3

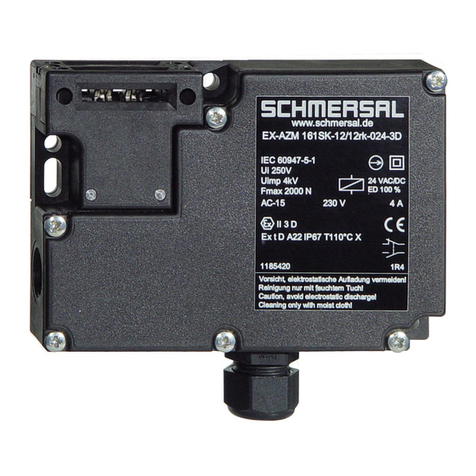

AZM 161 I

Operating instructions

Solenoid interlock

EN

Emergency exit

(Fitting and actuation only from within the hazardous area)

To activate the emergency exit of the T version in case of an emergency,

the orange lever must be turned to the stop in direction marked by

the arrow. The emergency exit function of the TD and TU versions is

activated by pressing the red pushbutton.

In this position, the safety guard can be opened. The blocking condition

is cancelled by turning the lever in opposite direction or by pulling back

the pushbutton. In unlocked position, the safety guard is protected

against unintentional closing.

Lateral emergency exit

(ordering suffix -T)

Emergency exit on the

cover side or on the rear side

(ordering suffix -TD/-TU)

The user must evaluate and design the safety chain in

accordance with the relevant standards and the required

safety level.

The entire concept of the control system, in which the safety

component is integrated, must be validated to the relevant

standards.

2.4 Technical data

Standards: IEC 60947-5-1, ISO 14119, BG-GS-ET-19

Enclosure: glass-fibre reinforced thermo-

plastic, self-extinguishing

Actuator and locking bolt: stainless steel 1.4301

Contact material: Silver

Coding level according to ISO 14119: high

Protection class: IP67

Contact type: Change-over contact with double break type Zb,

with galvanically separated contact bridges

Switching system:

A

acc. IEC 60947-5-1 slow action,

NC contact with positive break

Positive break travel: 10 mm

Positive break force: 10 N for each NC contact fitted

Connection: screw terminals or cage

clamps or connector

Cable type: flexible

Cable section: min. 0.25 mm², max. 1.5 mm²

(including conductor ferrules)

Cable entry: 4 x M16 x 1.5

Holding force Fmax:2000 N

Latching force: 30 N for ordering suffix R

Actuating speed: max. 2 m/s

Actuating frequency: max. 1000 operations/h

Mechanical life: > 1 million operations

Ambient temperature: –25 °C … +60 °C

Electrical data:

Utilisation category: AC-15, DC-13

Rated operating current/voltage Ie/Ue:

- CC, SK, ST 4 pole: 4 A / 230 VAC

2.5 A / 24 VDC

- ST 8 pole: 2 A / 24 VDC

Rated impulse withstand voltage Uimp:

- CC, SK, ST 4 pole: 4 kV

- ST 8 pole: 0.8 kV

Rated insulation voltage Ui:

- CC, SK, ST 4 pole: 250 V

- ST 8 pole: 60 V

Thermal test current Ithe:

- CC, SK, ST 4 pole: 6 A

- ST 8 pole: 2 A

Rated control voltage Us:24 VAC / DC;

110 / 230 VAC

Magnet: 100% ED

Power consumption: max. 10 W

Max. fuse rating: 6 A gG D-fuse

Required rated short-circuit current: 1000 A

Tightening torque rating: 4.4 lb in.

2.5 Safety classification

Standards: ISO 13849-1

Envisaged structure:

- Basically: applicable up to Cat. 1 / PL c

- With 2-channel usage and

fault exclusion mechanism*: applicable up to Cat. 3 / PL d

with suitable logic unit

B10d (NC contact): 2,000,000

B10d (NO contact) at 10% ohmic contact load: 1,000,000

Service life: 20 years

* If a fault exclusion to the 1-channel mechanics is authorised.

TF

d

10d op op

op

n

(Determined values can vary depending on the application-specific

parameters hop, dop and tcycle as well as the load.)

If multiple safety components are wired in series, the Performance

Level to ISO 13849-1 will be reduced due to the restricted error

detection under certain circumstances.

3. Mounting

3.1 General mounting instructions

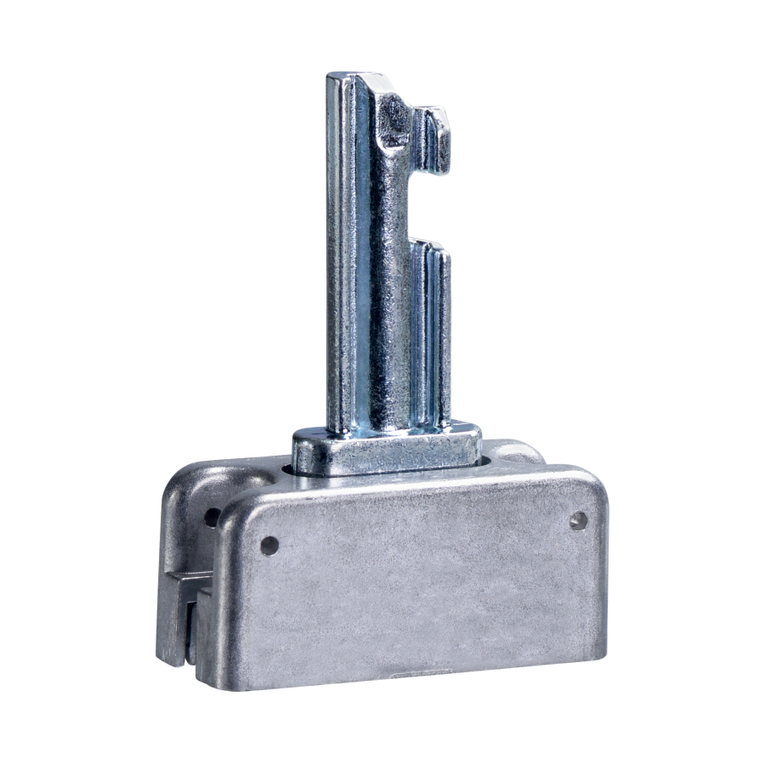

On delivery, the actuator is in inserted condition. For

power-to-unlock components, the actuator must be released

by means of the manual release. If the triangular key is

turned 180°, the locking bolt is pulled into the unlocking

position. The normal locking function is only restored after

the triangular key has been returned to its original position.

Three mounting holes are provided for fixing the enclosure. The

solenoid interlock is double insulated. The use of an earth wire is not

authorised. The solenoid interlock must not be used as an end stop.

Any mounting position. The mounting position however must be chosen so

that the ingress of dirt and soiling in the used opening is avoided. Unused

actuator openings must be sealed with slot sealing plugs.

The safety component and the actuator must be

permanently fitted to the safety guards and protected

against displacement by suitable measures (tamperproof

screws, gluing, drilling, pinning).

Please observe the remarks of the standards ISO 12100,

EN 953 and ISO 14119.