Pilot²

Doc. No 609 2210 v043

Table of contents Page

Introduction ...................................................................................................... 3

Symbols used................................................................................................... 4

First usage – Safety notes................................................................................ 5

Product description........................................................................................... 6

Operation ......................................................................................................... 6

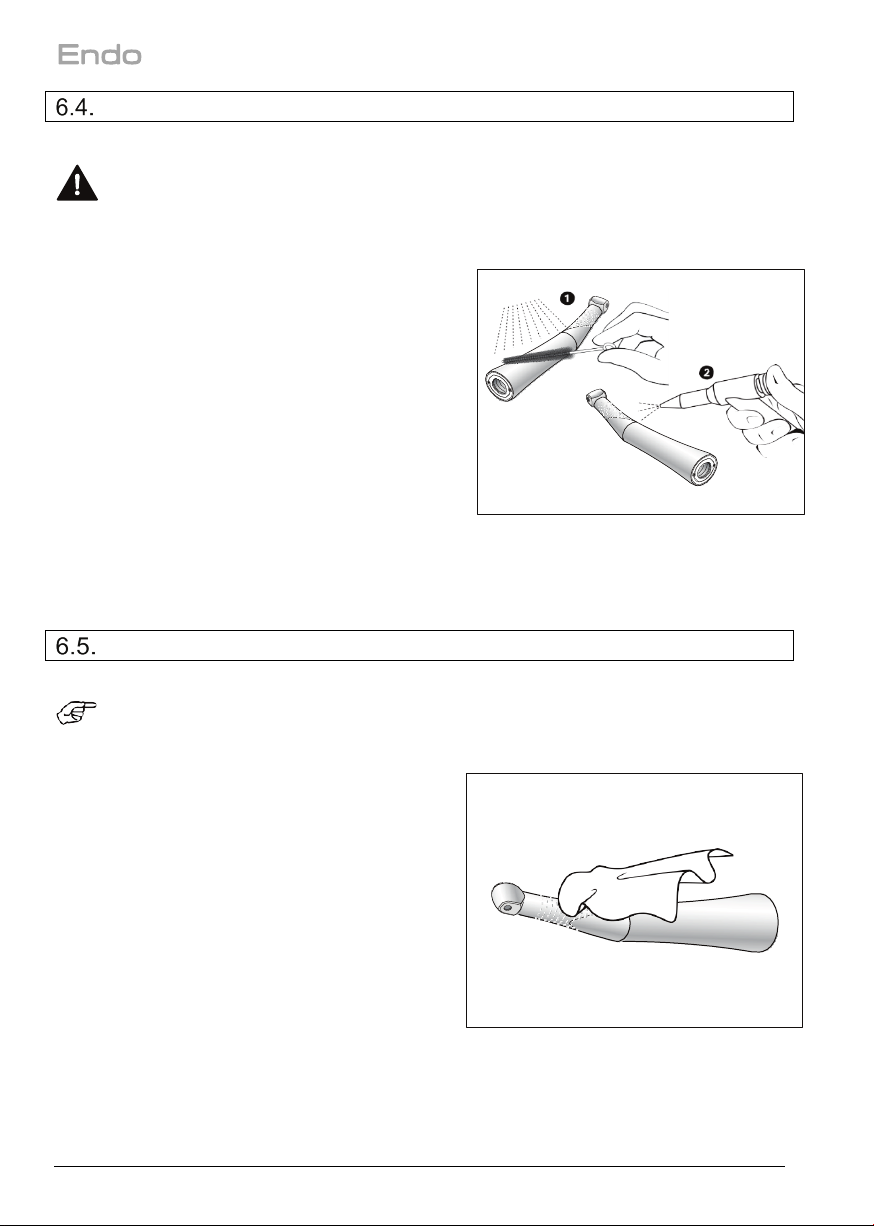

Assembly and removal..................................................................................... 6

Changing of the root canal instruments............................................................ 7

Test run ............................................................................................................ 7

Hygiene and maintenance ................................................................................... 8

Cleaning agents and disinfectants ................................................................... 8

Limitations on processing................................................................................. 8

Initial treatment at the point of use ................................................................... 9

Manual cleaning............................................................................................. 10

Manual disinfection

....................................................................................... 10

Automated cleaning and disinfection

........................................................... 11

Drying

............................................................................................................ 11

Inspection, Maintenance and Testing ............................................................. 11

Lubrication...................................................................................................... 12

Testing after Lubrication

............................................................................... 12

Packaging

...................................................................................................... 13

Sterilization

.................................................................................................... 13

Storage........................................................................................................... 14

Accessories.................................................................................................... 14

Technical data ................................................................................................ 14

Temperature information ................................................................................ 15

Ambient conditions......................................................................................... 15

Disposal ......................................................................................................... 15

Disposal of the contra-angle

............................................................................... 15

Disposal of the packaging material

...................................................................... 15

Liability ........................................................................................................... 16

Service ........................................................................................................... 16

Introduction

Customer satisfaction is our top priority. The present device was developed,

manufactured and tested in line with all applicable legal and normative provisions.

For your safety and for the safety of your patients

Prior to first use, please read through the present instructions. The user manual is

intended to give you information and explanations on the use of the device to ensure

undisturbed, economic and safe treatments.

It

explains how to use your medical device and guarantee a smooth and efficient operation.

Observe the safety notes.