Schmidt SS 20.415 Twin User manual

Other Schmidt Measuring Instrument manuals

Schmidt

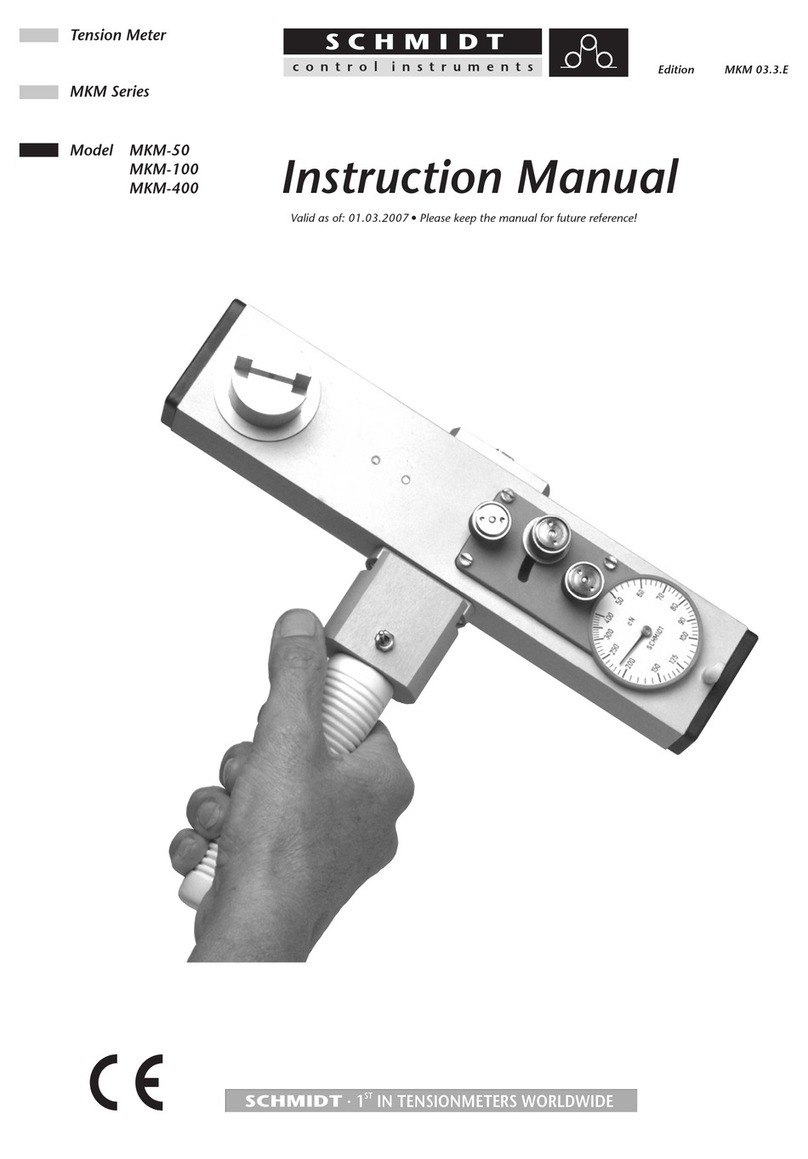

Schmidt MKM-50 User manual

Schmidt

Schmidt KLA User manual

Schmidt

Schmidt SC Series User manual

Schmidt

Schmidt RS8000 User manual

Schmidt

Schmidt SC Series User manual

Schmidt

Schmidt ZE Series User manual

Schmidt

Schmidt DXK User manual

Schmidt

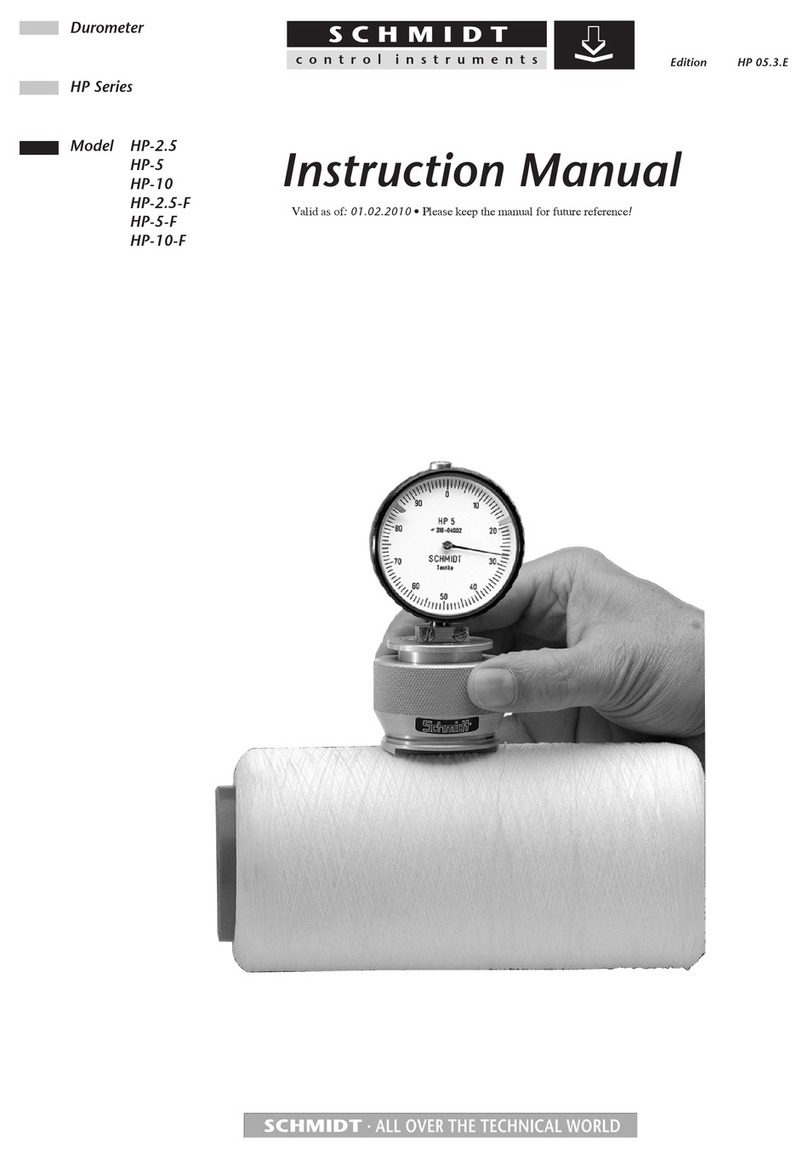

Schmidt HP Series User manual

Schmidt

Schmidt DHT-3 User manual

Schmidt

Schmidt ZED User manual

Schmidt

Schmidt DX2-50 User manual

Schmidt

Schmidt SHT Series User manual

Schmidt

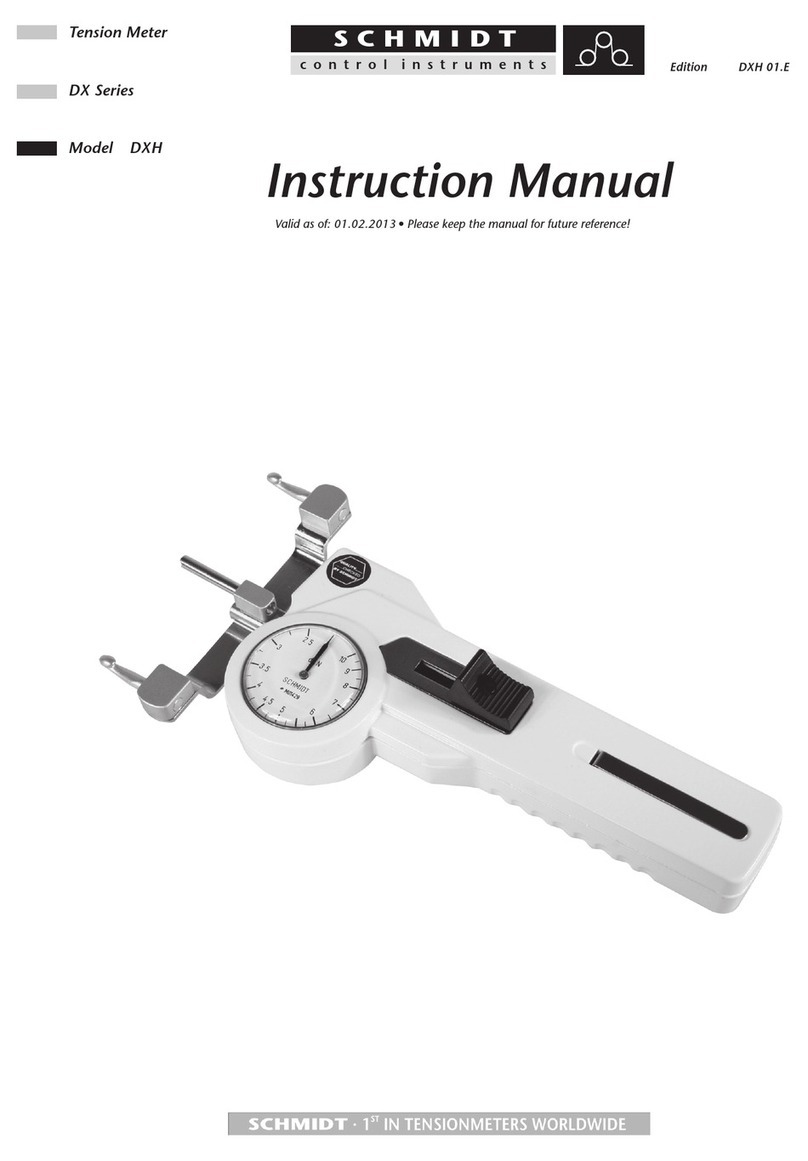

Schmidt DX Series User manual

Schmidt

Schmidt DN Series User manual

Schmidt

Schmidt DHT-2 User manual

Schmidt

Schmidt D-2005 Series User manual

Schmidt

Schmidt DW-U User manual

Schmidt

Schmidt DW-D User manual

Schmidt

Schmidt SS 20.400 User manual

Schmidt

Schmidt DX Series User manual