Contents

EN-US · 30.30.01.03064 · 01 · 12/22 3 / 24

Contents

1Important Information ...................................................................................................................................4

1.1 Note on Using this Document.............................................................................................................4

1.2 The technical documentation is part of the product ........................................................................4

1.3 Type Plate.............................................................................................................................................4

1.4 Symbols.................................................................................................................................................5

2Fundamental Safety Instructions................................................................................................................... 6

2.1 Intended Use ........................................................................................................................................ 6

2.2 Non-Intended Use................................................................................................................................6

2.3 Personnel Qualifications......................................................................................................................6

2.4 Warnings in This Document ................................................................................................................ 6

2.5 Modifications to the Product .............................................................................................................. 6

3Product description......................................................................................................................................... 7

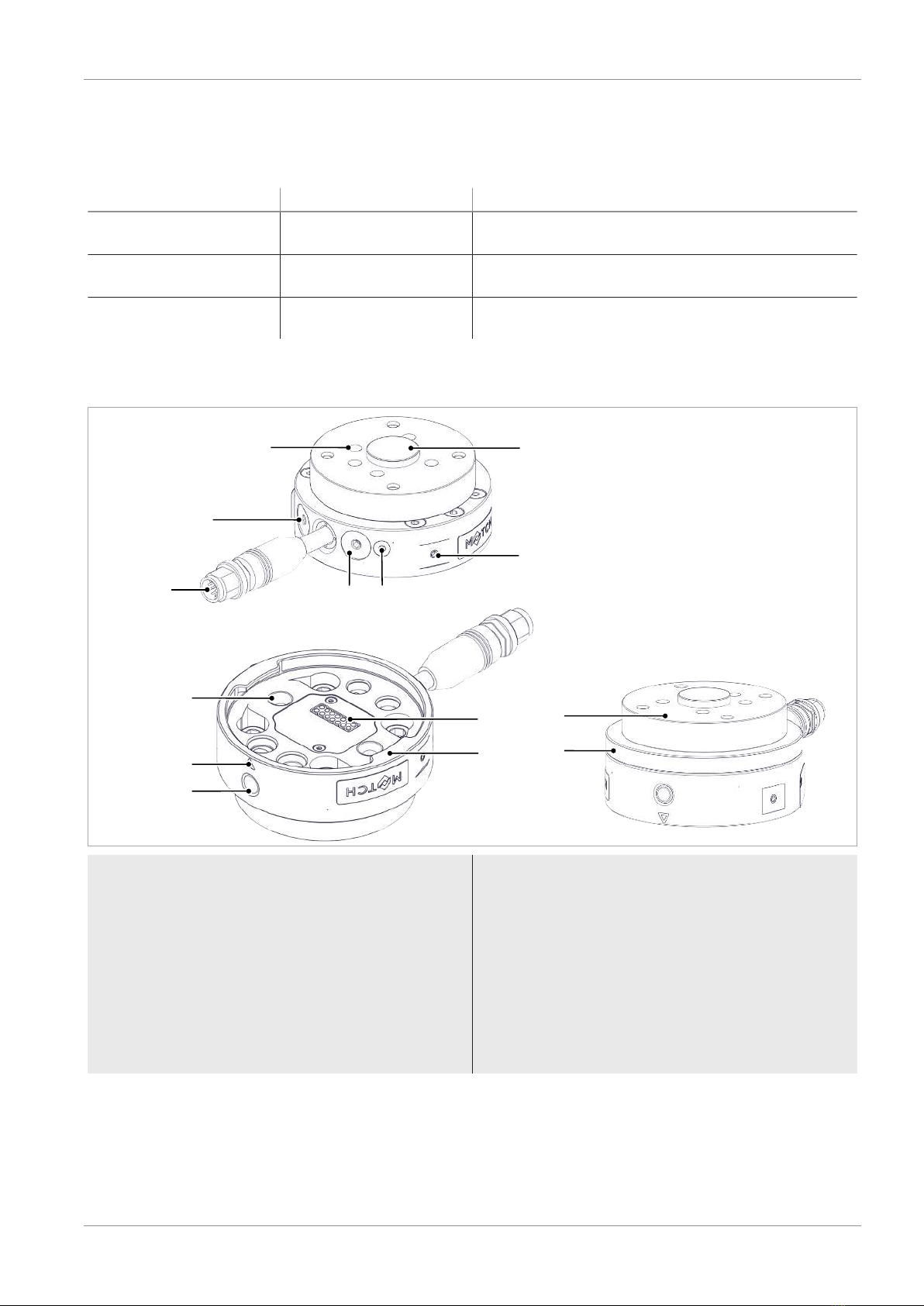

3.1 Product Variants ..................................................................................................................................7

3.2 Product Design.....................................................................................................................................7

3.3 Description of Functions...................................................................................................................... 8

3.4 LED Display...........................................................................................................................................8

3.5 Connect LED ......................................................................................................................................... 9

4Technical Data...............................................................................................................................................10

4.1 Tool-Changer-Specific Data............................................................................................................... 10

4.2 Technical Data....................................................................................................................................10

4.3 Maximum Forces and Torques ..........................................................................................................10

4.4 Dimensions ......................................................................................................................................... 11

5Transportation and Storage......................................................................................................................... 12

5.1 Checking the Delivery........................................................................................................................12

5.2 Unpacking the Device........................................................................................................................12

5.3 Transport / Storage / Preservation ....................................................................................................12

6Installation ....................................................................................................................................................13

6.1 General Mounting Information ........................................................................................................ 13

6.2 Mounting of the Variant with an Intermediate Flange ..................................................................14

6.3 Installing the Energy Supply .............................................................................................................15

6.4 Static Electricity..................................................................................................................................16

7Manual Robot Soft-Switch (Option)............................................................................................................ 17

8Maintenance and Cleaning ..........................................................................................................................18

8.1 Safety Instructions for Maintenance ................................................................................................18

8.2 Maintenance ......................................................................................................................................19

9Accessories ....................................................................................................................................................20

10 Taking the Product Out of Operation and Disposal................................................................................... 21

11 Declarations of Conformity.......................................................................................................................... 22

11.1 EC Conformity .................................................................................................................................... 22

11.2 UKCA Conformity ..............................................................................................................................23