Assembly and settings

8 01.00 | MMS-P22 / MMSK-P22 | Assembly and Operating Manual | en | 1566688

4 Assembly and settings

NOTE

The assembly instructions in this chapter are generally

applicable.

Module-specific assembly instructions for the sensor can be

found in the Assembly and Operating Manual for the module,

which can be downloaded at schunk.com

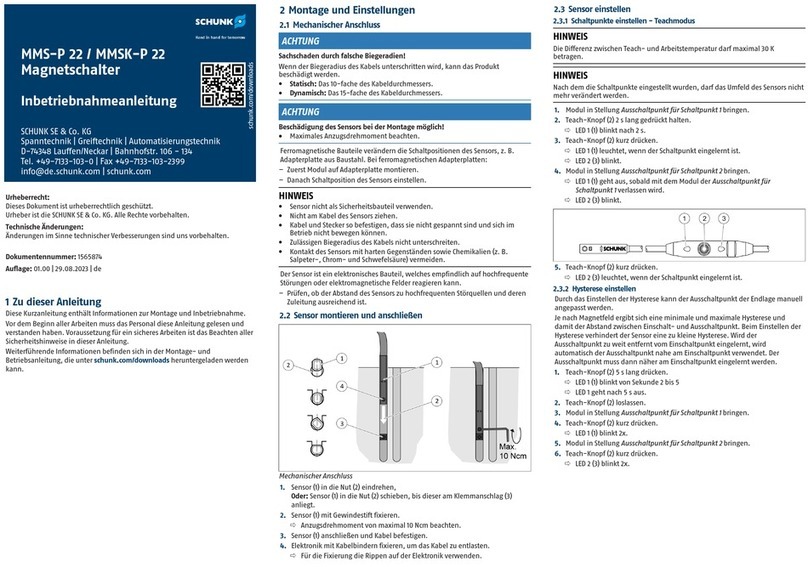

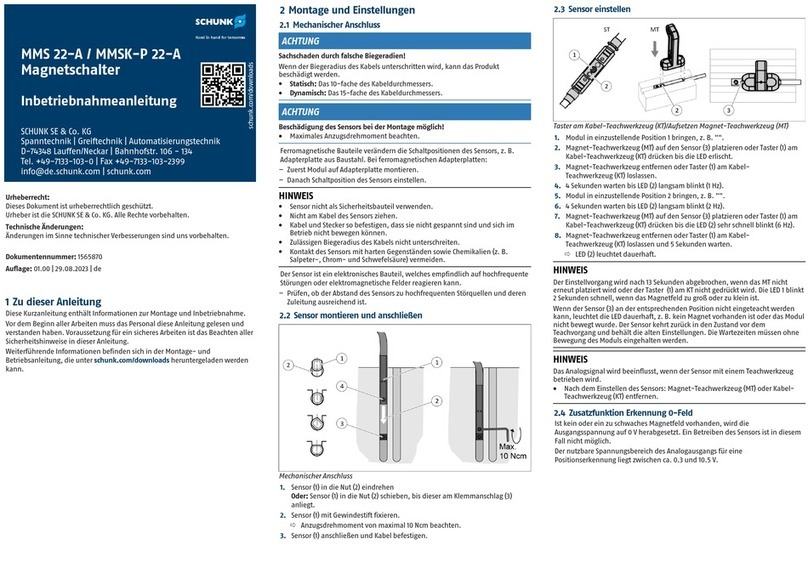

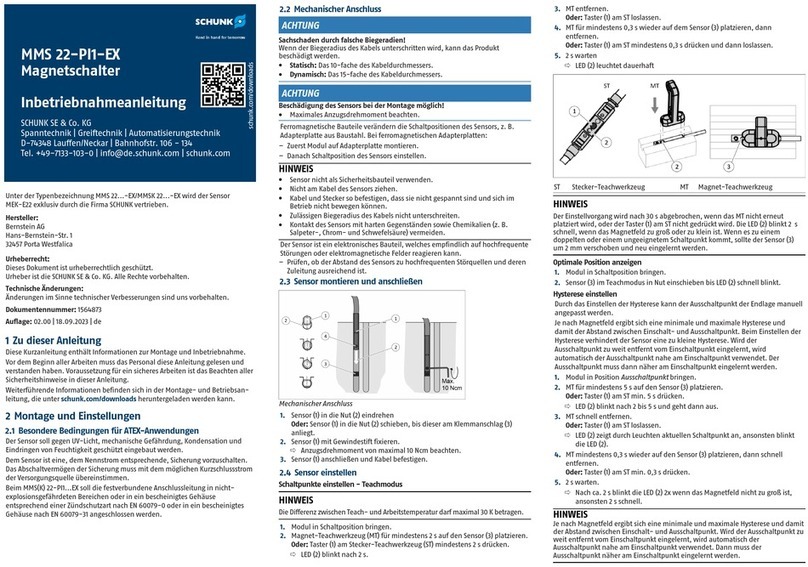

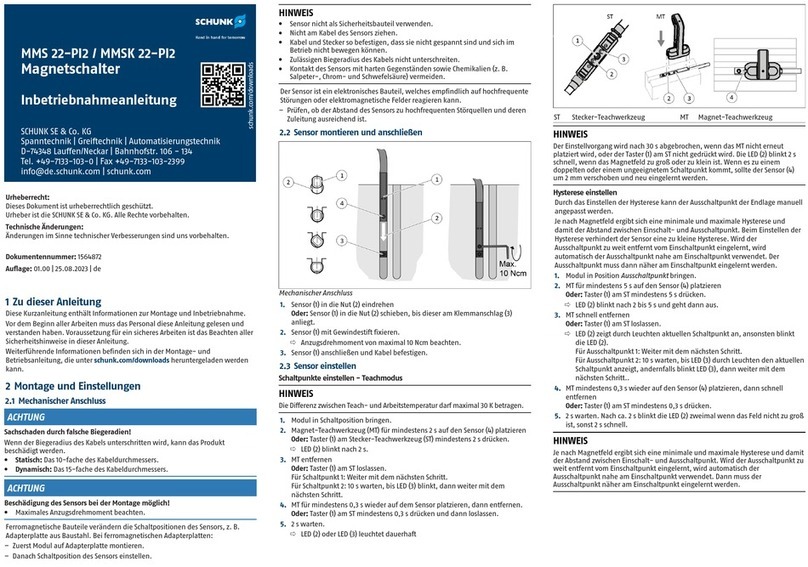

4.1 Mechanical connection

CAUTION

Property damage due to incorrect bending radius!

The product may get damaged if the cable's bending radius is

less than the minimum.

lStatic: 10 times the cable diameter.

lDynamic: 15 times the cable diameter.

CAUTION

Risk of damage to the sensor during assembly!

lObserve the maximal tightening torque.

Ferromagnetic components change the sensor's switching

positions, e.g. adapter plate made of construction steel. For

ferromagnetic adapter plates:

lFirst, install the module on the adapter plate.

lThen adjust the switching position of the sensor.

NOTE

lDo not use the sensor as a safety component.

lDo not pull on the cable of the sensor.

lSecure the cable and connection plug so that they are not

taught and cannot move during operation.

lDo not exceed the permitted bending radius of the cable.

lDo not allow the sensor to come into contact with hard

objects and chemicals (e.g., nitric acid, chromic acid and

sulfuric acid).

The sensor is an electronic component that can be sensitive to

high-frequency interference or electromagnetic fields.

lCheck whether there is sufficient distance between the sensor

and sources of interference and their supply cables.