Schmidt IL 30.0 Series User manual

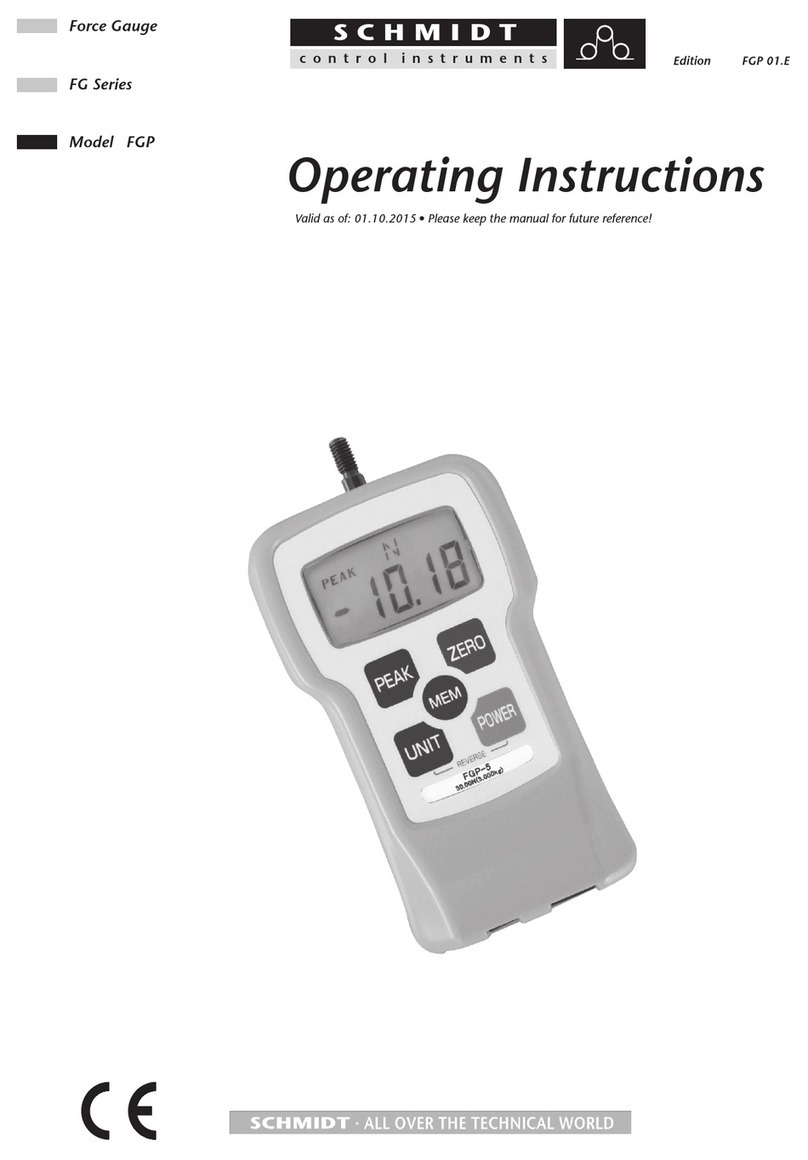

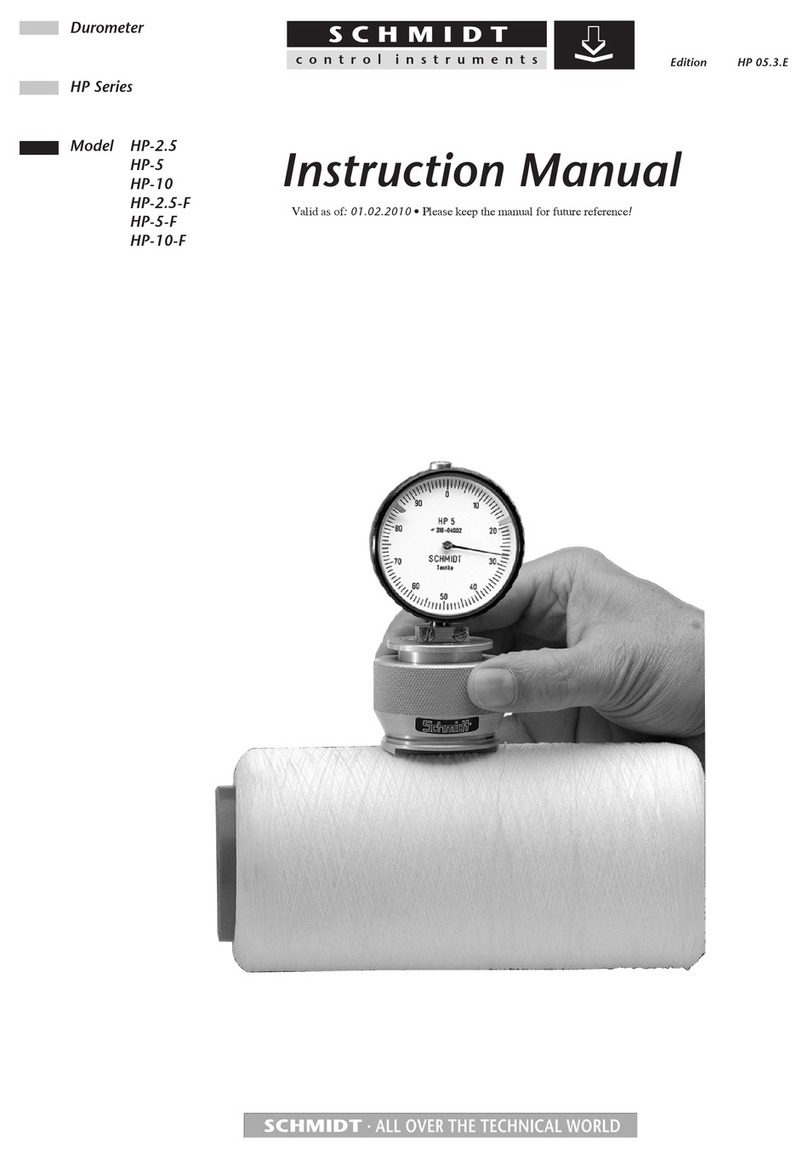

Other Schmidt Measuring Instrument manuals

Schmidt

Schmidt FS-422 Series User manual

Schmidt

Schmidt OS8000 User manual

Schmidt

Schmidt DHT-3 User manual

Schmidt

Schmidt ET Series User manual

Schmidt

Schmidt G2 TRIGGER DEADMAN User manual

Schmidt

Schmidt ZE Series User manual

Schmidt

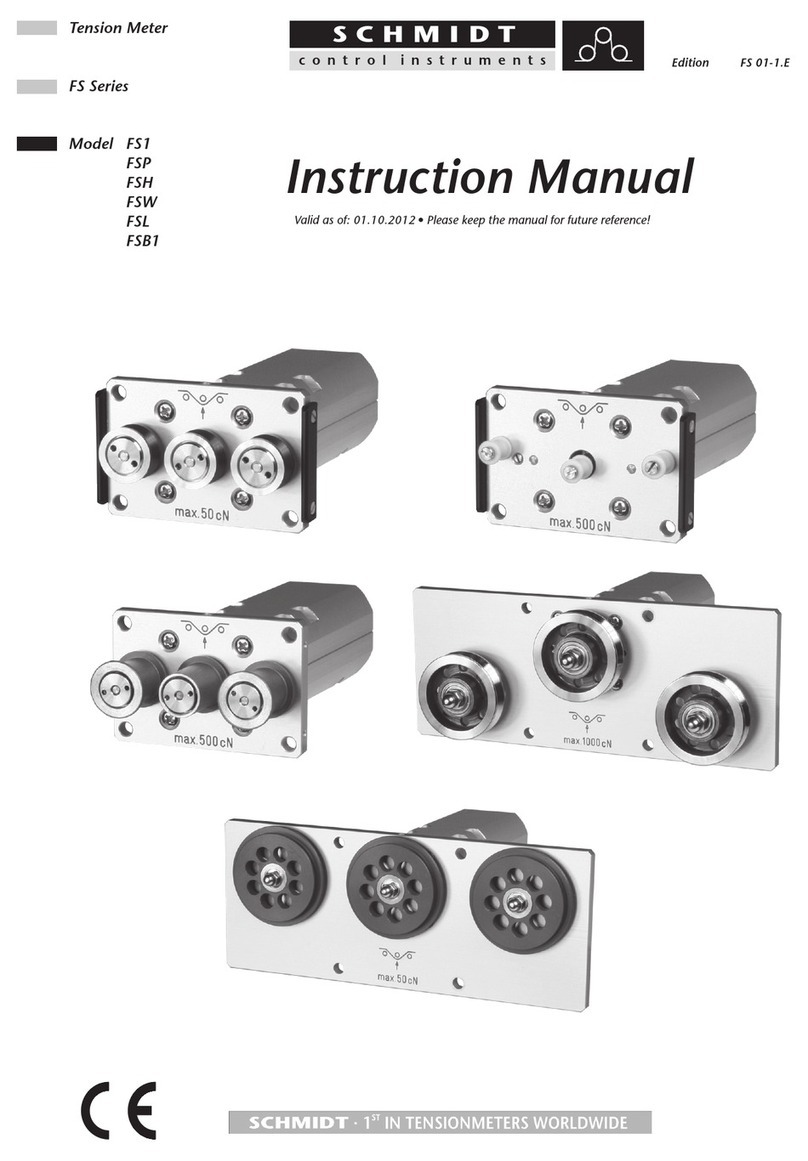

Schmidt FS Series User manual

Schmidt

Schmidt DX2-50 User manual

Schmidt

Schmidt MZ Series User manual

Schmidt

Schmidt SS 20.250 User manual

Schmidt

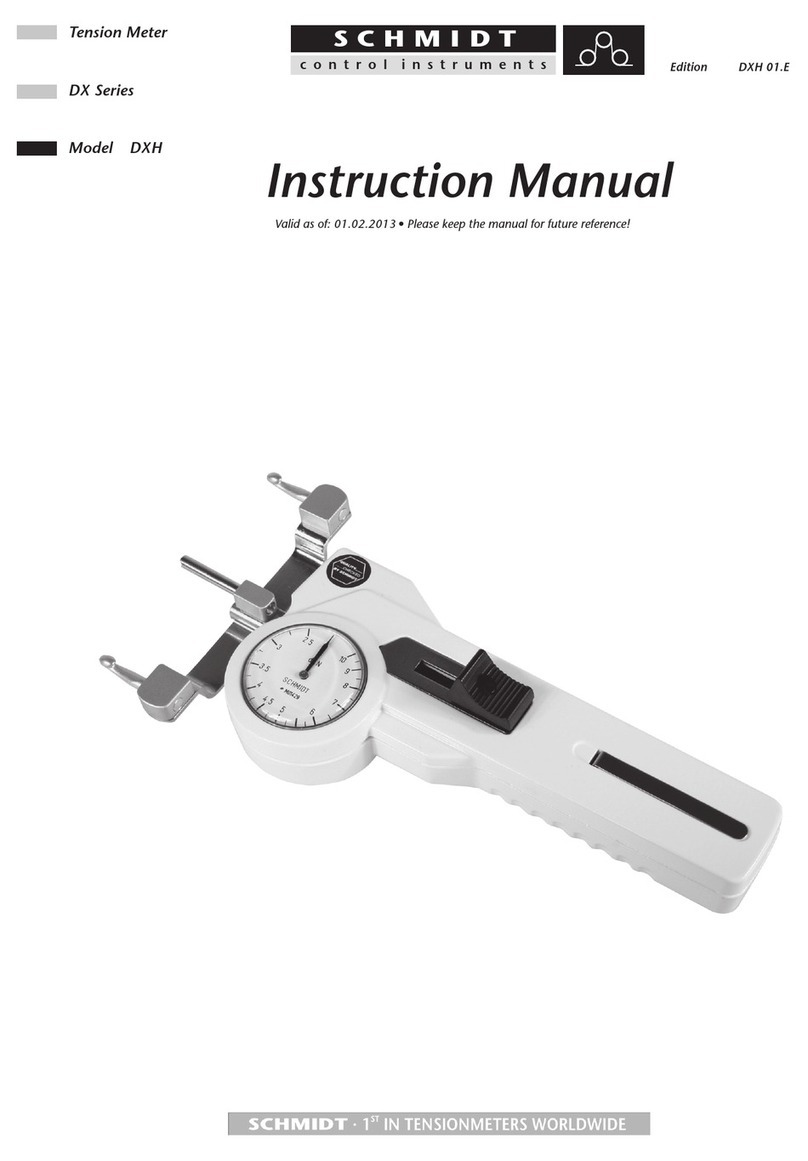

Schmidt DX Series User manual

Schmidt

Schmidt FS1-422 User manual

Schmidt

Schmidt Paper Schmidt PS8000 User manual

Schmidt

Schmidt FS Series User manual

Schmidt

Schmidt MK Series User manual

Schmidt

Schmidt Q-10 User manual

Schmidt

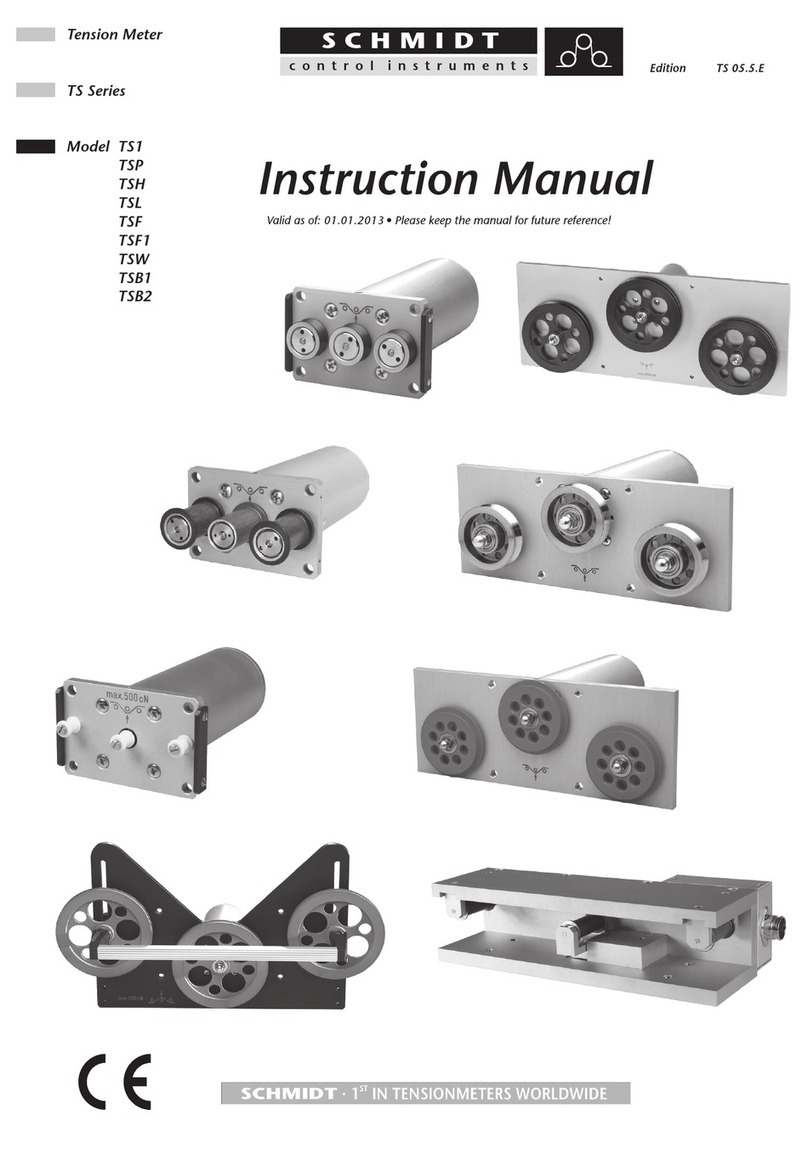

Schmidt TS Series User manual

Schmidt

Schmidt RM Series User manual

Schmidt

Schmidt OS8000 User manual

Schmidt

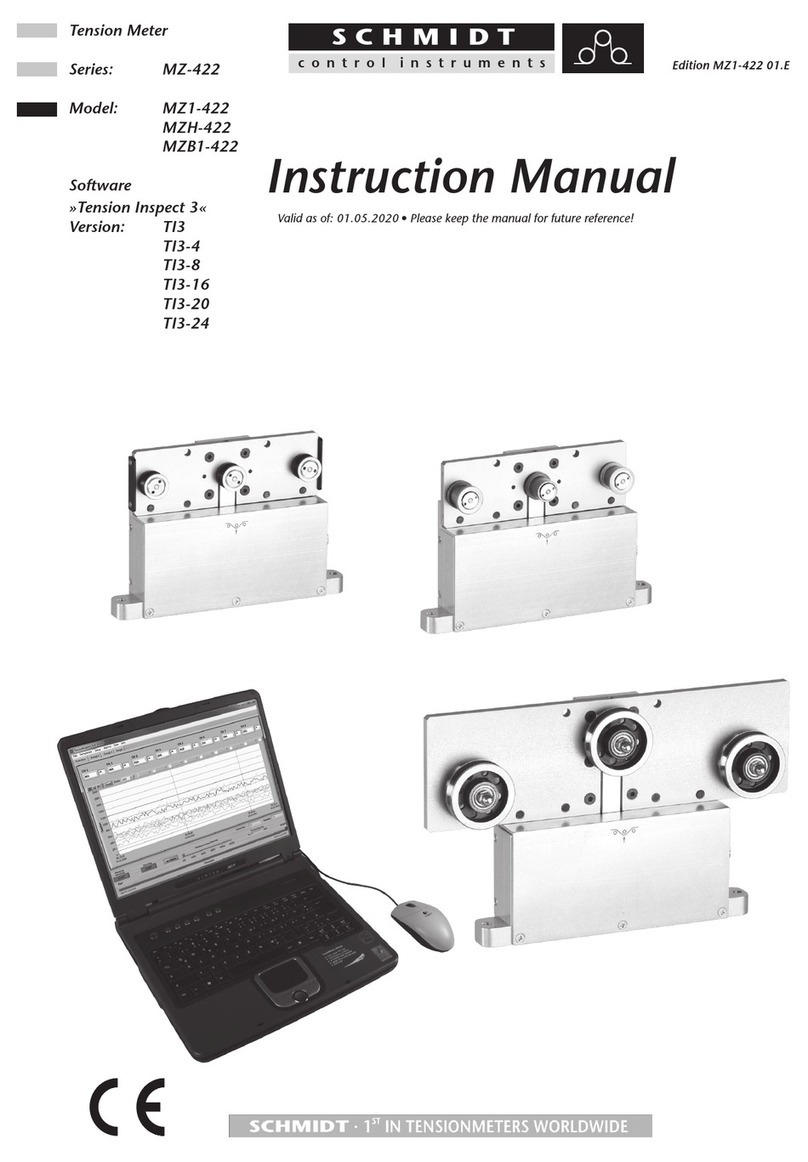

Schmidt MZ-422 Series User manual