SAFETY INSTRUCTIONS

Warning!

In order to avoid any risk of electrical shocks, injuries and fire, please follow the

enclosed safety instructions. Read and respect these instructions before using the

machine. Keep this document.

General safety instructions

Choice of tool

Use the appropriate tool. Do not use tools or adaptable devices of too low a power

rating to undertake heavy work. Do not use tools for other purposes than the work for

which they have been designed.

Maintenance and storage

Store your tools in a safe place. Unused tools must be stored in a dry, locked place,

out of reach of children. Maintain your tools carefully. Keep your tools clean to work

better and more safely. Follow indications relative to maintenance and indications

concerning changing accessories.

Keep handles dry and free of oil and lubricants.

Check whether the tool is damaged. Before using the tool, always carefully check that

parts are functioning perfectly. Check whether moving parts are functioning correctly,

whether they do not become stuck or if other parts are damaged. All the components

must be assembled correctly and satisfy conditions to guarantee the tool's perfect

operation. Every safety device, every switch and every other damaged or defective part

must be repaired or replaced appropriately by a qualified technician.

Coution!

Ensure that you use the tool and its accessories in accordance with the safety instructi-

ons. Also understand take account of the tool's possibilities by paying attention to the

working conditions and the task to be undertaken. Using the tool for tasks other than

those intended may be dangerous.

This tool satisfies safety rules in force. All repairs must be undertaken by qualified

professionals with original spare parts; if not, the tool may pose a danger for the user

and invalidate the guarantee.

Safety instructions for the user

Keep children away. Do not allow other people to touch the tool; keep them away from

your working area. Wear appropriate working clothes. Do not wear loose clothing or

jewels; they could be caught by moving parts. When working in the open air, it is

recommended that rubber gloves and anti-skid heeled shoes are worn. Wear a hair net

if you have long hair. Do not make the radius of your action too wide. Avoid adopting a

position which is tiring for the body; ensure that your support on the ground is firm, and

keep in balance at all times. Always be attentive. Look at your work, act in a sensible

way and do not use the tool when you are tired.

Safety instructions relative to the working area

Keep order in your working area. Disorder in the working area increases the risk of an

accident. Take account of the working area environment. Do not expose electrical tools

to rain. Do not use electrical tools in a moist or damp environment. Ensure that the

working area is well-lit. Do not use electrical tools if flammable liquids or gases are

nearby.

Specific safety instructions

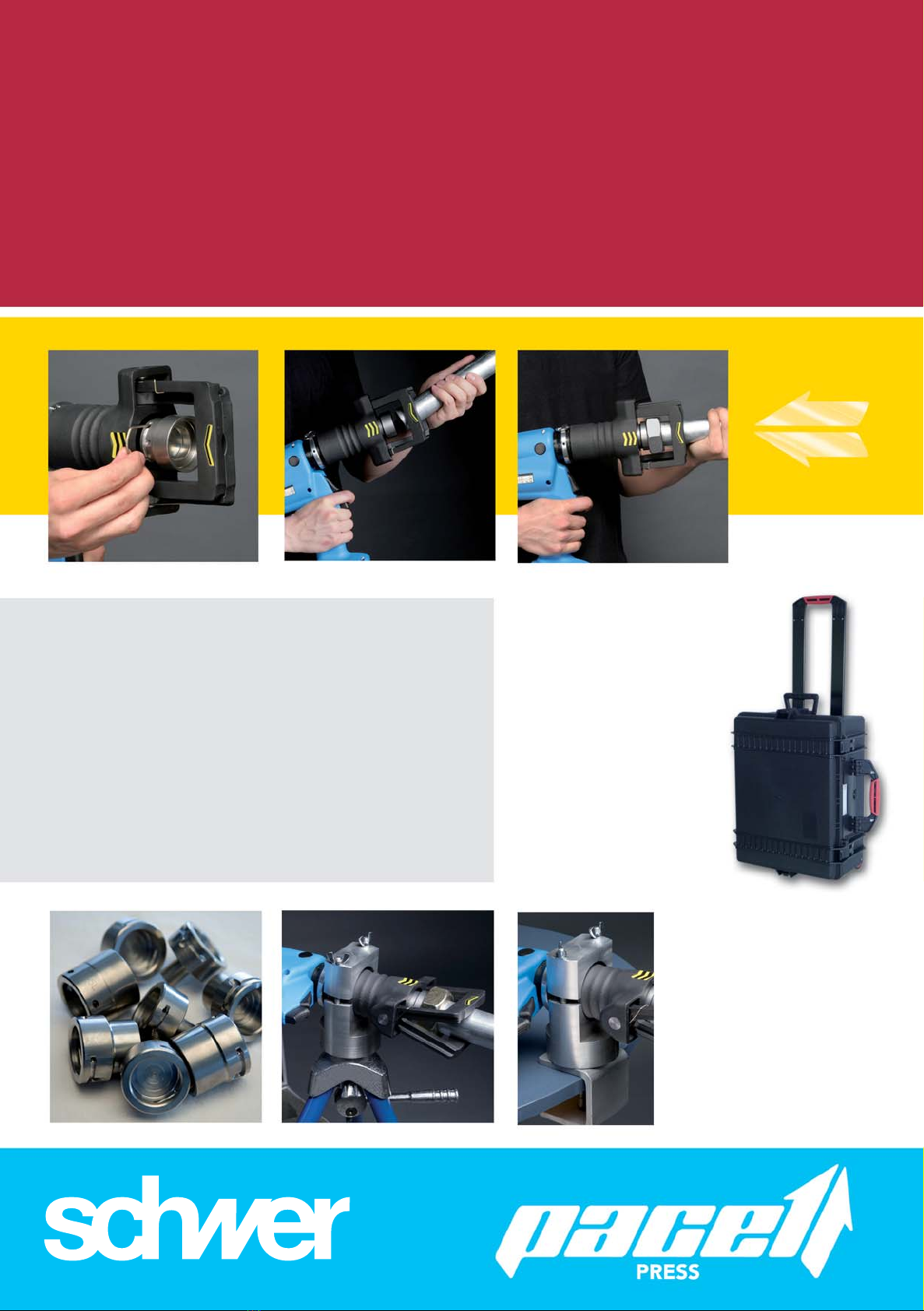

Pre-assembly machine

Do not put your fingers between piston and clamps when operating the machine.

Risk of injury.

Disposal

If you want to dispose this product, do not mix it with general household

waste. There is a separate collection system for used electronic products

in accordance with legislation that require proper treatment, recover and

recycling.

Warning

Do not remove the screw placed under the black plastic cap,

because the internal hydraulic pressure can reach 700bar during

normal use (this screw is only used by authorized technicians for

controlling the pressure)

Battery

The tool is supplied with unloaded batteries. Before using, load batteries by using the

charger supplied with the tool. Before a prolonged stocking, recharge battery.

Never short-circuit the connectors of a battery.

The battery pack contains dangerous products. Recycling of Ni-MH

rechargeable batteries must be made in conformity with dispositions

defined in the European regulation 91/157/CEE. Please, return your

used battery to any authorized distributor or to an existing collection

station to ensure its recycling.

If you want to dispose this product, do not mix it with general household waste. There

is a separate collection system for used electronic products in accordance with legisla-

tion that requires proper treatment, recover and recycling.

Charger

See battery charger instruction manual.

Advice

It is recommended to keep the tool away from dusty or rough places, in order to avoid

wrong working. Although this tool is robust, it must be handled with care. After use,

wipe the tool carefully and replace it in its case. In case of long storage, spray the me-

tallic parts of the tool with oil. Keep the tool inside, in a ventilated warehouse. Avoid fast

temperature changes, this can produce condensation.

Follow the Safety Instructions at work.

Schwer Fittings GmbH

Hans-Schwer-Platz 1

D-78588 Denkingen

Tel.: +49 (0)7424/9825-0

Fax: +49 (0)7424/9825-7900

info@schwer.com

www.schwer.com

RELIABLE

Pace1Press_GB 2016_Layout 1 12.09.16 14:21 Seite 7