Important Safety Instructions

1. Intended Use:

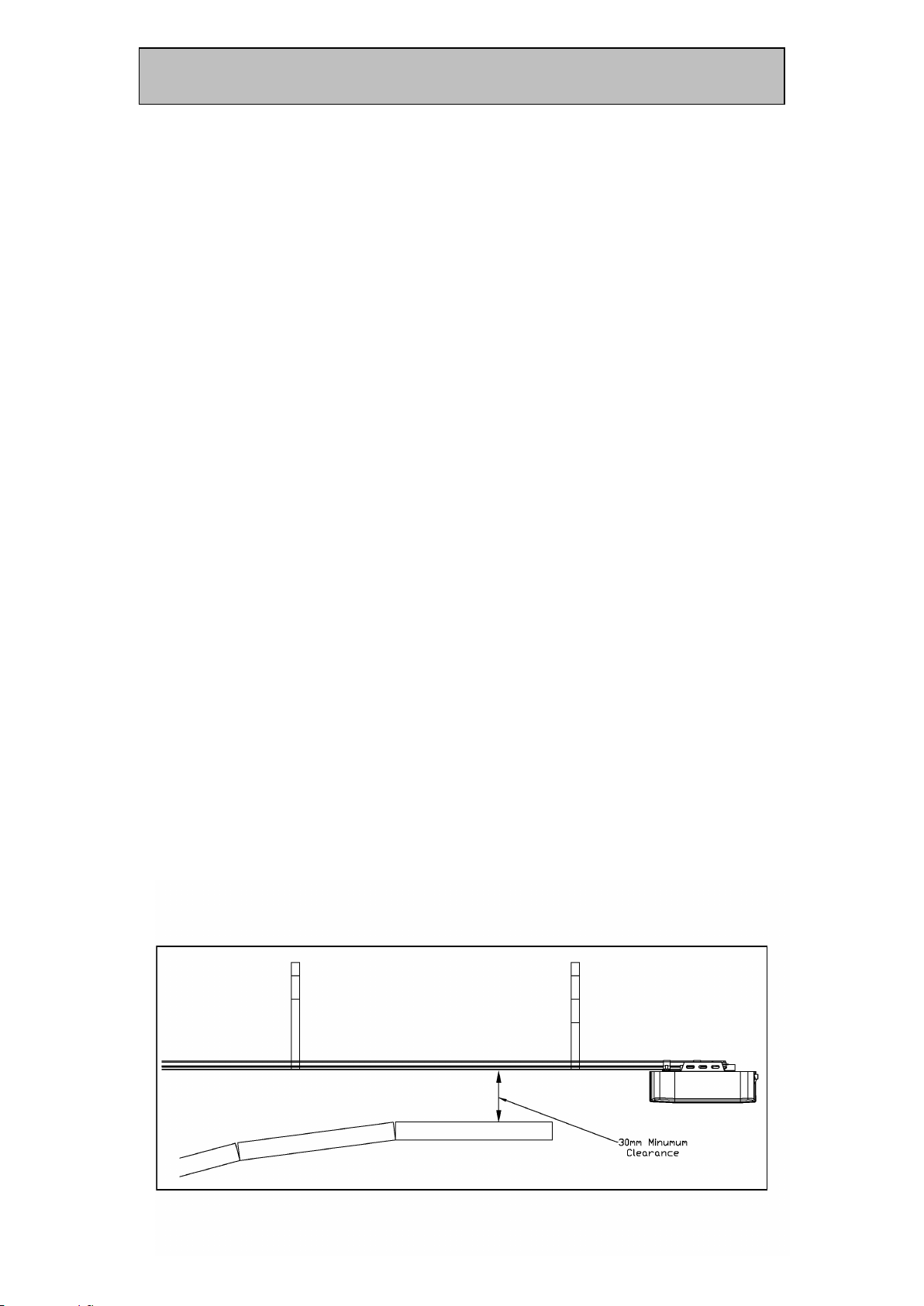

The garage door opener is designed exclusively for impulse operation of spring-balanced Sectional and Up & Over garage doors

in private / non-commercial operations. Door systems used in a public area have only one protective device, e.g. the force limiter,

and may only be operated under supervision. The garage door opener is designed for operation in dry rooms only.

2. Unintended Use:

The garage door opener must not be used for purposes other than for the automation of garage doors. Continuous operation and

the use in the commercial sector is not permitted. The opener must not be used with doors without fall protection.

3. Qualifications of the fitter and installer

Proper fitting and maintenance should only be done by a competent / specialist company or a competent / qualified person in

accordance with the instructions that can ensure the safe and flawless operation of the assembly. A competent person is, in

accordance with EN 12635, considered a person who has appropriate training, qualified knowledge, and practical experience in

order to mount a door system properly and safely.

4. Safety instructions for installation, repair, maintenance, and disassembly of the door system DANGER!

Compensation springs are under high tension

The adjusting or loosening the compensating springs can cause serious injuries! If necessary, maintenance and repair work must

be made by a trained door system technician only! Never attempt to replace, readjust, repair, or move the balancing spring for the

counterbalancing of the door or their holders. Inspect that the entire door system (pivots, door bearings, ropes, springs and

fastenings) for wear and possible damage. Check them for signs of rust, corrosion and cracks. Error in the door system or

misaligned doors can cause severe injury! Do not use the door system if repair or adjustment work needs to be done!

Mains Voltage

Danger! Risk of electrocution upon contact with the mains voltage. Therefore please note, the following instructions: Electrical

connections may only be performed by a qualified electrician. Electrical installation on site must comply with the relevant safety

regulations (230/240 V AC, 50/60 Hz).

Disconnect the opener from the mains before performing any opener service.

Dear Customer

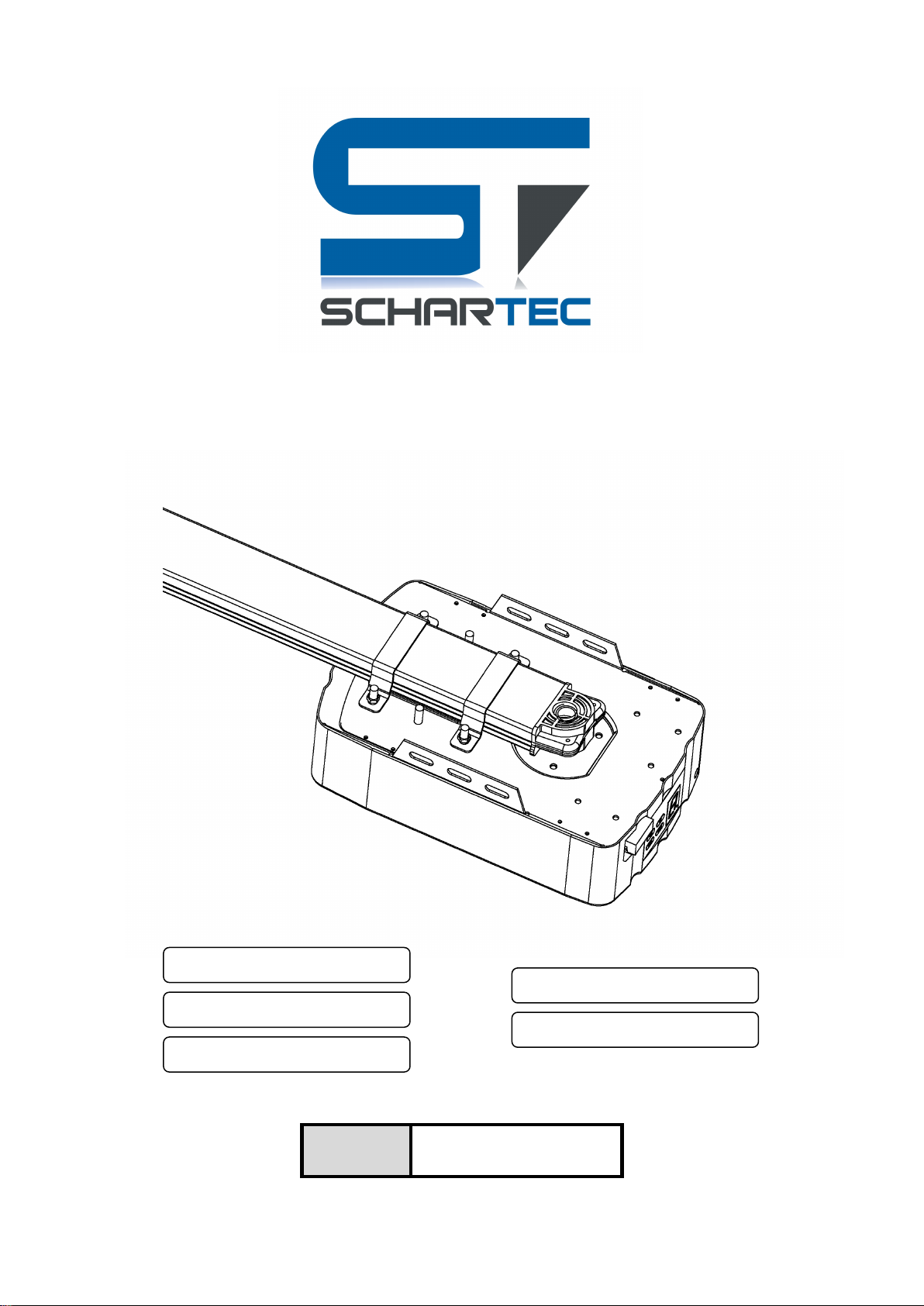

Thank you for choosing a quality product from Schartec. Thanks to our unique quality management system, we continuously

ensure that all Schartec openers meet the highest standards of quality and comfort. Thank you for your confidence in

purchasing our product and we hope you enjoy your new Schartec garage door opener!

Declaration of Conformity (CE)

Schartec Move series garage door openers meet the requirements of the applicable European and national guidelines.

Compliance was demonstrated that corresponding declarations, certificates, test reports and documents have been obtained by

the manufacturer and can be requested via www.schartec.de/en/. The FST-03 radio equipment type (Art.No.ST104032)

complies with Directive 2014/53 / EU. The full text of the EU Declaration of Conformity is available at the following Internet

address: www.schartec.de/en/