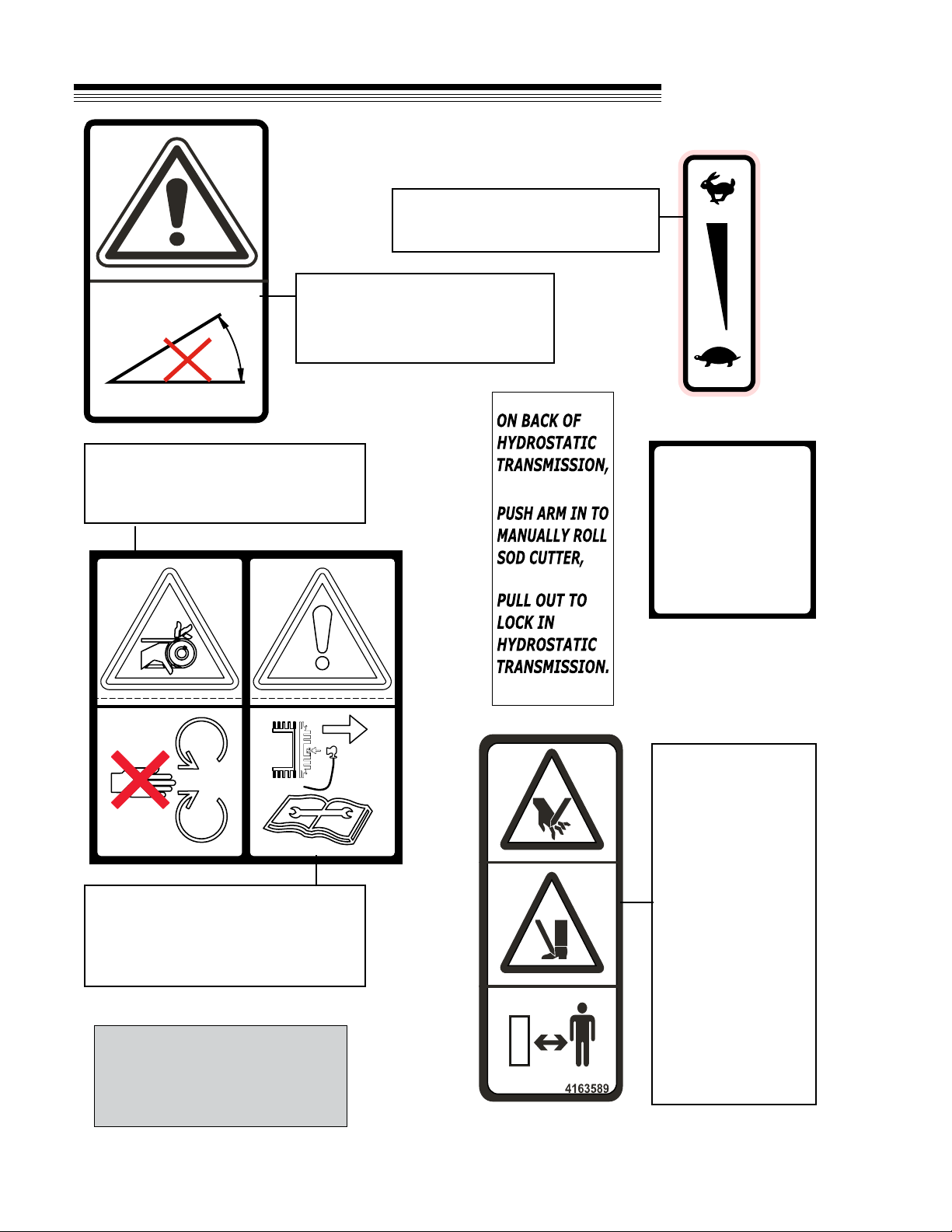

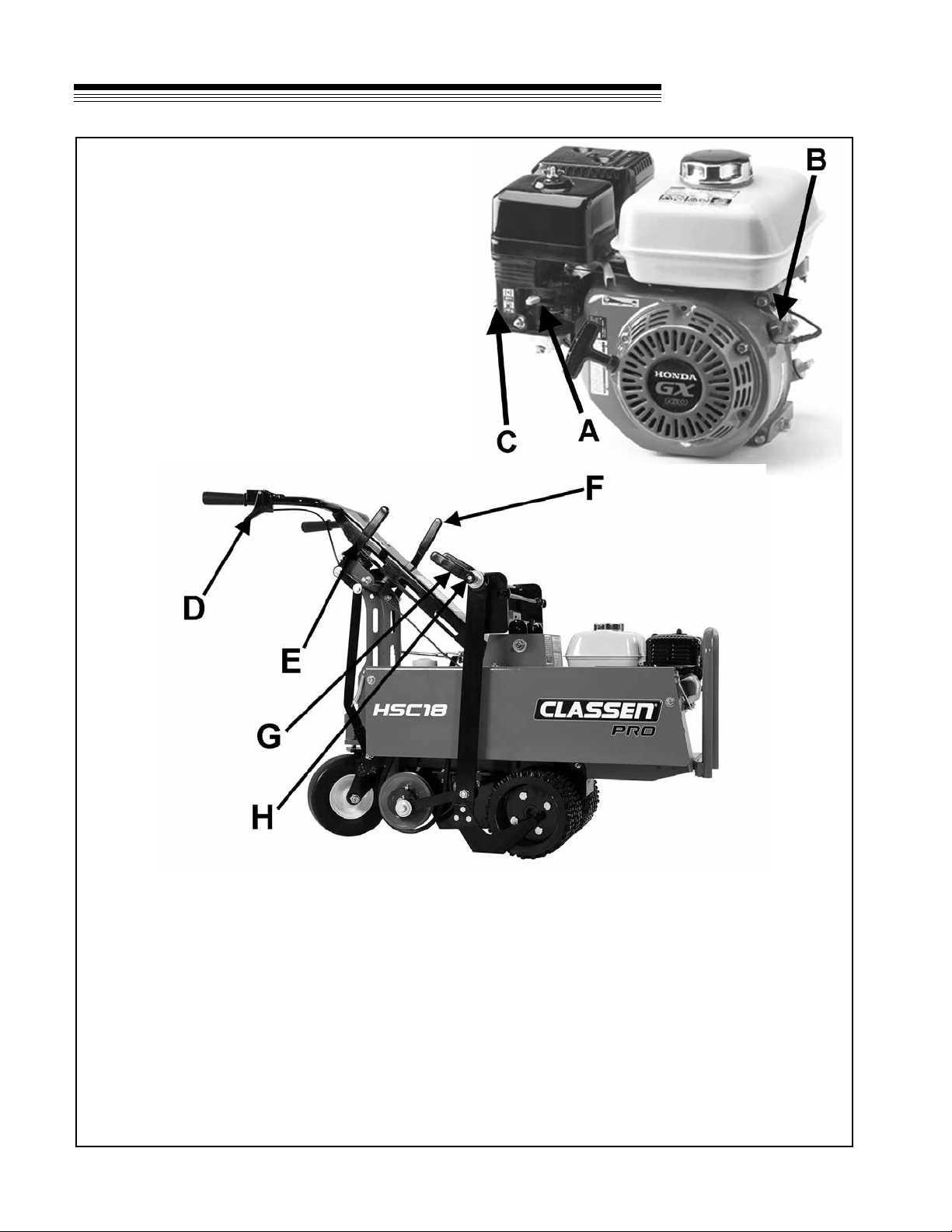

Machine Preparation

Operator preparation and

training

Read the Operation & Safety

Manual

• If an operator or mechanic cannot read English, it

is the owner's responsibility to explain this material

to them. If any portion of this material is unclear, con-

tact your factory representative for clarication.

• Become familiar with the safe operation of the

equipment, operator controls and safety signs. Be

prepared to stop the engine quickly in an emergency.

Do not operate or allow another person to operate

this machine if there are any questions about safety.

• All operators and mechanics should be trained. The

owner is responsible for training the users.

• Wear appropriate clothing, including safety goggles

or safety glasses with side shields when operating.

Do not operate barefoot or wearing open sandals.

Long hair, loose clothing or jewelry may get tangled

in moving parts.

• Wear hearing protection.

• Wear safety glasses.

•

Never allow underage children, unskilled or improperly

trained people to operate this equipment. Local regula-

tions can restrict the age of the operator.

• Keep warning labels and this operator's manual leg-

ible and intact. Replacement labels and manuals are

available from the factory.

• Do not operate machine while under the inuence of

drugs or alcohol.

• The owner/user can prevent and is responsible for

accidents or injuries occurring to themselves, other

people or property.

Site preparation and circumstances

• Evaluate the terrain to determine how to safely per-

form the job. Only use accessories and attachments

approved by the manufacturer.

• Clear the area to be cut of objects such as rocks,

toys, wire or other debris that may be thrown or get

tangled in the sod cutter.

• Identify and mark objects to be avoided such as

sprinkler heads, stakes, water valves, etc.

• Be sure the area is clear of pets and people, espe-

cially young children. Never assume they will remain

where you last saw them. Stop the machine if any

enter the area.

• Cut sod only in daylight or in good articial light.

Machine Preparation

• Do not tamper with or defeat safety devices. Keep

guards, shields and interlock safety devices in place

and in proper working condition. They are for your

protection.

• Keep all fasteners such as nuts, bolts and pins well

secured.

• Visually inspect blade and blade bolts for wear or

damage. Replace worn or damaged blades and

bolts.

• Verify that machine and attachments, if any, are in

good operating condition.

• Do not engage blade until ready to cut sod.

OPERATING SAFELY

In General

• Use extra care when loading or unloading the ma-

chine into a trailer or truck.

• Use caution when making turns and crossing roads

and sidewalks. Stop blade when not cutting sod.

• Do not run the engine in an enclosed area where

dangerous carbon monoxide fumes can collect.

• Never leave a machine unattended. Always turn off

blade and stop engine when leaving the operator po-

sition. When leaving the machine be sure the wheel

drive clutch is engaged.

• Use extreme caution when reversing or pulling ma-

chine towards you.

•

Starting Safety

• Start according to instructions in this manual or on

the machine.

• Before attempting to start the engine, make sure the

master clutch is disengaged.

• When starting the engine, make sure hands and feet

are clear of the blade.

• Do not change engine governor settings or over-

speed the engine. Operating the engine at excessive

speed can increase the hazard of personal injury.

SAFETY

3

PRO

SOD CUTTER