viii

TABLE OF CONTENTS

1Introduction....................................................................................................................................................................11

1.1Intended Use ........................................................................................................................................................... 11

1.2UnitWise Platform &

flexiWare

.................................................................................................................... 12

1.3

flexiVent

FX

System Overview.....................................................................................................................16

1.4Theory of Operation ............................................................................................................................................17

2Set up & Installation.................................................................................................................................................25

2.1Selecting a Location...........................................................................................................................................25

2.2Preparing for Installation...........................................................................................................................25

2.3Placing the System....................................................................................................................................... 28

2.4Connecting the Components................................................................................................................... 28

2.5Opening the

flexiVent

protective cover .............................................................................................33

2.6Working with an Alternate Module....................................................................................................... 34

2.7Configuring

flexiWare

.................................................................................................................................38

3Getting Started ......................................................................................................................................................... 39

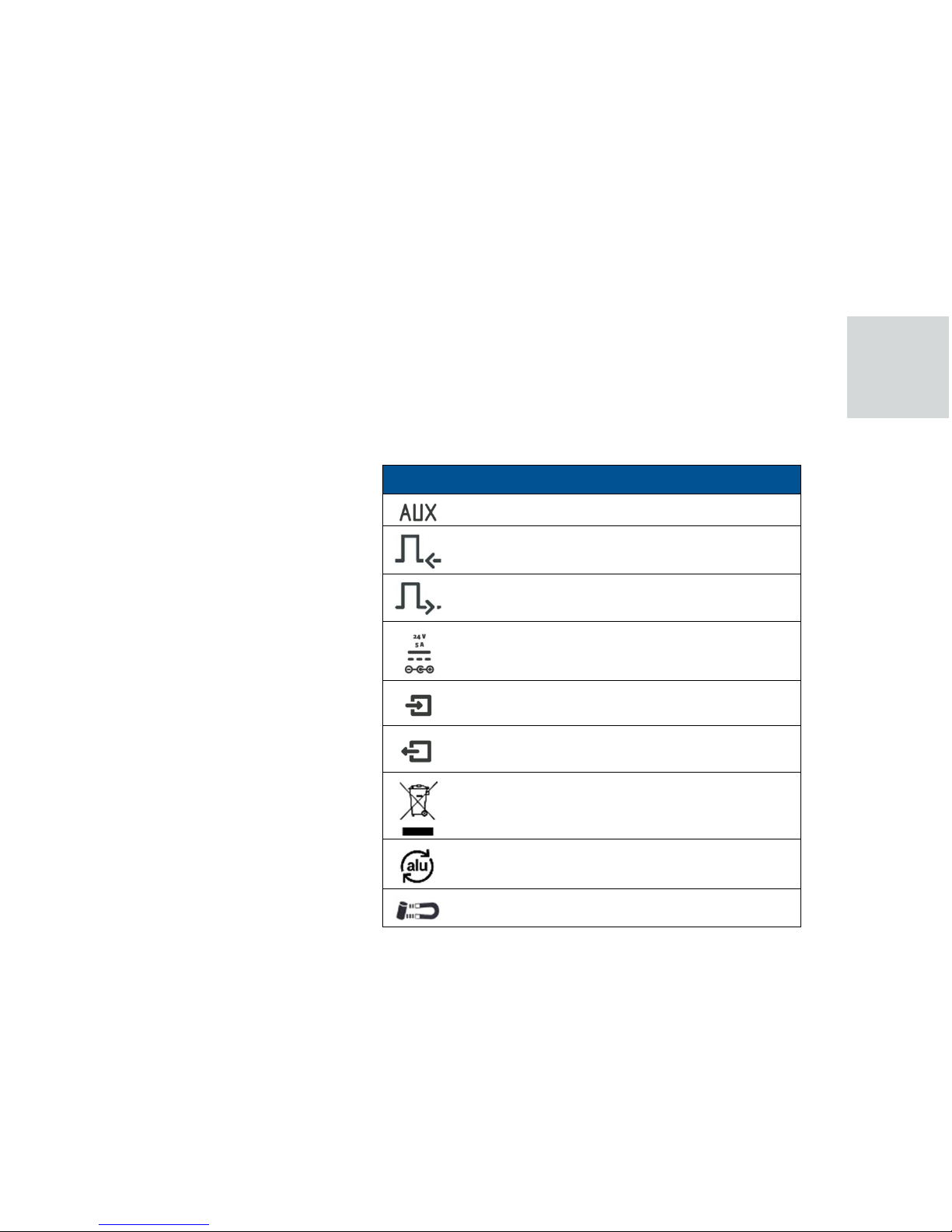

4Accessories ................................................................................................................................................................. 50

4.1UNIT Transducers...............................................................................................................................................50