2

Operating instructions

Emergency stop command device EX-RDRZ45 RT

EN

1.7 Exclusion of liability

We shall accept no liability for damages and malfunctions resulting from

defective mounting or failure to comply with this operating instructions

manual. The manufacturer shall accept no liability for damages

resulting from the use of unauthorised spare parts or accessories.

For safety reasons, invasive work on the device as well as arbitrary

repairs, conversions and modifications to the device are strictly

forbidden; the manufacturer shall accept no liability for damages

resulting from such invasive work, arbitrary repairs, conversions and/or

modifications to the device.

2. Product description

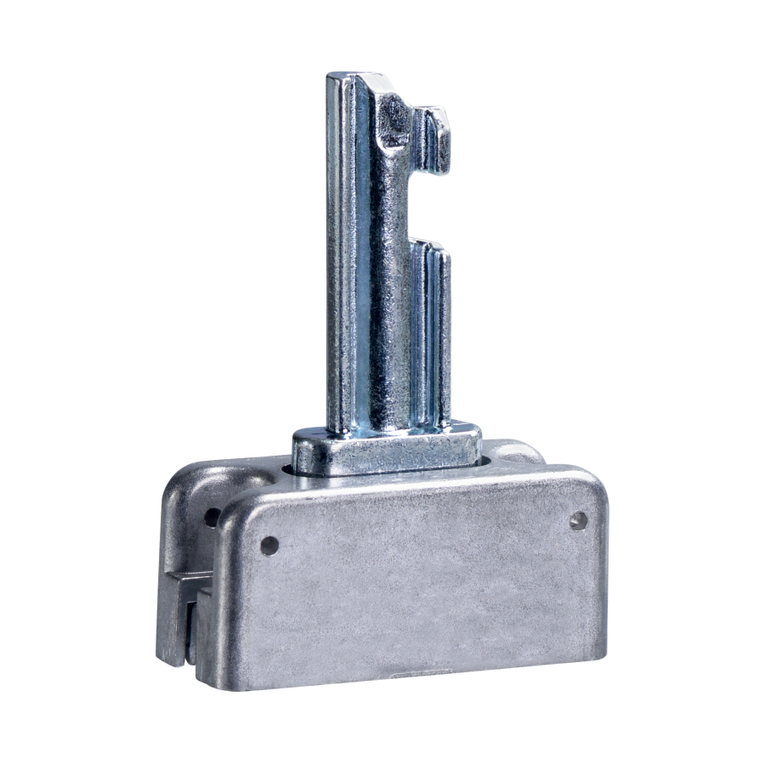

2.1 Ordering code

This operating instructions manual applies to the following types:

EX-RD

➀

➁ ➂ ➃

No. Option Description

➀

R Latching

➁

Z Release by pulling only

➂

45 Head diameter 45 mm

➃

RT Red colour

Only if the information described in this operating instructions

manual are realised correctly, the safety function and

therefore the compliance with the Machinery Directive and

the Explosion Protection Directive is maintained.

2.2 Special versions

For special versions, which are not listed in the order code below 2.1,

these specifications apply accordingly, provided that they correspond to

the standard version.

2.3 Destination and use

The EX-RDRZ45 RT series emergency stop command devices are

designed for use in emergency stop circuits to EN 13850.

Gas atmospheres

Please use the control devices and indicator lights in conjunction with

equipment of the appropriate "intrinsic safe" ignition protection type,

which is authorised for the corresponding field of application:

Zone 1: intrinsically safe current circuits of category ia or ib

(EN 60079-11)

Zone 2: intrinsically safe current circuits of category ia, ib or ic

(EN 60079-11)

Dust atmospheres

For Zone 21 and 22, the installation of the cables or wires is realised

with the appropriate ignition protection type (e.g. increased safety, EN

60079-7). No intrinsically safe current circuits are required.

Installation and maintenance requirements to the standard

series EN 60079 must be met.

Especially the capacitive and inductive parts of the intrinsically safe

current circuit must be observed. For non-linear current circuits,

Appendix A to EN 60079-11 (assessment of intrinsically safe current

circuits) must be included in the overall assessment.

For intrinsically safe current circuits with protection level ib, a safety

coefficient of 1.5 must be includet in the calculations, in accordance

with EN 60079-11 paragraph 5.3.

The user must evaluate and design the safety chain in

accordance with the relevant standards and the required

safety level.

Conditions for safe operation

The control devices are suitable for mounting in the enclosures of

the type Ex-EBG... (brand: Schmersal) or another enclosure or

operating panel, which is suitable for the zone (material: stainless

steel or metal with painted surface). These enclosures must meet

the requirements of IP65 or higher to IEC 60529 as well as the test

criterions to IEC 60079-0 paragraph 26.4.

The presence of small dust particles inside of the dust-proof IP65

enclosure must be excluded.

The specifications in the operating instructions manual or in the

technical data of the EC test certificate regarding the maximum

impact energy must be observed. Due to the specific impact energy,

the components must be fitted with a protection against mechanical

stresses.

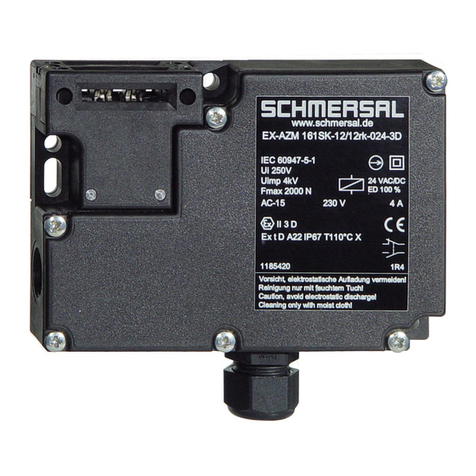

2.4 Technical data

Standards: IEC 60947-5-1, IEC 60947-5-5, IEC 60947-1,

EN 60079-0, EN 60079-11, EN 60079-14,

EN 60079-25, EN 60079-31

Operating element

EX-relevant Data:

EC-prototype test certificate: TÜV 08 ATEX 7685 U

-Designation

For EX-R command and signalling devices: LII 2G Ex ib IIC Gb

L

II 2D Ex tb IIIC Db

EC-prototype test certificate: TÜV 08 ATEX 7630 X

- Designation

For EX-R command and signalling devices

in enclosure EX-EBG:

L

II 2G Ex ib IIC T4 Gb

L

II 2D Ex tb IIIC T110°C Db

Ambient temperature Tamb:–20 … +55°C

Note external heat and/or cold source.

Protection class to IEC 60529: IP65

Evidenced impact energy

(according to EN 60079-0): 4 J

General technical data:

Design: round

Installation diameter: 22,3 mm

Grid dimensions: 50 × 60 mm

Front plate thickness: 1 … 6 mm

With identification label: 1 ... 5 mm

Mounting position: random

Switching frequency: 600 s/h

Actuating force: 2 N

Mechanical life (operations): 1 × 105

Materials: Front-ring brass, chromium-plated

Emergency stop label (yellow): PVC film

Device head: brass coated

Fixing: With mounting flange,

Tightening torque: 2 Nm

Shock resistance to IEC 60068-2-27: < 50 g

Resistance to vibrations to EN 60068-2-6: 5 g

Contact elements,

EX-relevant data:

Ambient temperature Tamb:–20 … +55°C

Mounting position: random

Number of: max. 2 (Pos. 2, 3)