7MN1661

GRIP TIGHT BUSHING KIT

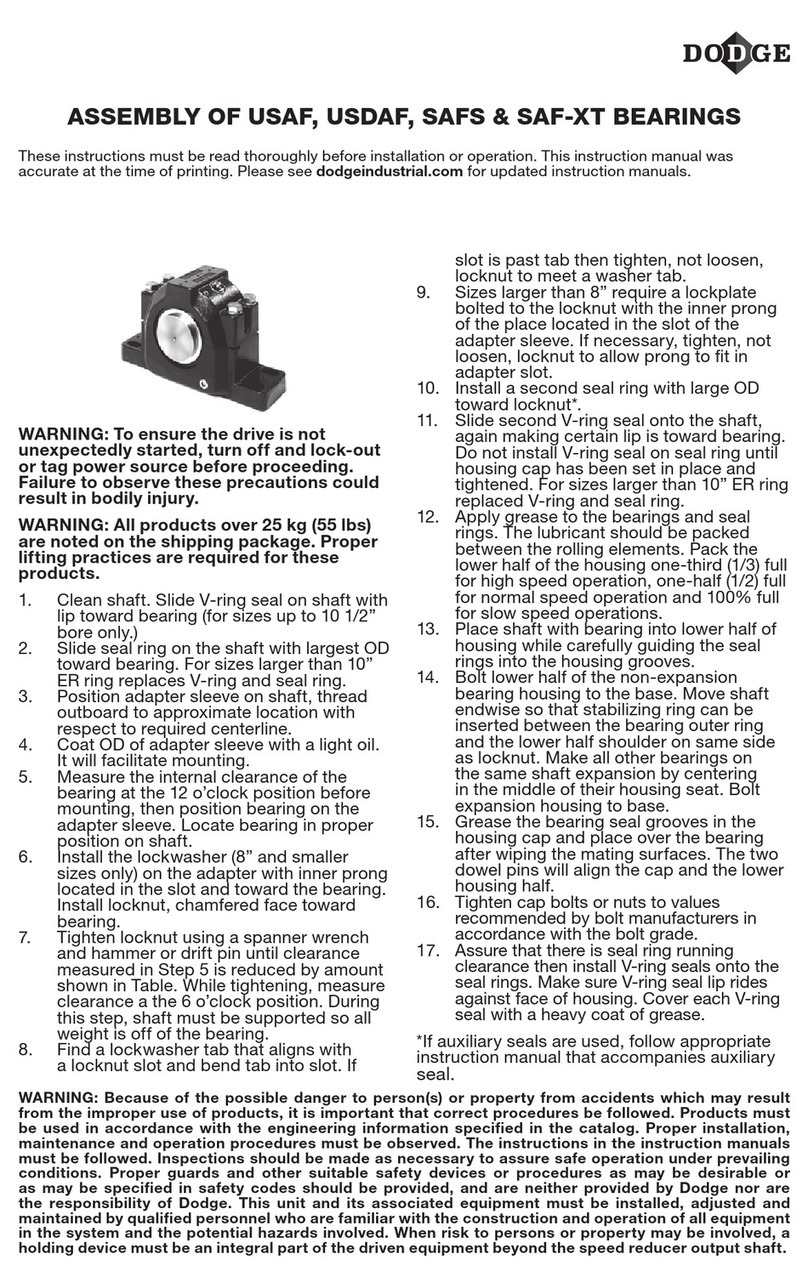

Clean the driven shaft and bore of the bushing inner sleeve to

remove any oil, grease, or dirt. Insert the bushing inner sleeve

into the bushing outer sleeve/nut assembly.

NOTE: If your Grip Tight bushing kit arrives without the lock nut

preinstalled, please return the kit to your local distributor for one

where the lock nut has already been installed on the outer sleeve.

If the inner sleeve threads do not engage with the lock nut, hold

the assembly in your hand with the lock nut towards you. Hit or

rap on the inner sleeve with a soft rubber mallet or the palm of

your other hand to seat the threads against the lock nut. Rotate

the nut clockwise until the threads in the nut engage the threads

in the inner sleeve. Slide the bushing assembly into the driven

shaft with the lock nut closest to the driven device and install a

key into the bushing.

NOTE: Using a key in the bushing(s) is the preferred arrangement

but is not required if two bushings are used. Keys are ALWAYS

required for brake motor applications. Two bushings are

recommended on size 35 and larger reducers. On smaller reducers,

if only one bushing is used, it is recommended a second bushing be

temporarily used to support the reducer during the installation of

the desired bushing.

Loosen the six hollow bore set screws and slide the reducer onto

the shaft bushing. Support the reducer to keep it from swinging

out of position.

WARNING: Failure to support the reducer may result in injury.

If two bushings are being used, install the second bushing into

the reducer on the opposite side of the reducer hollow bore.

When the reducer is located in the correct location, rotate the

nut on the bushing closest to the driven device clockwise with

a spanner wrench or a pair of large pliers until it is snug and

the reducer cannot be slid along the shaft. Tighten the nut and

additional ¾ to 1 turn on size 23 and 26 reducers, and additional 1

to 1-¼ turns on size 30 and 35 reducers and an additional 1-½ to

2 turns on size 40 and 47 reducers. Tighten the set screw located

on the nut. Repeat the nut tightening procedure for the other

bushing if used. Tighten the six hollow bore set screws.

WARNING: Failure to properly tighten the bushing assemblies may

cause equipment failure and personal injury.

Install the torque arm or other mounting bracket to keep the

reducer from rotating about the driven shaft.

NOTE: If the bushing rotates while tightening the nut on dual

bushing applications without keys, insert a set screw into the

hollow bore shaft and tighten the screw until it extends into the

keyway in the bushing inner sleeve.

TORQUE ARM BRACKET INSTALLATION

NOTE: The banjo style torque arm bracket should be mounted on

the reducer side closest to the driven equipment.

TORQUE ARM BRACKET INSTALLATION ON BEARING

COVER SIDE: Remove and discard the four retaining capscrews

located on the outside corners of the bearing cover. Do not

remove the two smaller capscrews. Locate the torque arm

bracket in the desired position. The torque arm bracket can be

positioned in 45 degree increments. Using the supplied longer

the bracket onto the bearing housing. The spacers are located

between the bearing cover and the torque arm bracket. Install

all four capscrews, spacers, and washers before tightening the

capscrews. Visually center the bracket bore ID with the output

shaft hub OD and lightly tighten the capscrews. Torque the

torque value listed below. Tighten the four capscrews to the

recommended torque value.

TORQUE ARM BRACKET INSTALLATION ON SIDE

WITHOUT BEARING COVER: Locate the torque arm

bracket in the desired position. The torque arm bracket can be

positioned in 45 degree increments. Using the supplied shorter

bracket onto the reducer. The spacers are located between the

reducer housing bosses and the torque arm bracket. Install all

four capscrews, spacers, and washers before tightening the

capscrews. Visually center the bracket bore ID with the output

shaft hub OD and lightly tighten the capscrews. Torque the

torque value listed below. Tighten the four capscrews to the

recommended torque value.

TORQUE ARM BRACKET INSTALLATION TO CUSTOMER’S

STRUCTURE: Prepare the reducer’s hollow output shaft

and selected bushing kit (if required) for mounting onto the

customer’s shaft. Follow the installation instructions for the

selected bushing kit provided in this manual. The straight bore

bushing kit and the grip tight bushing kit installation instructions

are on page 1 and page 7, respectively.

On the frame side of the torque arm bracket, install the inner

rubber isolator bushing half into bracket’s small bore ID. Slide

the Tigear-2 reducer onto the shaft until the inner torque arm

bushing touches the customer’s structure. The frame must

completely support/back up the 1.88” diameter bushing. Do

not tighten the reducer onto the customer’s shaft until after the

been tightened. Caution: To prevent injury, use a temporary

restraining device to hold the reducer onto the shaft during

the torque arm bracket assembly.

bolt/washer combination through the customer’s frame and the

length will be determined by the customer’s frame thickness. The

Do not use a fully threaded

bolt. On the reducer side of the torque arm bracket, install the

hardware components are properly aligned. Apply 243 Loctite to

to 200 in-lb torque.

Tighten the reducer onto the customer’s shaft in accordance

with the reducer or the selected bushing installation instructions.

The straight bore bushing kit and the grip tight bushing kit

installations instructions are on page 1 and page 7, respectively.

Remove temporary restraining device.