauthorised installation

-unauthorised electrical installation

-wrong operation

-misuse

-constructional alteration

-detaching security or protecting equipment

-and in case of using non-original Scharfen spare parts

any responsibility from our side is refused.

In above cases the operator acts on his own risk and is responsible himself for damages which might

occur.

Therefore, only use original Scharfen spare parts!

In case high pressure or steam cleaning devices or water plugs are used any claims

regarding warranty will be refused.

This is valid also for faults and damages which are caused by natural wear and tear.

The pictorial representation might differ from the machine supplied because of regional specific

requirements or as a result of technical improvement.

The contents of these operating instructions is not affected by that.

1.3. Notes regarding security

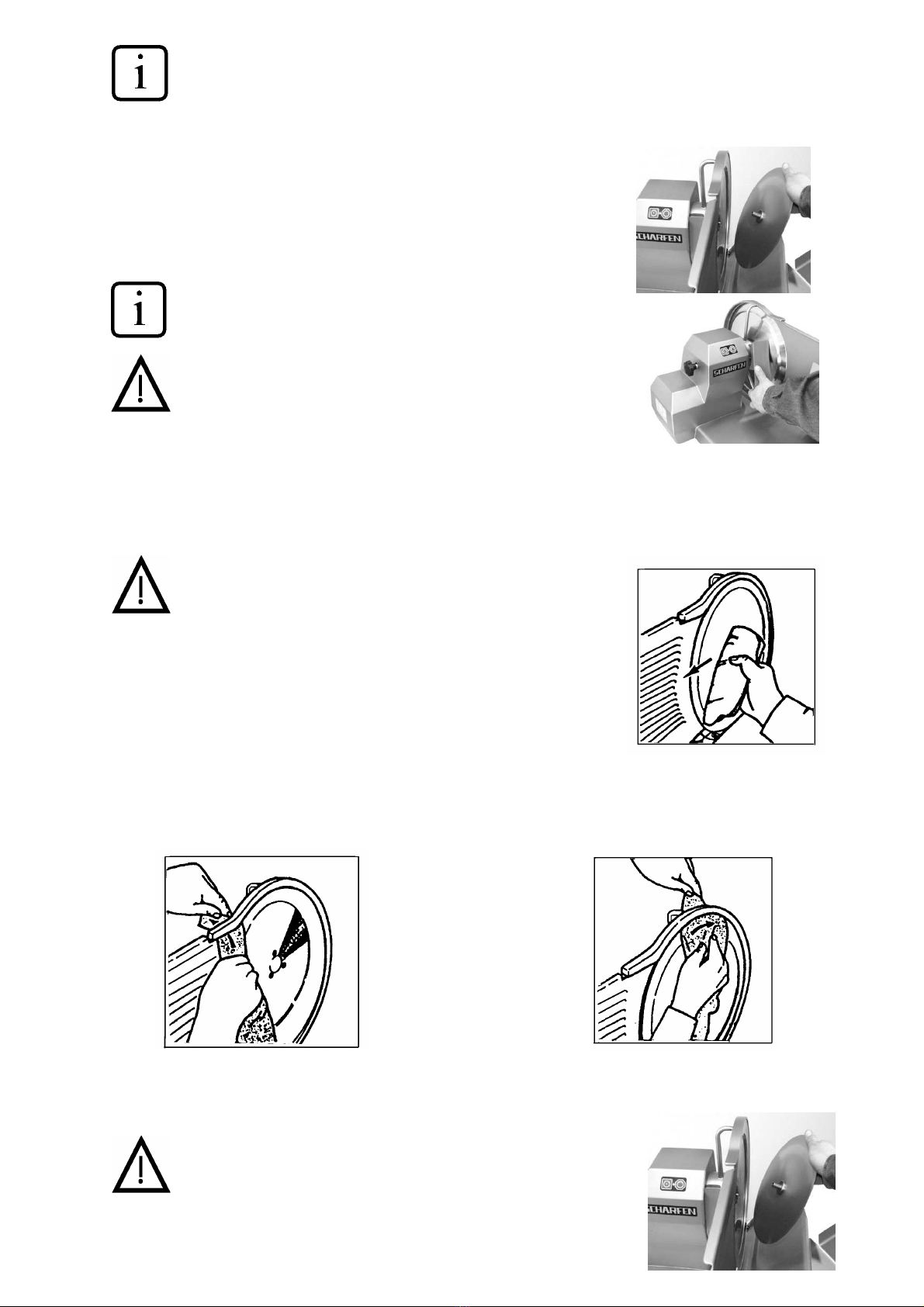

This machine corresponds to legal security and hygienic requirements. Nevertheless there is a risk of

getting hurt in case of wrong or inattentive operation or maintenance. Especially for your hands or fingers

there is a risk of injury. The operating staff has to be trained carefully how to operate and maintain this

machine according to these operating instructions.

Pay attention in any case to the following notes regarding security:

See to it that unauthorised, untrained persons and in particular children cannot start the

machine.

It is not allowed to detach, to modify or to disregard protecting or security equipment.

Otherwise there is a high risk of injury.

Always work with concentration, do not let distract yourself from your work.

Only cut food products as indicated in these operating instructions.

Never carry out experiments. Never try to cut foreign material.

Never cut deep frozen products.

Never check the sharpness of the blade with your fingers.