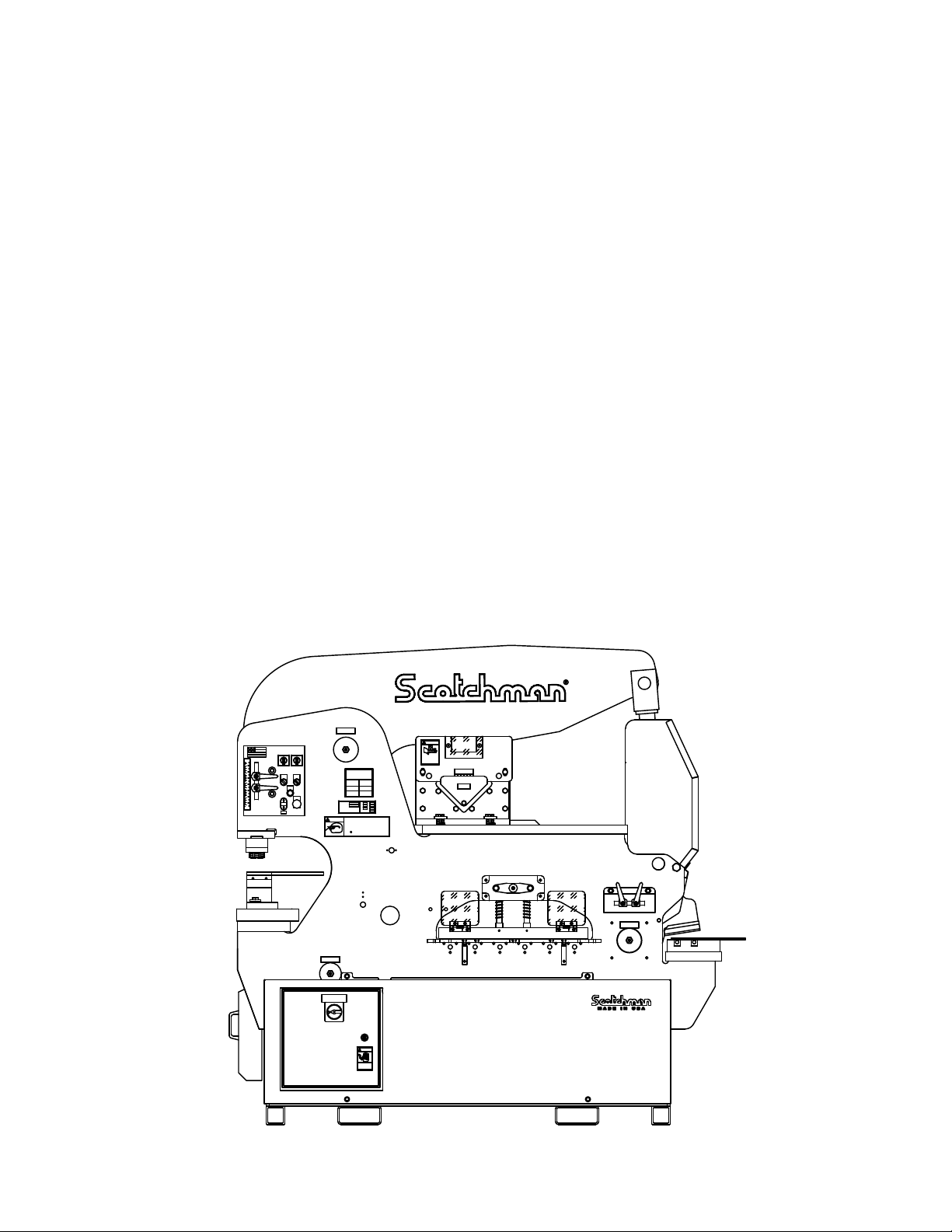

Scotchman DO-150-24M User manual

You have downloaded a manual for our

Model DO-150/240-24M Ironworker.

This manual does not include all of the

optional tooling for this machine.

If you would like a tooling manual, please

download our #40 Tooling Manual.

4185

DO NOT EXCEED

3 X 3 X 1/4

WHEN MITERING

0502003195

WARNING

TO PREVENT SERIOUS

BODILY INJURY

DO NOT PLACE FINGERS

BEYOND THIS GUARD

003140

013180

13179

201110

M6x12

201110

M6x12

201110

M6x12

201110

M6x12

013180

13179

201110

M6x12

201110

M6x12

201110

M6x12

201110

M6x12

17341

080435 Assy.

080430

230210230210

13220 - 3ph 13225 - 1ph

230 Volts

19121

OFF

EATON 11856

ELECTRICAL HAZARD

Turn off power

and lock out

before servicing.

DANGER

3122 1213

25525 Raw

224205224205

33176

80155

080174

243101

Assy.

13190

080061

080061

WARNING

SAFETY GLASSES REQUIRED WHEN

OPERATING OR OBSERVING THIS MACHINE

NEVER-

NEVER-

NEVER-

NEVER-

NEVER-

NEVER-

NEVER-

TO PREVENT SERIOUS BODILY INJURY

Operate, install tooling, service or adjust machine without

operator's manual and safety film.

Service machine with electrical power connected.

Operate any station without the respective strippers or

Operate machine with protective guards removed.

Place any part of your body under blade, punch or moving

Operate punch station without checking the punch to die

alignment and tightness.

Punch half holes, punch or shear unknown materials, side load

DO NOT REMOVE THIS SIGN FROM THIS MACHINE

REV. 0310

FOR MORE INFORMATION CONTACT SCOTCHMAN INDUSTRIES INC.

1-800-843-8844

003100

proper instructions and without reading and understanding the

hold-downs in place.

members.

(Check alignment and tightness daily.)

press brakes.

AT

SERIAL

SCOTCHMAN INDUSTRIES, INC.

PHILIP, SOUTH DAKOTA, U.S.A.

MADE IN U.S.A.

MODEL

FLA

HZ

PH

H.P. VOLT

BLADE LENGTH

PH. 605-859-2542

PSI

33149

33156

010117

80191

80211

80197

33018

80424 F

224205224205

224205224205

33157

13268

080174

243101

Assy.

080174

243101

Assy.

80156 Sales

033047

LUBRICATE

BEFORE

OPERATING

19103 0481

LUBRICATE

BEFORE

OPERATING

19103 0481

LUBRICATE

BEFORE

OPERATING

19103 0481

JOG

3200

STOP

START

START

RUN JOG

PUNCH TOOL

RUN PROBE

SHEAR NOTCH

START

MM. IN.

MM. IN.

90

80

70

60

50

40

30

20

10

10

90

80

70

60

50

40

30

20

3

2

1

3

2

1

0

004085

213012

213012

201240

201240

033707

080061

080061

037110

037105

201620

113017

113017

37107 - DO-135 & 150

37003 Assy

#037009 11,04

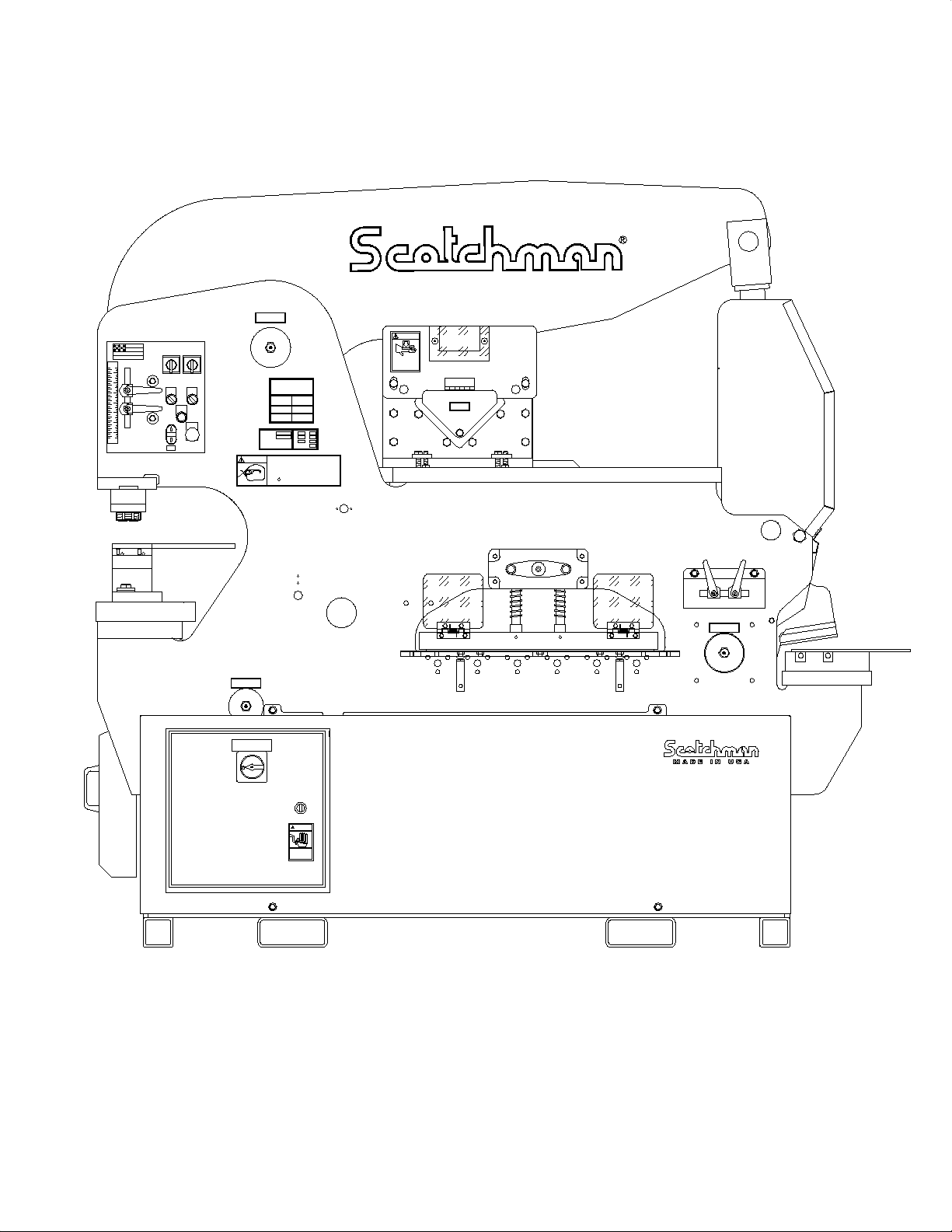

DUAL OPERATOR

150/240 - 24M

MACHINE CAPACITIES

SPEC. BASED ON MILD STEEL-65,000 PSI TENSILE

PUNCH

150 TONS

Ø47 THRU 25MM

Ø1-7/8 THRU 1.0"

FLAT SHEAR

1 X 14" - 3/4 X 24"

BLADE LENGTH 24" - 600MM

25X300 - 12X600MM

THROAT DEPTH

12" - 305MM

RECT. NOTCHER

76X127X12MM

3"X5"X1/2"

PUNCH STROKE

2.25" - 57MM

ANGLE SHEAR

150X150X12MM

6"X6"X1/2"

www.scotchman.com

MODEL

DO-150/240-24M

IRONWORKER

SCOTCHMAN INDS. - 180 E US HWY 14 - PO BOX 850 - PHILIP, SD 57567 Call: 1-800-843-8844

VERSION 5 - SEPTEMBER 2021

PAGE 2

4185

DO NOT EXCEED

3 X 3 X 1/4

WHEN MITERING

0502003195

WARNING

TO PREVENT SERIOUS

BODILY INJURY

DO NOT PLACE FINGERS

BEYOND THIS GUARD

003140

013180

13179

201110

M6x12

201110M6x12201110M6x12

201110

M6x12

013180

13179

201110

M6x12

201110M6x12201110M6x12

201110

M6x12

17341

080435 Assy.

080430

230210230210

13220 - 3ph 13225 - 1ph

230 Volts

19121

OFF

EATON 11856

ELECTRICAL HAZARD

Turn off power

and lock out

before servicing.

DANGER

3122 1213

25525 Raw

224205224205

33176

80155

080174

243101

Assy.

13190

080061

080061

WARNING

SAFETY GLASSES REQUIRED WHEN

OPERATING OR OBSERVING THIS MACHINE

NEVER-

NEVER-

NEVER-

NEVER-

NEVER-

NEVER-

NEVER-

TO PREVENT SERIOUS BODILY INJURY

Operate, install tooling, service or adjust machine without

operator's manual and safety film.

Service machine with electrical power connected.

Operate any station without the respective strippers or

Operate machine with protective guards removed.

Place any part of your body under blade, punch or moving

Operate punch station without checking the punch to die

alignment and tightness.

Punch half holes, punch or shear unknown materials, side load

DO NOT REMOVE THIS SIGN FROM THIS MACHINE

REV. 0310

FOR MORE INFORMATION CONTACT SCOTCHMAN INDUSTRIES INC.

1-800-843-8844003100

proper instructions and without reading and understanding the

hold-downs in place.

members.

(Check alignment and tightness daily.)

press brakes.

AT

SERIAL

SCOTCHMAN INDUSTRIES, INC.

PHILIP, SOUTH DAKOTA, U.S.A.

MADE IN U.S.A.

MODEL

FLA

HZ

PH

H.P. VOLT

BLADE LENGTH

PH. 605-859-2542

PSI

33149

33156

010117

80191

80211

80197

33018

80424 F

224205224205

224205224205

33157

13268

080174

243101

Assy.

080174

243101

Assy.

80156 Sales

033047

LUBRICATE

BEFORE

OPERATING

19103 0481

LUBRICATE

BEFORE

OPERATING 19103 0481

LUBRICATE

BEFORE

OPERATING

19103 0481

JOG

3200

STOP

START

START

RUN JOG

PUNCH TOOL

RUN PROBE

SHEAR NOTCH

START

MM. IN.

MM. IN.

90

80

70

60

50

40

30

20

10

10

90

80

70

60

50

40

30

20

3

2

1

3

2

1

0

004085

213012

213012

201240

201240

033707

080061

080061

037110

037105

201620

113017

113017

37107 - DO-135 & 150

37003 Assy

#037009 11,04

DUAL OPERATOR

150/240 - 24M

MACHINE CAPACITIES

SPEC. BASED ON MILD STEEL-65,000 PSI TENSILE

PUNCH

150 TONS

Ø47 THRU 25MM

Ø1-7/8 THRU 1.0"

FLAT SHEAR

1 X 14" - 3/4 X 24"

BLADE LENGTH 24" - 600MM

25X300 - 12X600MM

THROAT DEPTH

12" - 305MM

RECT. NOTCHER

76X127X12MM

3"X5"X1/2"

PUNCH STROKE

2.25" - 57MM

ANGLE SHEAR

150X150X12MM

6"X6"X1/2"

PAGE 3

SCOTCHMAN INDS. - 180 E US HWY 14 - PO BOX 850 - PHILIP, SD 57567 Call: 1-605-859-2542

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE #

1.0 INTRODUCTION 6

2.1 Warranty 7

SAFETY PRECAUTIONS 62.0

3.0

4.0

4.2

4.3

4.4

MACHINE DECALS

INSTALLATION AND SET UP

Physical Dimensions

Machine Moving Procedures

Physical Inspection

Electrical Requirements

Control Panel Functions

Machine Start Up

Machine Stroke Inspection And Adjustment

Punch & Tool Station

Notch and Shear Station

MAINTENANCE

Lubrication

Scheduled Maintenance

MACHINE OPERATION

Punch Operation

Bar Shear Operation

Shear Arm Adjustment

Shear Blade Adjustment

Rectangle Notcher Operation

Rectangle Notcher Blade Adj. Or Replacement

OPTIONAL TOOLS

6 x 6 Angle Shear

6 x 6 Angle Shear Installation

6 x 6 Angle Shear Operation

Rod Shear

Rod Shear Installation

Rod Shear Operation

4.4A

4.5

4.6

4.6A

4.6B

5.0

5.1

5.2

6.0

6.1

6.2

6.2A

6.2B

6.3

6.3A

7.1

7.1A

7.0

7.1B

7.2

7.2A

7.2B

8

20

18

15

14

12

10

10

30

28

26

26

24

23

22

44

42

42

40

38

36

30

49

49

48

45

45

45

4.1

7.1C 476" A.S. Miter Attachment Assembly

PAGE 4

SCOTCHMAN INDS. - 180 E US HWY 14 - PO BOX 850 - PHILIP, SD 57567 Call: 1-605-859-2542

6 x 6 90° V - Notcher7.3 50

SECTION DESCRIPTION PAGE #

7.5

7.5A

7.5B

12 & 24 Inch Brakes

Brake Installation

Brake Operation

Open End Brake

Open End Brake Installation

Open End Brake Operation

Channel Shear

Channel Shear Installation

Channel Shear Operation

Pipe Notcher

Pipe Notcher Installation

Pipe Notcher Operation

Pipe Notcher Capacities

Picket Fence Tool

Picket Fence Tool Installation

Picket Fence Tool Operation

Square Tube Shear

Square Tube Shear Installation

Square Tube Shear Operation

Optional Die Holders & Punch Retaining Nuts

Offset Die Holder for Flange Punching

2-1/2 x 3 Inch Die Holders

6 x 6 Die Holder

#45 Punch Retaining Nut

Heavy Duty Split-Ring Retaining Nut

48 Inch Back Gauge

Urethane Stripper

Installing The Urethane Stripper, Punch & Die

7.6

7.6A

7.6B

7.7

7.7A

7.7B

7.7C

7.8

7.8A

7.8B

7.9

7.9A

7.9B

7.10

7.10A

7.10B

7.10C

7.10D

7.10E

7.11

7.12

7.12A

58

58

56

56

56

53

52

64

64

63

62

62

62

58

68

68

68

66

66

66

64

74

74

72

70

70

68

7.4B

7.4A

7.4

7.3C

7.3B

7.3A 6 x 6 90° V - Notcher Installation

6 x 6 90° V - Notcher Operation

Blade Replacement

52

52

50

50

This manual suits for next models

1

Table of contents

Other Scotchman Industrial Equipment manuals

Scotchman

Scotchman GAA-500-90 CNC DT20 User manual

Scotchman

Scotchman IRONWORKER 6509-24M User manual

Scotchman

Scotchman GAA-600-90 CNC User manual

Scotchman

Scotchman PRESSPRO 66 User manual

Scotchman

Scotchman 6509-24FF User manual

Scotchman

Scotchman PRESSPRO 176MT User manual

Scotchman

Scotchman CPO-315-RFA-BL User manual