S

SE

ER

RV

VI

IC

CE

E

M

MA

AN

NU

UA

AL

L

3 of

79

___________________________________________________________________________

_______

ESIRIS -- Version 1.0 Date: 22.09.00

INDEX PAGE

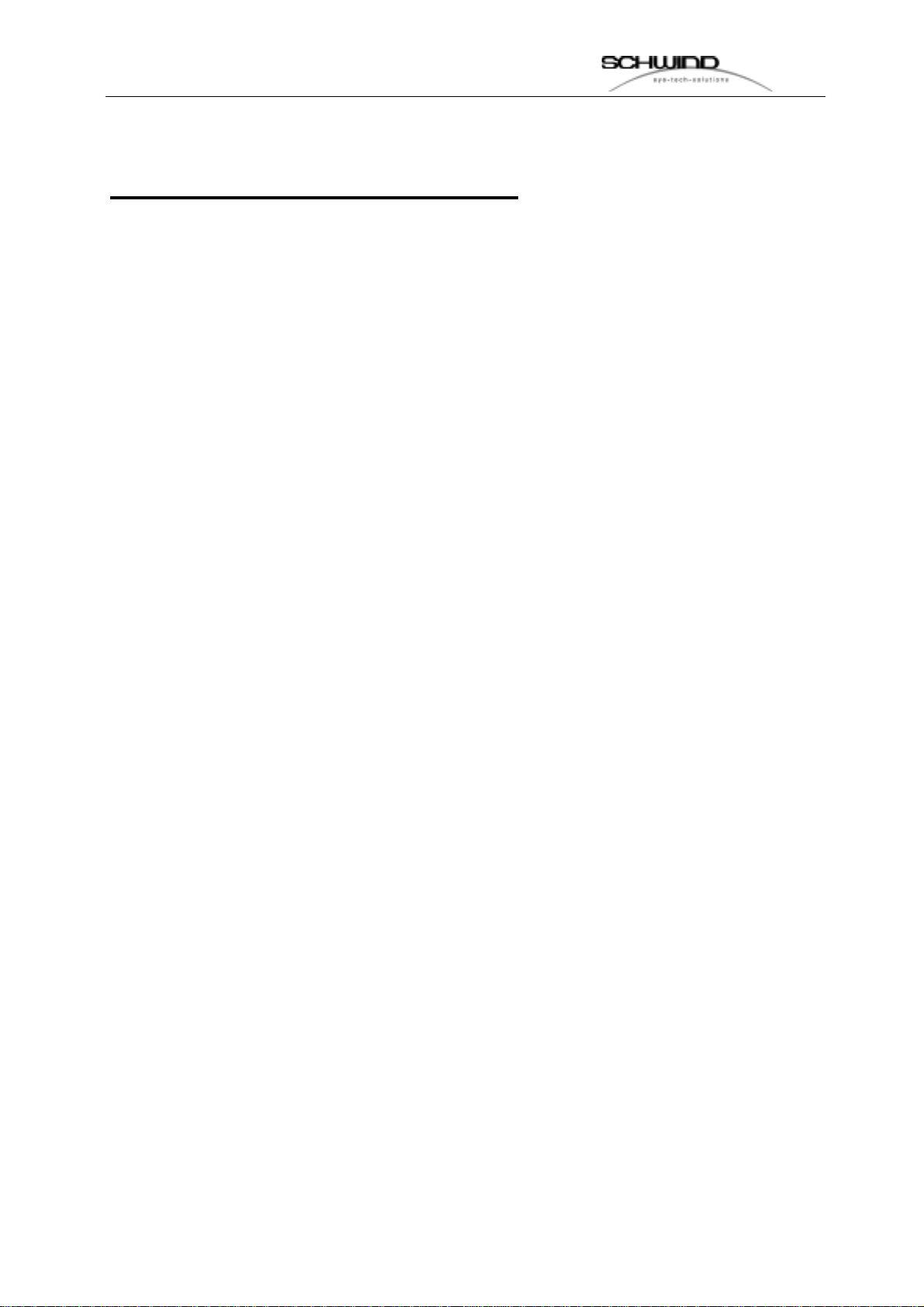

1. SECURITY OF DEVICE (LASER BEAM) ...........................................................................................5

GENERAL...................................................................................................................................................5

Alarm Shields and Type Shield............................................................................................................6

Accessible Beam Area.........................................................................................................................7

Protection Glasses...............................................................................................................................7

Working Gas........................................................................................................................................8

Gas containment:.................................................................................................................................8

DECLARATION OF MANUFACTURER (MPG)......................................................................................9

2. DESCRIPTION ..................................................................................................................................10

SPECIFICATION ........................................................................................................................................10

EXCIMER-LASER ......................................................................................................................................12

GAS SUPPLY............................................................................................................................................13

GASCONTAINMENT:..................................................................................................................................13

DELIVERY SYSTEM...................................................................................................................................14

MICROSCOPE AND ILLUMINATION ..............................................................................................................14

CONTROLLING..........................................................................................................................................15

PATIENT BED...........................................................................................................................................15

FOOT SWITCH..........................................................................................................................................15

RINSING OF OPTICAL BEAM DELIVERY SYSTEM .........................................................................................15

3. INSTALLATION REQUIREMENTS AND PREPARATIONS.............................................................17

WORKING ROOM......................................................................................................................................17

DIMENSIONS ESIRIS................................................................................................................................18

INPUT REQUIREMENTS .............................................................................................................................19

INSTALLATION AND ROOM PREPARATIONS FOR THE INSTALLATION...............................................................20

Minimum room dimensions (or room requirements)..........................................................................20

FLOOR REQUIREMENTS ............................................................................................................................20

INSTALLATION REQUIREMENTS .................................................................................................................20

Laser warning lamp ...........................................................................................................................21

Dimensions of boxes for the delivery.................................................................................................21

DELIVERY ................................................................................................................................................22

4. SOFTWARE DESCRIPTION BY SERVICE LOGIN..........................................................................23

MENU EXTRA ...........................................................................................................................................23

Menu Logfile ......................................................................................................................................23

Menu Parameter................................................................................................................................24

Distributor adress...............................................................................................................................25

MENU SERVICE........................................................................................................................................27

Menu Laser:.......................................................................................................................................29

Menu Scanner: ..................................................................................................................................35

Menu digital inputs / outputs..............................................................................................................36

Gascontainment:................................................................................................................................39

MENU ADJUSTMENT:.................................................................................................................................40

Laser:.................................................................................................................................................40

MENU TECHNICAL SECUTITY CHECK (TSC)...............................................................................................44

5. UNPACKING AND CONTROLLING.................................................................................................45

PUTTING INTO OPERATION........................................................................................................................46

WARRANTY..............................................................................................................................................47

6. DISMANTLING OF THE ESIRIS-LASERS .......................................................................................48