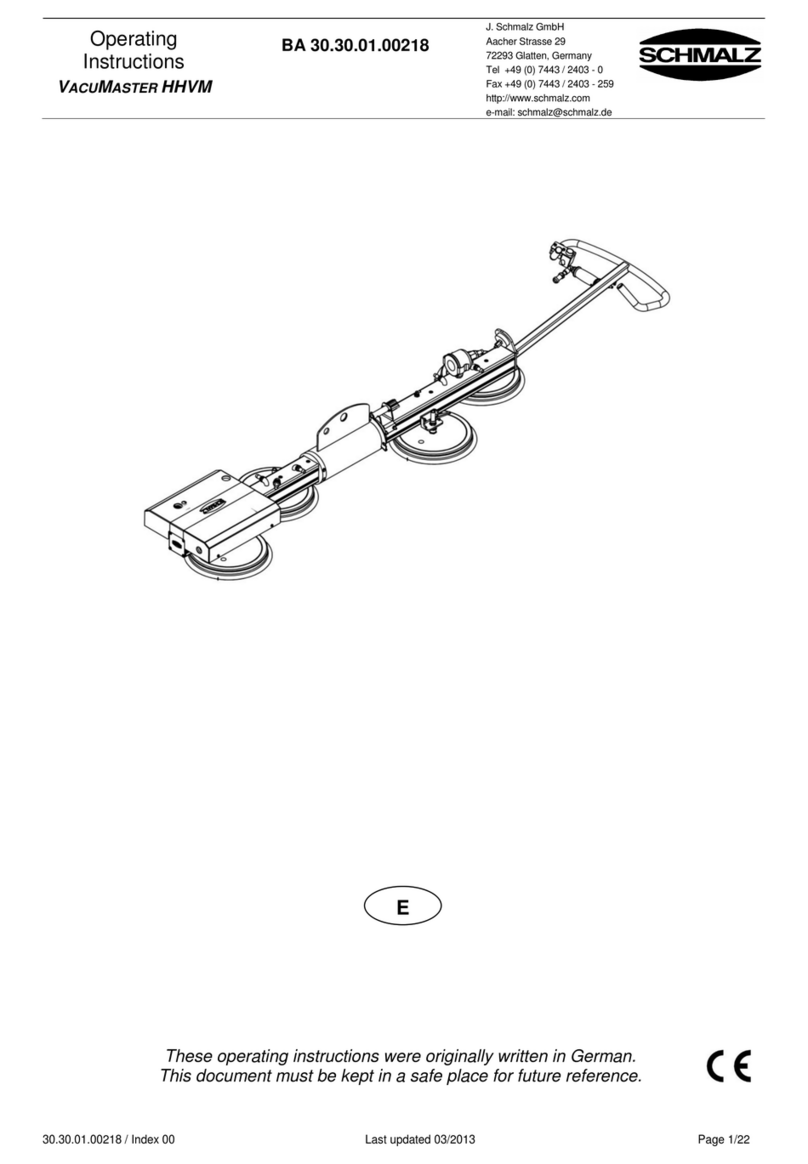

Operating Instructions

VACUMASTER

Chapter 1 / 2

Safety / Technical specific.

J. Schmalz GmbH

Aacher Straße 29

D - 72293 Glatten

Tel +49 +7443 / 2403 - 0

Fax +49 +7443 / 2403 - 259

http://www.schmalz.de

e-mail: schmalz@schmalz.de

30.30.01.00185 Status 03.2013 / Index 00 Page 6 / 28

The lifting devices from the series VACUMASTER (VM) B

BA

AS

SI

IC

C

and C

CO

OM

MF

FO

OR

RT

Twith

electrical vacuum generation are used to lift and transport flat parts, workpieces

and sheets of various materials at low heights. The item to be lifted must not

have a porous surface.

However, porous workpieces such as particle boards and MDF sheets can be

handled with the series VACUMASTER (VM) B

BA

AS

SI

IC

C

and C

CO

OM

MF

FO

OR

RT

Twith pneumatic

vacuum generation for lifting at low heights.

With devices from the series with pneumatic vacuum generation, workpieces

must be transported close to the floor. This means that the center of gravity of

the workpiece must not be lifted above 1.80 m.

The lifting device may only be used hung from a suspension bar / bolt.

No people or animals may be carried with the load or the lifting device!

For safety reasons, the lifting device may not be modified or changed

without approval.

The operating, maintenance and servicing conditions prescribed in these

operating instructions must be observed.

The permissible load must not be exceeded.

The continuous sound pressure output by the unit is les than 70 db(A).

As the load is held to the suction plates of the device, it falls down as soon as

the partial vacuum collapses.

This can be caused by a failure of the vacuum generator. In this case, a built-in

reservoir maintains the partial vacuum for a short safety period (depends on the

seal with the workpiece surface).

When there is a failure, set down the load immediately if possible.

If this is not possible, leave the danger area immediately.

The device generates very high suction which can suck in hair and items of

clothing. Do not look into the suction connection when the device is on. Eyes

can be sucked in.

The user’s workplace is at the operating lever. Users must stand so they can

see the vacuum manometer at all times.

1.9 Notes for users of

the lifting device

Users must be trained before starting the lifting device. You must have read and

understood the operating instructions, in particular the "Safety" chapter.

Ensure that only authorised personnel use the device.

You are responsible for third parties in the working area of the device.

The local safety regulations apply –in Germany BGR 500 among others.

Other safety instructions in this manual do not rescind these –they are to be

considered as additions.

1.10 Personal protection

equipment

When operating the device, always wear the following items:

Work shoes (with steel toe caps),

Sturdy working gloves.