SCHLAGEL, INC.

VGC Gate Control

Page 5

Testing Gate Motion

The following instructions will allow you to electrically operate the gate with the push buttons on the VGC

Panel. No position readout is available until the control has been configured in Learn Mode but gate

movement and sensor operation can be visually observed using the LED on the front of the control. In

Manual Mode you can make small positioning adjustments to check sensor operation or just position the

gate manually until a full configuration can be made at a later date.

Remove the power to the VGC drive.

Note: I you don’t know i the VGC Panel you are working with has been previously programmed, hold

the CLOSE button during the irst power-up to ensure the control is in Manual Mode. Once in Manual

Mode, it will always power-up to Manual Mode until the installer per orms the escape sequence. This

sequence will be explained near the end o these installation instructions.

Re-attach the VGC Panel to the inverter using the ribbon cable. Apply power to the drive.

The Control will display ’<- MANUAL MODE ->’ on the second line. You now have electrical control of

the gate movement using the VGC Panel pushbuttons.

Pressing the OPEN and CLOSE pushbuttons will move the gate in opposite directions. At this time the

control is not aware of the actual motor-rotation/gate-direction so OPEN and CLOSE have no literal

meaning. You can just ‘bump’ the gate a bit with the push buttons until you can establish if the direction of

the gate matches the push button name. The motor direction will be automatically compensated for during

the Learn Mode. If you will be using the gate in Manual Mode for sometime, you may want to electrically

change the motor rotation to match the push button description.

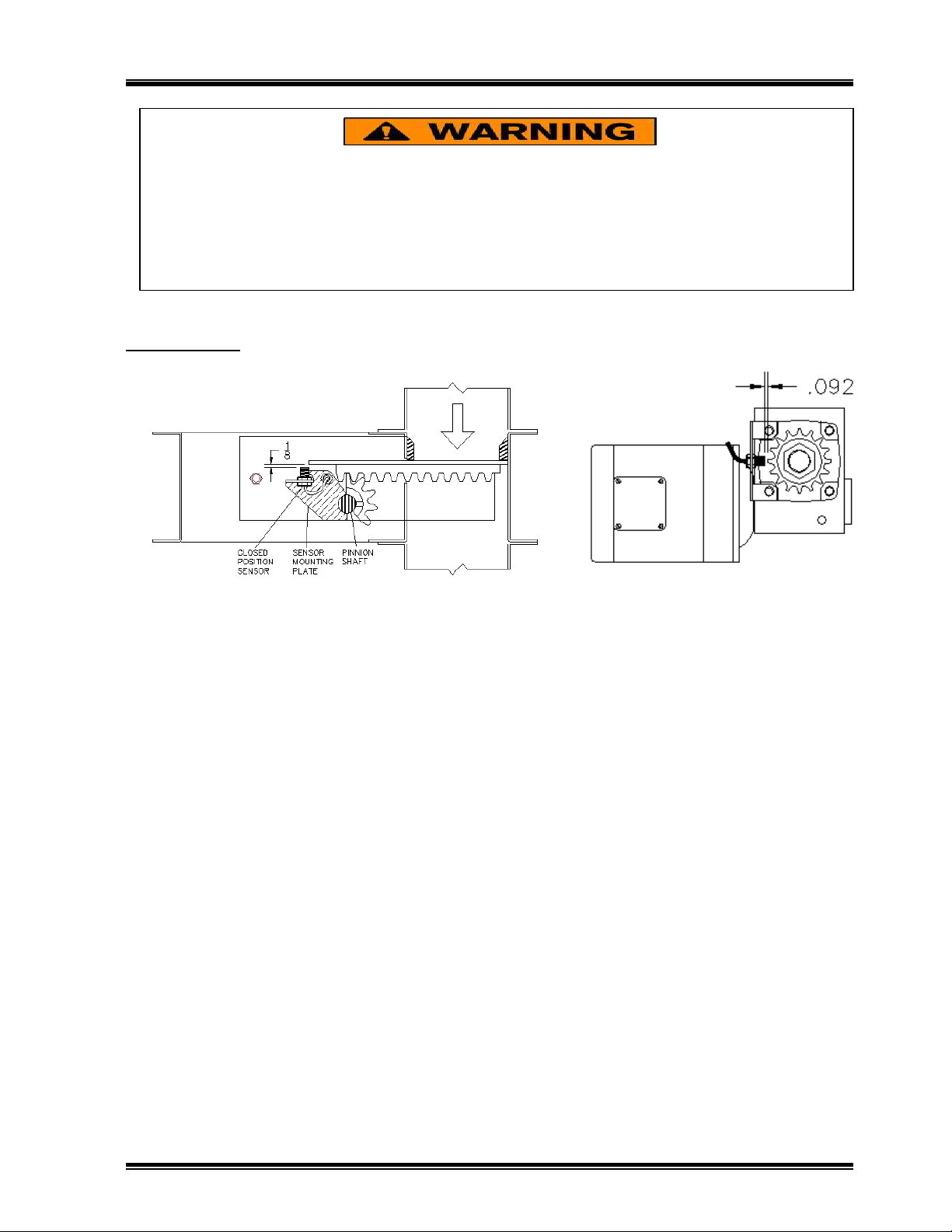

Fully close the gate. The LED should be in State . If not, the closed position sensor is miswired, has the

wrong barrier relay switch settings or is improperly adjusted.

Slightly open the gate about /4”. The LED should be in State 2. Again, check the close sensor if this is not

correct.

Depress and hold the OPEN button so the gate opens fully. During this time the LED should be in State 3.

The blinking pattern is reflecting the target wheel sensor state.

When the gate finishes its opening travel limit, the LED will return to State 2.

As a final check, the following two rules apply to the LED indicators on the barrier relay:

1. Lamp 1 must be yellow ONLY when the gate is fully closed. Lamp 1 must be off whenever

the gate is NOT fully closed.

2. Lamp 2 must blink yellow to off when the gate is moving.

If any of these conditions are not met, correct them before continuing.

AUTION! Be sure that moving the gate will not cause personal injury to someone near the gate.

Also make sure that opening the gate will not allow bulk product to mistakenly flow thru the gate.

The multi-colored LED at the top of the VGC Panel is used in Manual Mode to check the gate and

sensor operation. The colors and blink pattern have special meaning.

State : A steady Green state indicates the gate is fully closed.

State 2: A steady Yellow, Red, or off, indicates the gate is not closed.

State 3: A blinking pattern with State 2 colors means the gate is moving.