Interceptor

Interceptor

Page 3 of 6

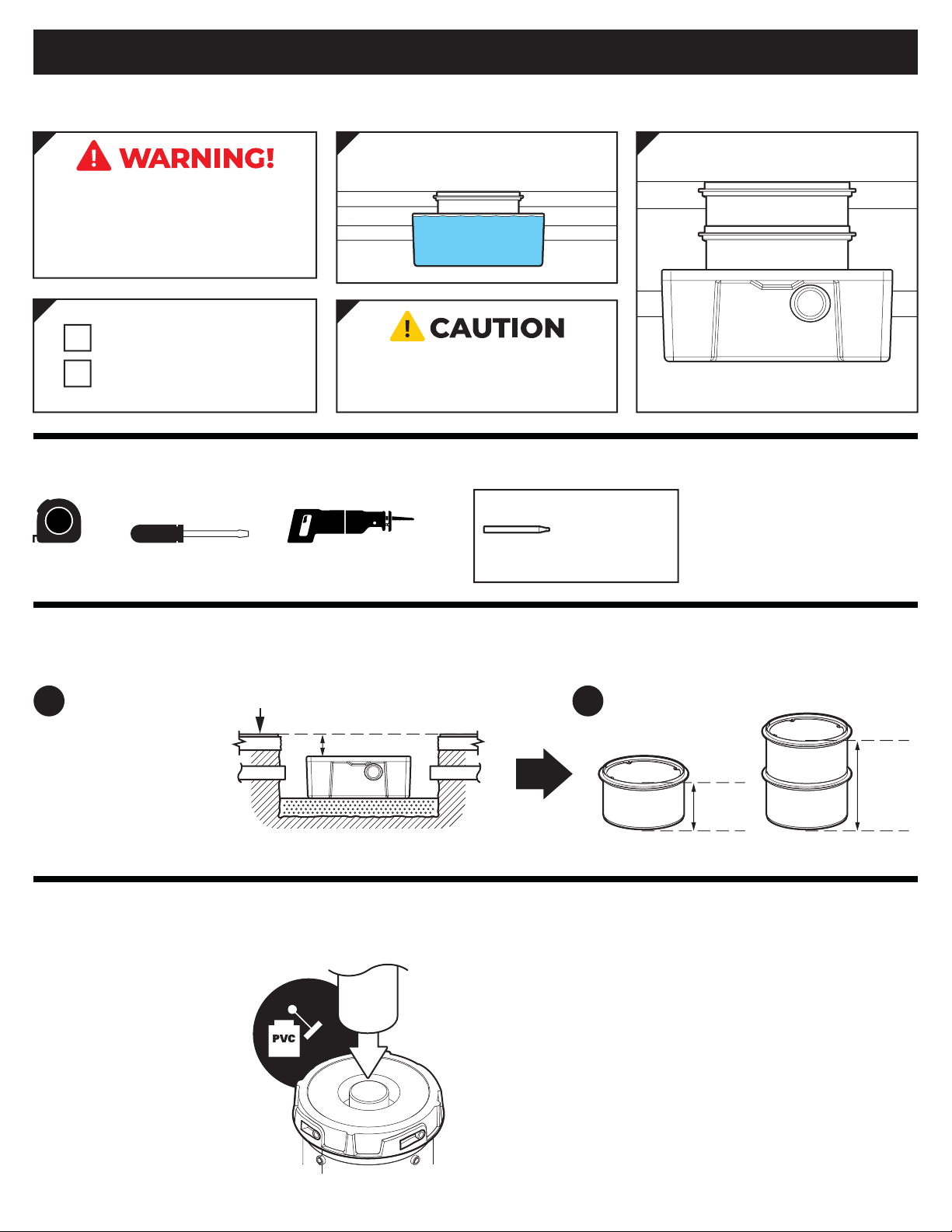

FCR1 Installation Guide

SPECIAL PRECAUTIONS

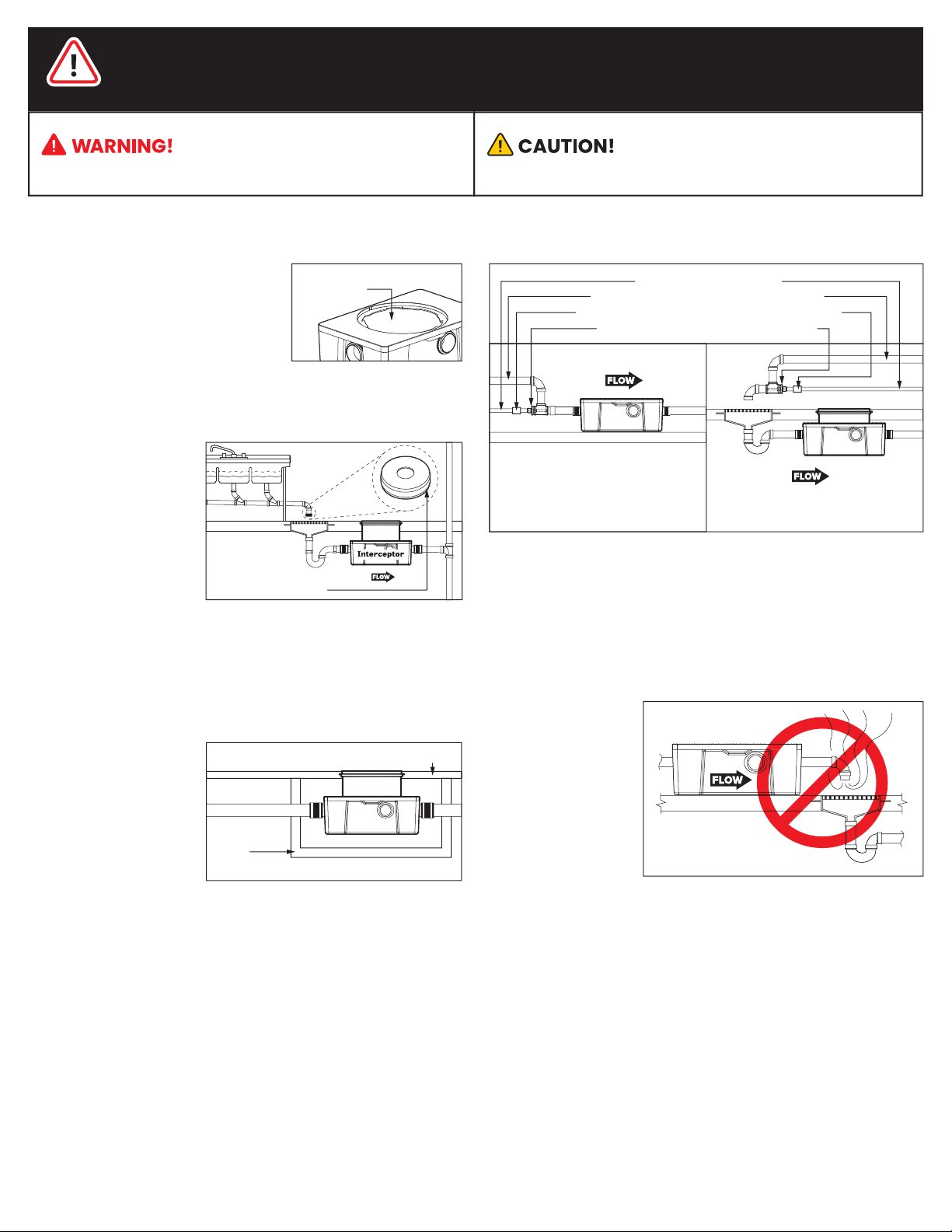

Install unit on solid, level surface in

contact with the entire footprint of

unit base; for suspended

installations design trapeze to

support the wet weight of the unit.

Do not partially support unit or

suspend unit using metal

U-channel to create a trapeze.

Fully Support Base of Unit

For above grade installations ensure

heavy inlet and outlet piping (such as

cast iron or long runs) is properly

supported or suspended during the

entire installation process to prevent

connection failure or damage to

bulkhead fittings.

Support Inlet and Outlet Piping

DO NOT

COMPACT

BACKFILL

For Schier Grease Interceptor Installations - Failure to follow this guidance

voids your warranty

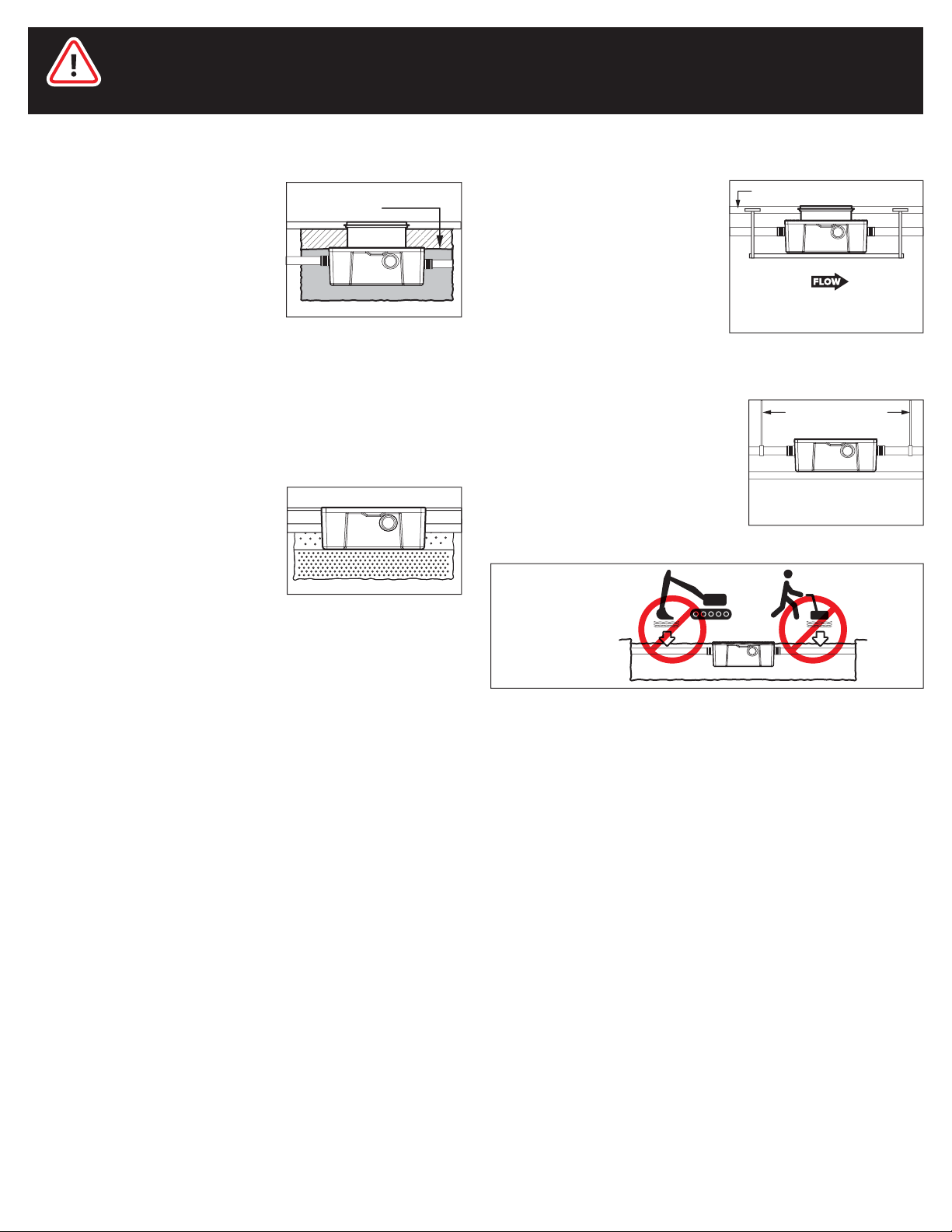

High Water Table Installations

Interceptors and risers are not designed

to withstand water table height in

excess of the top of the unit when buried

(see figure). If it is possible for this to

occur, install the interceptor and risers in

a water-tight concrete vault or backfill

with concrete or flowable fill (wet

concrete and flowable backfill should be

poured in stages to avoid crushing the

interceptor). At risk areas include but are not limited to tidal surge areas,

floodplains and areas that receive storm water. Great Basin™ models

that are direct buried in high water table scenarios must be installed

with an anchor kit. Models GB-50, GB-75, and GB-250 use model AK1

anchor kit. Model GB-500 uses model AK2 anchor kit for use with

deadmen anchors. Models GB-1000, GGI-750 and GGI-1500 use model

AK3 anchor kit for use with deadmen anchors.

max water table height

for direct burial

pipe supports

Interceptor

Interceptor

Interceptor

Interceptor

concrete floor

suspended installation

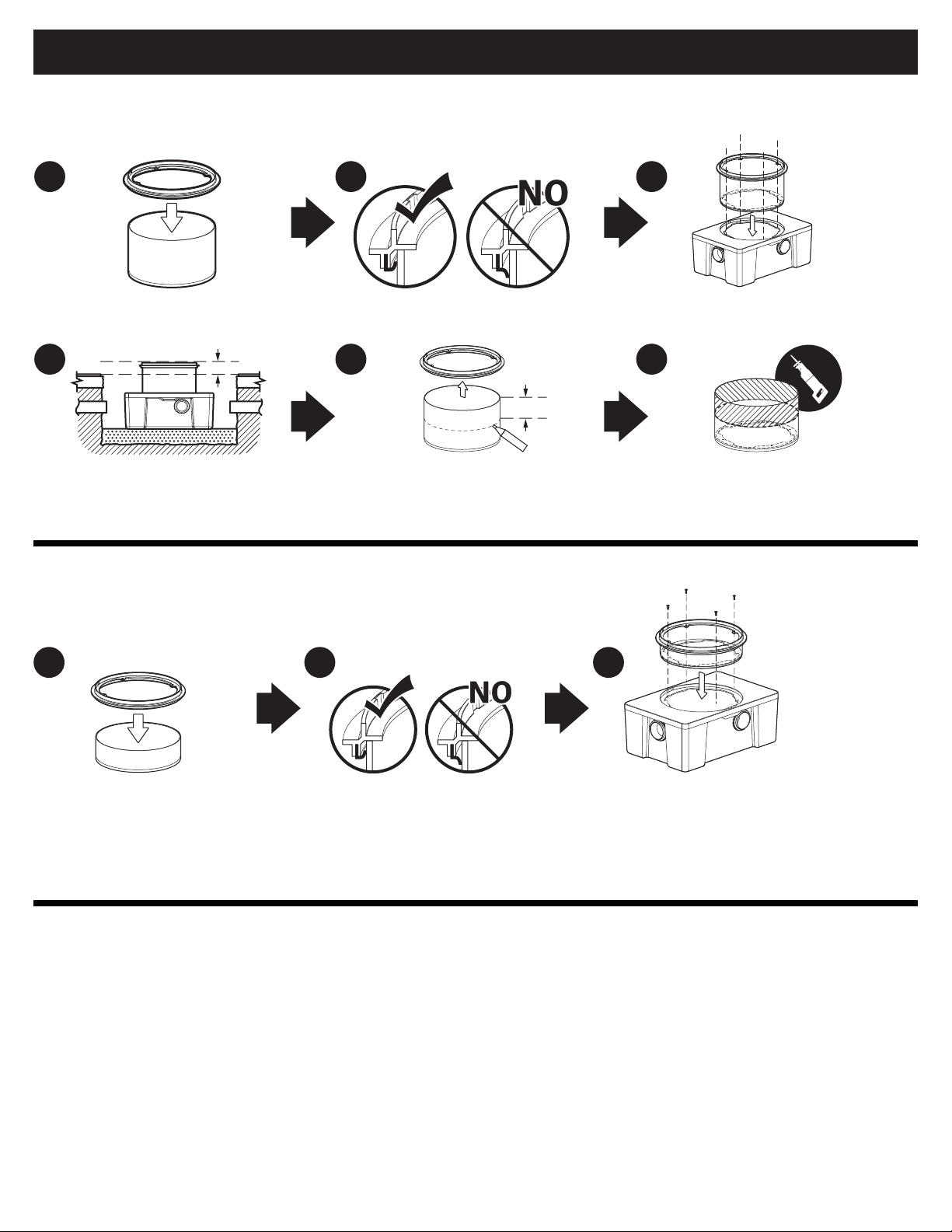

Flush-to-Grade Burials

Flush-to-Grade buried installations

(without a riser) are not recommended

for heavy foot traffic areas without the

use of an internal gusset support kit

SGK2 (for GB2) or SGK3 (for GB3).

Interceptor

Interceptor