Staubli GSRD Series User manual

1 / 8

E481686

MA000 (de_en)

Montageanleitung

MA000 (de_en)

Assembly instructions

MA402 (cn_en)

安装说明

MA402 (cn_en)

Assembly instructions

双叉形连接器

GSRD…

HP-GSRD...

Double fork plug

GSRD...

HP-GSRD...

目录

安全须知 2-3

推荐工具4

母排钻孔图4

连接母排5

角度和对准容差6

多母排系统中的短路电阻7

工程审议7

注释8

Content

Safety Instructions �����������������������������������������������������������������2 – 3

Recommended tools �������������������������������������������������������������������4

Busbar drilling plan ����������������������������������������������������������������������4

Assembly on the busbar ��������������������������������������������������������������5

Angular and alignment tolerances ������������������������������������������������6

Short-circuit resistance in multi busbar systems���������������������������7

Engineering considerations ����������������������������������������������������������7

Notes ������������������������������������������������������������������������������������������8

GSRD... HP-GSRD...

注意:

两种型号的安装过程相同。

Note:

The assembly process is identical for both types�

2 / 8

安全须知 Safety instructions

仅可使用 Stäubli 指定的部件和工具。自行装配时,切勿背离本手

册所述的制备及装配说明,否则 Stäubli 无法保证产品安全性或

性能达到官方技术参数。请勿以任何方式修改产品。

Use only the components and tools specified by Stäubli� In case

of self-assembly, do not deviate from the preparation and assem-

bly instructions as stated herein, otherwise Stäubli cannot give

any guarantee as to safety or conformity with the technical data�

Do not modify the product in any way�

可与 Stäubli 元件插合的非 Stäubli 原厂制造的连接器,在某些情

况下,某些制造商甚至将其描述为“与 Stäubli 兼容”,但该连接器

并不符合长期稳定安全的电连接要求,而且出于安全考虑,不得

与 Stäubli 元件插合在一起。因此,Stäubli 对因此类连接器(即未

经 Stäubli 批准)与 Stäubli 元件插合而造成的任何损失不承担任

何责任。

Connectors not originally manufactured by Stäubli which can be

mated with Stäubli elements and in some cases are even de-

scribed as ”Stäubli-compatible” by certain manufacturers do not

conform to the requirements for safe electrical connection with

long-term stability, and for safety reasons must not be plugged

together with Stäubli elements� Stäubli therefore does not ac-

cept any liability for any damages resulting from mating such

connectors (i�e� lacking Stäubli approval) with Stäubli elements�

如您未遵守上述警告,则 Stäubli Electrical Connectors (Stäubli)

不承担任何责任。

Stäubli Electrical Connectors (Stäubli) does not accept any

liability in the event of failure to observe these warnings�

IEC 60417-6182

安装需电气专业知识 Installation, electrotechnical expertise

产品可由具备电气技能或受过此方面指导的人员依照适用的

安全法规进行装配或安装。

The products may be assembled and installed by electrically

skilled or instructed persons duly observing all applicable safety

regulations�

IEC 60417-6042

注意电击风险 Caution, risk of electric shock

请在断电状态下工作

操作电气装置时,请遵守五项安全规定。

各电气装置确定后,应按照规定顺序执行以下五项基本要求(除

非另有必要理由):

• 完全分离;

• 确保不会重新连接;

• 确认无工作电压;

• 进行接地和短路;

• 针对临近带电部件提供防护。

任何从事此工作活动的人员均应具备电气技能或受过此方面指

导,或者由同等能力的人员监督。

来源:EN 50110-1:2013

Work in a de-energized state

Follow the five safety rules, when working on electrical installa-

tions�

After the respective electrical installations have been identified,

the following five essential requirements shall be undertaken in

the specified order unless there are essential reasons for doing

otherwise:

•disconnect completely;

•secure against re-connection;

•verify absence of operating voltage;

•carry out grounding and short-circuiting;

•provide protection against adjacent live parts�

Any person engaged in this work activity shall be electrically

skilled or instructed, or shall be supervised by such a person�

Source: EN 50110-1:2013

最终应用时,还应检查电击防护。 Protection against electric shock shall be checked in the end-use

applications too�

IEC 60417-6070

在负载下请勿断开连接 Do not disconnect under load

允许带电插拔。 Plugging and unplugging when live is permitted�

3 / 8

安全指令 Safety instructions

ISO 7000-0434B

注意 Caution

每次使用连接器前,需提前检查外部是否有缺陷(尤其是绝缘层)

如有安全疑虑,必须咨询专业人员或更换连接器。

Each time the connector is used, it should previously be inspect-

ed for external defects (particularly the insulation)� If there are any

safety concerns, an electrically skilled person must be consulted

or the connector must be replaced�

产品使用说明或技巧 Useful hint or tip

更多技术参数请见产品目录。 For further technical data please see the product catalog�

4 / 8

1

2

Ø5±0.1

22±0.2

15 h9

3

4

5

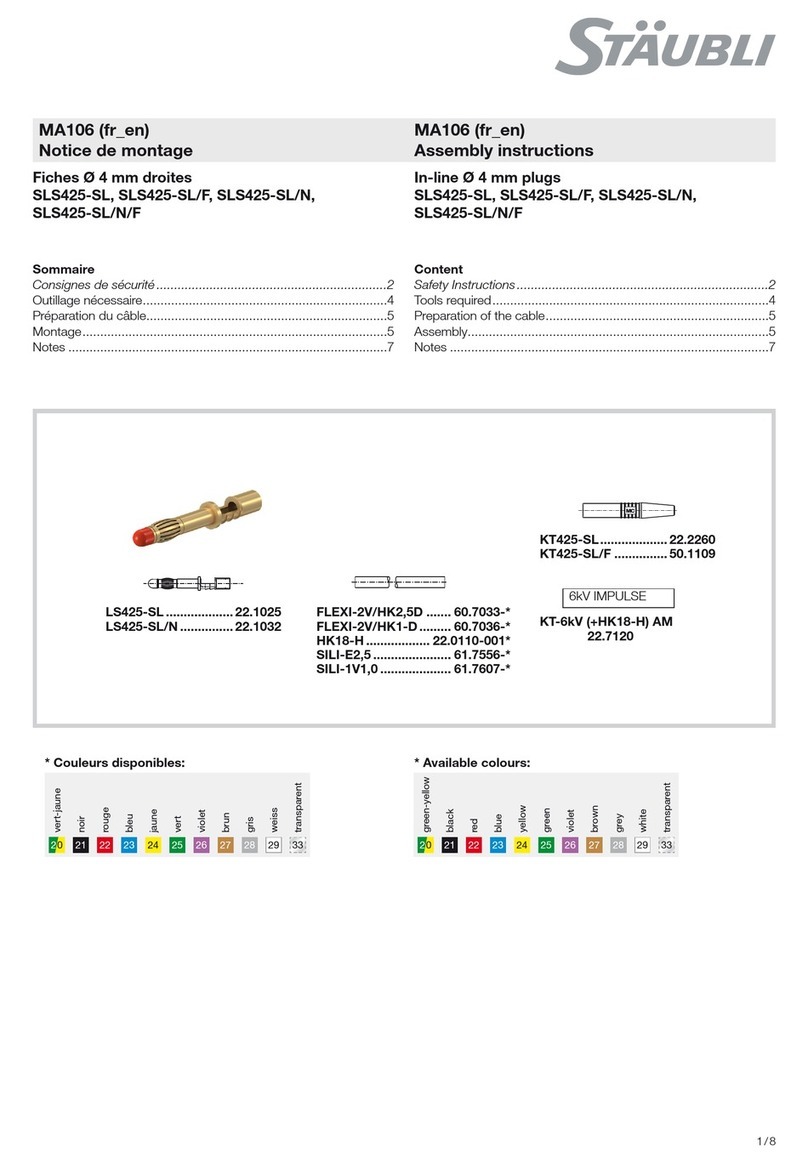

推荐工具 Recommended tools

(图1)

- 螺丝刀,尺寸 1。

(ill. 1)

Screwdriver size 1�

(图2)

弹簧卡环安装工具

(32/DIN 6799/短)。

(ill. 2)

Applicator for circlips

(3�2/DIN 6799/short)�

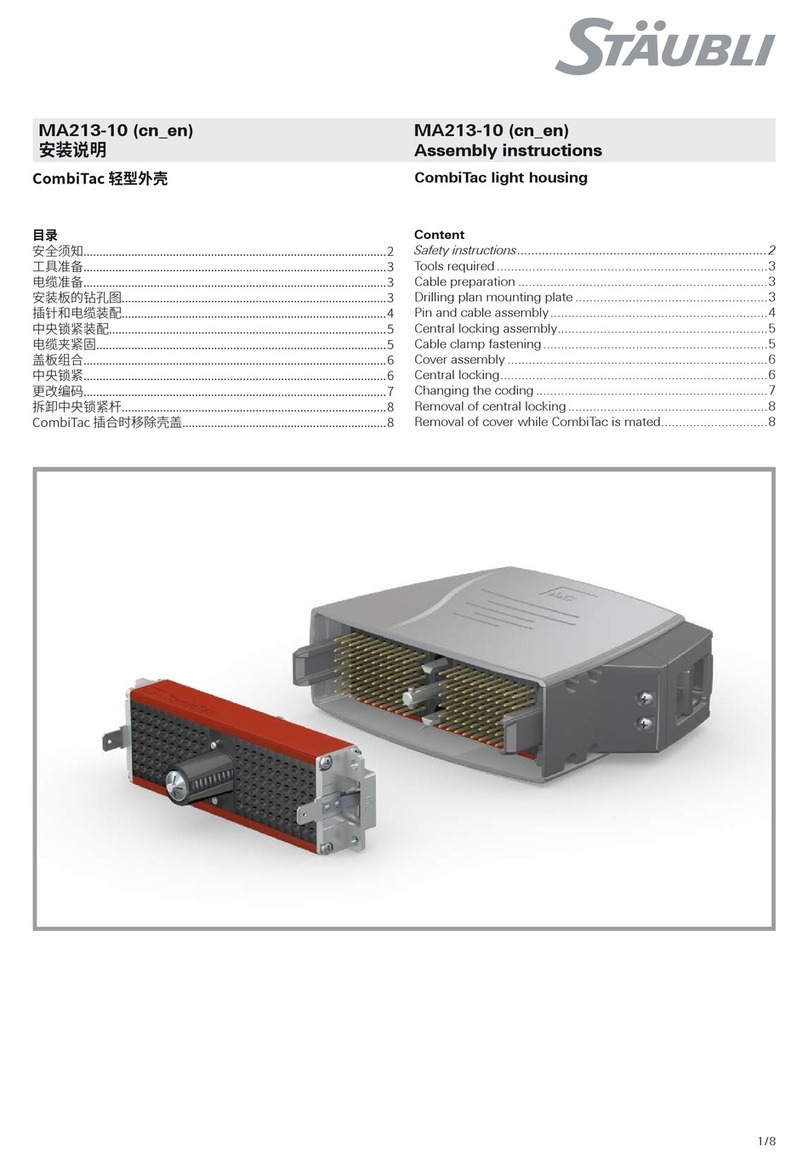

母排钻孔图GSRD... Busbar drilling plan GSRD...

母排钻孔图

HP-GSRD...

Busbar drilling plan

HP-GSRD...

母排倒角尺寸

HP-GSRD...

Contact knive dimensions

HP-GSRD...

Typ

Type 尺寸 A (mm)

Size A(mm)

GSRD...25 15 ±0.2

GSRD...50 25 ±0.2

GSRD...75 50 ±0.2

GSRD...100 75 ±0.2

Typ

Type

母排厚度 D (mm)

Busbar thickness D(mm)

5 6 6.35 10

GSRD...25 ±0.06 ±0.06 ±0.08 ±0.08

GSRD...50 ±0.08 ±0.08 ±0.1 ±0.1

GSRD...75 ±0.1 ±0.1 ±0.12 ±0.12

GSRD...100 ±0.12 ±0.12 ±0.15 ±0.15

母排厚度公差

Busbars thickness tolerances

D

钻孔图尺寸 A

Drilling plan dimension A

Typ

Type 尺寸 A (mm)

Size A(mm)

HP-GSRD...65 40

HP-GSRD...100 75

HP-GSRD...130 105

钻孔图尺寸 A

Drilling plan dimension A

Typ

Type

母排厚度 D

Busbar thickness D

15mm

HP-GSRD...65 ±0.15

HP-GSRD...100 ±0.18

HP-GSRD...130 ±0.2

D

母排厚度公差

Busbars thickness tolerances

2 bis 45° 2 to 45°

5 / 8

8

9

10

6

7

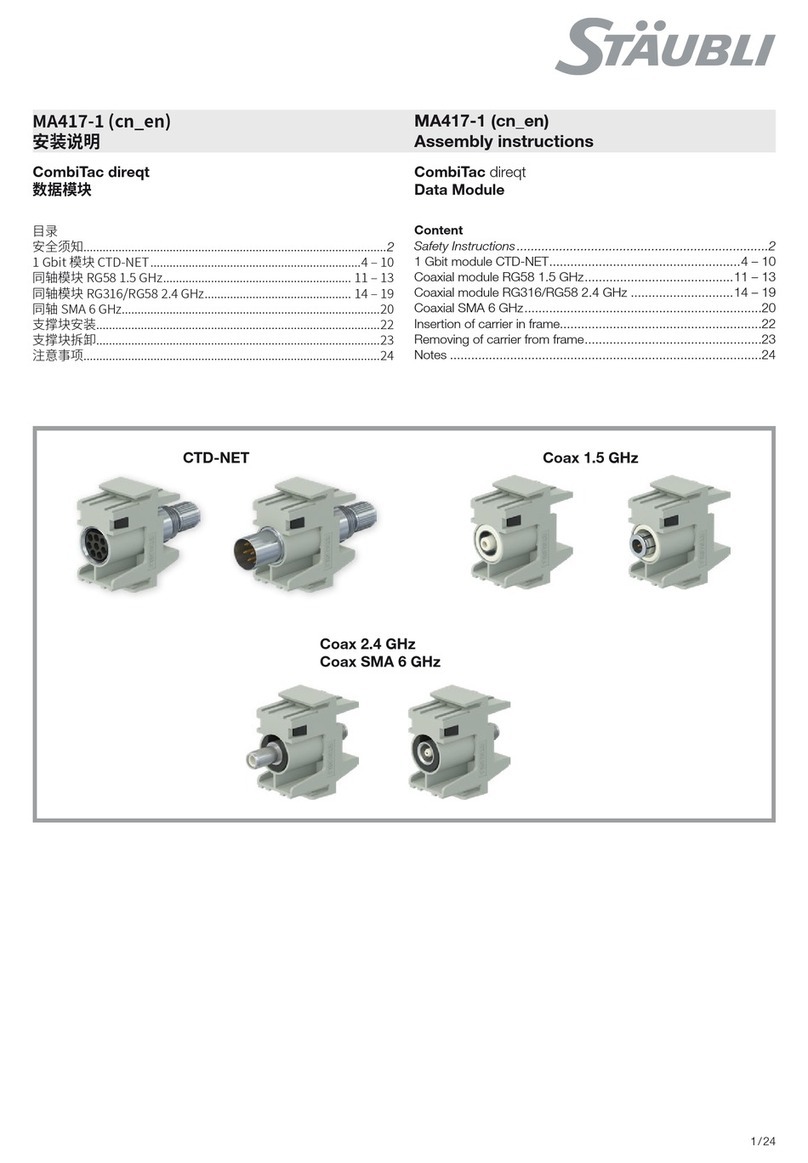

连接母排 Assembly on the busbar

(图6)

用尺寸 1 的螺丝刀,轻轻一压,就可以将

两个弹簧卡环拆下。

(ill. 6)

Using the size 1 screwdriver, both

circlips can be removed with slight

pressure�

注意:

按压弹簧卡环时,要小心手中的螺

丝刀:存在因打滑受伤的风险。

Note:

Be careful with the screwdriver

when holding the circlips: risk of injury

due to slipping�

(图7)

拆下两个 Ø 4 插销。

(ill. 7)

Remove both pins Ø 4�

注意 (HP-GSRD...):

将塑料导向套筒插入母排的钻孔。

Note (HP-GSRD...):

Insert the plastic guide sleeves in

the holes of the busbar�

(图8)

将叉形连接器插到母排上。

(ill. 8)

Insert the fork plug onto the busbar�

(图9)

将两个 Ø 4 插销插入钻孔。

(ill. 9)

Insert both pins Ø 4 into the drill holes�

(图10)

可以使用弹簧卡环安装工具安装弹簧卡环。

(ill. 10)

The circlips can be installed using the applicator for circlips�

6 / 8

11

12

13

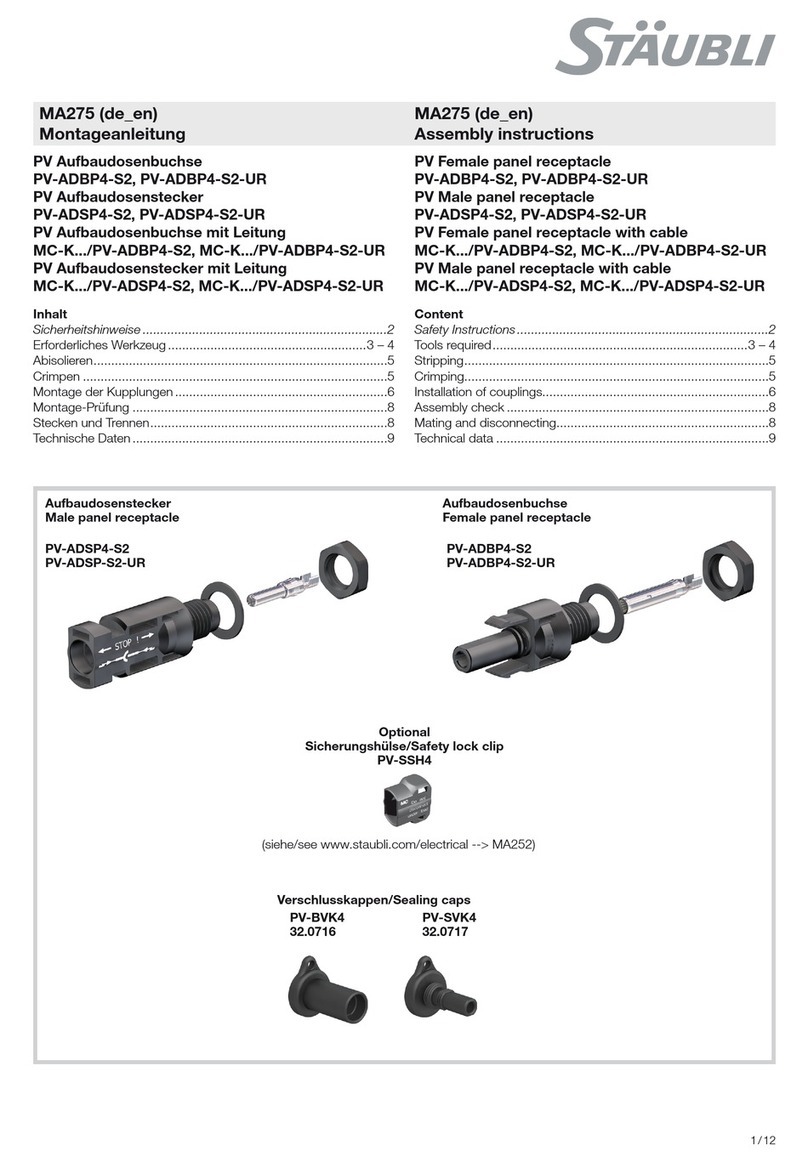

GSRD...

HP-GSRD...

GSRD...

HP-GSRD...

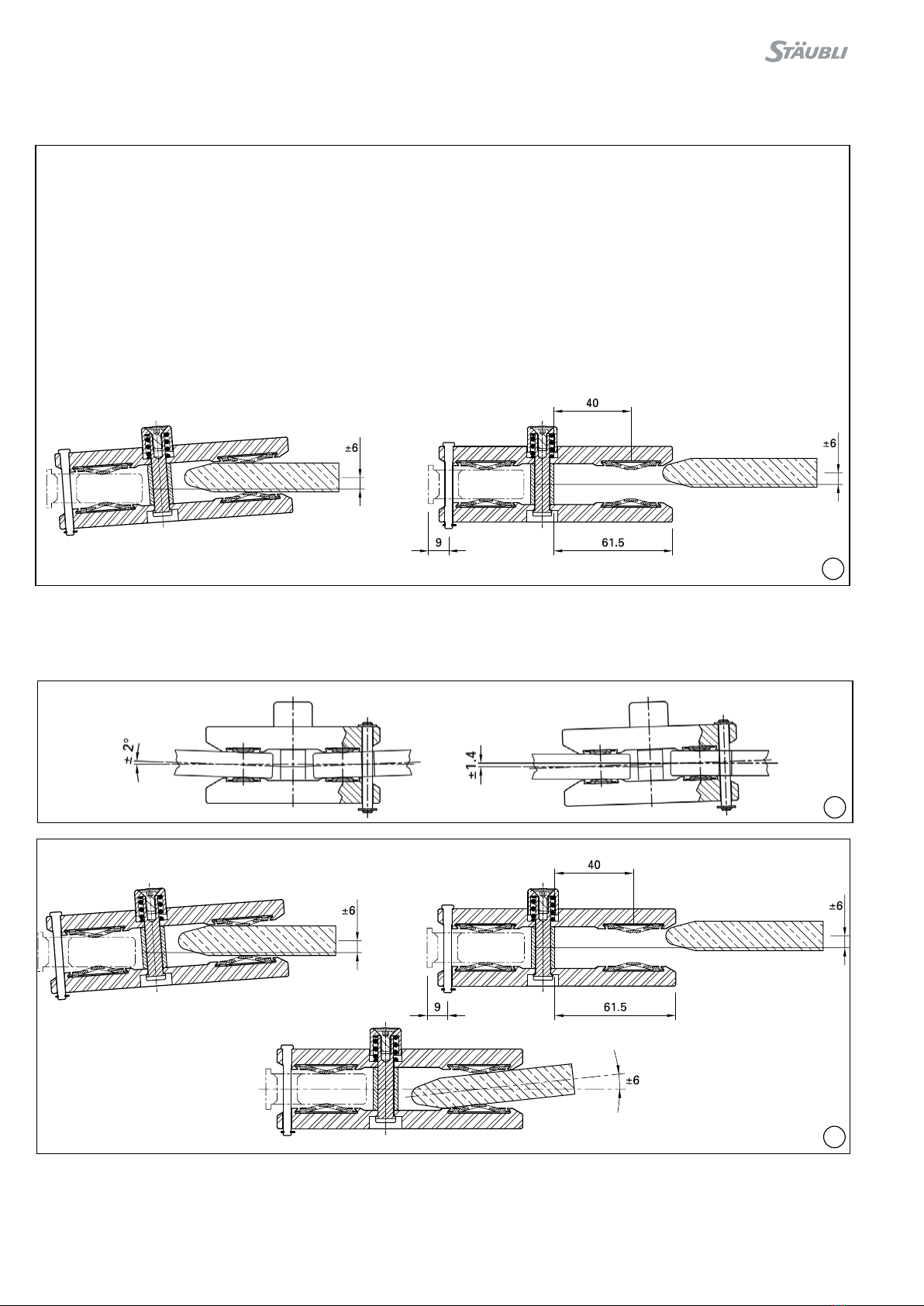

(图11)

将叉形连接器插到第二个母排上。

(ill. 11)

Insert the second busbar onto the fork plug�

角度和水平容差 Angular and alignement tolerances

7 / 8

多母排系统中的短路电阻 Short-circuit resistance in multi busbar systems

如发生短路,可能会产生非常高的电动力。

因此,为了确保安全运行,母排需要有足够的支撑。

If a short-circuit occurs, very high electrodynamic forces will

result�

Therefore for secure operation the busbars need to be supported

adequately�

(图10)

多母排系统中的母排和支架:在考虑了所有的边界条件后,客户需

要适当的调整距离 a 和 b

(ill. 10)

Busbars and supports in a multi busbar system: By accounting

for all boundary conditions the customer needs to adjust the

distances a and b suitably

依据UL E481686的工程审议 Engineering considerations according to UL File

E481686

文件 E481686,第 1 卷,第 1 节

工程审议:

File E481686, Vol. 1, Sec. 1

ENGINEERING CONSIDERATIONS:

仅可用于UL LLC确定接受使用的完整设备

接受条件

1 母排夹钳应使用母排进行温度测试。

2 额定电流大于 10kA 时,应对母排夹钳进行短路测试。

For use only in (or with) complete equipment where the accept-

ability of the combination is determined by UL LLC

Conditions of Acceptability –

1. Busbar clamps shall be temperature tested with bus bars�

2. Busbar clamps shall be short circuit tested for ratings above 10

kA�

8 / 8

制造商/Producer:

Stäubli Electrical Connectors AG

Stockbrunnenrain 8

4123 Allschwil/Switzerland

Tel. +41 61 306 55 55

Fax +41 61 306 55 56

www.staubli.com/electrical

© by Stäubli Electrical Connectors AG, Switzerland – MA402 – 01.2022, Index b, Marketing Communications – 保留修改权利/Subject to alterations

注意/Notes:

This manual suits for next models

1

Table of contents

Other Staubli Industrial Equipment manuals