2

Operating instructions

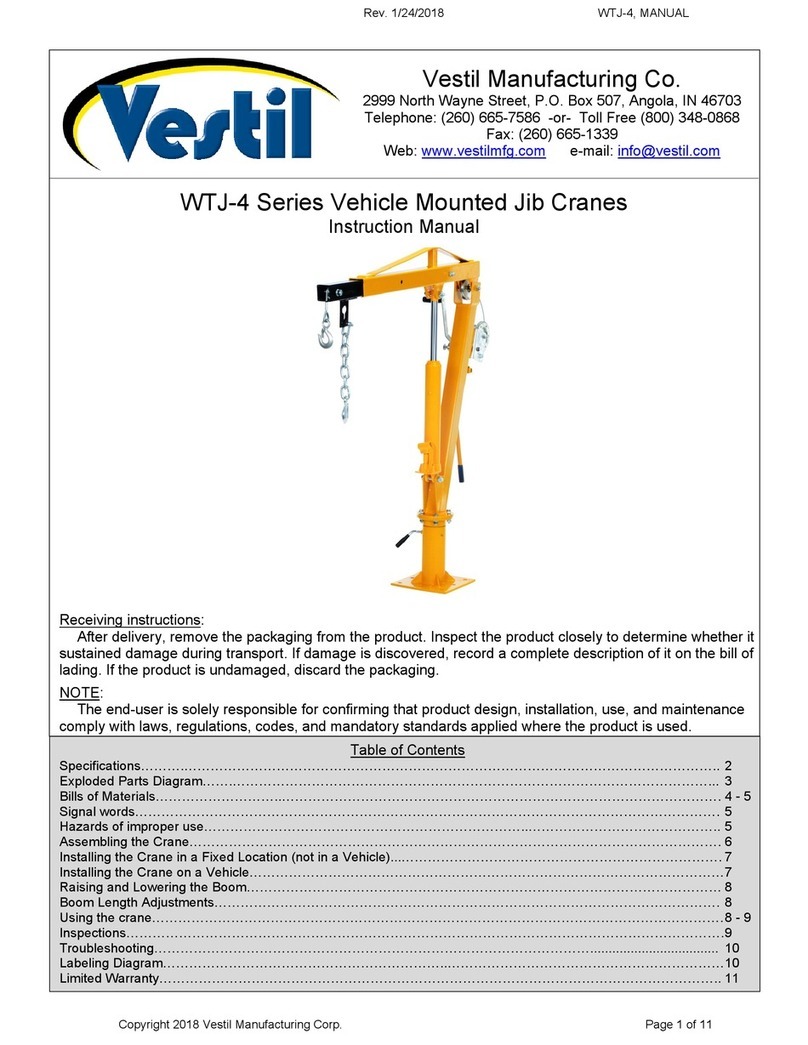

Solenoid interlock TZM/TZF

EN

1.7 Exclusion of liability

We shall accept no liability for damages and malfunctions resulting from

defective mounting or failure to comply with this operating instructions

manual. The manufacturer shall accept no liability for damages

resulting from the use of unauthorised spare parts or accessories.

For safety reasons, invasive work on the device as well as arbitrary

repairs, conversions and modifications to the device are strictly

forbidden, the manufacturer shall accept no liability for damages

resulting from such invasive work, arbitrary repairs, conversions and/or

modifications to the device.

2. Product description

2.1 Ordering code

This operating instructions manual applies to the following types:

TZ

➀➁➂➃➄

24VDC-

➅

No. Option Description

➀

M Power to lock

F Power to unlock

➁

Contact variants (also refer to 4.2)

Magnet Actuator

1 NC 1 NC / 1 NO

W 1 NC 1 NC / 1 NO

C1 NC / 1 NO 1 NC / 1 NO

CW 1 NC / 1 NO 1 NC / 1 NO

3 NC / 1 NO 1 NC 2 NC / 1 NO

W3OE 1 NC 2 NC / 1 NO

4 NC 2 NC 2 NC

W2MOE 2 NC 1 NC / 1 NO

➂

N Emergency release N

.NE Manual release .NE

.NEM Manual release .NEM

S Manual release using triangular key

SP Manual release with triangular key and

release bar

S.NF Emergency exit and manual release

➃

L with LED display

➄

.CHI Actuating head higher and rotated 180°

➅

3053 Customer-specific contact variant

Not all component variants, which are possible according to this order

code, are available.

The device variants .N, .NE and .NEM mentioned in the

order code under 2.1. are not consistent with test principle

BG-GS-ET-19.

Only if the information described in this operating instructions

manual are realised correctly, the safety function and

therefore the compliance with the Machinery Directive is

maintained.

2.2 Special versions

For special versions, which are not listed in the order code below 2.1,

these specifications apply accordingly, provided that they correspond to

the standard version.

2.3 Purpose

The solenoid interlock has been designed to prevent in conjunction

with the control part of a machine, movable safety guards from being

opened before hazardous conditions have been eliminated.

Interlocks with power to lock principle may only be used in

special cases after a thorough evaluation of the accident risk,

since the guarding device can immediately be opened on

failure of the electrical power supply or when the main switch

is opened.

The safety switchgears are classified according to

ISO 14119 as type 2 interlocking devices.

Manual release TZF..S (for set-up, maintenance, etc.)

The manual release is realised by turning the triangular key (included

in delivery) to the right (1), so that the locking bolt is pulled into the

release position. The normal locking function is only restored after the

triangular key has been returned to its original position (2). The manual

release must be sealed after being put into operation (e.g. sealant etc.)

to prevent its utilisation during operation. The manual release must not

be actuated when loaded by the safety guard.

Manual release TZF..SP (for set-up, maintenance, etc.)

The manual release is realised by turning the triangular key (included

in delivery) to the left (1) and by pulling simultaneously the release bar

(2), so that the locking bolt is pulled into the release position. After the

triangular key (1) has been turned back to the left, the release bar (2)

returns to its position and the normal locking function is restored. The

manual release must be sealed after being put into operation (e.g.

sealant etc.) to prevent its utilisation during operation. The manual

release must not be actuated when loaded by the safety guard.

Manual release TZF..S Manual release TZF..SP

2

1

2

1

Emergency release TZFN

(mounting only on the outside of the safety guard)

To realise an emergency release, the release button (1) must be pulled.

The release button latches. In this position, the safety guard can be

opened. To neutralise the blocked condition, use the triangular key (2)

(included in delivery) to turn the triangular screw to the left until the

release button returns to its original position. The released condition

may only be cancelled by an authorised person. The emergency

release must not be used when the machinery/plant is in operation.

1

2

The emergency release must be clearly labelled that it

should only be used in an emergency. The label can be

used that was included in the delivery.

The solenoid interlock should be installed and/or protected

so that an inadvertent opening of the interlock by an

emergency release can be prevented.