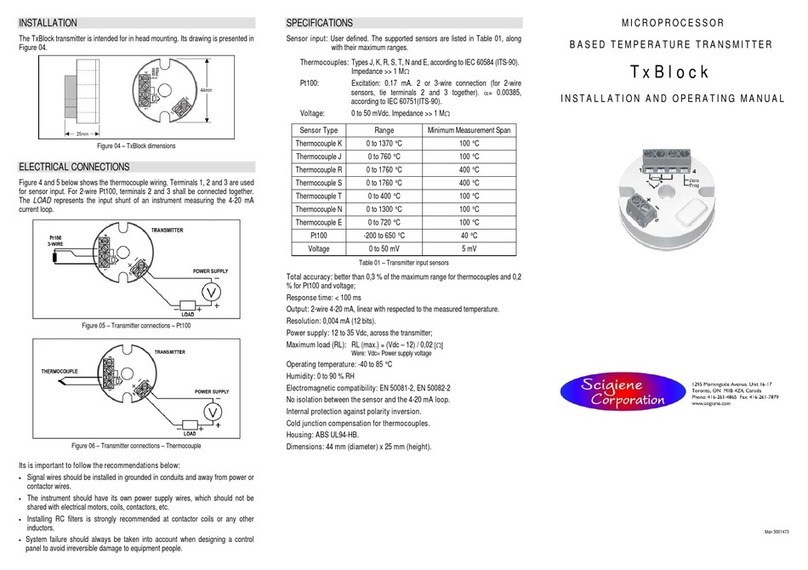

Table 01 –Transmitter input sensor

3. Filtration Optimization: Filters the measurements made by the

transmitter eliminating interferences from the electrical system that feeds

the process.

4. Sensor Failure: Establishes the behavior of the output when problems are

presented by the sensor. When Minimum is selected, the output current shifts to

< 4 mA (down-scale), typically used in refrigeration. When Maximum is selected,

if shifts to > 20 mA (up-scale), typically used for heating.

5. Zero Correction: Corrects minor errors presented by the transmitter, for

example, when the sensor is changed. See item Operation in this manual.

6. Transmitter Information: In this field, there are data that identify the

transmitter. This information must be informed in any consultation with the

manufacturer.

7. Read Configuration: When pressed, this allows one to read the

configuration on the transmitter connected.

8. Send Configuration: When pressed, this allows one to send the

configuration to the transmitter connected.

Note: If, on the purchase order, the user does not define a specific

configuration, the following configuration will be set:

•Pt100 sensor, range 0 to 100 °C, 0 °C zero correction.

•Filter to 60 Hz and maximum output for sensor failures.

4MECHANICAL INSTALLATION

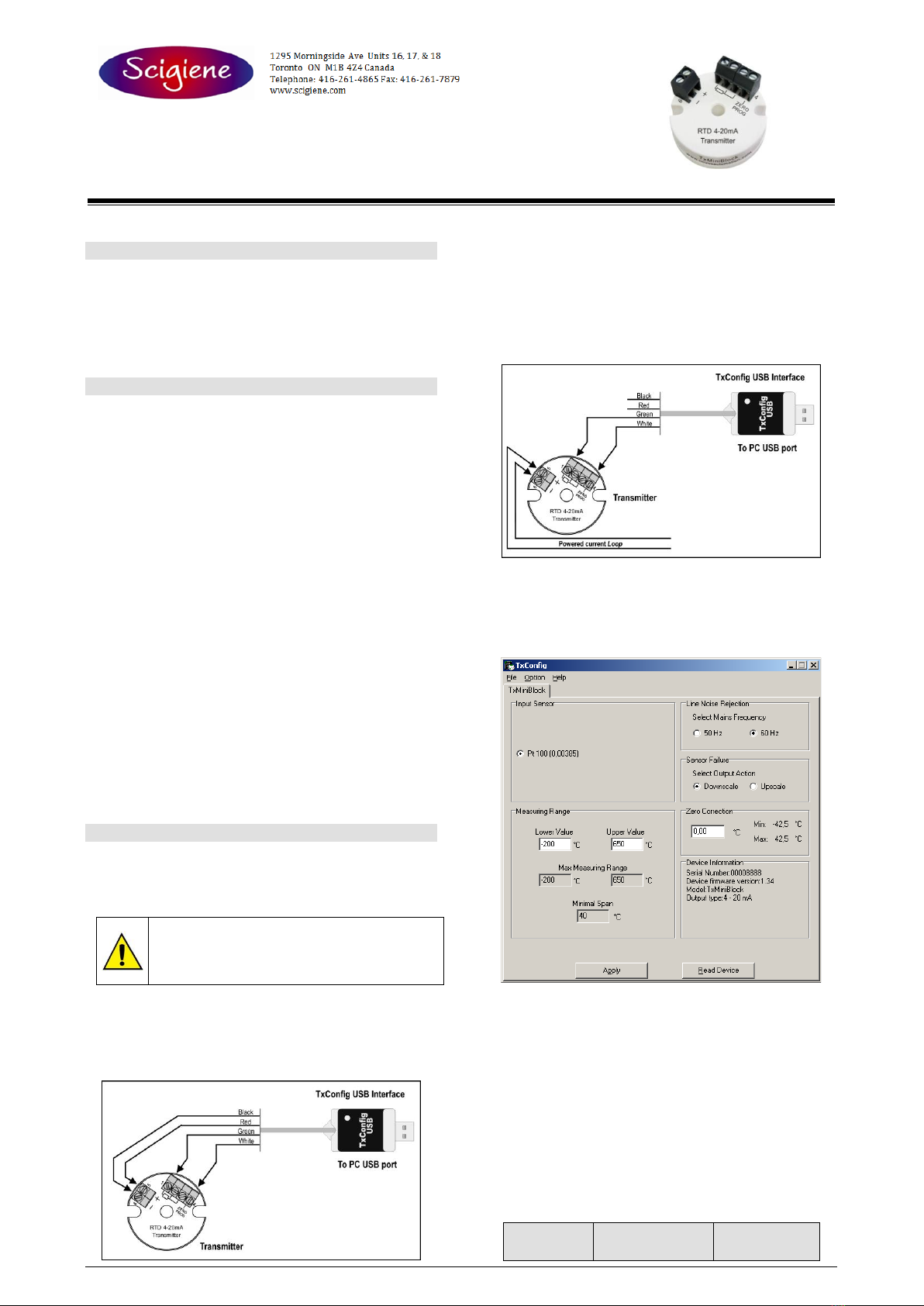

The TxMiniBlock transmitter is suitable to be installed on heads.

Figure 04 –Transmitter dimensions

5ELECTRICAL INSTALLATION

Polyamide housing for the terminals.

Section of the wire: 0.14 a 1.0 mm².

Recommended Torque: 0.8 Nm.

RECOMMENDATIONS FOR INSTALLATION

•Input signal conductors should run away from power and contactor wires,

if possible, in grounded conduits.

•The instruments must be powered by a suitable network for

instrumentation.

•System failure should always be taken into account when designing a

system to avoid irreversible damage to equipment or people. Installing

RC filters (47 and 100 nF, in series) is strongly recommended at

contactor coils or any other inductors.

ELECTRICAL CONNECTIONS

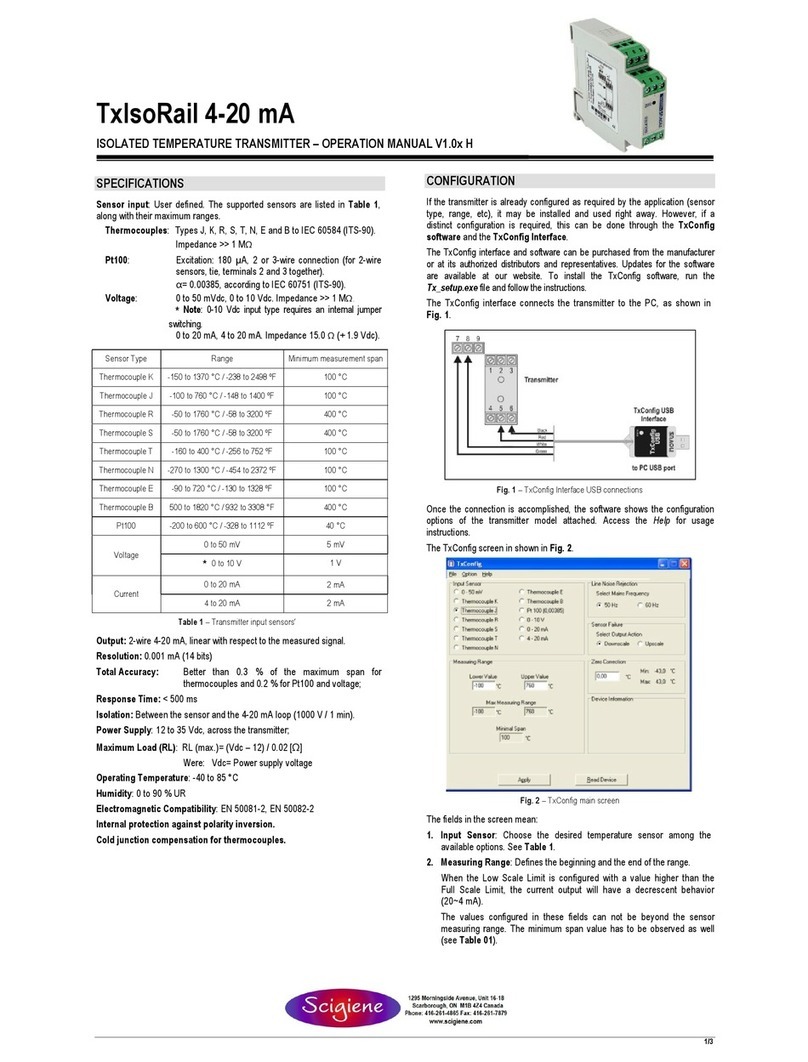

Figure 05 below shows the transmitter wiring. Terminals 1, 2 and 3 are used

for sensor input. For 2-wire Pt100, terminals 2 and 3 shall be connected

together. The LOAD represents the input shunt of an instrument measuring

the 4-20 mA current loop.

The figure below shows the electrical connections required. Terminals 1, 2 and

3 are used for the Pt100 input. For 2-wire Pt100, terminals 2 and 3 must be

interconnected.

Figure 05 –Transmitter electrical connections –Pt100

The LOAD represents the input shunt of an instrument measuring the 4-20

mA current loop (indicator, controller, recorder, etc).

6OPERATION

The sensor input is factory calibrated. Recalibration in the field is not

recommended, but it can be accomplished through the TxConfig software.

Contact the factory for the calibration procedure.

When necessary, fine adjustments to the transmitter output current can be

accomplished directly at the transmitter. To do so, short circuit transmitter

terminals 1and 4. After 2seconds, the output current starts to increase

gradually until it reaches 0.8 mA above the initial value. After reaching that

value, it drops to 0.8 mA below the initial value, increasing gradually again.

The user must monitor the output current and open the circuit when the current

reaches the desired value.

The offset correction can also be accomplished through the TxConfig

software. The TxConfig interface can be connected to the transmitter while it

is operating in the process. See in Figure 03 the Zero Correction field in the

main screen of the TxConfig software.

The user must choose the sensor span most suitable to the application. The

maximum and minimum sensor spans are limited in the TxMiniBlock and in

the TxConfig software. The user can configure any value within those two

limits.

It is important to note that the accuracy of the transmitter is always based on

the maximum range of the Pt100 sensor, regardless of the configured span. .

Example:

•Pt100 maximum span = 850 °C; 0.2% accuracy.

•Maximum error = 1.7 °C (0.2 % de 850 °C)

The error is the same no matter if total span is used (-200 to 650 °C) or a

narrower user-defined span is used, like 0 to 100 °C.

Note: When using a Pt100 simulator, make sure the TxMiniBlock’s Pt100

excitation current (0.20 mA) is compatible with the simulator specification.

7SAFETY INFORMATION

Any control system design should take into account that any part of the system

has the potential to fail. This product is not a protection or safety device and

its alarms are not intended to protect against product failures. Independent

safety devices should be always provided if personnel or property are at risk.

Product performance and specifications may be affected by its environment

and installation. It’s user’s responsibility to assure proper grounding, shielding,

cable routing and electrical noise filtering, in accordance with local regulations,

EMC standards and good installation practices.

8SUPPORT AND MAINTENANCE

This product contains no serviceable parts inside. Contact our local distributor

in case you need authorized service.

9LIMITED WARRANTY AND LIMITATION OF LIABILITY

NOVUS warrants to the original purchaser that this product is free from defects

in material and workmanship under normal use and service within one (1) year

from the date of shipment from factory or from its official sales channel to the

original purchaser.

NOVUS liability under this warranty shall not in any case exceed the cost of

correcting defects in the product or of supplying replacement product as herein

provided and upon the expiration of the warranty period all such liability shall

terminate.

For complete information on warranty and liability limitations, check

appropriate section in our web site