Figure 10

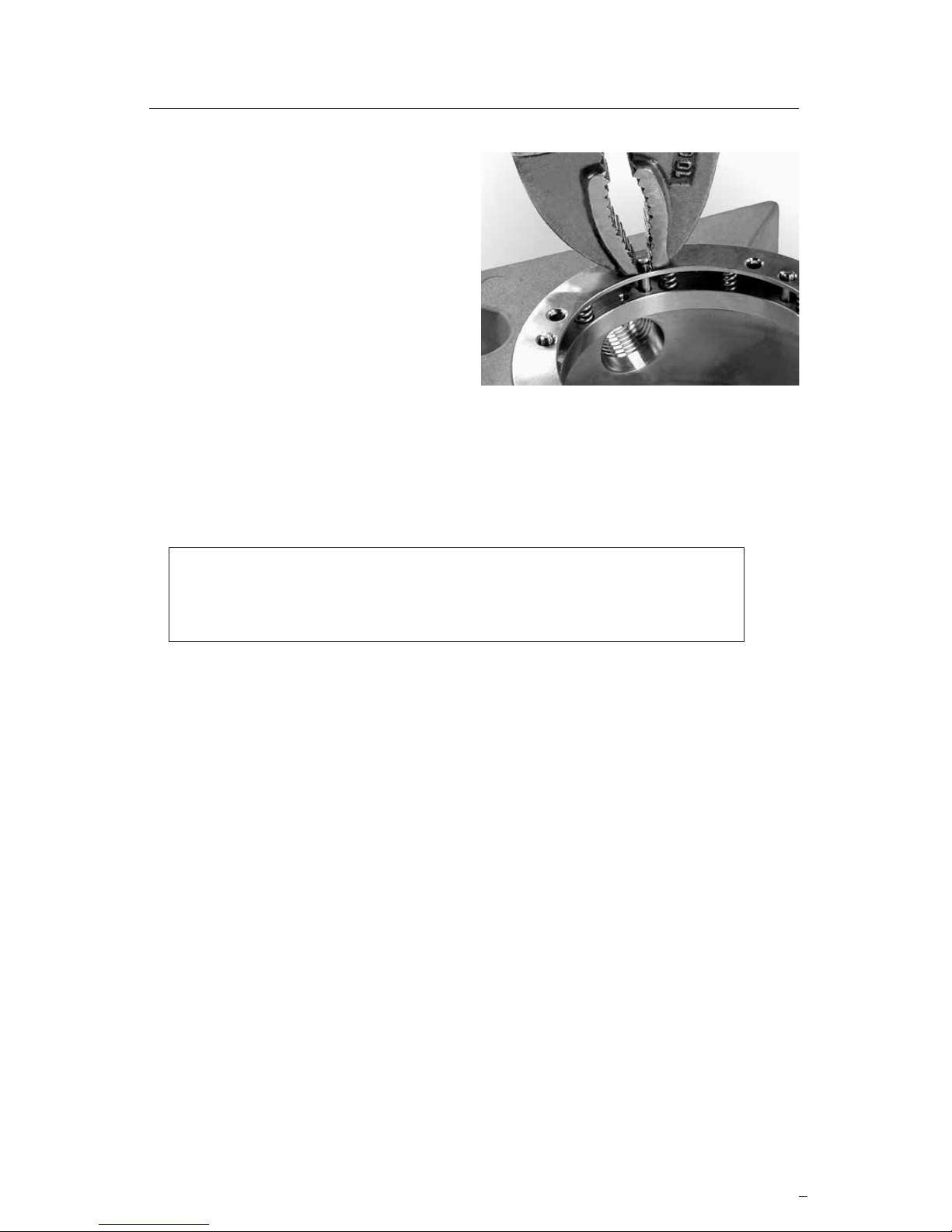

Figure 7

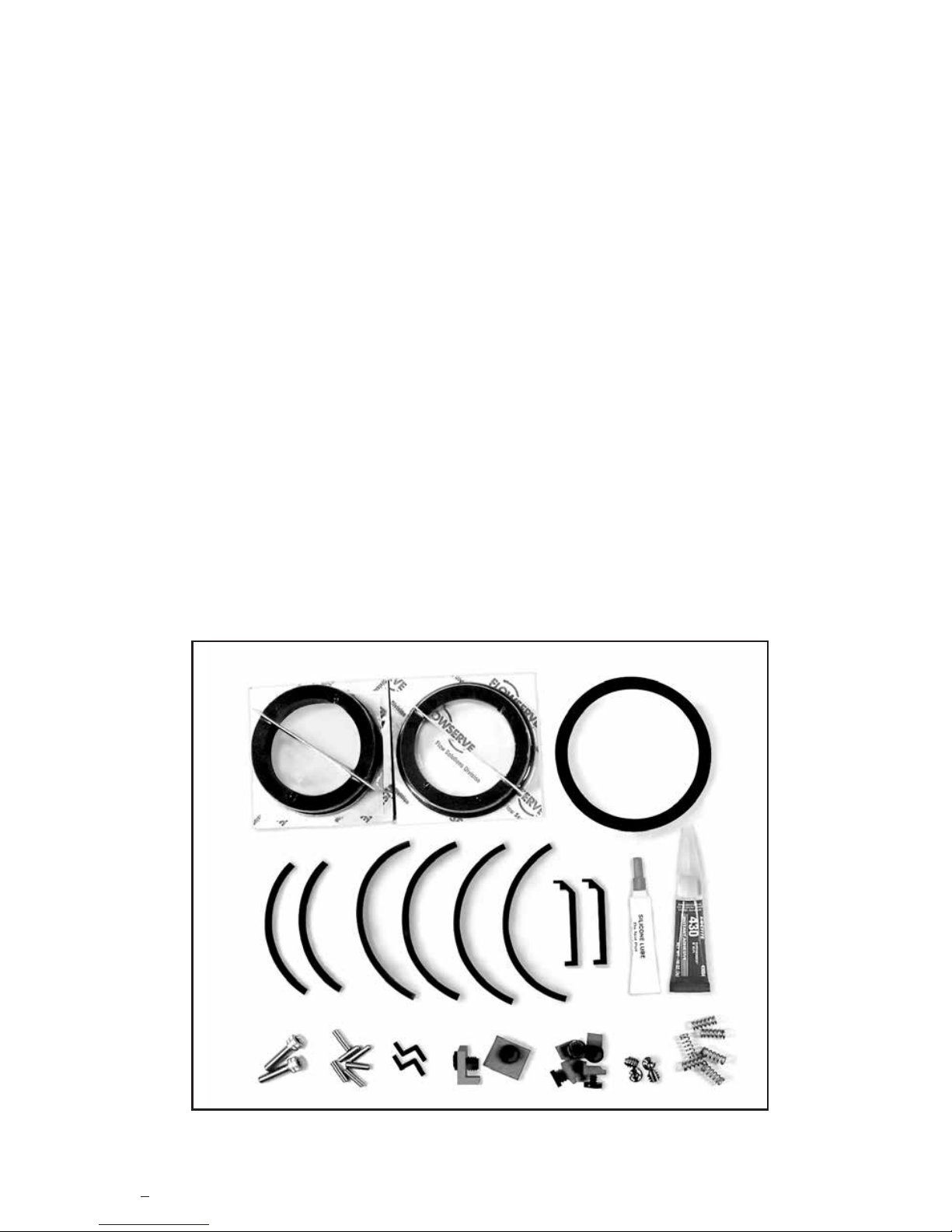

3 Sleeve Gasket and Rotating Face Gasket

Installation

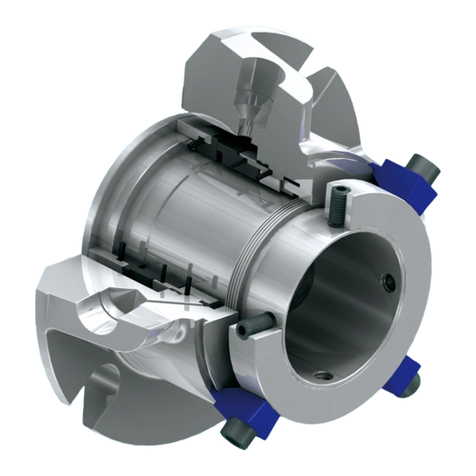

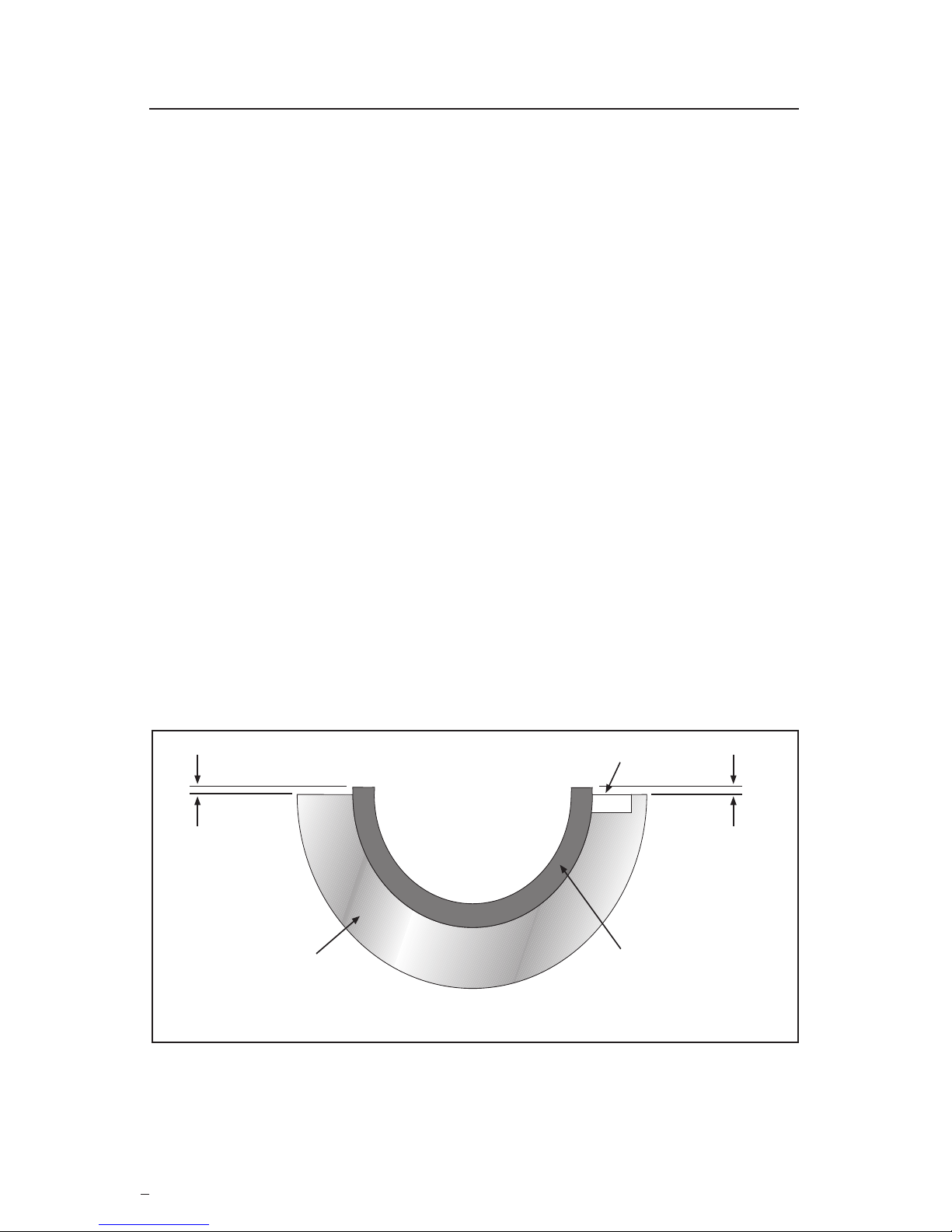

Figure 8

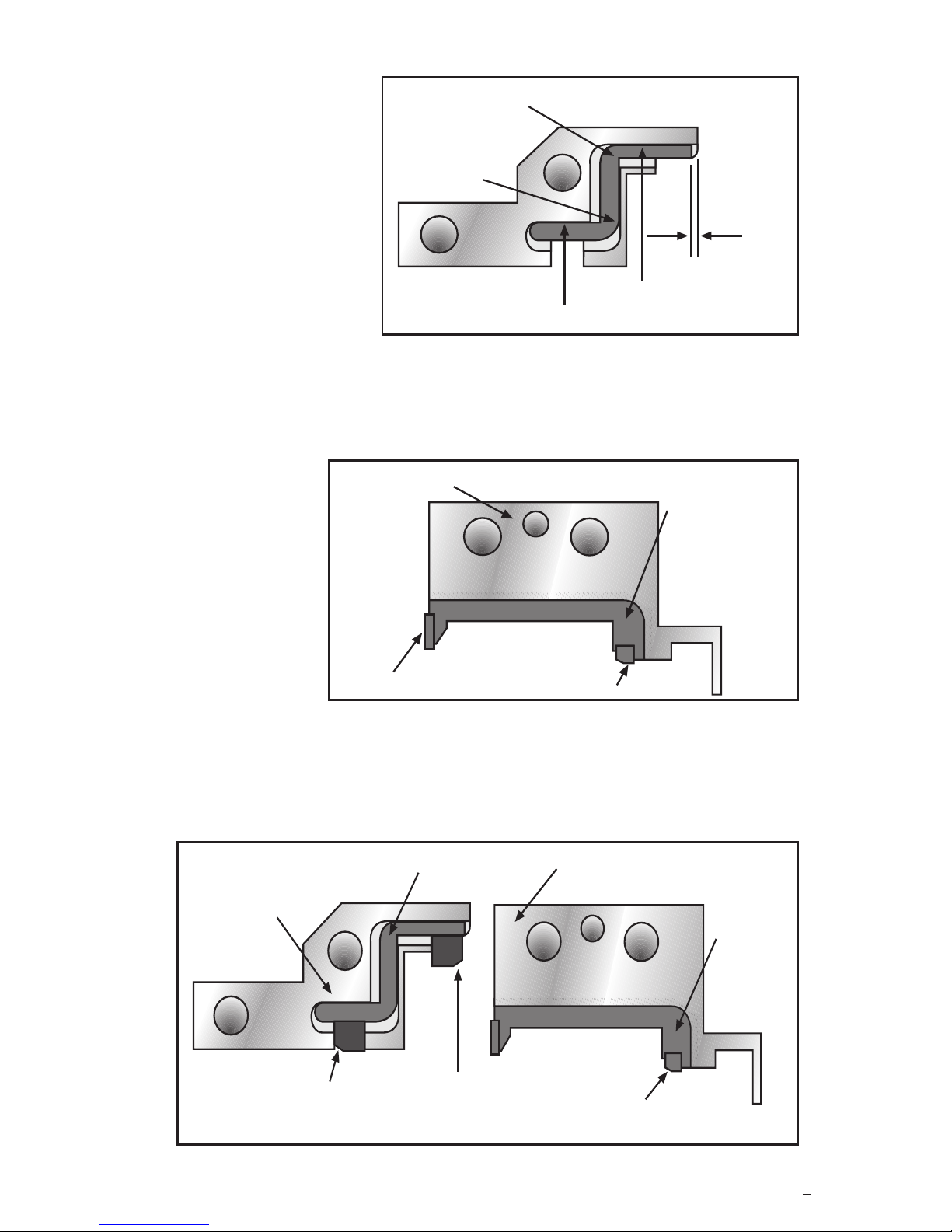

Figure 9

6

3.1 Wipe the sleeve gasket groove

clean with alcohol.

Caution: Consult material safety data sheets

for proper handling of alcohol.

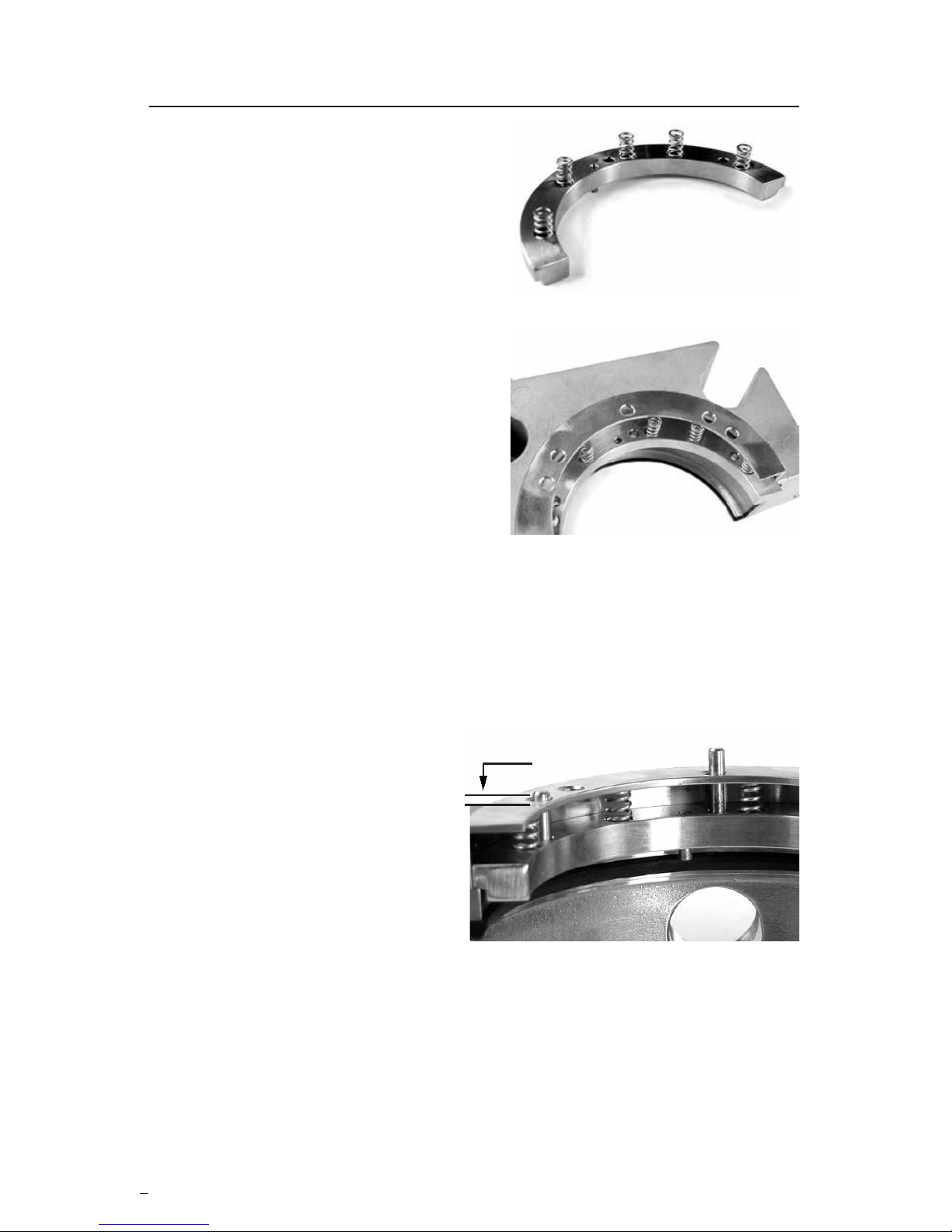

3.2 Install the sleeve gasket into the

groove. Hold the gasket in the

groove and adjust it so the end

extends 0.025 to 0.035 inch

(0.65 to 0.90 mm) past the seal

drive joint surface. See Figure 7.

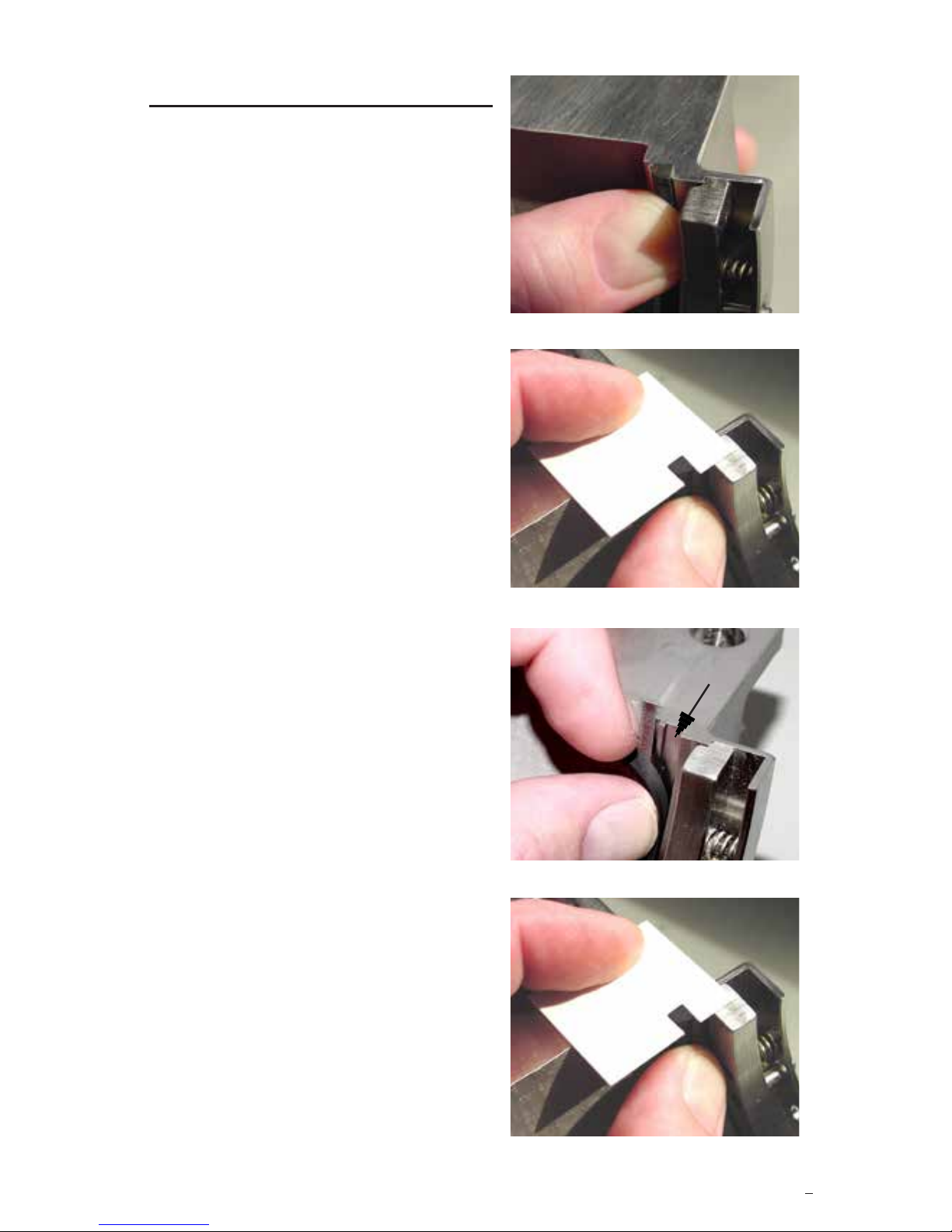

3.3 Check the gasket extension with

the 0.030 inch (0.76 mm) thick

"Proud" gauge. See Figure 8.

Note: All circumferential gaskets are

cut to the proper length at the factory

and require no further trimming. The

circumferential gaskets will appear to

be too long for the groove. The extra

length of the gasket is compressed

into the groove between the

glue points.

3.4 Pull back 0.50 inch (12.7 mm) of

the sleeve gasket and use a

paper clip to put two dots of

adhesive in the groove

approximately 0.25 inch (6.35

mm) and 0.50 inch (12.7 mm)

from the seal drive joint surface.

See Figure 9.

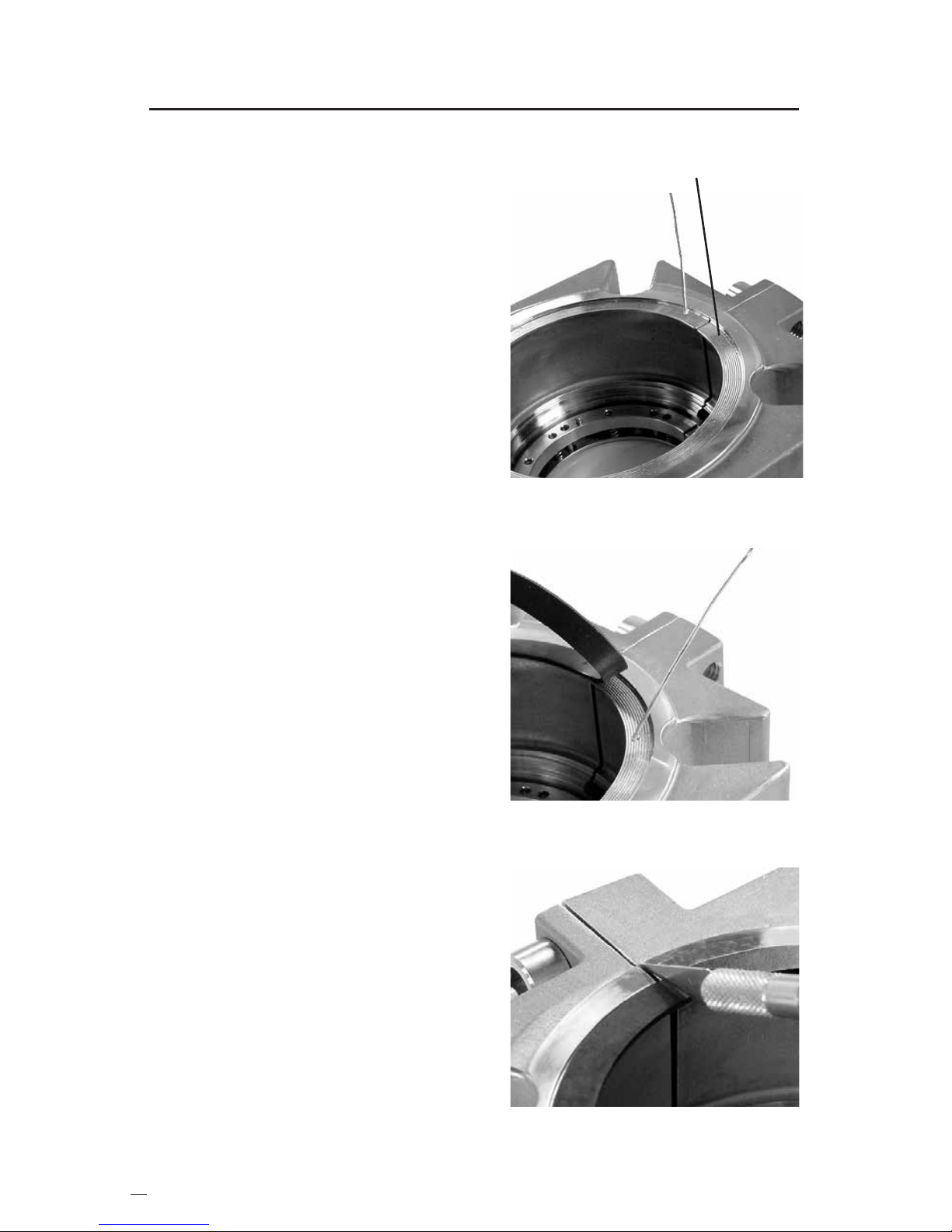

3.5 Push the end into the adhesive

and check the gasket extension

with the "Proud" gauge. Hold it

in place for 10 seconds.

See Figure 10.

3.6 Glue the other end of the sleeve

gasket in the groove using the

same procedure.