GBA Z 0697 2 E

BA Page 9 of 29 November 9, 2020

Last revised 11-2020 Rev. 2

Scholl Apparatebau GmbH & Co. KG

3 INSTALLATION

3.1 SCOPE OF DELIVERY

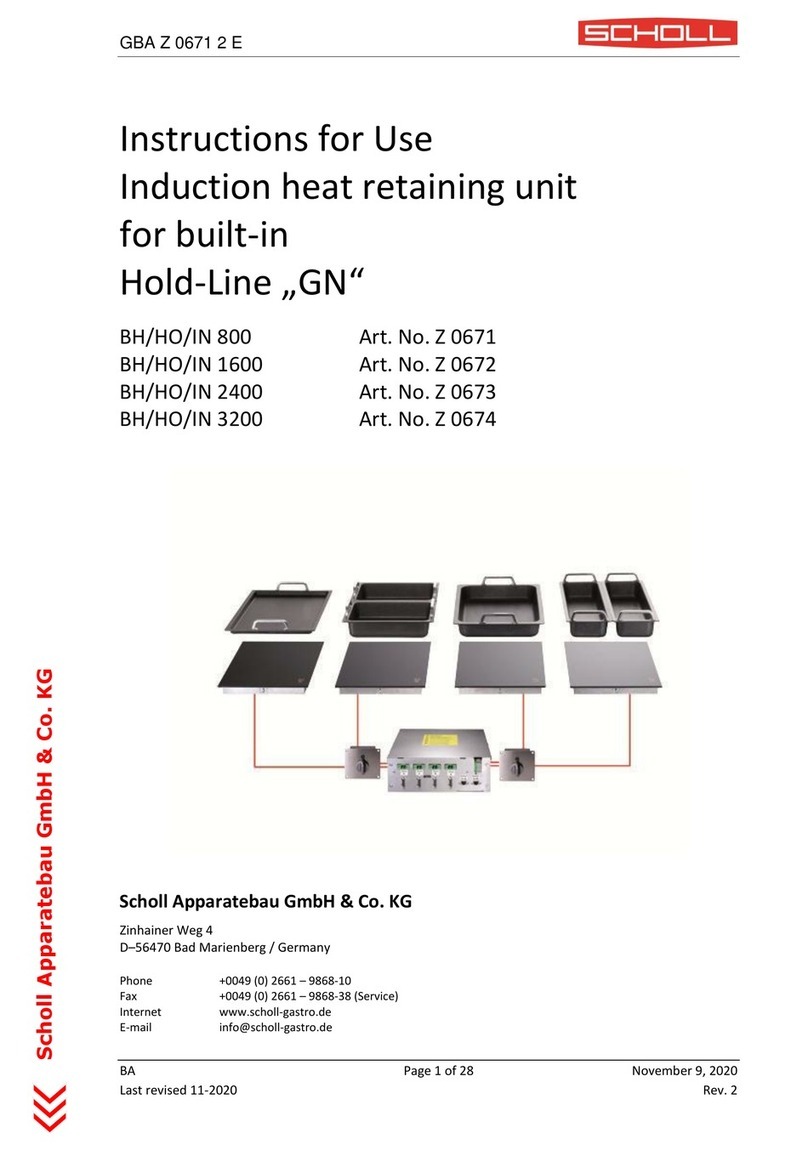

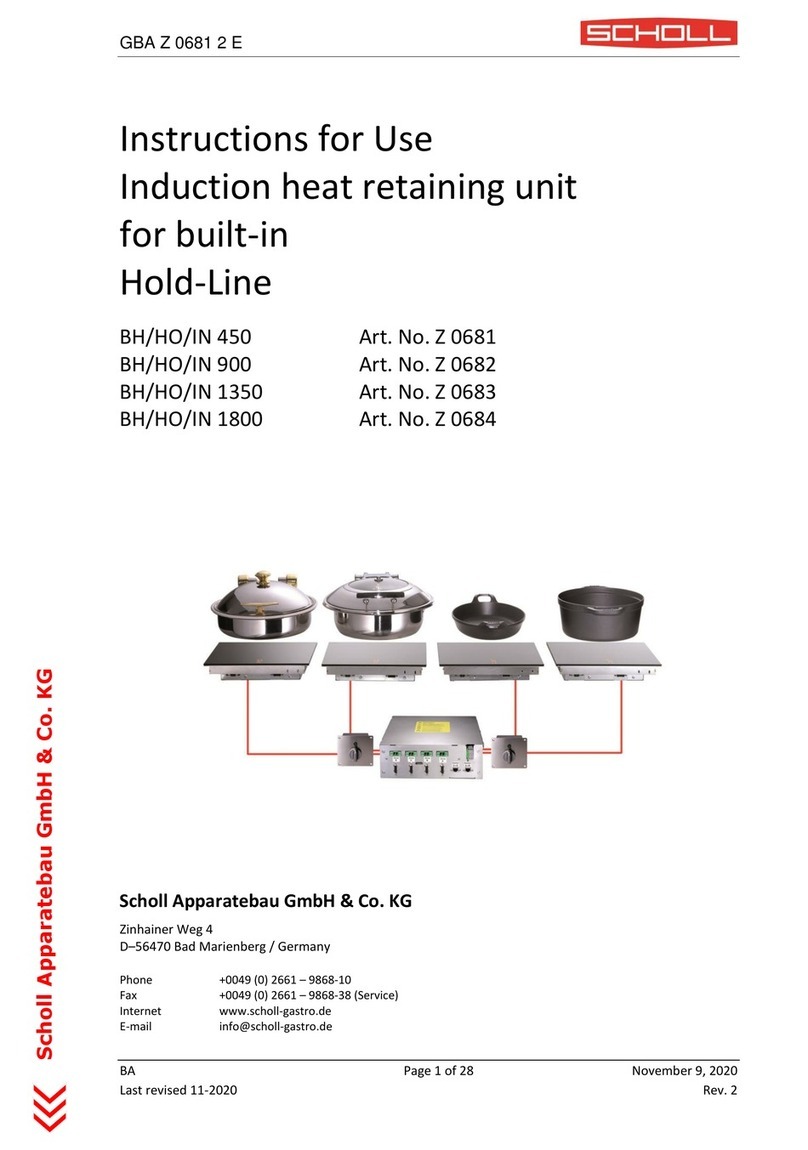

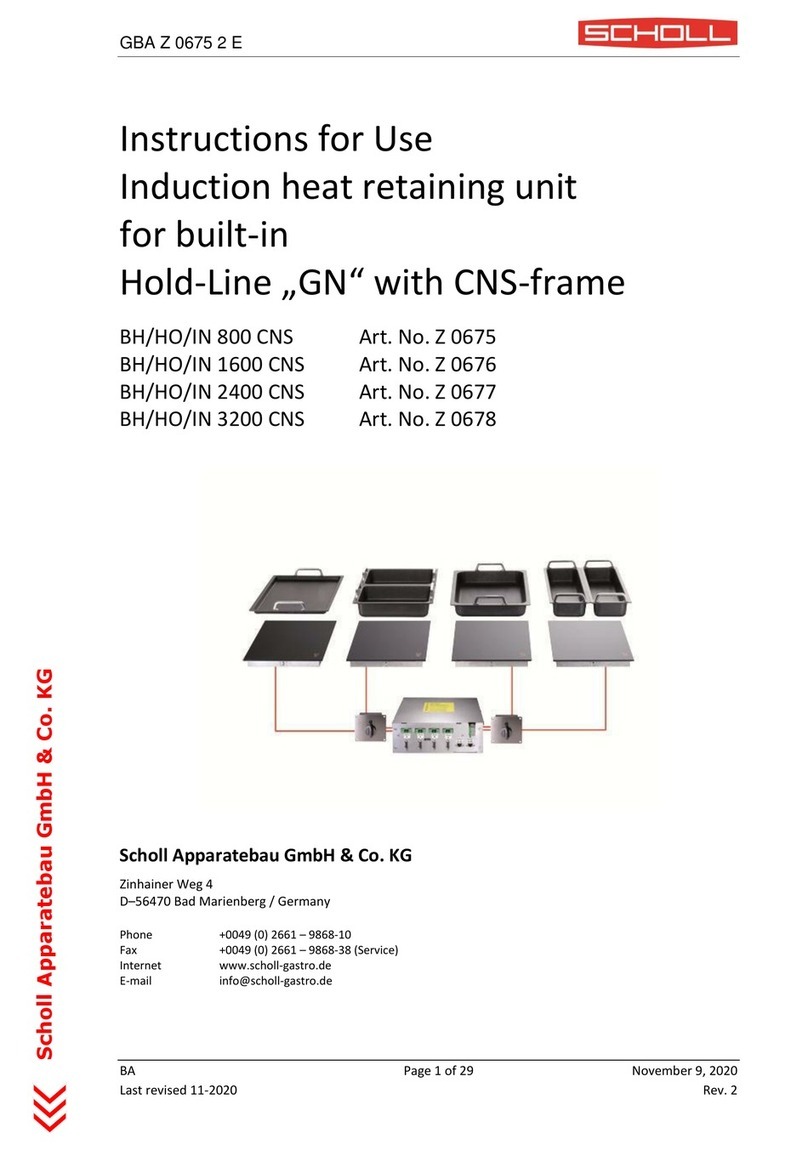

The generator is delivered with one to four built-in heat retention plates including glass tops and CNS-

frames and one to two operating units (with 1 heat retention plate 1 temperature operation unit –with 2 –

4 heat retention plates 2 temperature operation units).

Please note that the unit is not completely assem-

bled. Pay attention to the requirements of installa-

tion.

3.2 REQUIREMENTS OF INSTALLATION

The heat retention plate must be mounted on an even place like a table or counter which must be able to

withstand a loading of 40kg. The thickness of the top plate must not exceed 25mm. The generator can as an

example be fixed in a closed drawer with doors. Air inlet and air outlet must not be obstructed. The control

knob to operate the unit must be easily accessible.

RTCSmp Install Hold-Line units must only be fixed in closed counters.

The rear side of the induction unit below the fan (air intake) has to be absolutely free regarding to danger of

obstruction. An optimal air intake must not be reduced by the installation. The max air flow is 96m3/h and

therefore a minimal opening of 6000 mm2has to be maintained. If necessary, a perfect air supply has to be

guaranteed by adding a flexible air duct including a shackle (available as accessory). Pay special attention to

the air inlet and air outlet openings: there has to be a distance of at least 40mm between obstructions like

walls or floors. In addition to that, pay attention that the exhausted air is not recirculated together with the

fresh air. We recommend guaranteeing a supply of fresh air by fixing an air duct incl. shackle or by air open-

ings. The air exit must not to be hindered by any obstructions.

3.3 DEFINITION OF INTERFACES

Please observe the following rules:

•Check and ensure that the supply voltage and the line current matches the specifications given on

the rating plate.

When residual current circuit breakers are used, it has to be taken into account, that by switching on

an induction generator to a power supply system, leakage current can be caused for a short period

due to the asymmetry. This leakage current can activate the residual current circuit breakers. While

the choosing residual current circuit breakers, please note that the generator generates direct as

well as alternating current in high frequency areas of approx. 20 kHz. Our recommendation is to

choose a residual current circuit breaker suitable for these requirements. If the residual current cir-

cuit breakers are used as protection for People, the breakers must be in compliance to the specific

National and local regulations for personal security.

The minimal distance between the heat retaining plates is 10cm.

Connection A must be always connected.

•This induction unit is equipped with an internal air cooling system. Make sure that the air supply and

air exhaust are not blocked (wall, fabric etc.).