English

10. Model preparation

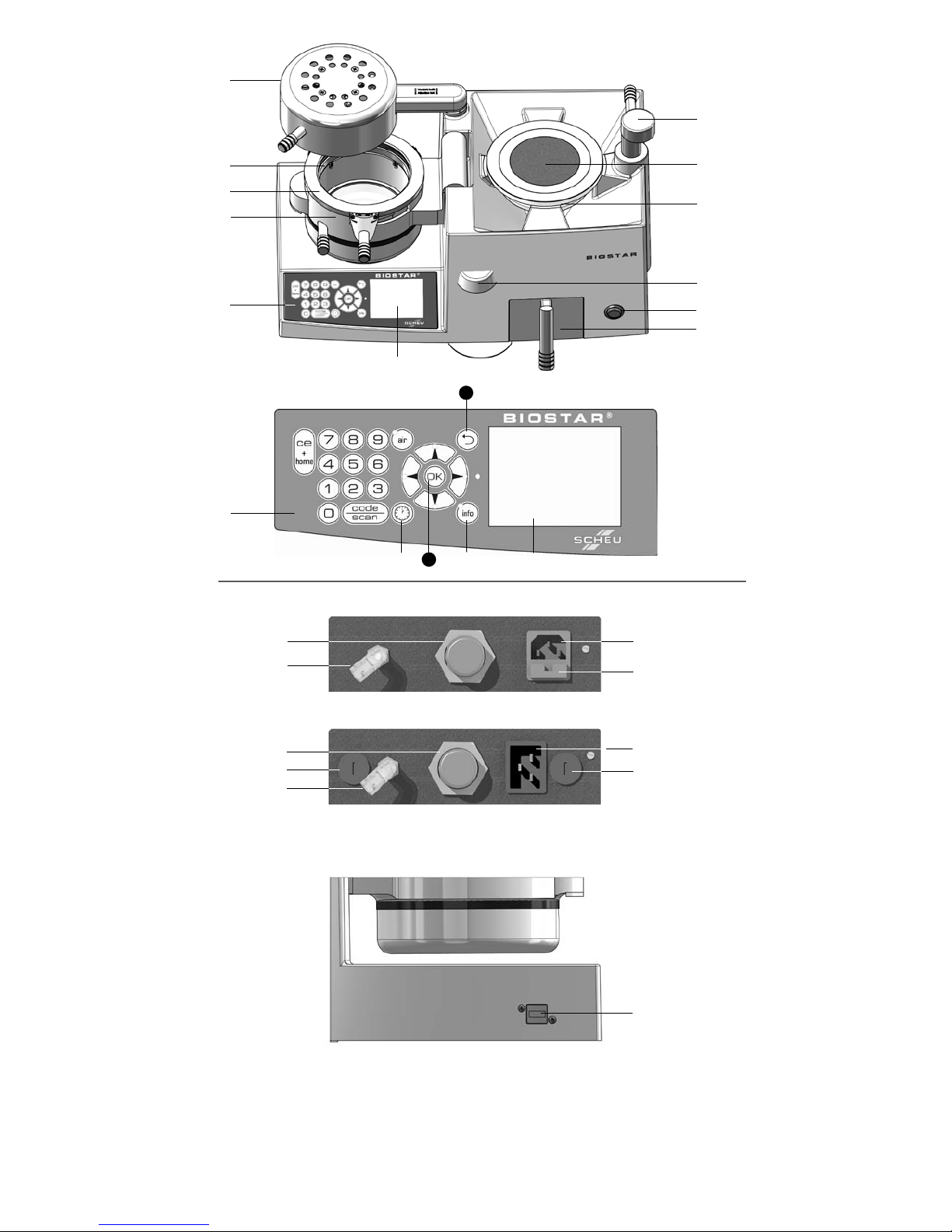

Whenusinghardorhard-elasticmaterial,modelsareplacedintothemodelcup4,lleduptoitsupperrimwithstainlesssteelpellets.Whenus-

ing soft elastic material, models can be placed on the working platform 6.In both cases, the model should be placed with the incisors facing to the

right towards the locking handle 3or to the left towards the pressure chamber 2toensureequalthicknessofthematerialbetweenthequadrants.

11. Scanning/programming by setting code or time

Ourpressuremouldingmaterialhasa3-digit-codewhereallrequiredinformationontemperature,heatingtimeandcoolingtimeisprogrammed.This

code is printed in plain text and as bar code on our pressure moulding blanks or foils, except for material with thicknesses below 0.1 and 0.15 mm.

After selecting your material, press the button „code/scan“.

The scanner Pisnowactivated.Presentonlynowthebarcodeofthechosenmaterialtothescanneruntilyouhearabeep.Alternatively,thecode

can be programmed manually.

Programthedigitsandconrmbypressingthebutton„code/scan“again.Youeitherhavetheoptiontoentertheheatingtimesmanually.Doingso,

press the key with the clock symbol Q,entertherequiredheatingtimeandconrmbypressingthebuttonQagain.

12. Heating

After programming, directly swivel the infrared heater 1over the fixed material. The temperature is regulated automatically by a thermo element.

The colour of the heater might vary from bright to dark.

13. Pressurising

Beforetheendoftheheatingcycleisreached,audiblebeepingsoundsareheard(+5sec.upto0sec.=beepingsounds/0sec.upto5sec.con-

tinuousbeepingsound).Theheatershouldbeswivelledbackat0sec.,at-5sec.theheaterisswitchedoffautomaticallyforsafetyreasons.Bring

the pressure chamber 2over the model by turning it 180° to the right (make sure the sealing surface is clean) and lock it into place by turning

the locking handle C180° forwards. Automatically the magnetic valve opens, the pressure chamber fills with air and the cooling time starts, signal

byblueLED.

14. Depressurising

Opticalsignals(blueashingLED)andacousticsignals(4beepingsounds)indicatethecoolingtimehaselapsed.Presstheashingbutton„air“ to de-

pressurise the pressure chamber.After approx. 3 seconds 4 beeping sounds indicate the end of depressurising.Now turn the locking handle 3180°

backwards, push the locking ring K to the left and open the pressure chamber 2. Remove the model. The machine can now be used for

the next pressure moulding operation.

15. Special programs using the heating support

Ifyouwanttofabricatepositioners,mouthguardsorsplints,youcanmanuallyprogrammetimeintervalsof60/120/180/240seconds.Doingso,the

pressure chamber has to be closed and the locking handle opened. These intervals are chosen to heat up or to seal the occlusal surfaces using the

heatingsupport.(REF3452).Afterhavingenteredthecorrespondingheatingtime,theinfraredheaterwiththeheatingsupporthookedinisswivelled

forwardsintheheatingposition.Dependingonthematerialthickness,thisoperationcanberepeatedseveraltimes.

16. Service/Maintenance

TheBIOSTAR®machine is maintenance free. However, the air tube including the filter element should be examined regularly. If moisture or debris

is released, the filter must be replaced. The model cup 4with air holes and model platform 6can be cleaned with an air nozzle or steam jet. The

reflecting parts of the pressure chamber should be cleaned regularly to obtain the best heating results. For cleaning remove the aluminium adjusting

ring Lfrom the pressure chamber 2completely. The sealing surfaces, the sealing ring and the 4 rivets and springs should be cleaned and lightly

greasedalso.Placetheadjustingringbackontherivetsandspringsensuringthatthesealingringcomestothetopandthatthewholeunitismovable.

Pleasealsorefertotheenclosed„Guidelinetosolvetechnicalproblems“.

17. Service updates

You‘llreceivearegistrationcardwiththemachine.Bysigning-up,you‘llbeprovidedautomaticallywithinformationonupdates.Youcandownloadthe

updates on our website www.scheu-dental.com/downloads/support.

ExtracttheletoanemptyandformattedremovableUSBdevice.ConnecttheUSBdevicetothetheservice interface Son the back of the machine.

Start the machine, then press 5 times the button „OK“. Now you‘ll be asked to enter the pass word for the service menu.

Enterthefigure „1“ and confirm by pressing the button „OK“.Bypressingaginthefigure „1”theupdatestarts.Aftertheupdateisnished,quit

the service menu by pressing the button „CE+home“.

Technical modification, which serve for improvement, are subject to our agreement. Reproduction, even in extracts, is only allowed with our written approval.