Add-on and Retrofit Sensor Connection Kits for Building Management Systems

ORDERING CODE ADD-ON/RETROFIT KIT DESCRIPTION

88009418 FP-BF-BMS-21/2-10

BMS Sensor Connection Kit

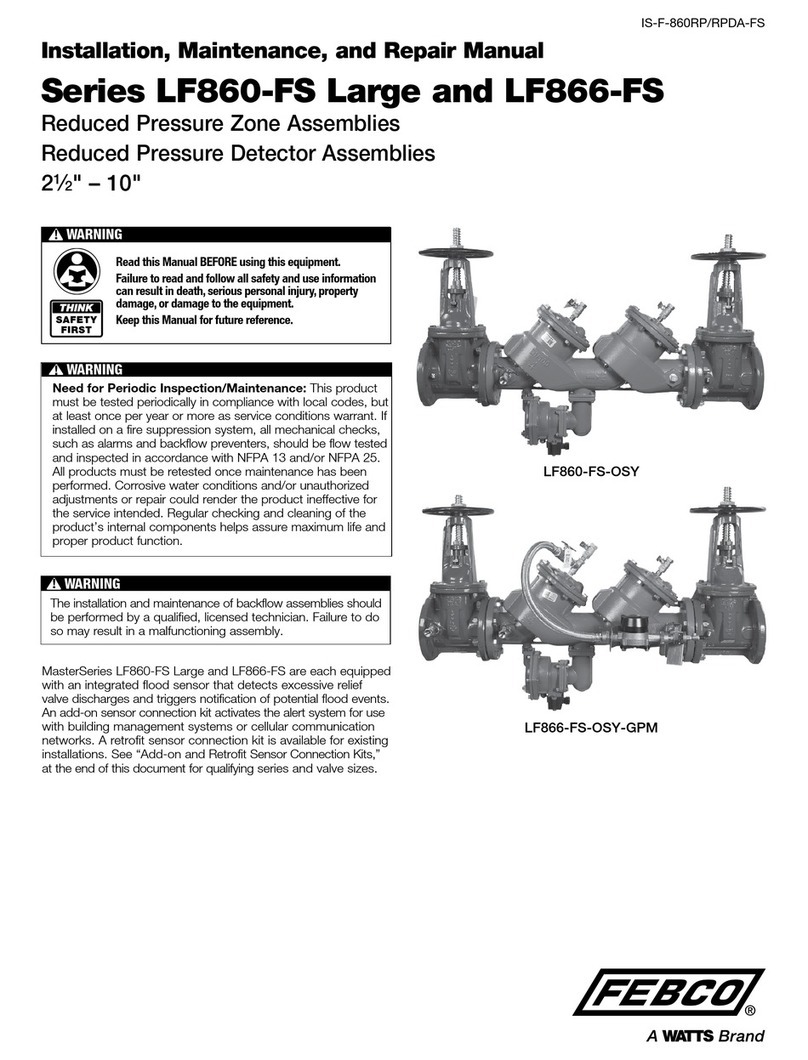

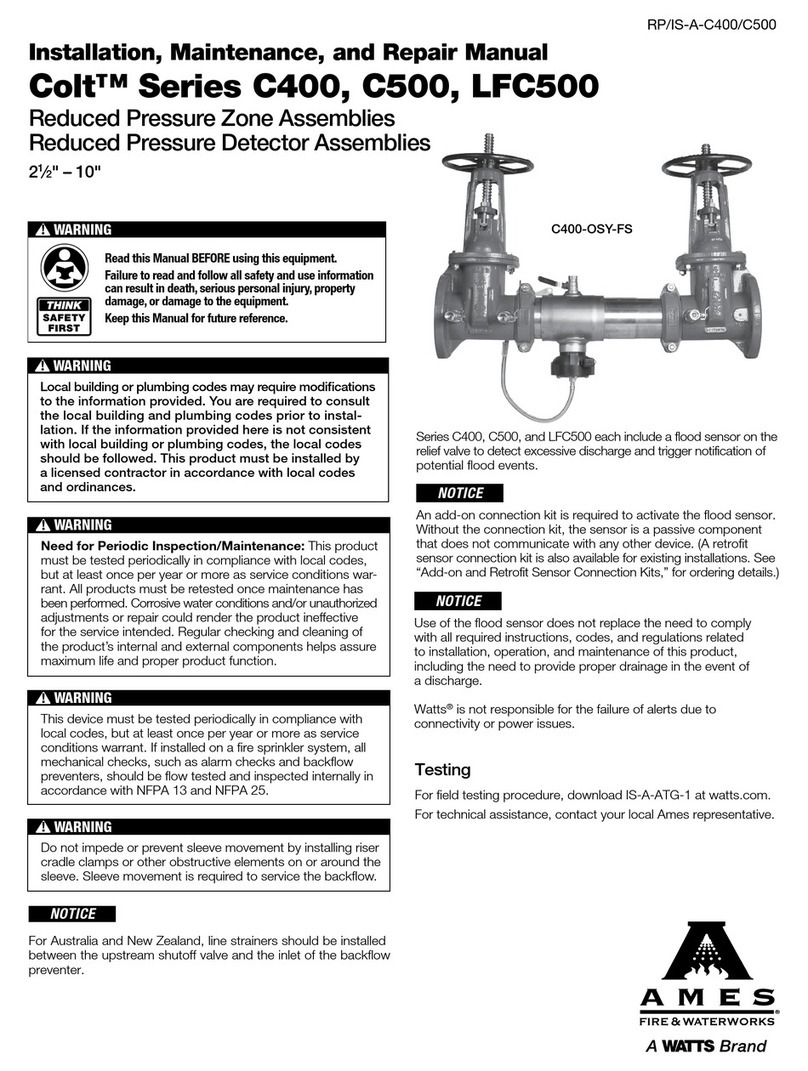

Series C400-FS, C500-FS, LFC500-FS

Sizes 2½" to 10"

Includes sensor activation module with cable, ground wire, and power adapter. Use

this kit to activate the integrated flood sensor and enable flood detection capabilities

on the relief valve of a new installation linked to a BMS controller (not included).

88009419 FP-RFK-BF-BMS-CFS-21/2-10

BMS Sensor Retrofit Connection Kit

Series C400, C500, LFC500

Sizes 2½" to 10"

Includes flood sensor, sensor activation module with cable, ground wire, and

power adapter. Use this kit to install the flood sensor and enable flood detection

capabilities on the relief valve of an existing installation linked to a BMS controller

(not included).

Add-on and Retrofit Sensor Connection Kits for Cellular Communication

ORDERING CODE ADD-ON/RETROFIT KIT DESCRIPTION

88009420 FP-BF-CFS-21/2-10

Cellular Sensor Connection Kit

Series C400-FS, C500-FS, LFC500-FS

Sizes 2½" to 10"

Includes sensor activation module with cable, Cellular Gateway with mounting kit,

ground wire, and power adapter. Use this kit to activate the integrated flood sensor

and enable flood detection capabilities on the relief valve of a new installation linked

to a cellular network to send alerts by email message, SMS text message, or

voice call.

88009421 FP-RFK-BF-CFS-21/2-10

Cellular Sensor Retrofit Connection Kit

Series C400, C500, LFC500

Sizes 2½" to 10"

Includes flood sensor, sensor activation module with cable, Cellular Gateway with

mounting kit, ground wire, and power adapter. Use this kit to install the flood sensor

and enable flood detection capabilities on the relief valve of an existing installation

linked to a cellular network to send alerts by email message, SMS text message,

or voice call.

Limited Warranty: Ames Fire & Waterworks (the “Company”) warrants each product to be free from defects in material and workmanship under normal usage for a period of one year from the date

of original shipment. In the event of such defects within the warranty period, the Company will, at its option, replace or recondition the product without charge.

THE WARRANTY SET FORTH HEREIN IS GIVEN EXPRESSLY AND IS THE ONLY WARRANTY GIVEN BY THE COMPANY WITH RESPECT TO THE PRODUCT. THE COMPANY MAKES NO

OTHER WARRANTIES, EXPRESS OR IMPLIED. THE COMPANY HEREBY SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO

THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

The remedy described in the first paragraph of this warranty shall constitute the sole and exclusive remedy for breach of warranty, and the Company shall not be responsible for any incidental, special

or consequential damages, including without limitation, lost profits or the cost of repairing or replacing other property which is damaged if this product does not work properly, other costs resulting from

labor charges, delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water conditions, chemical, or any other circumstances over which the Company has no control.

This warranty shall be invalidated by any abuse, misuse, misapplication, improper installation or improper maintenance or alteration of the product.

Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion or limitation of incidental or consequential damages. Therefore the

above limitations may not apply to you. This Limited Warranty gives you specific legal rights, and you may have other rights that vary from State to State. You should consult applicable state laws to

determine your rights. SO FAR AS IS CONSISTENT WITH APPLICABLE STATE LAW, ANY IMPLIED WARRANTIES THAT MAY NOT BE DISCLAIMED, INCLUDING THE IMPLIED WARRANTIES

OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL SHIPMENT.

RP/IS-A-C400/C500-FS 2303 7020349 © 2023 Watts

USA: Backflow T: (978) 689-6066 • F: (978) 975-8350 • AmesFireWater.com

USA: Control Valves T: (713) 943-0688 • F: (713) 944-9445 • AmesFireWater.com

Canada: T: (888) 208-8927 • F: (905) 481-2316 • AmesFireWater.ca

Latin America: T: (52) 55-4122-0138 • AmesFireWater.com