3

MZM 100 AS

Operating instructions

Electromagnetic solenoid interlock

EN

2.4 Technical data

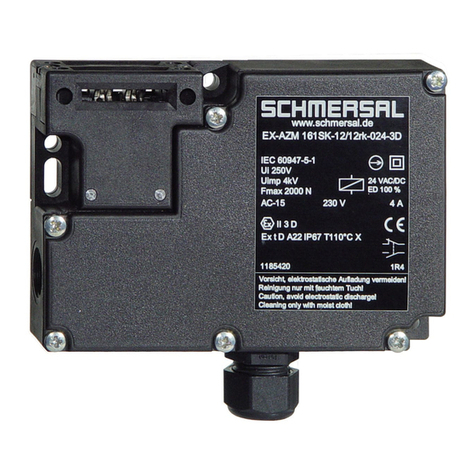

Standards: IEC 60947-5-1, IEC 60947-5-3, ISO 14119,

DIN EN 62026-2, ISO 13849-1, IEC 61508

Material of the housings: Plastic, glass-fibre reinforced

thermoplastic, self-extinguishing

Working principle: inductive

Coding level according to ISO 14119: low

Response time: < 150 ms

Duration of risk: < 150 ms

Time to readiness: < 4,000 ms

Mechanical data

Execution of the electrical connection: M12 connector plug, 4 poles

Mechanical life: > 1,000,000 operations

(for safety guards ≤ 5 kg;

actuating speed: ≤ 0.5 m/s)

Resistance to shock: 30 g / 11 ms

Resistance to vibration: 10 Hz … 150 Hz (0.35 mm / 5 g)

Holding force Fmax typically: 750 N

Holding force F guaranteed: 500 N

Electrically adjustable latching force: approx. 30 … 100 N

Permanent magnet (M), typically: approx. 15 N

Tightening torque for device fixation: max. 8 Nm

Ambient conditions

Ambient temperature: −25 °C … +55 °C

Storage and transport temperature: −25 °C … +85 °C

Relative humidity: 30 % … 95 %,

no condensation, no icing

Protection class: IP65 / IP67 to IEC 60529

Protection class: III

Insulation values to IEC/EN 60664-1:

- Rated impulse withstand voltage Uimp:0.8 kV

- Rated insulation voltage Ui:32 VDC

- Overvoltage category: III

- Degree of pollution: 3

Electrical data - AS-Interface

AS-i supply voltage: 26.5 … 31.6 VDC, protection

against polarity reversal

AS-i power consumption: ≤ 100 mA

AS-i device insulation: internal short-circuit proof

AS-i specification:

- Version: V 2.1

- Profile: S-7 B.F.E

AS-i inputs:

- Channel 1: Data bits DI 0/DI 1 = dynamic code transmission

- Channel 2: Data bits DI 2/DI 3 = dynamic code transmission

Databits condition static 0 or dynamic code transmission

AS-i outputs:

- DO 0: Magnet control

- DO 1 … DO 3: Latching force adjustment in 10 N steps

AS-i Parameter bits:

- P0: Actuator in

- P1: Solenoid interlock locked

- P2: Auxiliary voltage in

- P3: Internal device error

Parameter request: default value parameter request "1111" (0xF)

AS-i Input module address: 0

- preset to address 0, can be changed through

AS-interface bus master or hand-held programming device

Electrical data - auxiliary voltage (Aux)

Supply voltage UB: 24 VDC (−15 % / +10 %),

protection against polarity

reversal, stabilised PELV units

Power consumption: ≤ 600 mA

Magnet switch-on time ED: 100 %

Device fuse rating: ≤ 4 A (when used to UL 508)

LED switching conditions display:

(1) LED green/red (AS-i duo LED): Supply voltage /

communication error /

slave address = 0 /

periphery error detected

(2) LED red: Internal device error

(3) LED yellow: Device condition (Enabling status)

If the cable and connector assembly is not listed for Type 12

or higher, then the device MZM 100 … shall be used in a

Type 1 environment only.

Use isolated power supply only.

For use in NFPA 79 Applications only.

Adapters providing field wiring means are available from the

manufacturer. Refer to manufacturers information.

2.5 Safety classification

Standards: ISO 13849-1, IEC 61508

PL: e

Control Category: 4

PFH: ≤ 5.0 x 10-9 / h

SIL: suitable for SIL 3 applications

Service life: 20 years

3. Mounting

3.1 General mounting instructions

Please observe the relevant requirements of the standards

ISO 12100, ISO 14119 and ISO 14120.

The safety switchgear must be used as end stop.

Any mounting position. The system must only be operated with an

angle of ≤ 2° between the solenoid interlock and the actuator.

For fitting the MZM 100 AS and the actuator, two mounting holes for M6

screws with washers (washers included in delivery) are provided.

After fitting, the mounting holes can be sealed by means of the supplied

plugs. The plugs serve as a means of sealing the assembly openings

and are also suitable to prevent against tampering with the screw

connection. If necessary, these plugs can be removed from the actuator

by exercising pressure on the top side (in case of fitting with connector

downwards) or on the right-hand side on the plugs of the anchor plate.

Minimum distance between two devices: 100 mm

At an ambient temperature of ≥ 50 °C, the safety component

must be fitted so that it is protected against unintentional

contact with persons.

The safety component must be operated in the operating

direction of the latching force (refer to image).

±5mm

3mm

The actuator must be permanently fitted to the safety guards

and protected against displacement by suitable measures

(e.g. tamperproof screws, gluing, drilling of the screw heads).